Professional Documents

Culture Documents

Dehydrochlorination of PVC Compositions During The

Uploaded by

Francesca TeocoliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dehydrochlorination of PVC Compositions During The

Uploaded by

Francesca TeocoliCopyright:

Available Formats

Eurasian ChemTech Journal 4 (2002) 25-29

Dehydrochlorination of PVC Compositions

During Thermal Degradation

V.T. Lipik1,2, V.N. Martsul2 and M. J.M. Abadie1*

1

Laboratory of Polymer Science & Advance Organic Materials - LEMP/MAO, University Montpellier 2,

Science and Technology of Languedoc, Place Bataillon, 34095 Montpellier Cedex 05, France.

2

Byelorussian State University of Technology, Belarus, Minsk, Sverdlova str, 13a.

Abstract

The polyvinylchloride (PVC) differs from other polymer materials by low thermostability. The process

of dehydrochlorination takes place even at low temperatures. The purpose of this investigation was to

determine the influence of different PVC additives on formation of hydrogen chloride (HCl) from thermal

degradation in different gaseous fluids. It has been established that the HCl formation takes place more in

nitrogen as a medium than in air medium at a given temperature, especially for the high temperature

region. Dibutyl phthalate (as a plasticizer) in 25 mass % w.r.t. PVC, reduces the mass loss due to HCl

formation by about 5%, which is the result of two interaction processes - between HCl and plastifier

degradation products. It has been found that the addition of 5 mass % of stabilizer in PVC slows down the

process of dehydrochlorination and as a result the loss of mass is 2-5% less, compared to non-stabilized

samples. Calcium carbonate as a filler was found to be active above 400-500°C and reduction in mass loss

was found to be up to 15% at a temperature range of 800-900°C. Calculation of kinetic parameters shows

that the rate of dehydrochlorination depends on the composition of PVC. The activation energy of forma-

tion of HCl in air, in a temperature range of 400-600°C has been found to be 12.7, 13.3, 16.1 kJ/mol for

pure, plasticized and stabilized PVC, respectively. The results reported here shall be useful for develop-

ment of methods for waste utilization and their influence on the environment.

Introduction major impact on the environment. About 88 organic

compounds have been identified in the air from work-

The amount of plastics produced increases every ing zones, where PVC products are manufactured by

year, the majority of commodity plastics being the method of extrusion. About 67 of those organic

polyethylene, polypropylene, PVC and polystyrene. compounds have been identified to be hydrocarbons,

In terms of the quantity of production, PVC occupies 14 oxygen-containing compounds and 6 chlorine con-

second position, next to polyethylene [1]. The world taining compounds [5]. About 170 compounds have

production of PVC was 25 million tones in 1998, of been identified during the burning of PVC products,

which, 5 million tones were produced in Western Eu- some of which possess carcinogenic and mutagenic

rope [2]. It is projected that by 2002, the world and properties [6]. It is evident that the composition of

Europe production of PVC will reach 35 and 7 mil- the PVC compounds has a significant contribution

lion tones respectively. About 50% of PVC produc- on its thermal degradation process and hence on the

tion goes into building, 30% for packaging materials, volatile organic compounds generated.

8% for electronics, 9% for transportation and 3% for

other uses [3]. Of the total quantity of waste gener- Experimental

ated currently, plastics account for 8% and the con-

tribution of PVC is 15% [4]. PVC doesn’t burn, it is PVC powder produced by the French company

a good dielectric, possesses good characteristics. Yet, ATOchem with an average molecular weight of

the production of PVC and its waste utilization has a 255,000 and polydispersity of 1.77 has been used in

our investigation. The PVC compound consists of 25

*corresponding author. E-mail: abadie@univ-montp2.fr mass% of dibutyl phthalate as plastifier, 5 mass % of

2002 al-Farabi Kazakh National University

26 Dehydrochlorination of PVC Compositions During Thermal Degradation

lead dioxide as stabilizer and 25 mass % of calcium samples of PVC were put in a charging apparatus,

carbonate as filler. The purpose of this work was to made from the thermally stable ceramic material. Air

study the influence of the above mentioned additives at a flow rate of 300 ml/min., was used as a medium

on the formation of decomposition products during inside the heater, while nitrogen was used for oxy-

its thermal treatment in air and nitrogen. gen-free medium. The HCl formed during thermal

The experiments were carried out in an experi- degradation was absorbed into water, which was quan-

mental installation, consisting of a pipe-still heater, titatively measured using potentiometry. The materi-

with a range of heating temperature up to 1,200°C, als used in the experimental installation were neither

supplying gas (air, nitrogen) (Fig. 1). Temperature reactive with HCl nor had any affinity to absorb the

inside the furnace was controlled by the chromel- gas liberated. The error during absolute pH measure-

alumel thermocouple, attached to a millivoltmeter. The ment using Ionomizer was about 0.01%.

