Professional Documents

Culture Documents

Apeks OCTO+MK 2 SERVICE MANUAL

Apeks OCTO+MK 2 SERVICE MANUAL

Uploaded by

daviddealba0 ratings0% found this document useful (0 votes)

16 views16 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views16 pagesApeks OCTO+MK 2 SERVICE MANUAL

Apeks OCTO+MK 2 SERVICE MANUAL

Uploaded by

daviddealbaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 16

k

APEKS BEI EQUIPMENT LTD.

i

ENGLAND 881 2BT

OCTO x2

SERVICE

MANUAL

Quality in Action |

Apoks. Ware Equipment Ld |

nd 201 61 alm |

SECTION 1

wd

12

FAULT DIAGNOSIS

FAULTS IN THE REGULATOR

Air bubbles from Ihe

mouthpiece and/or

exhalation valve (with

the buoyancy device

deficted)

Additional possiple causes

of leakage (with the

buoyancy device inflated).

FAULTS IN THE POWER INFLATOR

Air bubbles from the

mouthpiece when the power

inflatar is operated,

Air bubbles from around

the power inflator bullion

or lock ting when

operated

Power inflator button is

stift to operate.

Buoyoncy device intiates

slowly or rapidly without

operating Ihe power

inflator.

POSSIBLE CAUSES

The intermediate air pressure

supplied by the first stage is

too high (Max. working pressure

should not exceed 160psi/

11.0 bar.

Insufficient free

movement in the lever

assembly (See Fig. 1)

Valve or lever (items 3 and 23)

sticking. (Operale Ihe lever

manually several times to

check smooth operation.

Worn or damaged or dirty

rubber valve seating (item 9)

damaged valve seat (item 6)

End cover (item 22) distorted

and presses against

diaphragm causing valve to

operate.

Valve seat (iter 6) is not

correctly located against the

shoulder in the valve body.

Gee Fig. 3).

Dirty or damaged ‘0’ seal

(item 14).

Darnaged or dirty ‘O°

seal (item 5)

Damaged casing (item 17) allows air to

leak back from the buoyancy device

Dirty or damaged "0

seal (item §).

Damaged case (item 17).

Lock ring (tern 28)

is loose.

Flexible button (item

29) is damaged or faulty

The valve core (item 31)

is foully

The valve core (item

31) is not securely

screwed into the

The voh

is faulty.

FAULTS IN THE ORAL

INFLATOR/DEFLATOR

Ait leaks trom the joint

between the regulator

and oral inflator bodies.

Air leaks from the oral

inflator orifice

Ait leaks from around oral

inflator button,

FAULTS IN THE QD COUPLING

(Gee tig. 4)

Coupling is difficult to

oF will not lock anto the

connecting nipple.

Coupling disconnects from

nipple In use.

Coupling is difficull lo

disconnect from nipple.

Coupling fails to self

seal when disconnected.

Coupling leaks when

connected to the nipple.

Dirty or damaged O°

seal (item 13),

Dirty or damaged

seating (Item 34).

Damaged seal in body

(ile 11).

Dirty or damaged 'O"

seal (item. 13)

POSSIBLE CAUSES

Problems with the @D

coupling are almost

invarlably due to

dirt or bulld-up of

deposits in or around

Ihe locking balls and

sleeve, Thorough

rinsing or soaking

the coupling in warm

watter followed by a

light application of

a water displacing

lubricant (eg. WD40)

normally cures these

problems.

Dirty or damaged 'O”

seal in coupling

(see above).

Damaged nipple.

SECTION 2

21

DISMANTLE AND REASSEMBLE

REMOVING THE POWER INFLATOR BUTTON ASSEMBLY

See Fig. 5

To remove the power inflator valve core (ile 31). First unscrew the lock

ting (item 28 righthand thread) and remove the flexible rubber button and

button support (items 29 and 30), Unscrew the valve core using a suitable

valve core key APTP29 or falling this, appropriate pliers may be used. It the

rubber seal on the valve core is nol removed intact on the valve core, the

seal should be carefully picked out of the valve body (item 2) and anew

core fitted,

RE-ASSEMBLING THE POWER INFLATOR

Is in reverse order always fit a new valve core if there Is any doubt abou!

