Professional Documents

Culture Documents

Chapter 5 - Rastra Arif Pradana - 6010221041

Uploaded by

Rastra Arif PradanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 5 - Rastra Arif Pradana - 6010221041

Uploaded by

Rastra Arif PradanaCopyright:

Available Formats

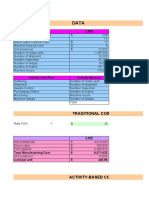

1 Machine setups $ 2,000 per setup

Level of setups 3 setup

Overhead cost 1

Machine setups * Level of setups $ 6,000

Material handling $ 2 per pound

Level of handling 900 pounds

Overhead cost 2

Material handling * Level of handling $ 1,800

Hazardous waste control $ 5 per pound

Level of hazardous waste 300 pounds

Overhead cost 3

Hazardous waste control * Level of hazardous

waste $ 1,500

Quality control $ 75 per inspection

Level of quality control 3 inspecion

Overhead cost 4

Quality control * Level of quality control $ 225

Other overhead costs $ 10 per machine hour

Level of other overhead costs 50 machine hours

Overhead cost 5

Other overhead costs * Level of other overhead

costs $ 500

Total overhead costs

Overhead cost 1 + Overhead cost 2 + Overhead

cost 3 + Overhead cost 4 + Overhead cost 5 $ 10,025

Total plates 100 plates

Overhead cost per unit

Total overhead costs / Total plates $ 100.25

Unit Cost per Plates

Direct material $ 120.00

Direct labor $ 40.00

Manufacturing overhead $ 100.25

Total cost per plate $ 260.25

2 Changed of Activity cost pool : Machine Setup

budjeted overhead cost machine setup $ 375,000

Number of setup 125

Pool rate

Budjeted overhead cost / Number of setup $ 3,000 per setup

Changed of Activity cost pool : Number of Inspection

budjeted overhead cost quality control $ 75,000

Number of inspection 500

Pool rate

Budjeted overhead cost / Number of setup $ 150 per inspection

Calculated the overhead with changed data

Machine setups $ 3,000 per setup

Level of setups 3 setup

Overhead cost 1

Machine setups * Level of setups $ 9,000

Material handling $ 2 per pound

Level of handling 900 pounds

Overhead cost 2

Material handling * Level of handling $ 1,800

Hazardous waste control $ 5 per pound

Level of hazardous waste 300 pounds

Overhead cost 3

Hazardous waste control * Level of hazardous

waste $ 1,500

Quality control $ 150 per inspection

Level of quality control 3 inspecion

Overhead cost 4

Quality control * Level of quality control $ 450

Other overhead costs $ 10 per machine hour

Level of other overhead costs 50 machine hours

Overhead cost 5

Other overhead costs * Level of other overhead

costs $ 500

Total overhead costs

Overhead cost 1 + Overhead cost 2 + Overhead

cost 3 + Overhead cost 4 + Overhead cost 5 $ 13,250

Total plates 100 plates

Overhead cost per unit

Total overhead costs / Total plates $ 132.50

Unit Cost per Plates

Direct material $ 120.00

Direct labor $ 40.00

Manufacturing overhead $ 132.50

Total cost per plate $ 292.50

conclution : the changes in manufacturing overhead cost(budjet for machine setup and number

of inspection) cause total cost per plate increased from $260.25 to $292.50

Nama : Rastra Arif Pradana

NRP : 6010221041

Prodi : S2 Teknik Industri

1. Sistem ABC adalah proses dua tahap pembebanan biaya ke produk. Pada tahap pertama, mengumpulkan

cost pool yang ditetapkan. Pada tahap dua, cost driver diidentifikasi untuk setiap cost pool yang ditetapkan

sebelumnya. Kemudian biaya di setiap kumpulan dibebankan ke setiap lini produk secara proporsional dengan

jumlah pemicu biaya yang dikonsumsi oleh setiap lini produk.

2. Cost per event for each cost driver:

Soldering $ 942,000 ÷ $ 1,570,000 = 0.6 /solder joint

Shipments $ 860,000 ÷ $ 20,000 = 43 /shipment

Quality control $ 1,240,000 ÷ $ 77,500 = 16 /inspection

Purchase orders $ 950,400 ÷ $ 190,080 = 5 /order

Machine power $ 57,600 ÷ $ 192,000 = 0.3 /hour

Machine setups $ 750,000 ÷ $ 30,000 = 25 /setup

Direct costs : Royal Nova

Material $ 2,336,000 $ 4,576,000

Direct labor $ 168,000 $ 396,000

Machine hours $ 288,000 $ 3,168,000

Total Direct Cost $ 2,792,000 $ 8,140,000

Assigned Cost :

