Professional Documents

Culture Documents

Drive Axle 300

Uploaded by

Cleveston MoraisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drive Axle 300

Uploaded by

Cleveston MoraisCopyright:

Available Formats

Technical specification

Atlas Copco Service

Drive axle 300

9851 3157 01. 03/2013 © Copyright 2013, Atlas Copco Rock Drills AB, Örebro, Sweden. Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies in particular to

trademarks, model denominations, part numbers and drawings. llustrations and photos in this brochure may show equipment with optional extras. Specifications and equipment subjects to change without

Superior quality mineral GL-5 oil for limited slip differentials

Drive axle 300 is blended for use in the wide variety of coefficient of friction to meet the specialized requirements of

equipment that is fitted with limited slip differentials. It can also limited slip differentials.

be used in other moderate to heavily loaded gear sets that will

This oil has the benefit of maintaining low temperature flow in

allow for the use of a friction modified, hypoid gear oil.

the designed temperature range, it is also effective at resisting

This oil was blended with specially selected additives that oxidation and maintaining oil film between gears.

would provide good anti-wear and anti-rust characteristics. The

notice. Consult your Atlas Copco Customer Center for specific information.

additives also impart thermal stability as well as the required

Lubricant characteristics Available volumes

PROPERTIES METHOD DRIVE AXLE 300 VOLUME PART NUMBER

SAE Viscosity grade SAE J 306 90 20 litres (5,3 gallons) 6060 0000 57

Kinematic viscosity at 40 °C (104 °F) ISO 3104 155 mm²/s 209 litres (55,2 gallons) 6060 0000 56

Kinematic viscosity at 100 °C (212 °F) ISO 3104 15 mm²/s SPECIFICATIONS, APPROVALS AND RECOMMENDATIONS

Viscosity index ISO 2909 96 API Service classification GL-5 limited slip

Density at 15 °C (59 °F) ISO 12185 909 kg/m³

Flash point (COC) ISO 2592 210 °C (410 °F)

Pour point ISO 3016 -18 °C (0 °F)

You might also like

- Hydraulic 150Document1 pageHydraulic 150Cleveston MoraisNo ratings yet

- Shell Spirax S3 G 80W90Document2 pagesShell Spirax S3 G 80W90Jorge Arrieta TorresNo ratings yet

- Shell Spirax S3 G80WDocument2 pagesShell Spirax S3 G80WNokiabhre WijayaNo ratings yet

- Katalog Suku Cadang Honda CB150R K15GDocument2 pagesKatalog Suku Cadang Honda CB150R K15GRaka ajaNo ratings yet

- Aurelia Ti 3030 - TDSDocument2 pagesAurelia Ti 3030 - TDSnoar anwarNo ratings yet

- 0401 Product InfoDocument2 pages0401 Product InfoJeisson HolguinNo ratings yet

- Aurelia: Trunk Piston Oil For Medium Speed EnginesDocument2 pagesAurelia: Trunk Piston Oil For Medium Speed EnginesFreddy FarukNo ratings yet

- Axle EPX 80W-90-pds-EngDocument2 pagesAxle EPX 80W-90-pds-EngVusal HasanovNo ratings yet

- Shell Omala S2 G 1000: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 1000: Performance, Features & BenefitsRaden ArdyNo ratings yet

- Roto Z en 2935004221Document2 pagesRoto Z en 2935004221Madjid HernandezNo ratings yet

- Gpcdoc Gtds Shell Omala s2 G 150 (En) TdsDocument3 pagesGpcdoc Gtds Shell Omala s2 G 150 (En) TdsMuhammad RipandiNo ratings yet

- Cat NGEO EL350: (Natural Gas Engine Oil)Document2 pagesCat NGEO EL350: (Natural Gas Engine Oil)Alfonso Alberto ArguelloNo ratings yet

- Mobilgear 600 XP: The Industr y Requirement For Wear ProtectionDocument2 pagesMobilgear 600 XP: The Industr y Requirement For Wear ProtectionprateekNo ratings yet

- GPCDOC Local TDS Switzerland Shell Spirax S6 GXME 75W-80 (en-CH) TDSDocument2 pagesGPCDOC Local TDS Switzerland Shell Spirax S6 GXME 75W-80 (en-CH) TDSgrs030391No ratings yet