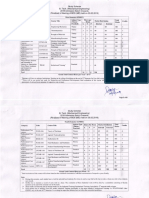

Fig. 1. Experimental installation. 1-container with nitrogen, 2-microprocessor, 3-tap, 4-sliding equipment, 5-quartz tube,

6-furnace, 7-absorbing bottle (dosimeter of chromatograph).

The heating rate during the course of thermo- %mass.HCl from maximal

stechiometrically possible

gravimetric analysis was 10°C/min., with an experi- 90

mental error of about 0.01 mass %. Gas Chromatog- 80

raphy with the built-in dynamic pyrrolitic alveole was

70

applied for the chromatographic studies, with flame

ionization detector (FID). The sample has been kept 60

in the furnace at the constant temperature for the pe- 50

riod, sufficient for complete destruction. The sam- 40

ples of polymers with mass 30-40 g were used during

30

investigation of thermal degradation processes of

pure PVC

PVC. 20 plastized PVC

plastized PVC with stabilizer ÐbO2

10 plastized PVC with calcium carbon filler

Thermal degradation of pure PVC 0

200 250 300 350 400 450 500 550 600 650 700 750 800 850 900

Temperature, Ñ

Some relationships which are presented in Fig. 2 Fig. 2. HCl formation during the thermal degradation of

and in Fig. 3. have been found while studying the PVC containing different additives, in air.

HCl formation as a result of thermal degradation of

pure PVC and that with different additives, both in hydrochlorination is generally completed at tempera-

the air and nitrogen. tures, at which the polymer chains have not faced

The data from literature confirm that there is ac- sufficient changes and the probability of interaction

celeration in the process of PVC degradation in pres- between HCl and additives is small. In the air me-

ence of air [7]. In the nitrogen medium the forma- dium, dehydrochlorination is completed at higher

tion of HCl starts at lower temperature (285°C) than temperatures and the HCl formation can be accom-

compared to air (319°C) [8]. The evolution of HCl panied by the degradation of polymer chains and in-

takes place in a narrow interval of temperature, with teraction between HCl and additives. Therefore, yield

nitrogen as the medium. In the nitrogen medium de- of HCl is more completed in the nitrogen medium

Eurasian ChemTech Journal 4 (2002) 25-29

V.T. Lipik et al. 27

%mass. HCl from maxima

stecheometrically possible

100

90

80

70

60

50

40

30

pure PVC

20 plastized PVC

plastized PVC whit stabilizer ÐbO3

10

plastized PVC whit calcium carbon filler Fig. 4. Themogravimetric analysis of pure PVC.

0

200 250 300 350 400 450 500 550 600 650 700 750 800 850 900

temperature,Ñ Thermal degradation of plasticized PVC

Fig. 3. HCl formation during the thermal degradation of

PVC containing different additives, in nitrogen. It can be assumed that the addition of plasticizers

to a polymer sample will have influence on the de-

than in the oxygen medium. hydrochlorination’s process, because of the interac-

The higher amount of HCl formation in the nitro- tion between HCl and other degradation products with

gen medium is probably determined by more com- the plasticizer molecules. During the degradation of

plete degradation of the terminal chains. In case of PVC in the air, the formation of HCl is slower from

air as compared to nitrogen, part of the chlorine (about the plasticized PVC, as compared to the virgin poly-

25% of the maximum possible) can remains in the mer. The plasticizer seems to degrade and comes out

residual units [9]. The amount of residual units of from the polymer earlier than the degradation of the

degraded PVC in nitrogen is lower, which accounts polymer itself, thus coinciding with HCl formation in

for the near completion of HCL formation in air. The the temporary interval. Part of the energy require-

fact that there is no significant amount of HCl liber- ment can be spent on the degradation of the plasti-

ated at a temperature of 600°C probably indicates cizer. Therefore, at equal temperatures, the plasticized

that there is some sort of reaction taking place be- PVC samples give less hydrogen chloride than pure

tween HCl and the unsaturated hydrocarbons formed. PVC. The plasticizer acts as a kind of inhibitor for

This has been confirmed from the results of chroma- the formation of HCl, although the plasticized sam-

tographic analysis of pyrolytic degradation products ple starts to degrade earlier because of the degrada-

of PVC. Above 600°C, the formation of benzyl chlo- tion of the plasticizer. At elevated temperatures, the

ride is increasingly observed [10]. The pyrolysis gas- difference in the quanity of HCl emitted for the plas-

eous products also contain sufficient quantity of un- ticized and unplasticized PVC samples reaches a 5

saturated hydrocarbons - ethylene, propylene, vinyl mass % (Fig. 2).

chloride, benzene vinyl, which can react with HCl by The products of PVC degradation, both unsatu-

addition reaction [11]. rated and saturated hydrocarbons, produce chlorin-

The results of thermogravimetric and chromato- ated hydrocarbons while coming in contact with HCl.

graphic analysis in air show that the major mass loss The first two peaks from the degradation of plasti-

corresponds to the emission of HCl, during the tem- cized PVC (TR1 and TR2) correspond to the degra-

perature interval of 240-380°C. During this interval, dation of the plasticizer whereas the third peak (TR3)

the mass loss of the PVC sample is about 64% of its corresponds to the formation of HCl and the forth

original mass (Fig. 4). The first peak (TR1) corre- peak (TR4) corresponds to hydrocarbon like degra-

sponds to HCl, whereas the second peak (TR2) cor- dation products (Fig. 5).

