Professional Documents

Culture Documents

05 Warehouse Sizing Distribution

Uploaded by

Karen CabreraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05 Warehouse Sizing Distribution

Uploaded by

Karen CabreraCopyright:

Available Formats

CHAPTER 5

Warehouse Sizing and

Storage Distribution

Supply Chain I

Mtro. William Delano Frier

CHAPTER OULTINE

1. DESIGN

2. SIZING METHODOLOGY

1. STANDARD REQUIRED SPACE

2. EXPECTED SERVICE LEVEL

3. COST

3. WAREHOUSE PRODUCTIVITY

Mtro. William Delano Frier 2

Design

• The objective of the design consists of answering

the following:

• Warehouse space required?

• Stocking space determination?

• Stocking location?

Mtro. William Delano Frier 3

Design

• Models

• Discrete Models

• The materials are considered static.

• Pallets, bags, containers.

• Continuous Models

• Materials are constantly being consumed.

• Silos, tanks.

Mtro. William Delano Frier 4

Design

• Stocking location is assigned by two

methods:

• Sequentially

• Benefits

• Simple to use.

• Product is stored sequentially by item numbers.

• Disadvantages

• Doesn´t consider the transaction volume.

• Products with high turnover can be stored in far

away locations.

• Transaction Flows

• Considers:

• Activity Level.

• Volume to be stored.

• It is preferred over the sequential method.

Mtro. William Delano Frier 5

Methodolology

• Methodology

1. Sizing

1. Standard Required Space

2. Expected Service Level

3. Costs

2. Warehouse Productivity

Mtro. William Delano Frier 6

Standard Required Space

• The number of spaces assigned to a certain product

must be enough to store the maximum expected

volume.

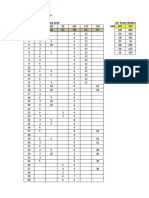

DAILY RE ORDER

DEMAND SUPPLY

PRODUCT (PALLETS) (PALLETS)

1 2 8

2 5 40

3 2 12

4 1 12

Mtro. William Delano Frier 7

Required Space

• Simulation….

DEMAND 2 5 2 1

SUPPLY 8 40 12 12

INITIAL INV 8 40 12 12 TOTAL

1 6 35 10 11 62

2 4 30 8 10 52

3 2 25 6 9 42

4 0 20 4 8 32

5 6 15 2 7 30

6 4 10 0 6 20

7 2 5 10 5 22

8 0 0 8 4 12

9 6 35 6 3 50

10 4 30 4 2 40

11 2 25 2 1 30

12 0 20 0 0 20

13 6 15 10 11 42

14 4 10 8 10 32

15 2 5 6 9 22

16 0 0 4 8 12

17 6 35 2 7 50

18 4 30 0 6 40

19 2 25 10 5 42

20 0 20 8 4 32

21 6 15 6 3 30

22 4 10 4 2 20

23 2 5 2 1 10

24 0 0 0 0 0

25 6 35 10 11 62

26 4 30 8 10 52

27 2 25 6 9 42

28 0 20 4 8 32

29 6 15 2 7 30

30 4 10 0 6 20

Mtro. William Delano Frier 8

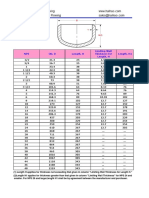

Required Space

• Analysis…. 62 42

SHORT EXCESS SHORT EXCESS

0 0 20 0

0 10 10 0

TYPE AMOUNT FREQUENCY 0 20 0 0

0 30 0 10

MAX 62 2 0 32 0 12

MIN 0 1 0 42 0 22

MODE 42 4 0 40 0 20

0 50 0 30

0 12 8 0

0 22 0 2

0 32 0 12

0 42 0 22

0 20 0 0

0 30 0 10

0 40 0 20

0 50 0 30

0 12 8 0

0 22 0 2

0 20 0 0

0 30 0 10

0 32 0 12

0 42 0 22

0 52 0 32

0 62 0 42

0 0 20 0

0 10 10 0

0 20 0 0

0 30 0 10

0 32 0 12

0 42 0 22

0 878 76 354

Mtro. William Delano Frier 9

Expected Service Levels

• Warehousing Capacity based on the probability of

space shortage.

n

Pr(faltantes = 0) = Pr(faltantes = 0 para Pj)

j=1

( )

n

Pr(faltantes = 0) = Fj Q j

j =1

Pr(faltantes 1) = 1 − ( )

n

Fj Q j

j =1

• where:

• Qj = Assigned storage for product j

• Fj(Qj) = Cumulative Distribution Function

• The cumulative distribution function (also called the distribution function) gives you the cumulative (additive)

probability associated with a function

Mtro. William Delano Frier 10

Expected Service Level..

