0 ratings0% found this document useful (0 votes)

2K views20 pagesPLC Practical PDF

Plc

Uploaded by

rajaskn22Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

0 ratings0% found this document useful (0 votes)

2K views20 pagesPLC Practical PDF

Plc

Uploaded by

rajaskn22Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

- Practical No. 1: Introduction to PLC: This section introduces the concept and basic functions of Programmable Logic Controllers.

- Practical No. 2: PLC Programming: Covers practical steps to program a PLC using handheld and computer interfaces.

- Practical No. 4: Basic Logic Operations: Introduces basic logic operations such as AND, NOT, OR functions within ladder logic diagrams.

- Practical No. 6: Introduction to 8051 Microcontroller: Details the 8051 microcontroller architecture and its features.

Object: Components/sub components of a PLC, learning functions of different modules of g Ploy

ject: .

Theory:

1 PROGRAMMABLE LOGIC CONTROLLER (PLC) is an industrial computer control system

continuously monitors the state of input devices and makes decisions upon a custom propan

to control the state of output devices.

‘Almost any production line, machine function, or process can be greatly enhanced using this

of control system, However, the biggest benefit in using a PLC is the ability to change and replicas

the operation or process while collecting and communicating vital information.

PLCs are designed for multiple input and output arrangements. They can withstand various temperature

ranges, electrical noises, vibrations, and impacts. Integrating a PLC into any production tine

mechanical process is highly beneficial. PLCs enable operation processes to be changed or replicated,

while simultaneously collecting and communicating important information.

‘There are four basic steps in the operation of all PLCs; Input Scan, Program Scan, Output Scan, and

Housekeeping. These steps continually take place in a repeating loop.

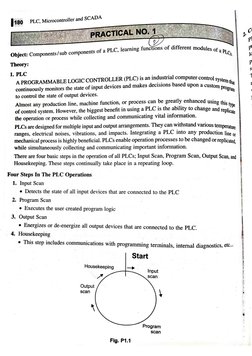

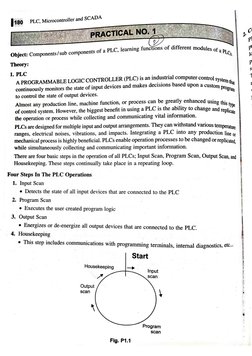

Four Steps In The PLC Operations

1. Input Scan

© Detects the state of all input devices that are connected to the PLC

2. Program Scan

Executes the user created program logic

3. Output Scan

Energizes or de-energize all output devices that are connected to the PLC.

4. Housekeeping

* This step includes communications with Programming terminals, internal diagnostics, etc.

Start

Housekeeping ner

A scan

Output

scan

Program

scan

Fig. P1.1

Practicals

4, Concept of PLC =

PLC Programmable Logic Concept Programmable logic controller is a microprocessor based

ing technique , which is used to perform many functions in industrial iced Programmable

logic controller operates similar to the ordinary controller. But in this system different operation are

performed by software If we want to change program it is only needed to change the program in the

software PLLC takes input instructions in the form of ladder diagram or computer software instructions

‘These instructions are decoded in CPU and CPU provides differed signals to control or to operate

many devices of System When these devices change their position or cause to change controlled

variable. A sample of controlled variable is given to CPU indicate that change in controlled variable

has been eliminated, PLC basically consists of a ladder network, which is performed according

requirements of the system.

Input and output device used in PLC:

(@) Input Device

An input device is a piece of computer hardware equipment used to provide data, and control

signals to an information processing system (IPS). Some examples of input devices include:

© Switches and push buttons

* Sensing devices

«Limit switches

* Proximity sensors

«Photoelectric Sensors

* Condition sensors

© Vacuum switches

‘© Temperature switches

© Level switches

© Pressure switches

(b) Output Devices :

‘An output device is any piece of hardware used fo communicate the results of data processing

cartied out by an IPS, and translate the information into an understandable form.

