Professional Documents

Culture Documents

ISOFLEX LDS 18 SPECIAL A 004013 PI GB en

Uploaded by

denisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISOFLEX LDS 18 SPECIAL A 004013 PI GB en

Uploaded by

denisCopyright:

Available Formats

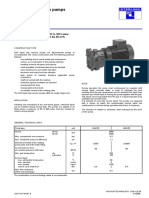

Product information

ISOFLEX LDS 18 SPECIAL A

Dynamically light, long-term lubricating grease

Your benefits at a glance

Long service life due to good corrosion protection as well as ageing and oxidation stability, hence cost savings

Tried-and-tested for many years, especially at high speeds and low temperatures

Low heating-up of bearings due to low lubricant friction leading to longer service lives

Your requirements - our solution Application notes

ISOFLEX LDS 18 SPECIAL A is a dynamically light long-term grease The lubricant is applied by brush, spatula, grease gun or grease

for plain and rolling bearings. It consists of ester oil, mineral oil and cartridge. Owing to the different compositions of elastomers and

lithium soap. The product is resistant to ageing, oxidation and water, plastic materials, compatibility tests are indispensable before series

and it protects reliably against corrosion. application.

Application Material safety data sheets

ISOFLEX LDS 18 SPECIAL A is suitable for plain and rolling bearings Material safety data sheets can be requested via our website

operating at low temperatures and/or high speeds, for example in www.klueber.com. You may also obtain them through your contact

grinding spindles, machine tool spindles, spindle bearings, textile person at Klüber Lubrication.

spindles, bearings in OE-spinning turbines, bearings in precision and

optical equipment.

Pack sizes ISOFLEX LDS 18 SPECIAL A

Cartrigde 400 g +

Can 1 kg +

Bucket 5 kg +

Bucket 25 kg +

Drum 180 kg +

Characteristics ISOFLEX LDS 18 SPECIAL A

Article number 004013

Composition, thickener lithium soap

Composition, type of oil ester oil , mineral oil

Colour space yellow

Texture homogeneous , short fibrous

Service temperature, lower limit -50 °C

Service temperature, upper limit 120 °C

ISOFLEX LDS 18 SPECIAL A , 004013, en-GB

Edition 03.03.2023 - replaces edition 20.02.2023

Product information

ISOFLEX LDS 18 SPECIAL A

Dynamically light, long-term lubricating grease

Characteristics ISOFLEX LDS 18 SPECIAL A

Density, Klüber method: PN 024, 20°C approx. 0.88 g/cm³

Worked penetration, DIN ISO 2137 / ASTM D217, 25°C, lower limit 265 0.1 mm

Worked penetration, DIN ISO 2137 / ASTM D217, 25°C, upper limit 295 0.1 mm

Shear viscosity, Klüber method: PN 008@DIN 53019-1, equipment: rotational viscometer, 2000 mPas

25°C, 300 s⁻¹, lower limit

Shear viscosity, Klüber method: PN 008@DIN 53019-1, equipment: rotational viscometer, 4000 mPas

25°C, 300 s⁻¹, upper limit

Kinematic viscosity of the base oil, DIN EN ISO 3104 / DIN 51562-1 / ASTM D445 / ASTM approx. 3.5 mm²/s

D7042, 100°C

Kinematic viscosity of the base oil, DIN EN ISO 3104 / DIN 51562-1 / ASTM D445 / ASTM approx. 15 mm²/s

D7042, 40°C

SKF-EMCOR, DIN 51802, Klüber method: distilled water, 168 h 0 corrosion degree

Low temperature torque, IP 186, -60°C, running torque ≤ 100 mNm

Low temperature torque, IP 186, -60°C, starting torque ≤ 1000 mNm

Dropping point, DIN ISO 2176 / IP 396 ≥ 190 °C

Speed factor (n x dm) approx. 1000000 mm/min

Minimum shelf life from the date of manufacture - in a dry, frost-free place and in the unopened 36 months

original container, approx.

Klüber Lubrication München GmbH & Co. KG /

Geisenhausenerstraße 7 / 81379 München / Germany /

Klüber Lubrication – your global specialist phone +49 89 7876-0 / fax +49 89 7876-333.