responds to hydrocarbon like degradation products. It has been shown by chromatographic analysis,

According to the results from chromatographic that the degradation products from plasticized PVC

data, there is also the formation of vinyl chloride, contain decomposition products such as dibutyl phtha-

methane, ethylene, carbon dioxide and other late, butane, butyl aldehyde, butyl alcohol, phthalic

byproducts formed along with HCl during the pyroly- anhydride, which are not typical of pure PVC. Also

sis of PVC. found is a significant quantity of butyl chloride (up

Eurasian ChemTech Journal 4 (2002) 25-29

28 Dehydrochlorination of PVC Compositions During Thermal Degradation

Fig. 6. Thermogravimetric analysis of PVC with calcium

Fig. 5. Thermogravimetric analysis of plasticized PVC. carbonate as filler.

to 2.5 mass %), as well as methyl-, ethyl-, and vinyl- heat treatment process.

chlorides. While studying the influence of the stabilizer at 5

mass %, it was discovered that the presence of the

Thermal degradation of PVC containing filler stabilizer reduces the HCl formation compared to

unstabilized PVC by about 2-5 mass % (Fig. 2 and

Fig. 3).

It is possible to assume that the calcium carbon-

Results from gas chromatography show that the

ate as additive in the amount of 25% should essen-

addition of lead oxide helps in the formation of

tially reduce the quantity of hydrogen chloride formed

branched hydrocarbons in products [10]. It has been

at the thermal degradation of PVC, resulting from

recognized that the addition of lead oxide results in

the following reaction:

the formation of high molecular weight polyaromatic

CaCO3 + 2HCl → CaCl2 + CO2 +H2O hydrocarbons, which are relatively non-volatile.

The process of dehydroclorination is a function of

The effects of fillers on the thermal degradation time, the medium (nitrogen or air) of reaction, for-

of PVC results are represented in Fig. 2 and Fig. 3. mulation of the PVC compound(s) as well as the heat-

The decrease of the HCl formation is observed at tem- ing rate. Therefore, the kinetic study of such a proc-

peratures higher than 350°C in air, whereas the same ess, which is useful for development of waste utiliza-

for nitrogen as the medium occurs at temperatures tion, is immensely important. The kinetic informa-

higher than 450°C. The highest amount of mass loss tion for the formation of HCl has been obtained un-

as a result of dehydrochlornation was 15 mass %, der different conditions. It has been observed that the

which occurs at temperature of 900°C and above. reaction follows a first order. Calculation of activa-

Thermogravimetric data has established that there is tion energy was done from the plot of lnK vs 1/T, as

interaction taking place between calcium carbonate, described in the literature [12]. The values of activa-

plasticizer and HCl (Fig. 6). The peak in the range of tion energy for the dehydrochlorination in air for sta-

temperatures 250-280°C (TR2, Fig. 5) corresponds bilized, plasticized and virgin PVC, in a temperature

to dibutyl phthalate decomposition. It can be assumed range of 400-600°C has been found to be 16.1, 13.3

that the absence of this peak in Fig. 6 may show a and 12.7 kJ/mol respectively. The additives do result

possible interaction between dibutyl phthalate degra- in a slow down in the rate of formation of HCl as

dation products and calcium carbonate. well as a reduction in the weight loss of PVC from

the process of dehydrochlorination.

Thermal degradation of stabilized PVC

Conclusion

It is known [6] that HCl catalyzes the process of

PVC dehydrochlorination. Therefore, the action of We have determined the influence of different PVC

some stabilizers, added to the polivinylchloride can additives on formation of hydrogen chloride (HCl)

neutralize the deleterious effect of the negligible from thermal degradation in different gaseous fluids.

amount of HCl formed during the initial stages of the It has been established that the HCl formation takes

Eurasian ChemTech Journal 4 (2002) 25-29

V.T. Lipik et al. 29

place more in nitrogen as a medium than in air me- par le Comité de Recherche ASME sur les déchets

dium at a given temperature, especially for the high industriels et urbains. Centre Unifié de Génie

temperature region. Dibutyl phthalate (as a plasticizer) Mécanique, 345 East 4th Street, NY 10017. New

in 25 mass % w.r.t. PVC, reduces the mass loss due York, vol. 36, 1997

to HCl formation by about 5%, which is the result of 5. Dmitraev M.T., Rastanikov E.G. - “Hygienic

two interaction processes - between HCl and plastifier evaluation of PVC: Destruction at extrusion”.

degradation products. It has been found that the ad- Hygiene and Sanitary, 4:26 (1986)

dition of 5 mass % of stabilizer in PVC slows down 6. Minsker K.S., Fedoseeva G.T. - Destruction and

the process of dehydrochlorination and as a result the stabilization of a PVC. Ed. Ìoscow, Chemis-

loss of mass is 2-5% less, compared to non-stabilized try, 1979, p.271.

samples. Calcium carbonate as a filler was found to 7. Ehrig R.J. - “Plastics Recycling: Products and

be active above 400-500°C and reduction in mass loss Processes”, Hanser Publishers., New York 1992,

was found to be up to 15% at a temperature range of p.289.