Soldering $ 231,000 $ 711,000

Shipments $ 163,400 $ 696,600

Quality control $ 340,800 $ 899,200

Purchase orders $ 549,900 $ 400,500

Machine power $ 4,800 $ 52,800

Machine setups $ 350,000 $ 400,000

Total Assigned Cost : $ 1,639,900 $ 3,160,100

Total Cost $ 4,431,900 $ 11,300,100

Calculations : Royal Nova

Material 4.000 x $ 584 22.000 x $ 208

Direct labor 4.000 x $ 42 22.000 x $ 18

Machine hours 4.000 x $ 72 22.000 x $ 144

Soldering 385.000 x $ 0.6 1.185.000 x $ 0.6

Shipments 3.800 x $ 43 16.200 x $ 43

Quality control 21.300 x $ 16 56.200 x $ 16

Purchase orders 109.980 x $ 5 80.100 x $ 5

Machine power 16.000 x $ 0.3 176.000 x $ 0.3

Machine setups 14.000 x $ 25 16.000 x $ 25

Profitability analysis : Royal Nova Total

Sales $ 4,560,000 $ 19,800,000 $ 24,360,000

Less: Cost of goods sold. $ 4,431,900 $ 11,300,100 $ 15,732,000

Gross margin $ 128,100 $ 8,499,900 $ 8,628,000

Units sold 4000 22000

Per-unit calculations:

Selling price $ 1,140,000 $ 900,000

Less: Cost of goods sold $ 1,107,980 $ 513,640

Contribution margin $ 32,020 $ 386,360

%Contribution margin 2.8% 42.9%

Nama : Rastra Arif Pradana

NRP : 6010221041

Prodi : S2 Teknik Industri

You might also like

- Chapter 5 - Exercise SolutionDocument7 pagesChapter 5 - Exercise SolutionLeo PriftiNo ratings yet

- Chapter 7Document8 pagesChapter 7Erlangga DharmawangsaNo ratings yet

- METU Industrial Engineering - Engineering Economy & Cost Analysis I Case StudyDocument6 pagesMETU Industrial Engineering - Engineering Economy & Cost Analysis I Case StudyOnur YılmazNo ratings yet

- Ch05 SolutionsDocument12 pagesCh05 SolutionsHạnh Đỗ Thị ThanhNo ratings yet

- 7114afe WK5 (WS3) AnsDocument8 pages7114afe WK5 (WS3) AnsFrasat IqbalNo ratings yet

- Product Cost From TraditionalDocument5 pagesProduct Cost From TraditionalPrijulNo ratings yet

- Solutions-Chapter 6Document4 pagesSolutions-Chapter 6Saurabh SinghNo ratings yet

- University of Finance and MarketingDocument8 pagesUniversity of Finance and MarketingQuế Phương NguyễnNo ratings yet

- Chapter 4 - Class ActivityDocument6 pagesChapter 4 - Class Activitymauricio ricardoNo ratings yet

- chapter 5Document9 pageschapter 5Dishantely SamboNo ratings yet

- Work-in-process costing and manufacturing overhead analysisDocument15 pagesWork-in-process costing and manufacturing overhead analysisGayathri22394No ratings yet

- Homework chapter 5 question 1: Manufacturing cost per unit traditional vs ABCDocument2 pagesHomework chapter 5 question 1: Manufacturing cost per unit traditional vs ABCMalene Mandrup TherkelsenNo ratings yet

- Cost AccountingDocument4 pagesCost AccountingChristian Mark PalayNo ratings yet

- Kerjakan 4-12 Dan 4 - 17: 1. "Plantwide"Document4 pagesKerjakan 4-12 Dan 4 - 17: 1. "Plantwide"natan. lieNo ratings yet

- Solution P5 - 4656Document5 pagesSolution P5 - 4656HO JING YI MBS221190No ratings yet

- PPC Ch. 4Document20 pagesPPC Ch. 4Mulugeta WoldeNo ratings yet

- Management Accounting 1 Group Assignment FIRST SEMESTER 2022 - 2121910004301Document12 pagesManagement Accounting 1 Group Assignment FIRST SEMESTER 2022 - 2121910004301Quế Phương NguyễnNo ratings yet

- Activity Based Costing: By: Kasahun N. (M.SC.)Document20 pagesActivity Based Costing: By: Kasahun N. (M.SC.)Mulugeta WoldeNo ratings yet

- Final for PDFDocument8 pagesFinal for PDFWaizin KyawNo ratings yet

- Process Costing Excel ExampleDocument3 pagesProcess Costing Excel Examplehub sportxNo ratings yet

- ABC COSTING FOR TRIMAKE LIMITEDDocument27 pagesABC COSTING FOR TRIMAKE LIMITEDchina xiNo ratings yet