Innovative tribological solutions are our passion. Through personal The data in this document is based on our general experience and knowledge at the time of

contact and consultation, we help our customers to be successful publication and is intended to give information of possible applications to a reader with technical

worldwide, in all industries and markets. With our ambitious technical experience. It constitutes neither an assurance of product properties nor does it release the user

from the obligation of performing preliminary field tests with the product selected for a specific

concepts and experienced, competent staff we have been fulfilling application. All data are guide values which depend on the lubricant's composition, the intended

increasingly demanding requirements by manufacturing efficient high- use and the application method. The technical values of lubricants change depending on the

performance lubricants for more than 90 years. mechanical, dynamical, chemical and thermal loads, time and pressure. These changes may

affect the function of a component. We recommend contacting us to discuss your specific

application. If possible we will be pleased to provide a sample for testing on request. Klüber

products are continually improved. Therefore, Klüber Lubrication reserves the right to change all

the technical data in this document at any time without notice.

Publisher and Copyright: Klüber Lubrication München GmbH & Co. KG. Reprints, total or in

part, are permitted only prior consultation with Klüber Lubrication München GmbH & Co. KG

and if source is indicated and voucher copy is forwarded.

ISOFLEX LDS 18 SPECIAL A , 004013, en-GB

Edition 03.03.2023 - replaces edition 20.02.2023

You might also like

- Isoflex Lds 18 Special A: Product InformationDocument4 pagesIsoflex Lds 18 Special A: Product InformationSimty AkterNo ratings yet

- ISOFLEX LDS 18 SPECIAL A UV 004176 PI GB enDocument2 pagesISOFLEX LDS 18 SPECIAL A UV 004176 PI GB endenisNo ratings yet

- Kluber - 50C Pour VSNU Isoflex LDS 18 Special ADocument2 pagesKluber - 50C Pour VSNU Isoflex LDS 18 Special AsbyeNo ratings yet

- Isoflex Topas Nca 52: Product InformationDocument2 pagesIsoflex Topas Nca 52: Product InformationnghiaNo ratings yet

- Isoflex Lds 18 Special A PDFDocument4 pagesIsoflex Lds 18 Special A PDFNorbertoRGNo ratings yet

- Polylub Ga 352 PDocument2 pagesPolylub Ga 352 PMuhammad Samsul HasanNo ratings yet

- Isoflex Tel 3000 AltempDocument2 pagesIsoflex Tel 3000 AltempJuan Gabriel Galvis ZuluagaNo ratings yet

- Isoflex Topas NB 52 NB 1521 PDFDocument4 pagesIsoflex Topas NB 52 NB 1521 PDFc108No ratings yet

- Isoflex Topas NB 5051Document2 pagesIsoflex Topas NB 5051jcapancho.pertuaNo ratings yet

- Control MagoutouxDocument2 pagesControl MagoutouxOsvaldo IngrisaniNo ratings yet

- Isoflex NCA 15Document2 pagesIsoflex NCA 15c108No ratings yet

- BARRIERTA GTE 403 EN enDocument2 pagesBARRIERTA GTE 403 EN enSiska JozefNo ratings yet

- Isoflex Topas NB 52 152Document4 pagesIsoflex Topas NB 52 152tapuskof1No ratings yet

- 263 DFDocument2 pages263 DFSanjeev PurriNo ratings yet

- TDS 化学技术说明书Document2 pagesTDS 化学技术说明书adam sumardinataNo ratings yet

- PI CENTOPLEX GLP 500 020181 GB enDocument2 pagesPI CENTOPLEX GLP 500 020181 GB enJuana Maribel Tocto LucarNo ratings yet

- Kluebersynth LR 44 21 GB enDocument2 pagesKluebersynth LR 44 21 GB enkarthik venkatachalamNo ratings yet

- Klüberplex GE 11-680: Product InformationDocument2 pagesKlüberplex GE 11-680: Product InformationmmrNo ratings yet

- Isoflex Topas L 32Document2 pagesIsoflex Topas L 32c108No ratings yet

- Poly Gear PG en PDFDocument2 pagesPoly Gear PG en PDFAlfredo CarlosNo ratings yet