800-900°C. Calculation of kinetic parameters shows 8. Hirschler M.M – “Thermal decomposition (STA

that the rate of dehydrochlorination depends on the and DSC) of PVC compounds under a variety of

composition of PVC. The activation energy of for- atmospherics and heating rated”. Europ. Polym.

mation of HCl in air, in a temperature range of 400- J., 22:153, (1986)

600°C has been found to be 12.7, 13.3 and 16.1 kJ/ 9. Grin G. - “Environmental - Aspects of Wastes

mol for pure, plasticized and stabilized PVC, respec- Incineration”, TNO Report (August 1990), p.

tively. These results should be useful for development 214.

of methods for waste utilization and their influence 10. Lipik V.T., Martsul V.N., Abadie M.J.M. - “Re-

on the environment. search of influence of the additives for composi-

tion of products in the pyrolysis of polyvinyl-

References chloride compositions”. Materials from Interna-

tional Scientific and Technical Conference –

1. Pronikov N.R. - “The world of PVC”. The Ma- Resources: energy saving technology in chemi-

terials and Technologies XXI Century. Minsk, cal industry and enterprise buildings materials».

3:8 (1996). Minsk, The Belorussian State Technological

2. Syrkina I.G., Treger J.A. - “PVC, present and University, 2000, pp. 438-442.

future”. Ecology and Industry of Russia, 6:29 11. Bulgakov. V.K., Kodolov V.I., Lipanov A.M. -

(2000). Burning Modulation of Polymeric Material.

3. Magin Jean N., Chanaler Stefan - “Le PVC et Ed. Ìoscow, Chemistry, 1990, p. 240.

ses Application, ATOchem”. Ed Techno-Nathan, 12. Semiokxin I.A., Strakxov B.V., Osipov A.I. -

1991. p.112. “Kinetics of Chemical Changes” Ed The Mos-

4. Rigo H. Gregor, Chandler A. John - “Rapport cow State University, 1995, p.351.

entre le chlore présent dans les flux de déchets et

les émissions de dioxine par les incinérateurs” Received 10 February 2001.

Eurasian ChemTech Journal 4 (2002) 25-29

You might also like

- Polyvinylchloride — 2: Main Lectures Presented at the Second International Symposium on Polyvinylchloride, Lyon-Villeurbanne, France, 5 - 9 July 1976From EverandPolyvinylchloride — 2: Main Lectures Presented at the Second International Symposium on Polyvinylchloride, Lyon-Villeurbanne, France, 5 - 9 July 1976A. GuyotNo ratings yet

- Thermal Degradation of PVC PlastigelDocument9 pagesThermal Degradation of PVC Plastigelkang8886021No ratings yet

- Convert Polyvinyl Chloride WasteDocument4 pagesConvert Polyvinyl Chloride Wastefarkad rawiNo ratings yet

- Studv of The Aroducts of PVC Thermal: Ian C. Mcneil& Livia Memetea & William J. ColeDocument11 pagesStudv of The Aroducts of PVC Thermal: Ian C. Mcneil& Livia Memetea & William J. ColeJull Carlos Pumaccajia CruzNo ratings yet

- Chemical Modification of Exible and Rigid Poly (Vinyl Chloride) by Nucleophilic Substitution With Thiocyanate Using A Phase-Transfer CatalystDocument5 pagesChemical Modification of Exible and Rigid Poly (Vinyl Chloride) by Nucleophilic Substitution With Thiocyanate Using A Phase-Transfer CatalystDaviVilaçaNo ratings yet

- Thermal Decomposition of PVCDocument15 pagesThermal Decomposition of PVCJen ChavezNo ratings yet

- Effects of Biobased Plasticizer on PVC PropertiesDocument10 pagesEffects of Biobased Plasticizer on PVC PropertiessavanNo ratings yet

- Pyrolysis Behavior of Electric Cable PVC Insulation MaterialDocument8 pagesPyrolysis Behavior of Electric Cable PVC Insulation Materialmontie3No ratings yet

- Estabilizante Térmico PVC PDFDocument14 pagesEstabilizante Térmico PVC PDFLinda AvelinoNo ratings yet

- Axcelis OxygenfreeplasmachipscalepkgDocument8 pagesAxcelis Oxygenfreeplasmachipscalepkgparam_i47No ratings yet

- The Effect of Some Fillers On PVC DegradationDocument8 pagesThe Effect of Some Fillers On PVC Degradationhabiba jamilNo ratings yet

- Assignment No.3: Asad AliDocument4 pagesAssignment No.3: Asad AliMuhammad UsamaNo ratings yet