- Amsoil 4TDocument2 pagesAmsoil 4THoàng Quang MạnhNo ratings yet

- 8100 Eco-Clean 0W-30: Fuel Economy Gasoline & Diesel Lubricant 100% SyntheticDocument2 pages8100 Eco-Clean 0W-30: Fuel Economy Gasoline & Diesel Lubricant 100% SyntheticRadu George MotocNo ratings yet

- Shell Omala S2 G 150: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 150: Performance, Features & BenefitsAzamuddin JasrelNo ratings yet

- Omala 460Document4 pagesOmala 460Asad InaamNo ratings yet

- Shell Omala S3 GP 320: Performance, Features & BenefitsDocument2 pagesShell Omala S3 GP 320: Performance, Features & BenefitsttchangcodonNo ratings yet

- Shell Omala S2 G 68: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 68: Performance, Features & BenefitsRaden ArdyNo ratings yet

- Shell Omala S2 G 100: Performance, Features & BenefitsDocument4 pagesShell Omala S2 G 100: Performance, Features & Benefitsرعد العكيليNo ratings yet

- Shield - Euro Tech 1Document2 pagesShield - Euro Tech 1Ali KhalidNo ratings yet

- Gpcdoc Local Tds Pakistan Shell Advance 4t Ax3 20w-40 (SG Ma) (Ur-Pk) TdsDocument2 pagesGpcdoc Local Tds Pakistan Shell Advance 4t Ax3 20w-40 (SG Ma) (Ur-Pk) TdsRoxanne ObleroNo ratings yet

- AeroShell Turbine Oil 560 DatasheetDocument4 pagesAeroShell Turbine Oil 560 Datasheetdarwin galindezNo ratings yet

- Omala S2 G 100Document3 pagesOmala S2 G 100AMITNo ratings yet

- 6100 Synergie 15W50 - GBDocument1 page6100 Synergie 15W50 - GBive2puNo ratings yet

- Gpcdoc Gtds Shell Spirax s3 Als 80w-90 (En) TdsDocument2 pagesGpcdoc Gtds Shell Spirax s3 Als 80w-90 (En) TdsFer EmilNo ratings yet

- TDS Shell Spirax s6 Gxme 75w-80Document2 pagesTDS Shell Spirax s6 Gxme 75w-80rstec pyNo ratings yet

- Shell Omala S2 G 320: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 320: Performance, Features & BenefitsMudabbir Shan AhmedNo ratings yet

- S2 G 100 - TDS PDFDocument3 pagesS2 G 100 - TDS PDFWawanDarmawanNo ratings yet

- GPCDOC Local TDS United Kingdom Shell Spirax S6 AXME 75W-90 (en-GB) TDSDocument2 pagesGPCDOC Local TDS United Kingdom Shell Spirax S6 AXME 75W-90 (en-GB) TDSMohan RaoNo ratings yet

- Shell Omala S2 G 320: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 320: Performance, Features & BenefitsVelibor KaranovicNo ratings yet

- Agma Ep - PDS E5 02Document2 pagesAgma Ep - PDS E5 02ZakNo ratings yet

- How To Use OilDocument3 pagesHow To Use OilMadhusudan SharmaNo ratings yet

- AmsoilSyntheticOilProductInfo SheetsDocument2 pagesAmsoilSyntheticOilProductInfo Sheetsapi-19921780No ratings yet

- Shell Omala 320 Data SheetDocument4 pagesShell Omala 320 Data SheetAyus SyariffianaNo ratings yet

- 1481 Omala s2 G 68Document2 pages1481 Omala s2 G 68Sivarama KrishnanNo ratings yet

- S2 G 460 - TDS PDFDocument3 pagesS2 G 460 - TDS PDFWawanDarmawanNo ratings yet

- Mobilgear SHC 3200 6800 PdsDocument2 pagesMobilgear SHC 3200 6800 PdsMohamed SalemNo ratings yet

- Omala S2 GX 150Document2 pagesOmala S2 GX 150Kieran MañalacNo ratings yet

- Omala S2 G 460Document3 pagesOmala S2 G 460Petrus MalailakNo ratings yet

- Shell Omala S2 G 320: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 320: Performance, Features & BenefitsMohd FaidzalNo ratings yet