* Valves ij

* Motor starters

+ Homs and alarms

© Stack lights i

* Control relays

* Pumps

© Printers

© Fans

a SCADA

Microcontroller ané

free Pc

js shown in above figure. Thy

3. Block Diagram FPLC sic controller (PLC) is 8 © PLC

i

‘The block diagram of progr

following basic sections ae-

OM

uo

TO

essor > u | OL—>

—> ree ul

FB To

oe output

Solenoids,

sont contactors,

limit switches, etc. Programming alarms, etc.

device

Fig, P1.2. PLC Block Diagram

(i) Processor section (CPU)

‘The processor section is brain of PLC which consists of RAM, ROM, logic solver and user

memory. The central processing unit is heart of PLC. CPU controls monitors and supervises

all operation within PLC. The CPU makes decision and executes control instructions based

on the program instruction in memory.

(i) Input and output module

The input module is a mediator between input devices and central processing unit (CPU)

which is used to convert analog signal into digital signal.

The output module is a mediator between output devices and central processing unit (CPU)

which is convert digital signal into analog signal. .

Power supply .

P is provi ;

say bine at pa the processor unit, input and output module unit. Power supply

ly mo i

volts. vunted unit. Most of the PLC operates on 0 volts DC and 24

(iv) Memory section

The memory section is the area of the

reieved. Data Memory is wret CPU it which data and information is stored and

re

code data etc. User memory contains sey

ne

Practicals 4834]

Ww Programming device

Programming devices are dedicated devices used for loading the user program into the program

memory or edit it and to monitor the execution of the program of the PLC. It is also used to

troubleshoot the PLC ladder logic program, Hand held terminal (HHT) or dedicated terminal

or personal computer are programming devices commonly used in most of the PLCs.

Result: Hence we learn about PLC, its concept and function of its different module.

rocontroller and SCADA

PRACTICAL NO. 2.)

ee

ing hand bar Zoprammer )

[84 PLC, Mic

Object: Practical steps in

interface.

programming a PLC (#) us

Theory:

ing Hand held programming:

Teg for programming a PLC for a certain application depends on the type of stand

xe procs aes,

en atarer software tool and the type of control application.

Step 1: Analyze and Get the Idea of Control Application ;

‘The primary step to prograin the PLC is to get the idea for which you are going to develop an application,

based program, if you are driving a line follower robot by the use of DC motor when the push bution

is pressed. This status must be displayed by the LED light when the motor gets tun on. The motors

also attached with a sensor (Here it is considered..as another switch) that detects obstacles, so when

this turned on, the motor should be tured off. And correspondingly, if the motor switched off, the

buzzer should be tuned on,

‘Switch

7

|

~ i:

he Design usin,

2 Flowchart

Brine te Mi Motor, A: input Switch 1,

lnies :

Bic is easy with the implementatio,

Fig. P21 PLO Contro} t

Step 2: List All the Conditions and Get Tole

The variables of the above

Buzzer, and the designing of the

below for the above application

Input Switch 2, L:LED and Bu:

n of flow chart, which is give?

Practicals 185]

Switch On A

Switch On C

Switch Of B

Switch OnB — |-_—»}Buzzeris On

Motor is started

and LED is on

Fig. P2.2 Flowchart of PLC Programming

suep3: Open and Configure the PLLC Programming Software

Open the programming software installed in the PC that comes with PLC hardware. Select the hardware

mde] of the PLC in the software and configure it with appropriate input and output modules. Select the

Inder language (LD) from the list of the programming languages, and choose the hardware processor

and give a name for the program.

