Professional Documents

Culture Documents

V-C27 (Bauberia)

Uploaded by

christiangrbrielOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V-C27 (Bauberia)

Uploaded by

christiangrbrielCopyright:

Available Formats

SPORE PRODUCTION IN 7 L AND 75 L STIRRED TANK BIOREACTORS

Jazmín Zúñiga Zamudio, Carlos Orozco Álvarez, Sergio García Salas.

Unidad Profesional Interdisciplinaria de Biotecnología. Departamento de Bioingeniería. Av.

Acueducto s/n. La Laguna-Ticomán. México, D. F., sgarciasa@ipn.mx

Key words: Bioinsecticide, entomopathogenic fungus, stirred tank bioreactor.

Introduction. Among the agents used for 1.80E+08 6.000

biological pest control are fungi and their

Dry weigth (g/L), Substrate (g/L)

1.60E+08

5.000

spores. One way to produce them at large 1.40E+08

scale is to grow fungi in liquid medium using 1.20E+08 4.000

Spores/mL

bioreactors. In a study of scaling up, the type 1.00E+08

3.000

of bioreactor and its operating conditions 8.00E+07

should be specified, with them a mixing 6.00E+07 2.000

conditions and mass and heat transfer should 4.00E+07

allow to obtain at large scale at least the 2.00E+07

1.000

same productivity and yields obtained at 0.00E+00 0.000

smaller scale. There are different strategies 0 20 40 60 80 100 120 140

for scaling up process, the most used are Time (h)

those based on the power consumed per unit

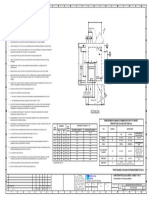

volume (1) and the volumetric ratio of oxygen Fig.1 Growth kinetics, substrate consumption and

transfer (2). production of Beauveria bassiana spores in 75 L stirred

tank bioreactor. Spores (○), dry weight (□) and substrate

The objetive of this work was to study the (Δ).

production of Beauveria bassiana spores in 7

L and 75 L stirred tank bioreactors.

The development of the scaling strategy

Methods. Beauveria bassiana BbPM inocula resulted in that it is feasible to produce the

were prepared using spores obtained in PDA Beauveria bassiana spores using low power

0

medium after 21 days of growth at 21 C, at a requirements in the order of 0025 W/L and a

6

concentration of 10 spores/mL. The culture oxygen transfer rate of 0.02 g/Lh, This was

medium used in the inoculum and in the possible because the fungus has a low

bioreactors was constituted by 14.5 mL/L of growth rate (μmax=0.044 h-1) and the culture

molasses, 6 g/L of (NH4) 2SO4, 3.5 g/L of reaches a relatively low cell concentration (≈

KH2PO4, 0.5 g/L of MgSO4, 0.1 g/L of NaCl 5 g/L).

and 0.1 g/L CaCl2. The temperature was 24

°C and pH 5.4. The bioreactors were Conclusions. Spore production in 7 L and 75

geometrically similar. The stirred tank had L was similar in spite of at 75 L the power

two Rushton turbines. The spore count was input and oxygen transfer rate was lower than

performed in a Neubauer chamber. The in 7 L. Thus, the same spore productivity can

oxygen transfer rate was determined with the be obtained at large scale with lower

dynamic method. operating costs.

Results. Fig. 1 shows the growth kinetics, Acknowledgements. Proyecto SIP

substrate consumption and production of 20120467 y COFAA-IPN.

Beauveria bassiana spores in 75 L stirred

tank bioreactor. The behavior of all variables References.

1. Razo E., Perez F., De La Torre M. (1997) Scale-Up of

is similar to that obtained with the 7 L stirred Bacillus thuringiensis Fermentation Based on Oxygen

tank bioreactor. The highest concentration of Transfer. J. Fermen. Bioeng. 6: 561-564.