- PVCDocument1 pagePVCSteven ObrienNo ratings yet

- 2011 - Reduction of Carbon Dioxide in Hydrothermal Craking of Polymer WastesDocument4 pages2011 - Reduction of Carbon Dioxide in Hydrothermal Craking of Polymer WastesMaría Andérez FernándezNo ratings yet

- Smoke Suppression in Plasticised ChlorinDocument4 pagesSmoke Suppression in Plasticised Chlorinxfactor gangaarNo ratings yet

- The Development of Synergistic Heat Stabilizers For PVC From Zinc Borate - Zinc PhosphateDocument119 pagesThe Development of Synergistic Heat Stabilizers For PVC From Zinc Borate - Zinc PhosphatevijaymwaghNo ratings yet

- Blends of Hydroxypropyl Methyl CelluloseDocument8 pagesBlends of Hydroxypropyl Methyl CelluloseKathyayani DNo ratings yet

- Chemical Engineering Journal: Wei Lu, Qianli Yang, Binhang Yan, Yi ChengDocument8 pagesChemical Engineering Journal: Wei Lu, Qianli Yang, Binhang Yan, Yi ChengAnonymous UW3ZRZNo ratings yet

- PVC Specific HeatDocument6 pagesPVC Specific Heatila_368684492No ratings yet

- A Novel Solution Process For The Synthesis of VO Thin Films With Excellent Thermochromic PropertiesDocument8 pagesA Novel Solution Process For The Synthesis of VO Thin Films With Excellent Thermochromic PropertiesShaiju S SNo ratings yet

- Photocatalytic Cement: A New Approach To Environmental ProtectionDocument7 pagesPhotocatalytic Cement: A New Approach To Environmental ProtectionRAHUL GUNDEBOMMUNo ratings yet

- Environmental TechnologyDocument12 pagesEnvironmental TechnologySara NaseriNo ratings yet

- Aranzabal 2009Document9 pagesAranzabal 2009bruno barrosNo ratings yet

- Polymers: The Effect of Introducing B and N On Pyrolysis Process of High Ortho Novolac ResinDocument17 pagesPolymers: The Effect of Introducing B and N On Pyrolysis Process of High Ortho Novolac ResinHiến Đinh VănNo ratings yet

- Grause 2015 SolubilityparameterDocument12 pagesGrause 2015 SolubilityparameterbharatmorwaniNo ratings yet

- PVC Green ProcessDocument21 pagesPVC Green Processburus_648558271100% (1)

- Applied Sciences: Effect of Acetone Content On The Preparation Period and CuringDocument12 pagesApplied Sciences: Effect of Acetone Content On The Preparation Period and CuringMuralidharNo ratings yet

- Manufacture of Phenol Formaldehyde Resin PDFDocument56 pagesManufacture of Phenol Formaldehyde Resin PDFAhmed Ali89% (19)

- Modified Sol-Gel Process For Synthesis of Molybdenum Oxide-Doped Titanium DioxideDocument6 pagesModified Sol-Gel Process For Synthesis of Molybdenum Oxide-Doped Titanium DioxideVijendra Singh BhatiNo ratings yet

- Modulus of Elasticity of PVB-2Document2 pagesModulus of Elasticity of PVB-2songyanxinNo ratings yet

- Borgianni, de Filippis - Gasification Process of Wastes Containing PVCDocument7 pagesBorgianni, de Filippis - Gasification Process of Wastes Containing PVCJorge VeraNo ratings yet

- Electrochemical Reforming of Glycerol in Alkaline PBI-Based PEM Reactor For Hydrogen ProductionDocument6 pagesElectrochemical Reforming of Glycerol in Alkaline PBI-Based PEM Reactor For Hydrogen Productionferonica chungNo ratings yet

- Determination of Total Organic Carbon Through Oxidation by Fotokatalitik-KonduktomeriDocument7 pagesDetermination of Total Organic Carbon Through Oxidation by Fotokatalitik-KonduktomeripakarpuangNo ratings yet

- Experimental Study of The OxidativeDocument13 pagesExperimental Study of The OxidativeRafael RíosNo ratings yet

- Bhasa Inggris KimiaDocument12 pagesBhasa Inggris KimiapakarpuangNo ratings yet

- PET Pyrolysis Conditions in Conical ReactorDocument6 pagesPET Pyrolysis Conditions in Conical ReactorZahid FarooqNo ratings yet

- Coating 2Document6 pagesCoating 2thai avvaiNo ratings yet

- Thermal Stabilizers For PVC A ReviewDocument8 pagesThermal Stabilizers For PVC A ReviewDarshan ShahNo ratings yet

- Fluidised Bed Pyrolysis of Polypropylene Over Cracking Catalysts For Producing HydrocarbonsDocument8 pagesFluidised Bed Pyrolysis of Polypropylene Over Cracking Catalysts For Producing HydrocarbonsGovind ManglaniNo ratings yet