- ABC and ABMDocument64 pagesABC and ABMBrian GiriNo ratings yet

- Calculating Product Costs and Prices Using Activity-Based CostingDocument2 pagesCalculating Product Costs and Prices Using Activity-Based CostingSholahuddin Al AyyubiNo ratings yet

- Ch04Hansen6e ABCDocument21 pagesCh04Hansen6e ABCTini SholihaniNo ratings yet

- Cost Information From Instructions Stick CollapsibleDocument2 pagesCost Information From Instructions Stick CollapsibleDanielNo ratings yet

- ABC Costing System Design StepsDocument25 pagesABC Costing System Design StepsMochamad PutraNo ratings yet

- California Creamery Case Study Activity-Based CostingDocument12 pagesCalifornia Creamery Case Study Activity-Based Costingsd_tataNo ratings yet

- ABC SystemDocument11 pagesABC SystemSyarifatuz Zuhriyah UmarNo ratings yet

- Activity-Based Costing and ManagementDocument64 pagesActivity-Based Costing and ManagementEsterYPNo ratings yet

- UntitledDocument17 pagesUntitledPiands FernandsNo ratings yet

- Accounting Homework Chapter 5Document3 pagesAccounting Homework Chapter 5Kimberly Garmon100% (2)

- Cost Allocation and Activity-Based Costing: Financial and Managerial Accounting 8th Edition Warren Reeve FessDocument39 pagesCost Allocation and Activity-Based Costing: Financial and Managerial Accounting 8th Edition Warren Reeve FessRafif AjieNo ratings yet

- Accounting & Control: Cost ManagementDocument22 pagesAccounting & Control: Cost ManagementdewyNo ratings yet

- AML-Excercise Week 4 (Reviandi Ramadhan)Document21 pagesAML-Excercise Week 4 (Reviandi Ramadhan)reviandiramadhanNo ratings yet

- BUS 5110 Managerial Accounting - Written Assignment Unit 4Document5 pagesBUS 5110 Managerial Accounting - Written Assignment Unit 4LaVida LocaNo ratings yet

- Cordova, Alexander JR - Individual TaskDocument6 pagesCordova, Alexander JR - Individual TaskAlexander CordovaNo ratings yet

- 1.-MBA-Activity-Based-Costing SolutionDocument2 pages1.-MBA-Activity-Based-Costing Solutionumangsharma0494No ratings yet

- No. 4Document5 pagesNo. 4martinus linggoNo ratings yet

- Destin Brass Products Co.: 1. Answer - 1Document5 pagesDestin Brass Products Co.: 1. Answer - 1Chetan DasguptaNo ratings yet

- Tahmina Ahmed Instructor Cost AccountingDocument19 pagesTahmina Ahmed Instructor Cost Accountingfaraazxbox1No ratings yet

- Problem-2.28 - & - 3.32 HMDocument8 pagesProblem-2.28 - & - 3.32 HMCorry MargarethaNo ratings yet

- Activity Based Costing Ch05 HorngrenDocument32 pagesActivity Based Costing Ch05 HorngrenSyahrani JuhermiNo ratings yet

- Problem 4 - 34 and 4 - 36Document8 pagesProblem 4 - 34 and 4 - 36anon_459698449No ratings yet

- Analyze manufacturing costs and variances for Marston, IncDocument11 pagesAnalyze manufacturing costs and variances for Marston, IncCharles GohNo ratings yet

- 8 Pricing Decisions Chapter 8 MADocument7 pages8 Pricing Decisions Chapter 8 MAPaola MancellariNo ratings yet

- Part 1a. Make or Buy Decision Make: 1,000 UnitDocument8 pagesPart 1a. Make or Buy Decision Make: 1,000 Unitthapin RfNo ratings yet

- LCD and LED Cost AnalysisDocument4 pagesLCD and LED Cost Analysisyola yufitanNo ratings yet

- Activity Based Costing AnalysisDocument3 pagesActivity Based Costing AnalysistutiNo ratings yet

- Calculating the Cost of Poor QualityDocument1 pageCalculating the Cost of Poor QualitybalajiNo ratings yet

- Yolla Ervira - 4112101105 - Tugas3Document6 pagesYolla Ervira - 4112101105 - Tugas3advokesmahmmbNo ratings yet

- BASIC COSTING PRINCIPLESDocument5 pagesBASIC COSTING PRINCIPLEScaleahmarshall03No ratings yet

- AccountingDocument4 pagesAccountingFerrNo ratings yet

- Managerial Accounting Assignment SolutionsDocument2 pagesManagerial Accounting Assignment SolutionsMuhammad AreebNo ratings yet

- Example-2 With SolutionDocument4 pagesExample-2 With SolutionDeepNo ratings yet

- Week 7 Tutorial Suggested Solutions (Students, Non-Printable)Document8 pagesWeek 7 Tutorial Suggested Solutions (Students, Non-Printable)Ai Tien TranNo ratings yet