8

spores reached was 1.69 x 10 spores/mL. 2. Rocha-Valadez J.A., Estrada M., Galindo E., Serrano-

This concentration is of the same order of Carreon L. (2006) From shake flasks to stirred

fermentors: Scale-up of an extractive fermentation

magnitude as that obtained in 7 L stirred tank process for 6-pentyl-a-pyrone production by Trichoderma

biorreactor, showing that the operating harzianum using volumetric power input. Process

conditions employed in the 75 L bioreactor Biochemistry 41: 1347–1352.

were adequate to meet the target of scaling

up.

You might also like

- Influence of Seed Sludge and Pretreatment Method On Hydrogen ProductionDocument9 pagesInfluence of Seed Sludge and Pretreatment Method On Hydrogen ProductionProfessor Douglas TorresNo ratings yet

- Sciencedirect: Industrial Tofu Wastewater As A Cultivation Medium of Microalgae Chlorella VulgarisDocument7 pagesSciencedirect: Industrial Tofu Wastewater As A Cultivation Medium of Microalgae Chlorella VulgariserlisaNo ratings yet

- Gannou 2009Document9 pagesGannou 2009ThobiasNo ratings yet

- Evaluation of A Novel Wave BioreactorR Cellbag ForDocument12 pagesEvaluation of A Novel Wave BioreactorR Cellbag ForAna Cristina GutiérrezNo ratings yet

- Zheng - Microbial Mass Production From Rice StrawDocument8 pagesZheng - Microbial Mass Production From Rice StrawJesenia Machicado CadimaNo ratings yet

- Peixoto 2011Document14 pagesPeixoto 2011Professor Douglas TorresNo ratings yet

- (ENV10) Anaerobic Wastewater Treatment To Yield Biogas: Norazwina Zainol, Rakmi Abd. RahmanDocument6 pages(ENV10) Anaerobic Wastewater Treatment To Yield Biogas: Norazwina Zainol, Rakmi Abd. RahmannycoNo ratings yet

- Treatability and Kinetics Studies of Mes PDFDocument8 pagesTreatability and Kinetics Studies of Mes PDFwilfredo suarez torresNo ratings yet

- Wu 2012Document7 pagesWu 2012f20221437No ratings yet

- Lo Del Almidon 1990Document5 pagesLo Del Almidon 1990Alessandra CalderonNo ratings yet

- Biodegradation of Municipal Wastewater With Local and C - 2014 - Procedia EngineDocument5 pagesBiodegradation of Municipal Wastewater With Local and C - 2014 - Procedia EngineMohamed FirthousNo ratings yet

- Effect of Mechanical Agitation On The Production of Cellulases by Trichoderma Reesei RUT - 30 in A Draft - Tube Airlift BioreactorDocument9 pagesEffect of Mechanical Agitation On The Production of Cellulases by Trichoderma Reesei RUT - 30 in A Draft - Tube Airlift BioreactormariaNo ratings yet

- Anaerobic Pre-Treatment of Slaughterhouse Wastewater UsingDocument7 pagesAnaerobic Pre-Treatment of Slaughterhouse Wastewater UsingPablo PiacentiniNo ratings yet

- Hybrid Anoxic ReactorDocument7 pagesHybrid Anoxic ReactorThirumurugan PandiyanNo ratings yet

- 10.1515 Helia.2001.24.35.47Document8 pages10.1515 Helia.2001.24.35.47tito cuadrosNo ratings yet

- Rafael EjemplosDocument7 pagesRafael EjemplosAntonio MoncayoNo ratings yet

- DR GopalbioflocpressDocument26 pagesDR GopalbioflocpressrrvlsolutionsNo ratings yet

- Acharya 2008Document6 pagesAcharya 2008Harsha Vardhan ReddyNo ratings yet

- Mata2016 CetDocument6 pagesMata2016 CetTeresa MataNo ratings yet

- 10 1016@j Ijhydene 2018 09 066Document8 pages10 1016@j Ijhydene 2018 09 066Juan Luis Saldaña MéndezNo ratings yet