• Example.....

In the warehouse where 5 products are stored,

the Service Level should cover the Mean+2.25 s.

The probability that several spaces required on a

particular day can be approximated by the normal

distribution.spaces

PRODUCT MEAN STD DEV

1 30 8

2 40 10

3 50 15

4 50 12

5 40 12

Mtro. William Delano Frier 11

Expected Service Level…

• Example...

• The number of spaces Q assigned to

product j is given by: Qj = Mj + zjsj

• where:

• Mj = Mean of required spaces per

day.

• zj = Safety Factor.

• sj = Standard Deviation for the

required spaces per day.

Mtro. William Delano Frier 12

• Example……

• Spaces

Service Levels

• Q1 = 30 + 2.25(8) = 48 spaces

• Q2 = 40 + 2.25(10) = 62.5 spaces

• Q3 = 50 + 2.25(15) = 83.75 spaces

• Q4 = 50 + 2.25(12) = 77 spaces

• Q5= 40 + 2.25(12) = 67spaces

Total = 339 spaces

• Service Level

• Fj = 0.5000 + Z2.25

• = 0.5000 + 0.4878(from Table or Excel) = 0.9878

• Probability of Zero space shortages

• FjQj = (0.9878)5 = 0.94047

• Probability of at least 1 space short per day

• 1- FjQj = 1-0.94047 = 0.05952

Mtro. William Delano Frier 13

Costs

• Objective

• Minimize the Warehousing Cost

( )

n

T

TC Q1 ,..., Q n = C o Q j + C

j =1 t =1

1, t

( , ) + C 2,t max(d t , j − Q j ,0)

min d t , j Q j

• Options to analyze:

• Warehousing owned storage space.

• Leased Space.

Mtro. William Delano Frier 14

Costs

Where,

• Qj = Owned storage capacity for product j.

• T= Length of the planning horizon (periods).

• dt,j = Storage space for product j during period t.

• C0= Present worth cost per unit storage capacity owned

during the planning horizon T.

• C1,t = Present worth cost per unit stored in owned space

during period t.

• C2,t = Present worth cost per unit stored in leased space

during period t.

Mtro. William Delano Frier 15

Costs

• To determine the optimal space.

1. Calculate C’ = C0 / (C2 - C1)

2. Sequence in decreasing order the

demand for space.

3. Sum the demand frequencies f.

4. When the partial sum of f is => C’ then

the optimum capacity equals that

demand level.

Mtro. William Delano Frier 16

Costs

• Example...

• What is the optimal space needed to store 1 product

during 10 periods, considering the following

information: Co = $20

• C1,t = $1

• C2,t = $4

• The space requirements are 4,6,8,10,9,8,7,6,5,4

during the periods 1 to 10 respectively.

Mtro. William Delano Frier 17

Costs

• C’ = 20/ (4-1) = 6.67

Espacio

Requerido Frecuencia Suma f

10 1 1

•Example...

9 1 2

8 2 4

7 1 5

Optimal Q =6

6 2 7

TC = $223

5 1 8

4 2 10

Mtro. William Delano Frier 18

Warehouse Productivity

• Objectives

• Minimize the time required to store and supply products.

• Requirements

– Have enough slots available to “assign” one to each product

(SKU)maintain the selection criteria.

Mtro. William Delano Frier 19

Objective Function

( pi , j t j ,k x j ,k )

T

minimizar f ( x) =

m n s j

i =1 j =1k =1

Sj

sujeto a :

= 1, k = 1,....., s

n

x j ,k

j =1

= j = 1,....., n

s

x j ,k S j,

k =1

x j ,k = (0,1) para j y k

Mtro. William Delano Frier 20

Variables

• Definition

• s = # of spaces

• n = # of products to store

• m = # of receipt and supply points.

• Sj = # of spaces required for product j.

• Tj = # of transactions for product j.

• pi,j = % of transactions from j to the receipt and supply point i.

• ti,k = Travelled time from i to space k.

• xj,k= 1, if j is assigned to space k= 0, if not

• f(x)= Estimated time to satisfy the system demand.