- OTR Synthetic Gear Lube SAE 75W-90 Available atDocument2 pagesOTR Synthetic Gear Lube SAE 75W-90 Available atBruce WappmanNo ratings yet

- GPCDOC Local TDS Bahrain Shell Omala S2 G 680 (Ar-BH) TDSDocument4 pagesGPCDOC Local TDS Bahrain Shell Omala S2 G 680 (Ar-BH) TDSAditomo PutrantoNo ratings yet

- Shell Omala S2 G 680 (Ar-BH) TDSDocument4 pagesShell Omala S2 G 680 (Ar-BH) TDSJavier GonzalezNo ratings yet

- Roto Z Fluid enDocument2 pagesRoto Z Fluid enвлад камрNo ratings yet

- Shell Advance 4T Ultra 15W-50 (SM MA2) (en-GB) TDSDocument2 pagesShell Advance 4T Ultra 15W-50 (SM MA2) (en-GB) TDSantvilaNo ratings yet

- MSDS - Magna-Plate-19263 19264 19265-TDDocument2 pagesMSDS - Magna-Plate-19263 19264 19265-TDMohamad HudhaNo ratings yet

- GPCDOC Local TDS Switzerland Shell Advance 4T AX7 10W-40 (SL MA2) (en-CH) TDSDocument2 pagesGPCDOC Local TDS Switzerland Shell Advance 4T AX7 10W-40 (SL MA2) (en-CH) TDSBernad BearNo ratings yet

- AISIN Fully Synthetic Motor Oil SN 5W 30-40-50 Product DatasheetDocument2 pagesAISIN Fully Synthetic Motor Oil SN 5W 30-40-50 Product DatasheetAhmad Azhar Ab Hamid100% (1)

- Shell Omala S2 G 680: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 680: Performance, Features & BenefitsRaden ArdyNo ratings yet

- High Performance Motorcycle Lubricant Technosynthese - EsterDocument1 pageHigh Performance Motorcycle Lubricant Technosynthese - EsterpletedNo ratings yet

- Shell Omala S2 G150 DatasheetDocument3 pagesShell Omala S2 G150 Datasheetphankhoa83-1No ratings yet

- 8100 Eco-Clean 5W-30: Gasoline & Diesel Engine Lubricant 100% SyntheticDocument2 pages8100 Eco-Clean 5W-30: Gasoline & Diesel Engine Lubricant 100% SyntheticRadu George MotocNo ratings yet

- Roto Inject Fluid NDURANCE enDocument2 pagesRoto Inject Fluid NDURANCE enMartín BaezaNo ratings yet

- 8100 X-MAX 0W-40 en FR Motul 17920 20210712Document4 pages8100 X-MAX 0W-40 en FR Motul 17920 20210712Y YmilkcNo ratings yet

- 8100 X-MAX 0W-40 en FR Motul 17920 20210712Document4 pages8100 X-MAX 0W-40 en FR Motul 17920 20210712Y YmilkcNo ratings yet

- ENEOS PCMO Mineral SN CF 10W 30 15W 40 20W - 090218Document1 pageENEOS PCMO Mineral SN CF 10W 30 15W 40 20W - 090218Muhammad YaniNo ratings yet

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- RR Brochure-MOBILE 2022Document8 pagesRR Brochure-MOBILE 2022Cleveston MoraisNo ratings yet

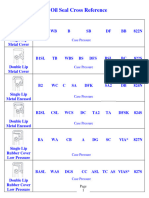

- Oil Seal Cross ReferenceDocument2 pagesOil Seal Cross ReferenceCleveston MoraisNo ratings yet

- PANORAMICA Transtecno ReggianaDocument1 pagePANORAMICA Transtecno ReggianaCleveston MoraisNo ratings yet

- 2013 Harley HQDocument100 pages2013 Harley HQCleveston MoraisNo ratings yet

- CP Pc500lc 10m0 S N 95001 Up (Chassi)Document466 pagesCP Pc500lc 10m0 S N 95001 Up (Chassi)Cleveston Morais100% (1)

- Tema ViDocument19 pagesTema ViCleveston MoraisNo ratings yet

- Kessler Axle Tool Set KitsDocument1 pageKessler Axle Tool Set KitsCleveston MoraisNo ratings yet

- PneumaticsDocument300 pagesPneumaticsCleveston MoraisNo ratings yet

- Check List MT5020 PM FrenchDocument33 pagesCheck List MT5020 PM FrenchCleveston MoraisNo ratings yet