- Lee Et Al 1998Document3 pagesLee Et Al 1998rinifiahNo ratings yet

- Algae ProductionDocument8 pagesAlgae ProductionmksrichaNo ratings yet

- Nobre2013 MicroalgaeDocument9 pagesNobre2013 MicroalgaeTeresa MataNo ratings yet

- Avoid Pitfalls of BioProcess Development PDFDocument8 pagesAvoid Pitfalls of BioProcess Development PDFkumar_chemicalNo ratings yet

- Anaerobic Digestates Grown Oleaginous Microalgae For Pollutants - 2022 - ChemospDocument9 pagesAnaerobic Digestates Grown Oleaginous Microalgae For Pollutants - 2022 - ChemospAbigailNo ratings yet

- Biogas GenerationDocument4 pagesBiogas GenerationneonpointNo ratings yet

- Solid Substrate Cultivation of Gibberella Fujikuroi On An Inert SupportDocument7 pagesSolid Substrate Cultivation of Gibberella Fujikuroi On An Inert Supportnaffy lizethNo ratings yet

- HA JBTS PublishedDocument4 pagesHA JBTS PublishedBriliant PersonNo ratings yet

- The Biobed® Egsb (Expanded Granular Sludge Bed) System Covers Shortcomings of The Upflow Anaerobic Sludge Blanket Reactor in The Chemical IndustryDocument5 pagesThe Biobed® Egsb (Expanded Granular Sludge Bed) System Covers Shortcomings of The Upflow Anaerobic Sludge Blanket Reactor in The Chemical IndustryTho HoangNo ratings yet

- Hammerschmidt2011 - Catalytic Conversion of Waste Biomass by Hydrothermal TreatmentDocument8 pagesHammerschmidt2011 - Catalytic Conversion of Waste Biomass by Hydrothermal Treatmentfarida_crNo ratings yet

- Microbial Enhanced Oil Recovery Potential of Surfactin Producing Bacillus Subtilis AB2.0Document7 pagesMicrobial Enhanced Oil Recovery Potential of Surfactin Producing Bacillus Subtilis AB2.022-08420No ratings yet

- Xilitol-Lecho FluidizadoDocument5 pagesXilitol-Lecho FluidizadoMaria Victoria Ortega RamosNo ratings yet

- 12 2010 PerformanceandmicrobialcommunitycompositionDocument15 pages12 2010 PerformanceandmicrobialcommunitycompositionOscar FranchiniNo ratings yet

- Apresentaçâo Resumo AbcmDocument6 pagesApresentaçâo Resumo AbcmRuan Vitor Cortelassi da CruzNo ratings yet

- Neyza Et Al. - 2014 - Growth of Microalgae Scenedesmus SP in Ethanol VinasseDocument6 pagesNeyza Et Al. - 2014 - Growth of Microalgae Scenedesmus SP in Ethanol VinassefvassisNo ratings yet

- Rhodopseudomonas Palustris: Research ArticleDocument9 pagesRhodopseudomonas Palustris: Research Articlecamilo.zolezziNo ratings yet

- TOTAL MicroalgaeDocument16 pagesTOTAL MicroalgaesafsyahNo ratings yet

- 1475 2859 9 42 PDFDocument11 pages1475 2859 9 42 PDFdivya_jspandianNo ratings yet

- Bioresource Technology: Yeong Hwan Seo, Il Gyu Lee, Jong in HanDocument5 pagesBioresource Technology: Yeong Hwan Seo, Il Gyu Lee, Jong in Hansam samNo ratings yet

- Anaerobic Digestion of Spent Wash Through Biomass Development For Obtaining BiogasDocument1 pageAnaerobic Digestion of Spent Wash Through Biomass Development For Obtaining BiogassanketNo ratings yet

- Ren 2010Document6 pagesRen 2010Rizka Aulia RNo ratings yet

- Study of Biodegradability of Organic Fraction of Municipal Solids WasteDocument10 pagesStudy of Biodegradability of Organic Fraction of Municipal Solids Wastefranklin hitler fernandez zarateNo ratings yet