Fig. P2.3. PLC Programming Software

Step 4: Add and Address Them

the Required Rungs ae

Add the required rungs based on the control application logic and giv

‘very input and outputs. The

re the address 0

adder logic diagram of the above discussed example is given below.

ler and SCADA

PLC, Microcontrol

[196 et 4 etl 4

A

ef} 4

Rung 2

B

Rung 3 aA KEL

c

BOA

Fig, P2.4 Example of Ladder Logic Program

Step 5: Check the Errors and Simulate It

Locate the Online section in the menu bar and select Online. Check for the errors and make necessary

changes after selecting Offiine. Again, go online and select the Run option to simulate. it,

Step 6: Download the Program to PLC CPU Memory

‘After the successful simulation of the program, download the program to CPU by selecting the Download

option through a network or communication cable.

() Using Computer Interface

These five steps will help you in your PLC programming.

(@ Define the task

(ii) Define the inputs and outputs

Gii) Develop a logical sequence of operation

(iv) Develop the PLC program

(v) Test the program

The five steps form the basis of all PLC development.

Result: Hence, we learn some common practical steps in PLC programming

=-4340 TZ,

Practicals 1934]

— opject* Basic logic operations, AND, NOT, OR functions

‘pheory?

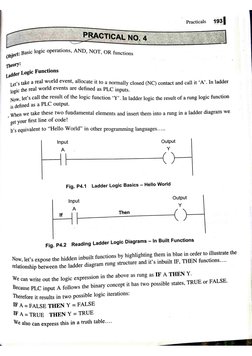

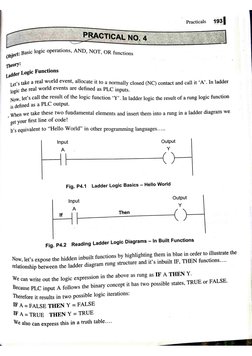

der Logic Functions

i's take a real world event, allocate it to a norms .

lope the real world events are defined as PLC inputs Slog (NC) contac nad salts

Now, let’s call the result of the logic fu “y .

jg defined as a PLC output. inction *Y’. In ladder logic the result of a rung logic function

| When we take these two fundamental elements and insert them into a rung in a ladder diagram we

get your first line of code!

It's equivalent to “Hello World” in other programming languages...

Input Output

7 pet te

4.1 Ladder Logic Basics - Hello World

Input Output

A Y

It Then (

4.2. Reading Ladder Logic Diagrams — In Built Functions

Fig.

tions by highlighting them in blue in order to illustrate the

Now, let’s expose the hidden inbuilt func

rung structure and it’s inbuilt IF, THEN functions...

Telationship between the ladder diagram

g as IF A THEN Y.

We can write out the logic expression in the above as run

‘TRUE or FALSE.

Because PLC input A follows the binary concept it has two possible states,

Therefore it results in two possible logic iterations:

IF A = FALSE THEN Y = FALSE

IF A= TRUE THEN Y = TRUE

We also can express this in a truth table...

[194 PLC, Microcontroller and SCADA

Truth Table

Output

Tnput

iagram we express it symbolically in the form of a

relay coil for the output. Remember the logic flow eh

fq

If we translate this into a ladder logic di

t of current flow in an electric circuit.

‘open (NO) contact for the input and a

left to right and follows the same concep!

‘The ladder logic truth table is shown below.

Ladder Logic Basics Truth Table — Hello World

Output

A Y

—

A= False /--—

A=True }_—__ (

ladder logic there are three more fundamental logic functions

Input

In order to fast track our understanding

that are essential to know.

You may be surprised, but wh

ised, len we combine these thi i i

to program the majority of automation control requireme ee en ele

The three functions are:

1. NOT

2. AND

3. OR

i) Ladder Logic NOT Function

So if PLC input A is FALSE

the result wi

TRUE the result will be FALSE, O° TRUE. And vise versa when PLC input A*

The NOT ion i i

Function is sometimes referred toas reverse Noslecth ;

ic. Check out the truth table below"

If we translate a NOT function into a I

form of @ normally closed (NC) contact

Truth Tat

Practicals 195]

~ NOT Function

—"

Tn

re Output

Y

False

Law ame

= False

ladder logic dia

The ladder logic truth table is shown below.

gram We express it symbolically in the

Ladder Logic Basics Truth Table - NOT Function

A

Not A

False

SE

True

SE

ie

SIE

(ii) Ladder Logic AND Function

The AND function examines multiple PLC inputs and has one resulting output.