Ihe integrity of this item. Press the valve core firmly Into the body whils!

turning it to ensure that the thread engages properly. tighten securely into

position (see Fig. 5).

22

REMOVING AND DISMANTLING THE REGULATOR VALVE

ASSEMBLY

First remove the power intiatar valve core as described in 2.1 then unscrew

the lock ring (item 18) and remove the front cover and diaphragm

‘assembly, using the service tool APTP 28 to prevent the valve body turning

(see Fig. 2) unscrew the QD nipple about 3-4mm. when the nipple is

released remove the service tool and use the partially unscrewed nipple to

help push the valve body out of the casing.

The valve seal (ilem 6) should now be removed from the valve body by

gripping the bore of the seat with internal circlip pliers and pulling it out.

Take care not fo damage the knife edge of the seat, The rubber valve

seating (lem 9) can now be removed and replaced without ony further

dismantling, otherwise proceed - using the special wrench APS 010 to

prevent the valve from turning, unscrew the nyloc nut (take note of how

far the nut is screwed on the valve to assist re-assembly) and remove the

lever and nylon anticriction washers.

RE-BUILDING THE REGULATOR VALVE ASSEMBLY

Locate the valve and spring in the valve body, and using a length of

0,375" /9mm dia tod, compress the valve and spring sufficien! lo allow the

lever, anti-fiction washers and nyloc nut to be replaced.

a

IMPORTANT

Ensure that the plastic friction insert in the nul is in good

condition, to prevent the nut unscrewing during use. Renew

the nut if in any doubt.

(Do not attempt to compress the valve and spring using the valve seat

(item 6) as this will almost certainly damage the rubber valve seating),

Ihnen using the special OCTO+ wrench to preven! Ihe valve turning,

replace the nyloc nut to approximately the same position prior to removal

Lightly lubricate the *O’ seal (item 14) and carefully replace the voive seat

in the body ensuring that it is pushed fully up to the shoulder (see fig. 3).

The valve assembly can now be replaced in the case and aligned as

shown in tig, 2. Fit and tighten the quick Connector nipple to the

proscribed torque, Re-assembie the power inflator as described in fig. 7.1

REMOVE AND DISMANTLE THE ORAL INFLATOR/DEFLATOR

NOTE: DO NOT SEPARATE THE REGULATOR CASE

(ITEM 17) AND ORAL INFLATOR BODY (ITEM 11) EXCEPT

TO RENEW THE ‘O’ SEAL (ITEM 13).

Unscrew the lock ring and remove the front cover and diaphragm.

Remove the posidrive screw behind the lever to release the oral

inflator body which con now be slid off its clove tail. Removing the

posicirive screw in the button will release all the remaining

components. (Use the fork end of the special OCTO+ wrench to

prevent the vaive turning).

Check the condition of the rubber valve seating and seat.

Assembly Is in the reverse order. (Do not overtighten the posidrive

screws),

SECTION 3

TESTING AND ADJUSTING THE REGULATOR

Wilh Ihe end cover and diaphragm assembly removed, connect the

regulator fo an air supply of 125-135 psi 8.5 - 9.5 bar. The objective is to

minimise the free movement in the lever by adjusting the nyloc nut as

shown in fig. 1. Its important to understand that the free movement In

the lever will be greater at higher pressure and less at lower pressure. The

recommended adjusting pressure of 125-135 psi/8.5-9.5 bar has been

chosen to give the regulator satisfactory performance across the range

of approximately | 10-160 psi/7.5-1 1.0 bar. Ideally. the best possible

performance would be achieved by adjusting the tree movernent witile

connected to the customers own fist stage, or an equivalent pressure.

Use the blade of the special OCTO+ wrench inserted through the

mauthpiece to prevent the valve tuming, as shown in fig. 1. Operate the

lever manually several times to test satistactory operation. Finally,

replace the diaphragm and end cover and les! for satisfactory

breathing.