- Option ModuleDocument12 pagesOption ModuleCleveston MoraisNo ratings yet

- PC350LC-8 SN B10001-UP Parts BookDocument568 pagesPC350LC-8 SN B10001-UP Parts BookCleveston Morais100% (2)

- Rear ModuleDocument275 pagesRear ModuleCleveston MoraisNo ratings yet

- Chemical Treatment Selection GuideDocument2 pagesChemical Treatment Selection Guidetanase.gabriel1993No ratings yet

- HEC-HMS QuickStart Guide 4.2 PDFDocument59 pagesHEC-HMS QuickStart Guide 4.2 PDFmarcelo buenoNo ratings yet

- Drillers Method Step One and Two WorkDocument4 pagesDrillers Method Step One and Two WorkDanciulescu Mircea GabrielNo ratings yet

- Refg Recovery SystemDocument19 pagesRefg Recovery Systemsend2jpsNo ratings yet

- Cindy 12 P - 300 P 9050097 en PDFDocument10 pagesCindy 12 P - 300 P 9050097 en PDFBorza DorinNo ratings yet

- DRAINSDocument11 pagesDRAINSAgus SugihartoNo ratings yet

- 1 - Application of Thermodynamics To Flow ProcessesDocument27 pages1 - Application of Thermodynamics To Flow ProcessesEllen Jane Ramos100% (1)

- Transporte de Crudo Tema PDFDocument9 pagesTransporte de Crudo Tema PDFChristian MaganaNo ratings yet

- Grinnell - Válvula de Diluvio para Sistemas Contra IncendiosDocument16 pagesGrinnell - Válvula de Diluvio para Sistemas Contra IncendiosYanhCarlosSantaCruzNo ratings yet

- Piping DWGDocument1 pagePiping DWGkapsarcNo ratings yet

- CH7 1Document25 pagesCH7 1Nikola TrnavacNo ratings yet

- CalculationDocument5 pagesCalculationjaiy12No ratings yet

- D51 Lubrication and Hydraulics BOBST EXPERTCUT 3Document28 pagesD51 Lubrication and Hydraulics BOBST EXPERTCUT 3DeniMestiWidianto100% (1)

- Adiabatic Capillary Tube Test Data For HFC-134aDocument10 pagesAdiabatic Capillary Tube Test Data For HFC-134aAhmed AlrubeayNo ratings yet

- Valvula Angular Fv-zw4100Document4 pagesValvula Angular Fv-zw4100juan yenqueNo ratings yet

- Marine Steam TurbinesDocument23 pagesMarine Steam TurbinesBlix KaneNo ratings yet

- Grundfos Irrigation Pump HandbookDocument104 pagesGrundfos Irrigation Pump HandbookGrundfosEgypt100% (2)

- Catalogo Da TEEJETDocument22 pagesCatalogo Da TEEJETRodrigoNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignrcalaforraNo ratings yet

- Steam Condenser - Lecture SlideDocument43 pagesSteam Condenser - Lecture SlideKing KNo ratings yet

- 160199Document59 pages160199isma_nashNo ratings yet

- TM 6 D 1Document254 pagesTM 6 D 1МиниКлипМиниКлипNo ratings yet

- 3-d Thermal Hydraulic Analysis Louver FinDocument11 pages3-d Thermal Hydraulic Analysis Louver FinAmin SyahNo ratings yet

- Roxhill Park Hydrologic Investigation and Recommendations March 2000Document28 pagesRoxhill Park Hydrologic Investigation and Recommendations March 2000WWRHAHNo ratings yet

- Dicet Flow Module 1Document27 pagesDicet Flow Module 1Julius ChavezNo ratings yet

- Assignment 04Document16 pagesAssignment 04Pritam SahNo ratings yet

- Fluid - Mechanics Kundu 2012 5th PDFDocument3 pagesFluid - Mechanics Kundu 2012 5th PDFSergioNo ratings yet

- Free Convection (Formulae & Problems)Document15 pagesFree Convection (Formulae & Problems)ananth2012No ratings yet

- Fluent-Intro 15.0 WS04 AirfoilDocument50 pagesFluent-Intro 15.0 WS04 Airfoilmatteo_1234No ratings yet

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)