If we translate an AND function into a ladder diagram we can express it symbolically in the form

of two normally open (NO) contacts (PLC inputs A and B) and a relay coil (PLC output Y).

They are all connected in line, just like a series connection in an electric circuit.

Input

A B Y

i And Then (

Input

Output

Fig. P4.3 Ladder Logic Basics - AND Function

This time we have also highligl

nted the hidden AND function to illustrate the relationship

between the ladder logic functions and the ladder diagram rung structure.

We can write out the logic expression above as IF A AND B THEN Y.

The AND function examines if all the PLC inputs are T'

also TRUE, However if any one of the PLC inputs is FALSE then the correspo!

also FALSE.

RUE, then the corresponding result is

nding result is

Because PLC input A and B follows the binary concept and are part ofthe AND fonction there

are four possible logis iterations.

—_—_—

196 PLC. Microcontolier and SCADA

Check out the truth table below..

‘Truth Table - AND Function

Input | Owput |

Y

False False False

False True False

True False False

True True True

‘The number of logic iterations increases with the number of PLC inputs (2PLC Inputs), But that

doesn’t matter too much with the AND function because the result can only be TRUE if all

the PLC inputs are TRUE.

If we translate an AND function into a ladder logic truth table we get the table below...

Ladder Logic Basics Truth Table ~ AND Function

Inputs Oui

A B Y

A= False

B = False | 7 \

C }

A= False

B> True ;

Y = False } ( )

Y = False f (

A= True

B= True

Epo

‘Nee

yi) vader Logic OR Function Practicals 1974]

(i

‘the OR function examines multiple PLC in

. puts:

sens an OR function ino a iden ae and has one resulting output.

ram We can,

of two normally open (NO) contacts (PLC inputs A aga ne re symbolically in the form

jnputs are placed in 5 . ind B) and a relay il (PL

‘The inpul Placed in the Tung in what is known as a by *y coil q shania Y).

el connection in an electric circuit, a branch. This is the equivalent of a

‘The output is then connected in line with the run

Bese

Input

” output

= Then cy |

| C} |

Or

Input

B

Fig. P4.4 Ladder Logic Basics - OR Function

This time we have also highlighted the hidden OR function when we create a branch (parallel

connection) with PLC input B across PLC input A.

We can write out the logic expression above as IF A OR B THEN Y.

‘The OR function examines if any of the PLC inputs are TRUE, then the corresponding result

is also TRUE. However, all the PLC inputs must be FALSE in order for the corresponding

result is also be FALSE.

Because PLC input A and

are four possible logic iterations.

Check out the truth table below...

‘ ‘Truth Table - OR Function s

B follows the binary concept and are part of the OR function there

Inputs Output

Y

fh 9 | PLC, Microcontroller and SCADA

Remember, the number of logic iterations increases with the number of PLC inputs (2°Ctapus),

But that doesn't matter too much with the OR function because the result can be TRUE if any

of the PLC inputs are TRUE.

If we translate an OR function into a ladder logic truth table we get the table below

Ladder Logic Basics Truth Table ~ OR Function

Output

Y

Input x3

A= False A t+—- ( J

B = False Input

Y = False B | |

Input

A= False A T (

B= True Input

Y =True B

Input

A=Tnue A

B= False Input

Y=True B

—

a

| 4H

YH

Result:

Hence, we learn about logic operation and, or, not,

el eree hs

[226 PLC. Microcontroller and SCADA

Object: Familiarization of micro controllers (8051) kit.