- Lee 2007Document7 pagesLee 2007niloy mominNo ratings yet

- Bio-Mimetic Oxygen Separation Via Hollow Fiber Membrane Contactor With O2 Carrier SolutionsDocument5 pagesBio-Mimetic Oxygen Separation Via Hollow Fiber Membrane Contactor With O2 Carrier SolutionsDarul Fahmi AfriliyantoNo ratings yet

- Materials Chemistry and Physics: 2 Derya Tekin, Derya Birhan, Hakan KiziltasDocument6 pagesMaterials Chemistry and Physics: 2 Derya Tekin, Derya Birhan, Hakan KiziltasMosinoiuNo ratings yet

- 1 FTPDocument14 pages1 FTPvsiNo ratings yet

- Tutorial Materials SelectionDocument2 pagesTutorial Materials SelectionSyahmiNo ratings yet

- Materials Chemistry A: Journal ofDocument7 pagesMaterials Chemistry A: Journal ofBhabani Sankar SwainNo ratings yet

- Polymer Processing With Super Critical Fluids by SG KazarianDocument24 pagesPolymer Processing With Super Critical Fluids by SG KazarianLia NashNo ratings yet

- Tio - Mediated Photocatalytic Degradation of A Textile Dye Derivative, Bromothymol Blue, in Aqueous SuspensionsDocument6 pagesTio - Mediated Photocatalytic Degradation of A Textile Dye Derivative, Bromothymol Blue, in Aqueous SuspensionsMootolik VorbaretNo ratings yet

- Simultaneous Liquefaction and Hydrodeoxygenation of Lignocellulosic BiomassDocument12 pagesSimultaneous Liquefaction and Hydrodeoxygenation of Lignocellulosic BiomassClaudia Elizabeth Ruiz DávilaNo ratings yet

- Production and Characterization of Adsorbent Materials From Sewage Sludge by PyrolysisDocument6 pagesProduction and Characterization of Adsorbent Materials From Sewage Sludge by PyrolysisRohan ChauguleNo ratings yet

- Polymers For Advanced Techs - 2022 - Yang - Plasticizing and Thermal Stabilizing Effect of Bio Based Epoxidized CardanolDocument14 pagesPolymers For Advanced Techs - 2022 - Yang - Plasticizing and Thermal Stabilizing Effect of Bio Based Epoxidized CardanolVickie HanNo ratings yet

- Hydrothermal Treatment of Palm Oil Mill Effluent PDocument9 pagesHydrothermal Treatment of Palm Oil Mill Effluent PsahrierNo ratings yet

- POFT - EditDocument5 pagesPOFT - Editchuah kelvinNo ratings yet

- 01 High-Efficiency Co-Liquefaction of Low-Rank Coal and PAEs-rich PVC Waste in Supercritical Water - Products Upgrading and DechlorinationDocument14 pages01 High-Efficiency Co-Liquefaction of Low-Rank Coal and PAEs-rich PVC Waste in Supercritical Water - Products Upgrading and Dechlorinationbambang.teknikkimia2022No ratings yet

- Synthesis of Alkali Activated Cement From Local Clay and Its CharacterizationDocument6 pagesSynthesis of Alkali Activated Cement From Local Clay and Its CharacterizationMeghaNo ratings yet

- Eco-profiles of PVC productionDocument15 pagesEco-profiles of PVC productionGuillianNo ratings yet

- 2793Document68 pages2793Jahadiel AguilarNo ratings yet

- 23 F Borsodi Full Paper IpcDocument9 pages23 F Borsodi Full Paper IpcHartono PrayitnoNo ratings yet

- Theoretical and Applied Aspects of 12dichloroethane Pyrolysis 2157 7544 1000189Document24 pagesTheoretical and Applied Aspects of 12dichloroethane Pyrolysis 2157 7544 1000189Fabio RibeiroNo ratings yet

- Evaluation of The Incorporation Ratio of Zno, Pbo and Cdo Into Cement ClinkerDocument8 pagesEvaluation of The Incorporation Ratio of Zno, Pbo and Cdo Into Cement ClinkerSalim ChahidNo ratings yet

- Systematic Study of H2 Production From Catalytic Photoreforming of Cellulose Over PT Catalysts Supported On TiO2Document8 pagesSystematic Study of H2 Production From Catalytic Photoreforming of Cellulose Over PT Catalysts Supported On TiO2Nguyễn Hoàng TuấnNo ratings yet

- What Is Compression SetDocument3 pagesWhat Is Compression SetFrancesca TeocoliNo ratings yet

- On The Viscoelastic Poisson's Ratio of Amorphous PolymersDocument15 pagesOn The Viscoelastic Poisson's Ratio of Amorphous PolymersFrancesca TeocoliNo ratings yet

- FAA Technical Center Test Methods for Composites Status ReportDocument238 pagesFAA Technical Center Test Methods for Composites Status ReportFrancesca TeocoliNo ratings yet

- On The Viscoelastic Poisson's Ratio of Amorphous PolymersDocument15 pagesOn The Viscoelastic Poisson's Ratio of Amorphous PolymersFrancesca TeocoliNo ratings yet