- Klübersynth GE 46-1200 EN enDocument4 pagesKlübersynth GE 46-1200 EN enkarenglzNo ratings yet

- AMBLYGON TA 30-1, TA 30-2: Special Greases For Long-Term Lubrication and High TemperaturesDocument2 pagesAMBLYGON TA 30-1, TA 30-2: Special Greases For Long-Term Lubrication and High TemperaturesErick AvilaNo ratings yet

- Kluberplex BEM 41 132Document4 pagesKluberplex BEM 41 132Maryasa RobedNo ratings yet

- CONSTANT GL 2000 EN enDocument2 pagesCONSTANT GL 2000 EN enSiska JozefNo ratings yet

- CentoplexDocument2 pagesCentoplexAnandh VairakkannuNo ratings yet

- BARRIERTA L 25 DL EN enDocument2 pagesBARRIERTA L 25 DL EN enSiska JozefNo ratings yet

- Klueberlub BE 41-1501 097115 PI GB enDocument3 pagesKlueberlub BE 41-1501 097115 PI GB enwajahat ali KhanNo ratings yet

- Klubersynth GE 46 1200Document2 pagesKlubersynth GE 46 1200karenglzNo ratings yet

- Kluebersynth UH1 64-62 096046 PI GB enDocument2 pagesKluebersynth UH1 64-62 096046 PI GB enmuhammad saputraNo ratings yet

- Klueber Isoflex Topas L 152 Rolling Bearing Grease For A Wide Service Temperature Range DatasheetDocument2 pagesKlueber Isoflex Topas L 152 Rolling Bearing Grease For A Wide Service Temperature Range DatasheetArifin SontaniNo ratings yet

- Syntheso Proba 270 enDocument2 pagesSyntheso Proba 270 entoughridin88No ratings yet

- Barelf Al: Auxiliary Synthetic LubricantsDocument1 pageBarelf Al: Auxiliary Synthetic LubricantsironiteNo ratings yet

- Barelf AL PDFDocument1 pageBarelf AL PDFironiteNo ratings yet

- WOLFRACOAT C FLUID 099118 PI GB enDocument2 pagesWOLFRACOAT C FLUID 099118 PI GB enwajahat ali KhanNo ratings yet

- SYNGEAR SH-1000 SERIES 340253 PI GB enDocument5 pagesSYNGEAR SH-1000 SERIES 340253 PI GB enCleiton Luiz CordeiroNo ratings yet

- Klberplex BEM 41-132 020256 PI EN enDocument4 pagesKlberplex BEM 41-132 020256 PI EN enalishahsavarNo ratings yet

- Klüber Summit RHT 68 EN enDocument2 pagesKlüber Summit RHT 68 EN enHectorNo ratings yet

- epona-z-220_TDS_v230221Document2 pagesepona-z-220_TDS_v230221Emre ÖzbilgiNo ratings yet

- Staburags Nbu 4 12Document4 pagesStaburags Nbu 4 12Imam SyahputraNo ratings yet

- STABURAGS NBU 12-300 KP 017062 PI GB enDocument2 pagesSTABURAGS NBU 12-300 KP 017062 PI GB enmuhammad saputraNo ratings yet

- Klberplex BEM 41-141 020320 PI EN enDocument2 pagesKlberplex BEM 41-141 020320 PI EN enHitaro VuNo ratings yet

- Klübersynth HBE 94-401: Synthetic Heavy-Duty Grease For Long-Term LubricationDocument4 pagesKlübersynth HBE 94-401: Synthetic Heavy-Duty Grease For Long-Term LubricationErico Haryanto LumbanrajaNo ratings yet

- GRAFLOSCON C-SG 2000 ULTRA EN enDocument2 pagesGRAFLOSCON C-SG 2000 ULTRA EN ensvntamil_159541837No ratings yet

- Klüberplex BEM 41-141: Product InformationDocument2 pagesKlüberplex BEM 41-141: Product InformationPRAKASH BNo ratings yet

- Klüberfood NH1 94-402Document2 pagesKlüberfood NH1 94-402Javier LemusNo ratings yet

- MICROLUBE GL 261 GL 262 EN enDocument4 pagesMICROLUBE GL 261 GL 262 EN enVendy KurniawanNo ratings yet