Theory:

ICROCONTROLLER :

sien: ‘The 8051 is a 8-bit microcontroller planned by

icro-controller has on-chip fringe devices. The * ; ean

mat he vanced for math and single Boolean operations. Its family MCS-51 incorporates 8031,

8051 and 8751 microcontrollers. atta’ st

In spite of it’s moderately, the 8051 is a standout amongst the most mainstres ocontrolles

being used today. Numerous subordinate microcontrollers have subsequent to been produced that

are in view of and perfect'with the 8051. In this way, the capacity to program 8051 is an essential

ability for any individual who arrangements to create items that will exploit microcontrollers.

e

2. FEATURES OF 8051

© 4096 bytes on-chip program memory.

‘* 128 bytes on-chip data memory.

« Four register banks.

128 User defined software flags.

© Two multiple mode, 16 bit timers/counters.

* Hardware Multiple and divide in 4ysec.

‘© 64Kb each program and external RAM addressability.

3. ARCHITECTURE OF 8051

The 8051 microcontroller comprises of CPU, two sorts of memory segments, data and output pots

uncommon capacity registers and control logic required for differem Peripheral functions. Thes¢

components comraunicates with 8-bit information BUS and Bus is Buffered to the outside through 4”

V/O port when memory is fancied,

Practicals 227

External

intomupts

ON-CHIP|

ROM

Bus 40 Serial

ay ‘10 a

bal TP EB nuh]

SOPESE | = sopr PoPi Pa Py THD RXD

“410 30 MHz

Normally 11.0592 MHz fciveoeOate

Fig. P61

4, PIN-OUT OF 8051

‘The 8051 microcontroller is bundled in a 40-pin DIP (Dual Inline Package) . Every microcontroller have

data and output ports. The 8051 has’32 V/O pins arranged as four 8-bit parallel ports (PO, Pl, P2, P3).

Every one of the four ports are bidirectional i.e. every pin will be designed as data or output or both.

Every single port pin are multiplexed with the exception of the pins of portl. Every port comprises of a

hook, a output driver and an information support. The pin description is explained below:

P10 wk

1

Pit 2 P00

P12 3 Pot

p13 4 P02

pia 15 pos

pis 16 Poa

p16 7 a

p17 18 Pos

9 POT,

P30

P3.t

P32

P33 Pay

Fat P26

i P25

P24

P23

P22

P24

2.0

Fig. P6.2

[228 PLC. Microcontroller and SCADA

PORT 1

Pins 1-8 . |

Port 1 pins can be used only as Input and Output /O pins.

PORT 2

Pins 21-28 |

ilized to get to outer memory. Port2 outputs the high request byy,

drives of port2 are uti smory. high re

of be ostside memory address when the location is 16-bits wide, generally Port2is utilized as yg

port.

PORT3

Pins 10-17

All port pins of port3 are multifunctional. They have special functions.

POWER-SUPPLY PINS

8051 operates on D.C power supply of +5v. The +5v is connected to the pins Vec (pin 40) and GND

is connected to the pin 20.

XTAL2 AND XTALI OSCILLATOR }

For generating an internal clock signal, the external crystal oscillator is connected at these two pins. |

|

Ce

18 XTAL2

Cy

18 XTAL1

20 GND

Fig. P6.3

ALE (ADDRESS LATCH ENABLE)

ADO to AD7 lines are multiplexed. To de-multip| i

; = lex these Ii i

address, an external latch and ALE signal of 3051 is used. Tp ae Kr eiaising lover baal

RST (RESET)

The pin is used to reset 8051. For i

$ . For proper reset operation, i i

two machine cycles, when crystal oscillator is running. Perce ast beheld igh a eas

PSEN (PROGRAM STORE ENABLE)

Pin 29 :

Itis the active low output c i to activate able signal of the external RO!

ive lox ontrol signal used tivate the en: ign:

EPROM. It is activated every six oscillator periods while reading the em al may

ternal memory.

ahd

Practicals 2284)

5A (EXTERNAL ACCESS)

pin 31

av the point en BA pin is high Goined with vec), the system gets to address 0000H through

iH are coordinated to interior ROM and project gets to addresses 1000H through FFFFH are

jinated to outside ROM/EPROM. At the point when EA is low (When Ov) all addresses (Q000H_

comEFH) got by project are coordinated to the outside ROM/EPROM.