Mtro. William Delano Frier 21

Warehouse

Optimization

• Exercise

Tenemos los sig. Espacios:

1 2 3 4 5

P3 6 7 8 9 10

* 11 12 13 14 15

16 17 18 19 20

P2 21 22 23 24 25

* 26 27 28 29 30

31 32 33 34 35

P1 36 37 38 39 40

* 41 42 43 44 45

46 47 48 49 50

Mtro. William Delano Frier 22

Warehouse

Optimization

• Exercise

• Access doors

• Probability of use P1= 10%, P2 = 40%, P3 = 50%

Mtro. William Delano Frier 23

You might also like

- Encyclopedia of American BusinessDocument863 pagesEncyclopedia of American Businessshark_freire5046No ratings yet

- Indian Law Solved Case StudiesDocument14 pagesIndian Law Solved Case StudiesJay PatelNo ratings yet

- Q3 Math 5 Item Analysis Mss MATH 5Document57 pagesQ3 Math 5 Item Analysis Mss MATH 5Buena RosarioNo ratings yet

- Distribution of Project: Grand Count 2 CountDocument8 pagesDistribution of Project: Grand Count 2 Countanna royNo ratings yet

- FMEA TemplateDocument54 pagesFMEA TemplateKaty SanchezNo ratings yet

- Bahagi 3 Digit - JawapanDocument44 pagesBahagi 3 Digit - JawapanSyamil AsyraafNo ratings yet

- DEEP BLUE Edition BLAZING RED Edition: RRI - RED - RULEBOOK - ENG - HG - v02 - 20202205 - LUMA - Indd 1Document12 pagesDEEP BLUE Edition BLAZING RED Edition: RRI - RED - RULEBOOK - ENG - HG - v02 - 20202205 - LUMA - Indd 1Andy StraussNo ratings yet

- Townend History and EconomicsDocument14 pagesTownend History and Economicsabrar mahir SahilNo ratings yet

- Wesley FrostDocument3 pagesWesley FrostDevin SaumNo ratings yet

- 01 CH Pelaihari2Document45 pages01 CH Pelaihari2Nendi SubaktiNo ratings yet

- Biñan City Senior High School-San Antonio Campus First Quarterly Test Practical Research 2 SY 2018-2019 Grade 12 - ICT 1 COMPROGDocument5 pagesBiñan City Senior High School-San Antonio Campus First Quarterly Test Practical Research 2 SY 2018-2019 Grade 12 - ICT 1 COMPROGMarlowe MarquezNo ratings yet

- Happy ODocument8 pagesHappy OGamer WorldNo ratings yet

- Organizacion de DatosDocument5 pagesOrganizacion de DatosIsai CubasNo ratings yet

- Pdvsa: Engineering Design ManualDocument5 pagesPdvsa: Engineering Design ManualCarlos AlvaNo ratings yet

- Benedict N. DoyleDocument1 pageBenedict N. DoyleShaddoll GostosaNo ratings yet

- San Francisco National High School Mean Percentage Score Grade 11-Gen. MathematicsDocument1 pageSan Francisco National High School Mean Percentage Score Grade 11-Gen. MathematicsMari An Darasin DaguinodNo ratings yet

- Performance Task in Statistics and ProbabilityDocument10 pagesPerformance Task in Statistics and ProbabilityClaire MacasaetNo ratings yet

- Coefficient CorrelationDocument5 pagesCoefficient Correlation키지아No ratings yet

- Statistical ClassWorkDocument29 pagesStatistical ClassWorkVishwas Kumar SinghNo ratings yet

- TensiónDocument14 pagesTensiónJhon ArchilaNo ratings yet

- GabrielDocument2 pagesGabrielAliandrey2No ratings yet

- Soal MultivariatDocument6 pagesSoal MultivariatHana Sekar Ayu EpNo ratings yet

- Unit Cost: $ 10.0 Order Cost: $ 1000.0 Lead Time: 4 Day(s) Reorder Point: 4200 Kits (70 Batches of 60) Order Quantity: 7200 Kits (120 Batches of 60)Document18 pagesUnit Cost: $ 10.0 Order Cost: $ 1000.0 Lead Time: 4 Day(s) Reorder Point: 4200 Kits (70 Batches of 60) Order Quantity: 7200 Kits (120 Batches of 60)Akshay GautamNo ratings yet

- T M 32132 Santander Key Skills 4 Times Table Ver 1Document4 pagesT M 32132 Santander Key Skills 4 Times Table Ver 1Coucou AbNo ratings yet

- Bab Iv Pengumpulan Dan Pengolahan Data A Pengumpulan DataDocument12 pagesBab Iv Pengumpulan Dan Pengolahan Data A Pengumpulan DataNira CaesarNo ratings yet

- Marketing Digital 24000 24000: Keyword Average Length CurrentlenghtDocument10 pagesMarketing Digital 24000 24000: Keyword Average Length Currentlenghtjesus salasNo ratings yet