- Klüberlub NH1 11-222 EN enDocument2 pagesKlüberlub NH1 11-222 EN enKamila AriasNo ratings yet

- Klüberlub BE 71-501: Special Lubricating Grease For Rolling and Plain BearingsDocument4 pagesKlüberlub BE 71-501: Special Lubricating Grease For Rolling and Plain Bearingsphucdc095041No ratings yet

- Tds Renolin CLP enDocument7 pagesTds Renolin CLP enrytNo ratings yet

- PDS - Mobilgrease XHP 460 SeriesDocument3 pagesPDS - Mobilgrease XHP 460 SeriesJuanSantillanNo ratings yet

- 93 Sinopec Extreme Pressure Lithium Complex GreaseDocument3 pages93 Sinopec Extreme Pressure Lithium Complex GreaseAmadeus CocaNo ratings yet

- Wolfrakote Top PasteDocument2 pagesWolfrakote Top PasteWillian BrandãoNo ratings yet

- Molykote G 1001 PdsDocument2 pagesMolykote G 1001 PdsDicky PratamaNo ratings yet

- Energrease HTG 2 PDFDocument2 pagesEnergrease HTG 2 PDFLê Duy PhongNo ratings yet

- Staburags Nbu 30 PTMDocument2 pagesStaburags Nbu 30 PTMYogi PamungkasNo ratings yet

- Mobilgrease XHP 222 PdsDocument2 pagesMobilgrease XHP 222 PdsmuhammadNo ratings yet

- Asonic Ghy 72Document4 pagesAsonic Ghy 72AmeerudinSiddiquiNo ratings yet

- Klübersynth UH1 64-62 EN enDocument2 pagesKlübersynth UH1 64-62 EN enKamila AriasNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Contra Recuos e Rodas Livres StieberDocument97 pagesContra Recuos e Rodas Livres StieberdenisNo ratings yet

- RSCI Manual enDocument4 pagesRSCI Manual endenisNo ratings yet

- Folha de Dados P-956-Fc - RsciDocument4 pagesFolha de Dados P-956-Fc - RscidenisNo ratings yet

- CR Manual enDocument2 pagesCR Manual endenisNo ratings yet

- Tas Product Catalog 2023Document223 pagesTas Product Catalog 2023denisNo ratings yet

- Installation & Removal Instructions For B-LOC Keyless Locking DevicesDocument16 pagesInstallation & Removal Instructions For B-LOC Keyless Locking DevicesTaufik RahmanNo ratings yet

- Chain Maintenance PDFDocument13 pagesChain Maintenance PDFjesusmemNo ratings yet

- Barmex Magna Drive MGD y MGTL Brochure 2008Document8 pagesBarmex Magna Drive MGD y MGTL Brochure 2008denisNo ratings yet

- PDF Magnadrive Presentation CompressDocument42 pagesPDF Magnadrive Presentation CompressdenisNo ratings yet

- SEW Compact Constant Speed Reducer MC SeriesDocument195 pagesSEW Compact Constant Speed Reducer MC SeriesDênis DáyolNo ratings yet

- LLH (Long Life Holdbacks) : Backstopping Technology Sprag DesignDocument16 pagesLLH (Long Life Holdbacks) : Backstopping Technology Sprag DesignDênis DáyolNo ratings yet

- Rexnord CP040 NewDocument28 pagesRexnord CP040 NewdenisNo ratings yet

- Rexnord CP040 NewDocument28 pagesRexnord CP040 NewdenisNo ratings yet

- KSP Piping Materials Product GuideDocument5 pagesKSP Piping Materials Product GuideTejas DesaiNo ratings yet

- Insulating OilDocument11 pagesInsulating Oilakiey_0577No ratings yet

- Ebook Principles of Chemistry A Molecular Approach, 4e Nivaldo J. TroDocument113 pagesEbook Principles of Chemistry A Molecular Approach, 4e Nivaldo J. Troesource36No ratings yet

- Division Achievement Test in Science 9Document5 pagesDivision Achievement Test in Science 9Rosalyn Angcay Quintinita100% (1)