5, $051 0SC

1n 8051, # macl

ods). Every state is partitioned into two stages (Phas

Mock is dynamic and Phase 2 clock is dynamic amid

¢> exillator periods, (Sate 1, Phase 1) to (Sate 6, Phase 2) of | Hees

1D MHz. Every stage goes on for one oscillator period.

{LLATOR AND CLOCK

hhine cycle comprises of a succession of 6 states numbered $1 to $6 (12 oscillator

e 1 and Phase 2). Amid Phase 1, Phase 1

‘ase 2. A machine cycle comprises Of

if the oscillator recurrence is

1¢——_ One machine cycle

voles ezles[ voor | || rare =| Lv ee =

XTAL

Fig. P6.4

6, Kit Content:

1 x 8051 Development Board with AT89S52 Controller

1 x MAX232 IC

1 x DS1307 IC

« 1.x ULN2003 IC

«1x 16x2 LCD (Female)

« 1x8 Pin Female to Female Connecting Wire”

* 1x3 Pin Female to Female Connecting Wire

« 2.x 4 Pin Female to Female Connecting Wire

© 1x 8051 USBASP Programmer

bout 8051 Microcontroller architecture,

Result: Hence, we learn al pin diagram an its kit.

[230 PLC. Microcontroller and SCADA

PRACTICAL NO. 7

Object: Testing of general input/ output on micro controller board.

Theory:

1. Testing of Input/output Ports:

In this example I will explain how to use I/O ports of ‘8051 microcontroller. Input to the microcontroller

can be given through push button and output can be seen through LED. Firstly all the port pins are

defined. Port 2 is used as output port and port 3 is used as input port. These Ports are initialized with

0 (to write) and 1 (to read) logic respectively. Delay function is used to give the delay in showing

output. Frequency of crystal should be set to 11.059MHz. Program is written in C language using

“Keil”. software and hex file is loaded in the microcontroller.

D1

a Rt

Soy ‘=

— LED-YELLOW

C1 D2

=| ut 2 R2 a

on “pe Shee ubvetiow

* ES ext

.

os > —@: |

RET — LED-YELLOW

R4 D3.

.

©

300. .

—_LED-YELLOW

18

P10 P3.0/AxD} #10

2elory — paampfett

P12 P3.DiNTOLEI2

P13 PaginTifet3

Pid

PLS

P16

PIT

\TESC51

. a

Fig. P7.1

i Practicals 231]

2, WORKING of input output ports 8051 m

‘ . icrocontroller:

When we run the simulation, if first

be ON according to the respective input of

then delay call is passed large integer value,

Programming Code:

#include

sbit Led1 & P20;

sbit Led2 = P241;

sbit Led3 = P22;

sbit Led4 = P23;

sbit Button] = P30; /Defining Button Pins

sbit Button2 = P31;

sbit Button3 = P32;

sbit Button = P343;

‘MDefining LED Pins

void Delay(int); MDelay function declaration

int main ()

{

P2 = 0x00, Hased as.autput port

P3 = OxFF; /used as input port

do

{ 1

if(Button] == 0) INE 1switch pressed

=1 MMst LED ON

Delay(1000);

Ledl = LED OFF

if(Button2 == 0 ) inf 2°switch pressed

Led2 = 1; 172° LED ON

[282 PLC, Microcontroller and SCADA

if(Button3 == 0 )

{

Led3 = 1; /LED ON

Delay(1000); //Delay

Led3 = 0; //LED .QFF

}

if(Button4 == 0 )