- 06a. JPPJN - Noss JamDocument9 pages06a. JPPJN - Noss JamSiti MaryamNo ratings yet

- Multi Channel Queueing Able and Baker ExampleDocument4 pagesMulti Channel Queueing Able and Baker ExampleKanwar ZainNo ratings yet

- Lansia & Remaja Bulan Mei 2018: Enziy Riang HepatDocument10 pagesLansia & Remaja Bulan Mei 2018: Enziy Riang Hepatrozita r.o.lamahodaNo ratings yet

- DROPS CalculatorDocument13 pagesDROPS Calculatorpradheepeswaran81No ratings yet

- CallebDocument1 pageCallebGuizinho GaymerNo ratings yet

- CallebDocument1 pageCallebGuizinho GaymerNo ratings yet

- Otomotiv Kabloları ECE-R118 / Automotive Cables ECE-R118 Flry-BDocument1 pageOtomotiv Kabloları ECE-R118 / Automotive Cables ECE-R118 Flry-BElbruz AugurNo ratings yet

- 53 Raices 1Document3 pages53 Raices 1MaríaParionaRamirezNo ratings yet

- Peter DawsonDocument3 pagesPeter DawsonGunnar LopezNo ratings yet

- Bert LowryDocument3 pagesBert LowryDevin SaumNo ratings yet

- Lesson Plan 3 3 TuklasinDocument33 pagesLesson Plan 3 3 TuklasinMhavz D DupanNo ratings yet

- Modified Achievement Test Form AP CONSOLIDATEDDocument8 pagesModified Achievement Test Form AP CONSOLIDATEDBlas RaagasNo ratings yet

- Book 4 AaaaDocument8 pagesBook 4 AaaaMark Patrics Comentan VerderaNo ratings yet

- Book 4 ADocument8 pagesBook 4 AMark Patrics Comentan VerderaNo ratings yet

- Love LeteerDocument8 pagesLove LeteerMark Patrics Comentan VerderaNo ratings yet

- Data ScafoldingDocument11 pagesData Scafoldinguni medNo ratings yet

- School of Computing - Placement Statistics (25-09-2021)Document12 pagesSchool of Computing - Placement Statistics (25-09-2021)Aditya RaiNo ratings yet

- Business Cycle Expansions and Contractions - Months of DurationDocument3 pagesBusiness Cycle Expansions and Contractions - Months of DurationblijeanphilippeNo ratings yet

- Estudio de Clasificacion Vehicular (Conteo) : Trayler Total Micro BUS Camion Semi TraylerDocument1 pageEstudio de Clasificacion Vehicular (Conteo) : Trayler Total Micro BUS Camion Semi TraylerCristian Portella DelgadoNo ratings yet

- Chart Title: Zinc Content % Specific Gravity (@20 C Temp) ZN Cl2 Concentration %Document6 pagesChart Title: Zinc Content % Specific Gravity (@20 C Temp) ZN Cl2 Concentration %gurunathadampureNo ratings yet

- Pedoman Penskoran Pilihan Ganda UsbnDocument2 pagesPedoman Penskoran Pilihan Ganda UsbnNanangNo ratings yet

- Me Gusta 1 Matematica I - DocenteDocument44 pagesMe Gusta 1 Matematica I - DocentefabbiolorenaNo ratings yet

- 5 6183541433404753273Document12 pages5 6183541433404753273PRABHAKAR SINGHNo ratings yet

- Ficha Sem NomeDocument1 pageFicha Sem NomeArthur OliveiraNo ratings yet

- SABADocument15 pagesSABAjuan usugaNo ratings yet

- IEEE754Document4 pagesIEEE754Ano nymNo ratings yet

- Mutu Poli BaruDocument5 pagesMutu Poli BaruLightNo ratings yet

- Din 172 179Document1 pageDin 172 179Dule JovanovicNo ratings yet

- Tugas Kelompok UasDocument6 pagesTugas Kelompok UasHartini hartiniNo ratings yet

- RRI BLU Rulebook ENG v05 LightDocument12 pagesRRI BLU Rulebook ENG v05 LightJosé LópezNo ratings yet

- Exercise: Demand Forecasting: Forecast of The DemandDocument4 pagesExercise: Demand Forecasting: Forecast of The DemandTest MockNo ratings yet

- Elois BircherDocument3 pagesElois BircherDevin SaumNo ratings yet

- Plan Pembuatan Rorak 2019 Act Plan Pembuatan Rorak 660 AFD SAI 660Document7 pagesPlan Pembuatan Rorak 2019 Act Plan Pembuatan Rorak 660 AFD SAI 660fattih19diwa_fdhNo ratings yet