Test the regulator. power inflator and oral inflator for satisfactory

operation. and finally for air lightness by immersing the assembly in

water and observing for leaks.

SECTION 4

ANNUAL SERVICE REQUIREMENTS

The complete unit except for

Ihe mouthpiece.

Separation of the casing (item 17)

and oral inflator body (item 11),

Should be dismantled. cleaned (see note) and examined, for signs of

deterioration. in particular the diaphragm and exhalation valve, should

be closely scrutinised, the neck of the exhalation valve where it

attaches to the diaphragm should be slrelched and examined for

cracks or spiils. If in doub! Ihis should be renewed.

‘0’ seals items 5, 10, 13, 14 the valve seating iter 9 and the valve core

item 31 must be renewed any other items may be renewed at the

Technicians discretion with reference to the guarantee.

After cleaning and examination the regulator should be re-assembled

and tested according to this manual,

NOTE: Never use any type of solvent fo clean the rubber parts of the

regulator.

Parts are best cleaned by soaking in hol soupy water.

Il is permissible to use a solvent to remove any adhesive

residue from (itern 26) when renewing the seating.

FIGURE 1 (SEE SECTION 3)

4 ADJUST THE NYLOC

NUT USING A 7/32"

(OR 5.5 MM SOCKET

0.25 -0.75 MM

FREE MOVEMENT SPECIAL WRENCH TO

AT 125 ~ 135 PSI 4 PREVENT THE VALVE

B5-95BAR TURNING.

ADJUST THE

NYLOC NUT

PRESS INE BLADE OF THE

SPECIAL WRENCH OR A SUITABLE

SCREW DRIVER AGAINST TIC

‘VALVE HEAD TO PREVENT IT

TURNING.

‘SPECIAL WRENCH

APS 010,

IHE VALVE BODY (EM 2) AND THE CASING (ILM.

17) HAVE CORRESPONDING LOCATION FLATS TO.

PREVENT POSSIBLE MOVEMENT OF THE VALVE BODY

IN SERVICE. THE FLAT IN THE CASING IS NOT

SIRONG FNOUGH TO PREVENT TURNING OF THF

VALVE BODY WHEN TIGHTENING THE QD NIPPLE. A

SPECIAL SERVICE TOOL APTP 28 MUST BE USED.

OTHERWISE DAMAGE TO THE CASING IS POSSIBLE.

HOLD THE SERVICE TOOL FIRMLY INTO THE POWER

INFLATOR HOUSING WHILE FITTING OR REMOVING

THC NIPPLE.

FIGURE 2

FIGURE 3

HARD UP TO

SHOULDER

‘VALVE SEAT

TEM 6

THE VALVE SEAT IS NORMALLY HELD UP TO THE

SHOULDER BY AIR PRESSURE.

IF REMOVED THE SEAT MUST BE REPLACED UP TO.

THE SHOULDER. LIGHILY LUBRICATE WITH SILICONE

GREASE BEFORE FITTING. TAKE GREAT CARE NOT TO

DAMAGE THE KNIFE EDGE OF THE VALVE SEAT.

FIGURE 4

si

is

POSITION OF SLEEVE

WHEN FIT

THE REGULATOR MAY BE FITTED WITH ONE OF

SEVERAL SIMILAR TYPES OF QD COUPLING.

IN ALL CASES IT IS ESSENTIAL THAT THE SLEEVE MUST

SLIDE UP TO THE SHOULDER OR CIRCLIP WHEN

FITTED ON THE NIPPLE. IF THE SLEEVE DOES NOT

SLIDE COMPLEFTFLY UP TQ THF SHOULDER WHEN

FITTED. IT I$ POSSIBLE FOR ACCIDENTAL

DISCONNECTION TO OCCUR.

IH VALVE CORE (TPM 31) SHOULD BE LEVEL WITH,

OR JUST BELOW THE DIAMETER OF THE VALVE BODY

(TEM 2) WHEN CORRECTLY FITTED.