- Principles of Steady-state Heat Transfer in RadiationDocument47 pagesPrinciples of Steady-state Heat Transfer in RadiationKamal JamaliNo ratings yet

- Influence of Heat Treatment On Antioxidant Capacity and (Poly) Phenolic Compounds of Selected VegetablesDocument8 pagesInfluence of Heat Treatment On Antioxidant Capacity and (Poly) Phenolic Compounds of Selected Vegetablesgisella_sc603No ratings yet

- Improving The Sulfate Attack Resistance of Concrete by Using Supplementary Cementitious Materials (SCMS) : A ReviewDocument17 pagesImproving The Sulfate Attack Resistance of Concrete by Using Supplementary Cementitious Materials (SCMS) : A Reviewsyed danish hasanNo ratings yet

- Grade 10 2017 Controlled TestDocument10 pagesGrade 10 2017 Controlled Testrowan chibiNo ratings yet

- Carboxylic Acids and Their Derivatives.Document31 pagesCarboxylic Acids and Their Derivatives.AmanyNo ratings yet

- Diode Fundamentals: Materials, PN Junction, and Circuit ModelsDocument27 pagesDiode Fundamentals: Materials, PN Junction, and Circuit ModelsHassen MibarNo ratings yet

- Liquid ring vacuum pumps in compact designDocument7 pagesLiquid ring vacuum pumps in compact designDarwin Barra TorresNo ratings yet

- Concentrated Volumetric Solutions Traceable to SRM of NISTDocument6 pagesConcentrated Volumetric Solutions Traceable to SRM of NISTDilraj SinghNo ratings yet

- WPS PQR For S 1 S Piping 02Document5 pagesWPS PQR For S 1 S Piping 02ravi00098No ratings yet

- Pre-Qualification Docs ListDocument11 pagesPre-Qualification Docs ListNikhil RajuNo ratings yet

- Classic ExperimentsDocument53 pagesClassic ExperimentsAbhay Kumar100% (1)

- MAT. VOLATIL ASTM E872-82 (Reapproved 2013)Document3 pagesMAT. VOLATIL ASTM E872-82 (Reapproved 2013)Andrea Urbano NilaNo ratings yet

- Life Cycle Assessment of Soap and DetergentsDocument14 pagesLife Cycle Assessment of Soap and Detergentstewegeb5100% (3)

- Criteria For Vacum TestDocument7 pagesCriteria For Vacum TestlightsonsNo ratings yet

- Cambridge Assessment International Education: Environmental Management 0680/22 May/June 2018Document10 pagesCambridge Assessment International Education: Environmental Management 0680/22 May/June 2018Suyathi MugunthanNo ratings yet

- TYPE 1604/2609/3609: First Edition API 682 Type C Sealol Metal Bellows SealsDocument6 pagesTYPE 1604/2609/3609: First Edition API 682 Type C Sealol Metal Bellows SealsKapa KamalakarNo ratings yet

- Data 2Document1 pageData 2Radha NandhiniNo ratings yet

- Paper 1 June 2008Document20 pagesPaper 1 June 2008Arushad AhmedNo ratings yet

- Azeotropic & Extractive DistillationDocument39 pagesAzeotropic & Extractive Distillationsatyacrazy100% (3)

- Evaluation of Physico-Chemical Parameters and AntiMicrobial Studies of Delonix Regia and Piliostigma Thonningii Seed OilDocument4 pagesEvaluation of Physico-Chemical Parameters and AntiMicrobial Studies of Delonix Regia and Piliostigma Thonningii Seed OilIjsrmt digital libraryNo ratings yet

- Role of Chemical EngineerDocument5 pagesRole of Chemical EngineerRichard MamoneNo ratings yet

- AminesDocument53 pagesAminesasheethio4No ratings yet

- HAZOP Worksheet - Case2Document6 pagesHAZOP Worksheet - Case2jenish parekhNo ratings yet

- DM Lec 8Document7 pagesDM Lec 8Ali NazarNo ratings yet

- Activity 3 - Mineral and The Nature of RockDocument2 pagesActivity 3 - Mineral and The Nature of RockSedsed QuematonNo ratings yet

- Clobazam EP 11.0Document2 pagesClobazam EP 11.0Alejandro RestrepoNo ratings yet