- Haihao CapDocument1 pageHaihao CapDeden SobirinNo ratings yet

- Fred SchenckDocument3 pagesFred SchenckDevin SaumNo ratings yet

- Government Publications: Key PapersFrom EverandGovernment Publications: Key PapersBernard M. FryNo ratings yet

- BCDR AT&T Wireless CommunicationsDocument17 pagesBCDR AT&T Wireless CommunicationsTrishNo ratings yet

- Jis B 1196Document19 pagesJis B 1196indeceNo ratings yet

- Plan Bee Project To Empower 20 Women in Chitral Proposal - 10!12!2016Document17 pagesPlan Bee Project To Empower 20 Women in Chitral Proposal - 10!12!2016Cristal Montanez100% (1)

- Exercise Books EthiopiaDocument23 pagesExercise Books EthiopiaDilip Kumar Ladwa100% (3)

- HSC Economics Essay QuestionsDocument5 pagesHSC Economics Essay QuestionsYatharth100% (1)

- MBA Result 2014 16Document7 pagesMBA Result 2014 16SanaNo ratings yet

- OpinionLab v. Iperceptions Et. Al.Document34 pagesOpinionLab v. Iperceptions Et. Al.PriorSmartNo ratings yet

- Western Railways (Survey & Construction) : Request For Proposal (RFP)Document155 pagesWestern Railways (Survey & Construction) : Request For Proposal (RFP)Ramesh KumarNo ratings yet

- Commercial Invoice Vishvamata WOODWARD FINAL DRIVER BOXDocument1 pageCommercial Invoice Vishvamata WOODWARD FINAL DRIVER BOXSiva RamanNo ratings yet

- From Good To Great: An Introduction To Servant Leadership Gemeco March 2018Document33 pagesFrom Good To Great: An Introduction To Servant Leadership Gemeco March 2018Papa KingNo ratings yet

- Frauds in Indian Banking SectorDocument5 pagesFrauds in Indian Banking SectorPayal Ambhore100% (1)

- Strategic Management ModelsDocument24 pagesStrategic Management ModelsAnubhav DubeyNo ratings yet

- Entry Modes AnalysisDocument24 pagesEntry Modes AnalysisShona JainNo ratings yet

- Fundamentals of Corporate Finance 4th Edition Parrino Test BankDocument35 pagesFundamentals of Corporate Finance 4th Edition Parrino Test BankbrumfieldridleyvipNo ratings yet

- Evaluating Personnel and DivisionsDocument37 pagesEvaluating Personnel and DivisionsGaluh Boga KuswaraNo ratings yet

- Issue 7: October 1998Document68 pagesIssue 7: October 1998Iin Mochamad SolihinNo ratings yet

- Abm 2 DiagnosticsDocument2 pagesAbm 2 DiagnosticsDindin Oromedlav LoricaNo ratings yet

- CAS 610 Using Internal Auditor PDFDocument11 pagesCAS 610 Using Internal Auditor PDFLIK TSANGNo ratings yet

- Afp Vs NLRCDocument2 pagesAfp Vs NLRCRyan AnatanNo ratings yet

- Mergers and AcquisitionDocument17 pagesMergers and AcquisitionKhushal Mittal33% (3)

- The Entrepreneurial ProcessDocument13 pagesThe Entrepreneurial ProcessNgoni Mukuku100% (1)

- Na SW Atio Witch Onal HB (NP Lpa Bang PSB Aym Gla B) Men Des NT SHDocument37 pagesNa SW Atio Witch Onal HB (NP Lpa Bang PSB Aym Gla B) Men Des NT SHArafatNo ratings yet

- Ooad With Uml2.0Document679 pagesOoad With Uml2.0Vener GuevarraNo ratings yet

- Labrel 104-195Document1,014 pagesLabrel 104-195Maria Seleena HipolitoNo ratings yet

- Evolution: Maintenance ObjectivesDocument8 pagesEvolution: Maintenance ObjectivesAkshay SharmaNo ratings yet

- SAG - Front Office Services NC IIDocument6 pagesSAG - Front Office Services NC IImiles1280No ratings yet

- OTS Prepay and Valuing Individual Mortgage Servicing Contracts - A Comparison Between Adjust Rate Mortgages and Fixed Rate MortgagesDocument16 pagesOTS Prepay and Valuing Individual Mortgage Servicing Contracts - A Comparison Between Adjust Rate Mortgages and Fixed Rate MortgagesfhdeutschmannNo ratings yet

- GEOVIA Whittle BrochureDocument4 pagesGEOVIA Whittle BrochureMahesh PandeyNo ratings yet