{

Led4 = 1; /LED ON

Delay(1000); //Delay

Led4 = 0; //LED OFF

}

while(1);

}

void Delay(int k)

{

int j;

inti;

forlimO;i

You might also like

- BHEL Jagdishpur Summer Training OverviewNo ratings yetBHEL Jagdishpur Summer Training Overview17 pages

- B.tech 7th Sem Previous Year Question .No ratings yetB.tech 7th Sem Previous Year Question .10 pages

- Programmable Logic Controller (PLC) - Programming LanguagesNo ratings yetProgrammable Logic Controller (PLC) - Programming Languages23 pages

- Submited by:-VII Semester, IV Year Electrical Engineering Submitted To0% (1)Submited by:-VII Semester, IV Year Electrical Engineering Submitted To23 pages

- Experiment # 01: Verification of Star/delta Load Transformation Using Resistive Load0% (1)Experiment # 01: Verification of Star/delta Load Transformation Using Resistive Load3 pages

- A Report On The "3-Phase Line Fault Detector" Ee344 Minor Project - I100% (1)A Report On The "3-Phase Line Fault Detector" Ee344 Minor Project - I34 pages

- Mechanical Power Developed by A Synchronous MotorNo ratings yetMechanical Power Developed by A Synchronous Motor3 pages

- Smooth Start of Single Phase Induction Motor: Project Seminar On100% (2)Smooth Start of Single Phase Induction Motor: Project Seminar On11 pages

- Introduction To Programmable Logic Controllers22% (18)Introduction To Programmable Logic Controllers11 pages

- Energy Conservation in Electrical MachinesNo ratings yetEnergy Conservation in Electrical Machines59 pages

- 132 KV Gss Chambal Powerhouse Sodala, JaipurNo ratings yet132 KV Gss Chambal Powerhouse Sodala, Jaipur37 pages

- Training Report On 220/132KV SubstationNo ratings yetTraining Report On 220/132KV Substation34 pages

- UPPCL Technical Interview Question Paper 2011 Placement Model Question Paper JbigDeaL0% (1)UPPCL Technical Interview Question Paper 2011 Placement Model Question Paper JbigDeaL4 pages

- Example Of: (Z) Matrix Building AlgorithmNo ratings yetExample Of: (Z) Matrix Building Algorithm10 pages

- 6TH Sem Electrical All Question Paper 2022No ratings yet6TH Sem Electrical All Question Paper 202210 pages

- Electrical Machine BEU Patna Notes and PYQNo ratings yetElectrical Machine BEU Patna Notes and PYQ27 pages

- Electrical Drives and Control by Bakshi M.v.bakshiNo ratings yetElectrical Drives and Control by Bakshi M.v.bakshi4 pages

- Experiment No-01 AIM: To Perform No Load Test On 3ø Induction MotorNo ratings yetExperiment No-01 AIM: To Perform No Load Test On 3ø Induction Motor17 pages

- RGPV Syllabus Btech Ee 5 Sem All SubjectsNo ratings yetRGPV Syllabus Btech Ee 5 Sem All Subjects17 pages

- Unit-6 - Eds - Power Factor Improvement & Voltage Control100% (1)Unit-6 - Eds - Power Factor Improvement & Voltage Control83 pages

- Expulsion and Valve Type Lightning ArrestersNo ratings yetExpulsion and Valve Type Lightning Arresters13 pages

- Understanding Programmable Logic ControllersNo ratings yetUnderstanding Programmable Logic Controllers31 pages

- Introduction to Programmable Logic ControllersNo ratings yetIntroduction to Programmable Logic Controllers26 pages

- PLC Ladder Logic: Nano PLC Micro PLC Mini PLC Compact PLC Small PLC Brick PLC Medium PLC Large PLC Modular PLCNo ratings yetPLC Ladder Logic: Nano PLC Micro PLC Mini PLC Compact PLC Small PLC Brick PLC Medium PLC Large PLC Modular PLC12 pages