- El EnshasySboulardiiDLRDocument7 pagesEl EnshasySboulardiiDLRMinh AnhNo ratings yet

- Treatment of Wastewater From A Monosodium Glutamate Manufacturing Plant Using Successive Yeast and Activated Sludge SystemsDocument7 pagesTreatment of Wastewater From A Monosodium Glutamate Manufacturing Plant Using Successive Yeast and Activated Sludge SystemsMinh Hằng ĐặngNo ratings yet

- International Biodeterioration & BiodegradationDocument8 pagesInternational Biodeterioration & BiodegradationVeredAlostaNo ratings yet

- Javed IqbalDocument5 pagesJaved IqbalAnh NguyenNo ratings yet

- Effect of Aeration and Agitation Rates and Scale-Up On Oxygen Transfer Coefficient, Kla in Exopolysaccharide Production From Enterobacter Cloacae WD7Document13 pagesEffect of Aeration and Agitation Rates and Scale-Up On Oxygen Transfer Coefficient, Kla in Exopolysaccharide Production From Enterobacter Cloacae WD7Alen AgicNo ratings yet

- Screening Test: Determine The Removal Efficiency of Enzymes Against A PseudomonasDocument7 pagesScreening Test: Determine The Removal Efficiency of Enzymes Against A PseudomonastxhitechNo ratings yet

- Population Changes of Eubacteria, Sulfate-Reducing Bacteria and Methanogenic Archaea in An Anaerobic Reactor Processing Ethanol Distillery VinasseDocument13 pagesPopulation Changes of Eubacteria, Sulfate-Reducing Bacteria and Methanogenic Archaea in An Anaerobic Reactor Processing Ethanol Distillery VinasseyutefupNo ratings yet

- Millán Oropeza Fernández Linares2017 - Article - BiomassAndLipidProductionFromN PDFDocument9 pagesMillán Oropeza Fernández Linares2017 - Article - BiomassAndLipidProductionFromN PDFGris PatyNo ratings yet

- Priyono 2013Document7 pagesPriyono 2013Dicki HarissandiNo ratings yet

- Biological Nutrient Removal in A Small-Scale MBR Treating PDFDocument9 pagesBiological Nutrient Removal in A Small-Scale MBR Treating PDFAlejandra Medina ArmijoNo ratings yet

- Model Based Constant Feed Fed-Batch - Sorbose Production Process For Improvement in - Sorbose ProductivityDocument8 pagesModel Based Constant Feed Fed-Batch - Sorbose Production Process For Improvement in - Sorbose ProductivitySagar DhuriNo ratings yet

- Bioresource Technology: Case StudyDocument8 pagesBioresource Technology: Case StudyAlma Ruby Felix PugaNo ratings yet

- International Biodeterioration & Biodegradation: Toruloides Using An Open-Bubble-Column Reactor Under Non-AsepticDocument10 pagesInternational Biodeterioration & Biodegradation: Toruloides Using An Open-Bubble-Column Reactor Under Non-AsepticFalcon ChauNo ratings yet

- 1 s2.0 S0960852415008603 MainDocument7 pages1 s2.0 S0960852415008603 MainHuynh Minh Quan B2014431No ratings yet

- Bioprocessing for Cell-Based TherapiesFrom EverandBioprocessing for Cell-Based TherapiesChe J. ConnonNo ratings yet

- Biogas Production: Pretreatment Methods in Anaerobic DigestionFrom EverandBiogas Production: Pretreatment Methods in Anaerobic DigestionNo ratings yet

- Emulsion-based Systems for Delivery of Food Active Compounds: Formation, Application, Health and SafetyFrom EverandEmulsion-based Systems for Delivery of Food Active Compounds: Formation, Application, Health and SafetyShahin RoohinejadNo ratings yet

- Applications SeawaterDocument23 pagesApplications SeawaterQatar home RentNo ratings yet

- Meno's Paradox of Inquiry and Socrates' Theory of RecollectionDocument10 pagesMeno's Paradox of Inquiry and Socrates' Theory of RecollectionPhilip DarbyNo ratings yet