- Item To Classify Standard Actual Type of VarianceDocument7 pagesItem To Classify Standard Actual Type of Variancedavid johnsonNo ratings yet

- Bco322 Budgeting and ControlDocument10 pagesBco322 Budgeting and ControlHà Biên Lê ĐặngNo ratings yet

- Handout 601 - TRADITIONAL COSTING SYSTEMDocument7 pagesHandout 601 - TRADITIONAL COSTING SYSTEMDeedra DavidsonNo ratings yet

- 16 Destinbrass - Solution-EnG YtcAIvEG2FDocument12 pages16 Destinbrass - Solution-EnG YtcAIvEG2Fshubhangi.jain582No ratings yet

- WTP Brochure 020817Document12 pagesWTP Brochure 020817Ravindra VemuriNo ratings yet

- 1338-Right Angle Gear Drives PDFDocument7 pages1338-Right Angle Gear Drives PDFdgkmurtiNo ratings yet

- Role of International Standards in the Fourth Industrial RevolutionDocument24 pagesRole of International Standards in the Fourth Industrial RevolutionRinto Erwiansa PutraNo ratings yet

- BS en 12099Document7 pagesBS en 12099OmerfAtaNo ratings yet

- Company Profile Spring SCDocument27 pagesCompany Profile Spring SCRich PrayerNo ratings yet

- New High-Performance, Low-Power STN2100 OBD Interpreter IC Now AvailableDocument3 pagesNew High-Performance, Low-Power STN2100 OBD Interpreter IC Now AvailablePR.comNo ratings yet

- BP Final Report 03.23.07Document337 pagesBP Final Report 03.23.07hazopmanNo ratings yet

- Overseas Job Visa Consulting in GhanaDocument9 pagesOverseas Job Visa Consulting in GhanadevrajnNo ratings yet

- Fashioned From NatureDocument4 pagesFashioned From NatureSamantha Valencia LeivaNo ratings yet

- A PowertrainAP1 en 170315Document11 pagesA PowertrainAP1 en 170315JinalSNo ratings yet

- Digital Product Definition Engineer ResumeDocument2 pagesDigital Product Definition Engineer ResumeAbhishek MNNo ratings yet

- Lamborghini HistoryDocument22 pagesLamborghini HistoryJirawat Kim Harnsiriwatanakit100% (1)

- Taller 2 Preicfes de Inglés.Document2 pagesTaller 2 Preicfes de Inglés.lizeth zamudio rojasNo ratings yet

- SAP BW Training Part 1Document44 pagesSAP BW Training Part 1Abdelhamid HarakatNo ratings yet

- G-4201 Volvo penta quan trọng PDFDocument310 pagesG-4201 Volvo penta quan trọng PDFleejoNo ratings yet

- BS en 12310-2Document12 pagesBS en 12310-2rajivr_ranjan_verma100% (1)

- Information Flow Modelling Ebook ExtractDocument18 pagesInformation Flow Modelling Ebook ExtractJohn Owens100% (5)

- The Effect of Maintenance Department Performance and Service Quality of Offshore Vessel On Increased Charterer SatisfactionDocument8 pagesThe Effect of Maintenance Department Performance and Service Quality of Offshore Vessel On Increased Charterer SatisfactionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dhs S&T 2011 Long Range Baa 11-03Document37 pagesDhs S&T 2011 Long Range Baa 11-034pavlikNo ratings yet

- Blended BersinDocument11 pagesBlended Bersinapi-296981722No ratings yet

- Senior Marketing Manager Healthcare in San Francisco CA Resume Kathryn MorganDocument3 pagesSenior Marketing Manager Healthcare in San Francisco CA Resume Kathryn MorganKathrynMorganNo ratings yet

- The Indian Lubricant Market - Survival of The SlickestDocument3 pagesThe Indian Lubricant Market - Survival of The SlickestajakbbNo ratings yet

- GGA - Cost IndexDocument24 pagesGGA - Cost IndexAIRBUS320100% (1)

- Unified ArchitectureDocument6 pagesUnified ArchitectureAnil VishwakarmaNo ratings yet

- Aviation Acronyms and MnemonicsDocument4 pagesAviation Acronyms and MnemonicsJay VeteNo ratings yet

- BLF574Document18 pagesBLF574terminator_palitoNo ratings yet

- Powder CoatingDocument15 pagesPowder Coatinganon_778165449No ratings yet

- Mohammed Othman Ezzat CV A.005Document4 pagesMohammed Othman Ezzat CV A.005Medo O. EzzatNo ratings yet

- RtosDocument78 pagesRtossekinNo ratings yet

- EjectionDocument32 pagesEjectionsk9145No ratings yet