DO NOT OVERTIGHTEN, THIS MAY CAUSE DAMAGE

TO THE CORE MECHANISM OR SEAL.

IF THE RUBBER SEAL IS NOI REMOVED INTACT WITH

THE CORE) IT MUST BE CAREFULLY PICKED OUT AND

ANEW CORE FITTED, IF THE SEAL IS ACCIDENTALLY

PUSHED INTO THE VALVE BODY IT CAN USUALLY BE

SHAKEN OUT THROUGH THF BORE OF THE QD.

NIPPLE. IT 1S ESSENTIAL THAT THE OLD SEAL IS

REMOVED FROM THE VALVE BODY.

FIGURE 5

.03" MAX

THE SHOULDER OF THE CORE SHOULD BE LEVLL

WITH OR JUST BELOW THE DIAMITER OF THE VALVE

BODY.

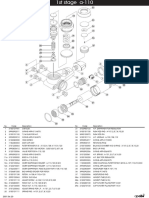

3) 4A

n Ge 7

@ ,

20. . SS aa

a ZANE

" |

S| |

& i

— CERN

w.

A

27 13 28 29 30

36

OCTO + MK2

TEM PART NO. DESCRIPTION

1 AP 1434 MOUTHPIECE

2 AP 1702 OCTO+ MK2 VALVE BODY

3 AP 1676 OCTO+ VALVE

4 AP 1677 MOUTHPIECE CLIP

5 AP 1438 ‘O' RING

6 AP 1703 OCIO+ MK 2 VALVE SEAT |

8 AP 1710, OCTO+ MK 2 QUICK DISCONNECT NIPPLE

9 AP 1680 OCTO+ VALVE SEATING |

10 AP 1445 *O' RING \

1 AP 1681 OCTO+ ORAL INF. BODY

12 AP 1709 PIN (IF FITTED)

13 AP 1154 OF RING

14 AP 1409 ‘O’ RING

15 AP 1441 SPRING

16 AP 1589 SCREW

7 AP 1705 OCIO+ MK 2 REGULATOR BODY

18 AP 1683 OCTO+ LOCKING RING

19 AP 1431 DIAPHRAGM PAD

20 AP 1429 EXHAUST VALVE

a AP 1430 DIAPHIRAGM

fe AP 1684 OCTO+ END COVER

23 AP 1685 OCTO+ LEVER

24 AP 1686 OCTO+ NYLOC NUT

vas) AP 1687 OCTO+ ANIF-FRICTION WASHER \

26 AP 1693, OCTO+ ORAL VALVE SEAT

27 AP 1689 OCTO# ORAL INFLATION VALVE

28 AP 1706 BUTTON LOCK RING

29 AP 1708 OCTO+ INFLATOR BUTTON

30 AP 1707, BUTTON INSERT |

al AP 1704 VALVE CORE

32 AP 1571 SPRING

33 AP 1694 OCTO+ BUTTON HEAD

3A AP 1691 OCTO+ THRUST WASHER

38 ‘AP 1154 “O' RING

36 APOIS7 OCTO+ MK 2 HOSE

37 AP 1409 ‘O' RING.

SERVICE TOOLS

38 APIP25 ALICNING TOOL

30 APTP29 VALVE CORE KEY

40 APSO10 SPECIAL WRENCH

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ex Reg2ndDocument57 pagesEx Reg2nddaviddealbaNo ratings yet

- Reg 1 StmoistureDocument3 pagesReg 1 StmoisturedaviddealbaNo ratings yet

- A1071st RegDocument41 pagesA1071st RegdaviddealbaNo ratings yet

- Apollo Non-Moisturizing Reg. Sch.Document3 pagesApollo Non-Moisturizing Reg. Sch.daviddealbaNo ratings yet

- A110 1st08juneDocument1 pageA110 1st08junedaviddealbaNo ratings yet

- Ap4497 Flight 1st Stage Maint ManxDocument21 pagesAp4497 Flight 1st Stage Maint ManxdaviddealbaNo ratings yet