- Dermatology Skin in Systemic DiseaseDocument47 pagesDermatology Skin in Systemic DiseaseNariska CooperNo ratings yet

- Book 1518450482Document14 pagesBook 1518450482rajer13No ratings yet

- Fire Protection in BuildingsDocument2 pagesFire Protection in BuildingsJames Carl AriesNo ratings yet

- Lamentation of The Old Pensioner FinalDocument17 pagesLamentation of The Old Pensioner FinalRahulNo ratings yet

- Inside:: Issue 4 - February 2004 Bi-Monthly Warhammer E-ZineDocument40 pagesInside:: Issue 4 - February 2004 Bi-Monthly Warhammer E-ZineJoe BloggsNo ratings yet

- Nanolithography - Processing Methods PDFDocument10 pagesNanolithography - Processing Methods PDFNilesh BhardwajNo ratings yet

- How He Loves PDFDocument2 pagesHow He Loves PDFJacob BullockNo ratings yet

- Clark SM 616 Service ManualDocument20 pagesClark SM 616 Service Manualenid100% (55)

- Injections Quiz 2Document6 pagesInjections Quiz 2Allysa MacalinoNo ratings yet

- Dwnload Full Principles of Economics 7th Edition Frank Solutions Manual PDFDocument35 pagesDwnload Full Principles of Economics 7th Edition Frank Solutions Manual PDFmirthafoucault100% (8)

- Listen and Arrange The Sentences Based On What You Have Heard!Document3 pagesListen and Arrange The Sentences Based On What You Have Heard!Dewi Hauri Naura HaufanhazzaNo ratings yet

- Notes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0MDocument1 pageNotes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0Mسجى وليدNo ratings yet

- Triaxial Shear TestDocument10 pagesTriaxial Shear TestAfiqah Nu'aimiNo ratings yet

- Synthesis, Analysis and Simulation of A Four-Bar Mechanism Using Matlab ProgrammingDocument12 pagesSynthesis, Analysis and Simulation of A Four-Bar Mechanism Using Matlab ProgrammingPedroAugustoNo ratings yet

- Lesson 3 - ReviewerDocument6 pagesLesson 3 - ReviewerAdrian MarananNo ratings yet

- Quiz 140322224412 Phpapp02Document26 pagesQuiz 140322224412 Phpapp02Muhammad Mubeen Iqbal PuriNo ratings yet

- A Survey On Security and Privacy Issues of Bitcoin-1Document39 pagesA Survey On Security and Privacy Issues of Bitcoin-1Ramineni HarshaNo ratings yet

- Executive Summary-P-5 181.450 To 222Document14 pagesExecutive Summary-P-5 181.450 To 222sat palNo ratings yet

- KsDocument5 pagesKsnurlatifahNo ratings yet

- DeliciousDoughnuts Eguide PDFDocument35 pagesDeliciousDoughnuts Eguide PDFSofi Cherny83% (6)

- Bullshit System v0.5Document40 pagesBullshit System v0.5ZolaniusNo ratings yet

- Evs ProjectDocument19 pagesEvs ProjectSaloni KariyaNo ratings yet

- 8051 NotesDocument61 pages8051 Notessubramanyam62No ratings yet

- Physics Education Thesis TopicsDocument4 pagesPhysics Education Thesis TopicsPaperWriterServicesCanada100% (2)

- Anemia in PregnancyDocument5 pagesAnemia in PregnancycfgrtwifhNo ratings yet

- Jackson V AEGLive - May 10 Transcripts, of Karen Faye-Michael Jackson - Make-up/HairDocument65 pagesJackson V AEGLive - May 10 Transcripts, of Karen Faye-Michael Jackson - Make-up/HairTeamMichael100% (2)

- Genetics Icar1Document18 pagesGenetics Icar1elanthamizhmaranNo ratings yet

- Case Study 2Document5 pagesCase Study 2api-247285537100% (1)