- Question About The Relationship Between Elastic Modulus and CreepDocument3 pagesQuestion About The Relationship Between Elastic Modulus and CreepFrancesca TeocoliNo ratings yet

- Shore A To DDocument1 pageShore A To DJhonny MedinaNo ratings yet

- Weathering Degradation Mechanisms of Chlorinated PVC: International Journal of Plastics Technology December 2013Document13 pagesWeathering Degradation Mechanisms of Chlorinated PVC: International Journal of Plastics Technology December 2013Francesca TeocoliNo ratings yet

- Influence of Mechanical Properties of PolypropylenDocument11 pagesInfluence of Mechanical Properties of PolypropylenFrancesca TeocoliNo ratings yet

- Radiation Resistance of ElastomersDocument3 pagesRadiation Resistance of ElastomersFrancesca TeocoliNo ratings yet

- Axorad: Radiation Resistant Cables For Scientific & Nuclear ApplicationsDocument50 pagesAxorad: Radiation Resistant Cables For Scientific & Nuclear ApplicationsFrancesca TeocoliNo ratings yet

- Full Text 01Document101 pagesFull Text 01Francesca TeocoliNo ratings yet

- Ultra High Molecular Weight Polyethylene - UHMWPE - AsDocument27 pagesUltra High Molecular Weight Polyethylene - UHMWPE - AsFrancesca TeocoliNo ratings yet

- Influence of Gamma Radiation On EPDM Compounds PropertiesDocument6 pagesInfluence of Gamma Radiation On EPDM Compounds PropertiesFrancesca TeocoliNo ratings yet

- Heliyon: Experimental Study of Consistency Degradation of Different Greases in Mixed Neutron and Gamma RadiationDocument11 pagesHeliyon: Experimental Study of Consistency Degradation of Different Greases in Mixed Neutron and Gamma RadiationFrancesca TeocoliNo ratings yet

- RadJ 2018 02 016Document8 pagesRadJ 2018 02 016Francesca TeocoliNo ratings yet

- Experimental Study of Materials Radiation Resistance in Reactor Mixed Fields For The Construction of The SPES Facility at LNLDocument10 pagesExperimental Study of Materials Radiation Resistance in Reactor Mixed Fields For The Construction of The SPES Facility at LNLFrancesca TeocoliNo ratings yet

- An Overview of Basic Radiation Effects On PolymersDocument35 pagesAn Overview of Basic Radiation Effects On PolymersFrancesca TeocoliNo ratings yet

- Changes of Chemical Structure and Mechanical PropeDocument14 pagesChanges of Chemical Structure and Mechanical PropeFrancesca TeocoliNo ratings yet

- Synthesis and Characterization of Oligosalicylaldehyde-Based Epoxy ResinsDocument5 pagesSynthesis and Characterization of Oligosalicylaldehyde-Based Epoxy ResinsFrancesca TeocoliNo ratings yet

- Review of Aging Data On Epdm O-Rings in The H1616 Shipping PackageDocument36 pagesReview of Aging Data On Epdm O-Rings in The H1616 Shipping PackageFrancesca TeocoliNo ratings yet

- Acceptance Criteria For Polymers Energiforskrapport 2015 157Document48 pagesAcceptance Criteria For Polymers Energiforskrapport 2015 157saeedahmad901No ratings yet

- Prediction of The Lifetime of Nitrile-Butadiene Rubber by FT-IRDocument4 pagesPrediction of The Lifetime of Nitrile-Butadiene Rubber by FT-IRFrancesca TeocoliNo ratings yet

- Oxidation of Rubbers Analysed by HATR/IR Spectroscopy: Polymer Degradation and Stability November 1998Document8 pagesOxidation of Rubbers Analysed by HATR/IR Spectroscopy: Polymer Degradation and Stability November 1998Francesca TeocoliNo ratings yet

- PolymerDocument25 pagesPolymerMeng HeangNo ratings yet

- ARTIGOFINAL - 1516 1439 MR 1980 5373 MR 2016 0562Document11 pagesARTIGOFINAL - 1516 1439 MR 1980 5373 MR 2016 0562Francesca TeocoliNo ratings yet

- Investigation of Ageing Behaviour of Nitrile - Butadiene Rubber With Added Graphene in An Accelerated Thermal Ageing EnvironmentDocument9 pagesInvestigation of Ageing Behaviour of Nitrile - Butadiene Rubber With Added Graphene in An Accelerated Thermal Ageing EnvironmentFrancesca TeocoliNo ratings yet

- Inorganic Chemistry Self-Tests and ExercisesDocument50 pagesInorganic Chemistry Self-Tests and ExercisesThomas Oliver Lowbridge80% (10)

- Heuristics for Removing Exothermic HeatDocument13 pagesHeuristics for Removing Exothermic HeatVishal Kumar JhaNo ratings yet

- 5A. Gas TurbinesDocument4 pages5A. Gas TurbinesKathlyn Kyle MoralesNo ratings yet

- Quantum Spin LiquidDocument8 pagesQuantum Spin LiquidFederico GaleanoNo ratings yet

- Btech Syllabus For Gndec LudhianaDocument38 pagesBtech Syllabus For Gndec Ludhianaਅਰ ਜੋਤNo ratings yet

- Materials Letters: A. Piglione, B. Dovgyy, C. Liu, C.M. Gourlay, P.A. Hooper, M.S. PhamDocument4 pagesMaterials Letters: A. Piglione, B. Dovgyy, C. Liu, C.M. Gourlay, P.A. Hooper, M.S. PhamCarmen StefanescuNo ratings yet

- 1 s2.0 S0141813021000076 MainDocument8 pages1 s2.0 S0141813021000076 MainhawNo ratings yet

- Cyclone Design - Stairmand MethodDocument4 pagesCyclone Design - Stairmand MethodFaizan AhmedNo ratings yet

- 2007 Echeverri, Measurements and CFD Simulation of The Flow in Vacuum PansDocument13 pages2007 Echeverri, Measurements and CFD Simulation of The Flow in Vacuum PansnghiNo ratings yet

- Thermal Management Silicones For Electronics BrochureDocument12 pagesThermal Management Silicones For Electronics BrochureZenón RodríguezNo ratings yet

- Boiler Tube Failures: Pradip PatelDocument69 pagesBoiler Tube Failures: Pradip PatelVishnu ParvandaNo ratings yet

- Chemoselective Reductions With Sodium BorohydrideDocument6 pagesChemoselective Reductions With Sodium BorohydrideVassili RevelasNo ratings yet

- SdarticleDocument5 pagesSdarticleAradenatorix VeckhomNo ratings yet

- Summative Assessment Grade 11Document9 pagesSummative Assessment Grade 11Tamerlan KudaibergenNo ratings yet

- Double Indicator Acid Base Titration AnalysisDocument6 pagesDouble Indicator Acid Base Titration Analysismscharlenec100% (4)

- BE184P Exercise 1.1a SpectrophotometryDocument9 pagesBE184P Exercise 1.1a SpectrophotometryDen CelestraNo ratings yet

- Flame PhotometryDocument8 pagesFlame PhotometryNimra MalikNo ratings yet

- Fundamentals On HVAC Systems PresentationDocument52 pagesFundamentals On HVAC Systems PresentationJane NixonNo ratings yet

- UHC Gen Chem 2 ManualDocument67 pagesUHC Gen Chem 2 ManualShumeng YangNo ratings yet

- International As: CHEMISTRY (9620) CH01Document25 pagesInternational As: CHEMISTRY (9620) CH01任思诗No ratings yet

- V International Zhautykov Olympiad Theoretical CompetitionDocument8 pagesV International Zhautykov Olympiad Theoretical CompetitionMatei Ionita100% (1)

- Scale Formation in Reheating FurnaceDocument7 pagesScale Formation in Reheating FurnaceDeepti ShakyaNo ratings yet

- Neighbouring Group Participation PPT by Faiza ShahDocument17 pagesNeighbouring Group Participation PPT by Faiza Shahsweety_syed93% (14)

- FCTN ListDocument9 pagesFCTN ListBaqirMuhammadNo ratings yet

- 1 - Galvanic CellDocument6 pages1 - Galvanic CellafifiNo ratings yet

- Rao Gunti, Asokan - 2012 - Thermodynamic, Raman and Electrical Switching Studies On Si15Te85-xAgx (4 X 20) Glasses (3) - AnnotatedDocument6 pagesRao Gunti, Asokan - 2012 - Thermodynamic, Raman and Electrical Switching Studies On Si15Te85-xAgx (4 X 20) Glasses (3) - AnnotatedJagan KbNo ratings yet

- Exp 6Document7 pagesExp 6Virga Aliefiansyah PradanaNo ratings yet

- Nama: Caisar Sabili Ramadhani NPM: 2018210205 Kelas: D2 (Dua) Kelompok: 2 (Dua)Document5 pagesNama: Caisar Sabili Ramadhani NPM: 2018210205 Kelas: D2 (Dua) Kelompok: 2 (Dua)Caisar Sabili RamadhaniNo ratings yet

- Science F1 - MatterDocument6 pagesScience F1 - MatteramyryuzainiNo ratings yet

- Stoichiometry IGCSE Chemistry STB Grade 10 PDFDocument6 pagesStoichiometry IGCSE Chemistry STB Grade 10 PDFRudyWahyudiNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNo ratings yet

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Pharmaceutical Blending and MixingFrom EverandPharmaceutical Blending and MixingP. J. CullenRating: 5 out of 5 stars5/5 (1)

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Operational Excellence: Journey to Creating Sustainable ValueFrom EverandOperational Excellence: Journey to Creating Sustainable ValueNo ratings yet

- Guidelines for Process Safety Acquisition Evaluation and Post Merger IntegrationFrom EverandGuidelines for Process Safety Acquisition Evaluation and Post Merger IntegrationNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Pharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryFrom EverandPharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryOtilia M. Y. KooNo ratings yet

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsFrom EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNo ratings yet

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet