Professional Documents

Culture Documents

V102 600 2974

V102 600 2974

Uploaded by

smlvl010 ratings0% found this document useful (0 votes)

20 views20 pagesOriginal Title

V102-600-2974

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views20 pagesV102 600 2974

V102 600 2974

Uploaded by

smlvl01Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 20

AdebideAqua

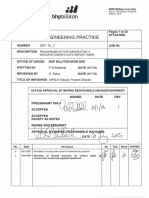

Client: SA Water

Project: Adelaide Desalination Project (ADP) ~ D&C

Location: Adelaide, South Australia

Project No. 2974

)

Construction Execution Procedure

SUPER DUPLEX PIPING-

WELDING and NDE

Document No. V102-600-2974

“APPROVED FOR

Cea CONSTRUCTION

Gicaadan peecrpgeeat

) evi eo

faz [bate | Oneripion aro [ Soy | GK | Oetn [_Pronaed_|Gested | Rrpoved

‘| ain Prlivary ts ewew | er

wren [ itera eviow a

[eR WT ed

© | oaza | Hesrorat Cnt T new ‘or 4

Sm aged

1 | era | rd etree wow [or

2 | sme | eames ™

> | es | Sarge

a en Ais ed

‘Adelaide Aqua D8 Construction Execution Procedure

Super Duplex Piping Welding & NOE ‘CEP No, Vioz-coo 2674

‘Adelide Desalination Project ADP D&C Revision

‘SAWator Date: 17 une 2010

‘Table of Contents

1.9 PURPOSE AND SCOPE. se 3

20 DEFINITIONS & ABBREVIATIONS nnn : 3

3.0 REFERENCE DOCUMENTS. soon a

3 CODESISTANDARDS. ~ es

3.2 PROJECT TECHNICAL SPECIFICATIONS vom ns ne 8

33 WORK METHOD STATEMENTS... v= ss 3

4.0 RESPONSIBILITIES nnn : vo

580 WORK METHODOLOGY - WELOING. rn

51 GENERAL... — vn at

52 WELDING PROCEDURES eonn — 4

60 WORK METHODOLOGY - NON DESTRUCTIVE EXAMINATION (NDE). : °

62 RADIOGRAPHY SPECIFIC =

83 TRACEABILITY nee :

64 DOCUMENTATION... a 7

85 REPORTING ener _ ~

66 DOCUMENT STRUCTURE FOR SUPERDUPLEX PIPING.

7.0 WORK METHODOLOGY - FLANGES, PIPE SUPPORT AND INLINE ASSEMBLY...

73 INLINE INSTRUMENTS. . = 45

80 HANDLING, STORAGE, — ent

8.0 QUALITY RECORDS vcs nnnnnn 18

8.4 INSPECTION AND TESTING.. : “8

92 FORMS onnnnnnnnn : — ~ so

109 SYSTEM REVIEW.. 16

{1.0 ACTIVITY SCHEDULEIILESTONES vn 16

120 CONSTRUCTION RESOURCES crn 46

M0 SURVEY AND SET OUT nner 16

10 SITE ACCESS nnn a

150 TEMPORARY SERVICES ns 16

160 HAZARD IDENTIFICATION, RISK ASSESSMENT AND CONTROL 16

$7.0 ATTACHMENTS on : 7

ATA ATTACHMENT 1- LOGIC DIAGRAM ~ WELDING, NOT ve ct

17-2 ATTACHMENT 2- GUIDELINES FOR COMPLETING NDE & UPDATING WELD RECORDS ..18

47.3 ATTACHMENT 3~ PIPING WEEKLY RADIOGRAPHY REPORT. oy

{74 ATTACHMENT 4-LOGIC DIAGRAM ~ QAQC = WELDING, woven 8D

Adelaide Aqua DBC ‘Construction Execution Procedure

Super Duplex Piping Wetting & NOE ‘CEP No, vinz-so0 2574

‘Adelaide Desalination Projet ADP OC Revision

SaWater Date: 7 une 2040

4.0 PURPOSE AND SCOPE

20

30

‘Tha purpece of is cacurent 0 rode neo 0 eld personne forthe mantoring and

ere ef he see febeeaon, isan ard ron deavulveexansnason (NDE) of super dislex

Pipra on We Acclase Desalinalon Pree‘ io enase tat work i ead Ot ats en

cortsnoe wih approved AFC Drawings, Projet Tectncal Spcietion, SA Wat Guldlns ang

‘Standard, Codes ane Standards

The scope covers fabrication, instaltion.inspacton, teng ard docimentaon assailed wth

\ltngardineaiason of super dus ing.

ABBREVIATION:

ARDRC Adelaide Aqua Deion and Const

Saw SAWater

w Irdependent Veter

Noe Non Cestuctve Examination

RE(RT) ——_Ratiogatle Examination

PE (PT) Panavarexamnaton

MEQ) Magneto Pari Exainason

UE(UT) —Utrasene Examination

PWT” Post Wiel Heat Treatment (tot applabieo te vals of Super Dilex pina)

“The word shal inscates a reuiement

‘The word "should ndetne 9 commendation

REFERENCE DOCUMENTS:

24 CODESISTANOARDS

‘ASHE 831.3 Process Ping Code

ASME D— Quatcaton Stoner fer Welling an Brazing Proceces,

Wilcers, razrs and Welding and Braxng Operstors

ASHE V~ Non Daewusve Examination (NOE)

{ASTIE G42.03~ Stardar tot Math fr Fitng and Crovlon Coreion Resistance of

Shllss sto and loted Alys by Uso ef Ferre Choride Sluon

ASTI £552 ~ Standard Test Mathes for Ostemring Velumie Froaon by Sytemate

Hansa Pit Cone

32. PROJECT TECHNICAL SPECIFICATIONS

"H832402.00007-123-0006~ Techical Spodcason. Moac Piping Fabeaton, Testa

snd istataten

H332402:000007-29-0001 -Teehnea Speccaton: Pong Material

32400-000-00-24-001 - Duablty Pian

“76.61 ~ Pract Undersaning ad ierpetation of Tectia Standard TS 3a Welding

Specicalon Wading & Wang Procosire Qaliiston

TS ata Walling Specfeatien -Weldrg & Welding Procacure Guaifiaton

33. WORK METHOD STATEMENTS

"MS 052.077-2074 = nsalaton of Superypex Ping RO Rack Bt

Wns 088.017-2974 ~ Requirements or Welding, NDE. PWHT & Traceabhy

Poses

Adelaide Aqua D&C ‘Constiuction Execution Procedare

Super Dupox Piping Welding & NOE ‘CEP No, Vi02 600.2974

‘Adelside Deesinaton Project ADP D&C Revision

SAWiater Date: 17umne 2010

40 RESPONSIBILITIES

oy

52

‘The pay responsi fr the cov ane supervision ofthe wating eho Walng Superior who

Sallis oely wih th Welding Engh, Waldng postr ard the AteaPlaing Suparntonden

tha cies ee ftons:

CConsructon Manager|

Projet manager (ech)

‘Guay Engincer

Wielding Enginasr

Wien inspector

‘aaPing Superintendent

ConsumabiesStreman

Wilco

NDE Contactor

WORK METHODOLOGY — WELDING

GENERAL

‘War also, is CEP sat be read in conurton wih WN 08007-2074 - Requirement

Wielng NOE, PWHT & Trocaabiy

‘At Wald sal be cared out accordance wth ASME 63. 2.2008

‘cold Inspacton and Test Pian (TP) sta be prepared (194-017-2874), This chal indy he

‘oes Mepecten requroments te super duplex ping mater be wee

Sutin. wong supervision snd inspection personel shall be employed to ensure tht veld

report maltainedaccuresly Thies espockly mata lhe fishing sage eonroton >

‘core welding ates independent from the pling an pune ing euerviion so at tho rope,

iting ae reeling, ofa slgment adusiments ste recated n'a indeoenent and verable

‘matios. The Welding Sopenier shoud superin every 10-12 alder, The Wacing Superior

‘eponsiielor orang

8) Corecty quite ae approved welders reassigned o each veld.

b)Woldingis card ut cordance wth approved welding procecies,

©) Carectconcumsles reissued o and used by the welder

(6) The welder’ equipments properly maltsines ane ved

1) Weater protection and acess are proves fr safe work o required ashy

4) To pride enthe jo’ ting of recommend resocaton to werk ses and Werk type ae

sopropae fo a weicers perfomance,

‘No pressure tasng of sing systems shall be suthrized unl weling J NDE tothe passe

Sort buna tery te) as Den Conse, sped are vg Sate apres

WELDING PROCEDURES

‘Alaldingprocedues eal be quid in accordance with ASME Section I

1) AADAC shall be responsible for rapation and qualcalon of Welling Procedure

Speciteations (WPS) Each WPS shall leary stele the various [le configuratons iat

‘evered by ne proposed document

2) Each wading procedure qusliiaon reco (POR) shall be supported with the welding

coreumadles ana caso meatal cericaice used Yo" ine quieabon canon along WO

‘Rochon tat documentation which shal indude covosion lets o ASTM G48 Method "A nd

Slome Phase delemiraton to ASTM E862,

‘Adelaide Aqua D&C Constracton Execution Procedure

‘Super Duplex Piping Welding & NDE ‘CEP No. i02-6002574

‘Adelaide Desalination Projet ADP O&C Revision 4

‘SAWater Date: #7 June 2010

43) The ADAG Weng Engineer shal be givan the eoporuiy io winess al Welding Procedure

Gustfcatens. AADEC sal ge amiimur emma race of forty lg (8) hers to Wand SA

‘ator Reprosertaive pri to earmencing o Walag Procedure Cualistons

4) RA-DBC shat hard stamp ow sess ype) or theese use an indelible ink market ny the

Selang procedure tat coupon n te presence ofthe Wo” SA Waar Reposaaive. The et

‘upon shat cantante fling Ifrmaton az miriam, POR suet oF eat rau lest

upon Wectieaten, welders idenicalon number, dale welded, weg. Sotion, weldng

posers Base rata danienton

15) ARDEC Welding Engoae is responsible for ensuring ha al necossary tesng I permed to

‘ually he WP in accovcance win reject Speccasons ang governing eodesandas

6} The AADAC Waldng Engineer sal be given te opportunity 0 wines he mechanical leis of

tne Weng Procedure specimers

7) The AADAC shal submit ot results of Weldng Procedure Guaf{eaton ingot wath Procedure

‘Ghattcaten corto Vand SA Water Ropreseriate or vrleston ony.

1) AADAC shal prepare and malntalo a eumary fa Welding Procedures,

9) AADAC Welding Engineer shal rriow al welding proodurs submited, and ens that hey

fly cover be work scope. quail! an euihoises, ACOBC Welding Engear may give se

‘matory eporval oat work

10) AA-DEC Wilding Engner shal adic of the dosamant ate

49) Appoable wed proces sha bea ac wor action bath a site ann fan she,

53 WELDER CONTROL

531 Qualfeation

‘AW sal be quali in accordance wih ASME Seton

1 RABE shal Be responce for qualiletion of Welder, Weldog Opeators and tack

‘raers In acserdance wth Ne governing codes ard projet spectcadone associa! wh

the soope of ware

2. ARDEC Welding Enginar shat be gvonthe oppor te witness the qutieation teat

3. ARDEC shal ge minimum foumat notice of fory ae (48) hows wo IV and SA Water

Reprossiaivepto commencing Welder an Walling Dera Cuaileason Tess.

4. Ad Wider Qvaleaton Tats shall be documented ard documentation cal Be spertely

‘ompled foreach wading process

5 Compete et eeupene habe raked with the wader numer, date welded, WPS ued in

‘he quatifeaten, wecing poston, welding process and he tp Gatun fees eos ae a

©. AADAC shat submit uty complet documentation ccompanid by NATA endesed et

reports eV and SA Water Representative for veication ony.

7. ANDBC WielingEnginoer acceptance ofa Welersilding Operators requted pier to

ommeneing reduction weling.

8 Al eco hal be stocaed a unique icenfcaton number. The number shall con of he

(Convactnurber lowed by Int fotowed by unique soquental ruber.

8. ARDEC ispectr shat mainain regster of qualifed Welders detaling mts of

‘uations

10. Where uneatefocony welding geformance is reveaig, an investigation Into the cause and

‘eng’ comers neon thal be impsmented though re ceaieson,

11. Where two (2) Waldre share the welding an ane waldment the fowlng shal epoy fo

elder perorrarcefecads.

12) Each Welder sale tributed wth 0.5 for elements completo

Page 120

‘Adolside Aqua D&C constuction Execution rocadare

‘Super Duplex Piping Welding & NOE ‘CEP No Vi02.00.2978

‘Adlai Desalination Project ADP D&C Revisions

‘Samatee Date: +7 sine 2010

1) Where he wads sutjct to NDE and consis, fen each Walder shall be atibutce

‘ith forwatment tat campy. ().

6} Whare the nds sutject to NDE and does not cay, non each Welder shal be

‘aluted wat 0.3 fr welereris iat 60 rl comply (ONC) ures canoe Sealy

Seiemined sinewen

4) Winerein exces of wo (2) Weldra she tha wei of one walmant he above sal

‘aly bul srenlage sous lo wach welds shat be adsted scene

12 AADAC shal prepare and issue each Wear with an entiation Badge cai the

Iimis of quatiators. A emininum requrerent fe badge shal Incl

8) Welder name an denfeaion Number

2») Walang process uses

1) Us of Guastcaton

2) Pholograph of Welder

19) RADKC-QC Waldng Engineer andlor Welang Inspects seceptance snare

12 During production welding, the AADAC Wecrg Inepactr shal encize tat Welds!

‘Badges ae aval for rie and ole te care aualicton sali

532 Production

1. Alling sha be inpacios by te Wing Sune ard Wein Inspector as par the

rgoroments of ASME’ 8912008. The Welding Suparranr and Welsng Insaecr 3

response for eset:

18) The wel is comes ars visilly scoala,

b) To aberve ona apt check si the acts depo by welders unde is supervision

©) To roper the compton of actus welding dey by dey 10 Welding Engioor using

Inomatie namtereané vals numbers, Sraange and sksihas as necessary oly and

‘Sowa nay al wang

4) To ene thatthe welder hos hisher perfomance repaid back on atimaly basis

12) To.onace that apa are propery cared au and that a welders race’ penalty tots

re uty toned

2 Fromtho Daly Welding Reper(DWR), tha Wosingepactor shall nominate ho wel to bs

rnondoctucvely examined. The slecdon shal be baked upon vst repectn

Goraderatons AADAC Technical Spctieaton 1882408 G000-07-123-000 - ete Phy

Faieaton Techy and ieallaion as por perontage NDE requirements and weld

poromance stor

3) The Welding Enzinwe shal randomiy review ard accopt the omit election er

‘there sae! adonsl welcs sn approine

b) Whenever pact, he voids solete! for NDE wit be cairbuted evenly coset

Bipinoine mbors inthe spots ping da.

©) Walang Engine stat beable demonarat at eoch wolde's work nas boon Nor-

Destnsive Teste (NDE) by Ft forthe fat en (0) welds produced foreach poss,

‘het tay re quails.

4) No Welders work sna remsin unchecked fea pred greater than 3 wooks regress

ft il workout

18) The requosing of NDE ete a stated above Is captured vla the daly welding ropor.

(own,

533 Consumables

1. Tha Steeman/Consumsbie oowellar shall ensure all tanding of walcing consumables is

fartamed in socardaca vit manufacturer recommendation a wrt gucesnee propre Oy

the Walang Engines” A copy e he approved gullies shal bo lcaled the corsurade

‘toracom pire commencing welding aes,

Page Bota

‘Adelaide Aqua DBC CConstuction Execution Procedure

Super Duplex Piping Walding & NDE ‘Ce No. Viozs00.2574

‘Adelide Desalination Project ADP OSC Revision

‘sawater Date: 7 June 2010

2, The consumable consol al be adequstely tained fo conairg consumables.

2. copy fl consumate cartates shall be submited to the AADC Welding Engineer or

ornate representative Io releuapproal par uso. Weld Engin shal Plan 9 co3Y

ferrecars

4, AADEC Vieng Engineer shal ensure hat ceriates ae evaable fe ech Bach aumbe of

‘onsrareceved str. eaestes ar ro vale, eoneurabes sl nl be wed aed

‘mum ba removes tom steabecto storage areas

5. Per to commencing wading acives, Weng Enginoer or rominaiad roreseiaive shall

‘ensue the hanclinge welding conumatls es pr manufactur roarerdabon

6. Welding consumes sha bo isued to tha wader via‘ wit chit ystem (Farm No. Fi2e

(017-2914) The ct shal be croetod bythe Welln Supenaor eo aaa eau rat te core

arcurmebes ae being eed ry given ask

7. Asa minimum, the eit shal contain he fallowng information, — Welders pumber, and date of

IS, WPS-No, consumable andlszebaien rumba, tie malaal ype To be welded, Welag

Separors nae and sane,

534 Woldmarking

{Ath fiis upshage ofeach pressure relsning wide othe Welding Inspector shal Seay

‘ent to mates boing farad by lacing the matte ype, C8, 8S, ele. adjacent ©

‘he od jit preparation on each pipe.

ach waldo shal te slocale a unaue wld number, 28 describe Inte tte below

aaron, ‘Waa bang

[wei mck inte wertshop Sir, Sv ae |

[Wes made inte oY |]

‘lachmentwelds

‘Wels outs of iia cops

‘To weld rumber and the smetilrening ruber shall be marked adacont to the wot nt

than eae ik marr Thamar shal bo ected st asta stance away fom th wld

Jai, opr 200mm) 203510 vod otlteraton dung wele cleaning poveeces,

hen wolé detects are revealed by ary of tho NOE metres to the exon hat the wal has 0 bo

‘epered, We Wels rumder end tte unigse NDE umber shal be alowed by a eporopato Su

‘dace nto Tatler? a taous

TTABLE-1

Stage of Repair ‘Symbol | __ Numbering Convention

Fret Reba on th rial weld Ri) PWR, PoootRT

‘Second Rear on he oil wld R2__|FWwira: ono

“This Reps (gina weld et ou an Nt | FWIN: PoooNt

replaced)

Subsequent cu ous of ign weld TNe__|_FHVIN@: POODIN, NS ete

‘Sobeeqenl epsrto hee ou wld Mant | PonONiR

‘Subsequent ox ot and ropa tothe TeRy | POOOINRS, NIR2, Nz,

orginal weld NERZ NSA, NORD te

ole R= ep N= new weld aed dante wequanal umber,

‘Adelaide Agua DEC ‘Construction Execution Procedure

‘Super Duplex Piping Welding & NDE “CEP No, vioz coors

‘dead Desatinaion Project ADP D&C Revision &

SaWiater Dave: 7 dune 2010

“The marking shal remain nat unl ae re pressure tsting has teen competed and veri by ho

‘SAWWater representative.

The

eldeceldng operator shall mark the weld with his unique Menéeston number and the date

‘wade, immediatly upon conpeson ef the in.

The

Wilding Inspector shal mark the joints NDE unique umber adjacent to the welded oi upon

sta acceptanc.

535 Welding heat input

535

1. Tha Welding inspector ena reord deta of Hast put checks partarmed dng production

steing. The “et Iput Log orm ehal be ase FPG7-097-2074 lg het ioe shal nek

‘ehoeed the average one values sped on he appropiate WPS,

2. The Welding inspec shal pvr vad heat irout checks ona least 10% of the watson

‘Super Duplex matorls on daly bans; Ns sha loo ensure that 10% of each welders

veldmente sre soca fe

‘3. Each welders work sha be checked to ensure compliance wth specie requirements of is

document

4. RADEC Welding Engines reserves te ght to nora the wal fo be checked a and when

doomed neceesary

el repairstecapping

No welding eps re-caping of welds shal be performed on any nsialston ues

‘thse by AADEC.

\Wielang Inepecio eh comple a Wel Reps Authorisation Report F 148-017-2978 and aubit

lo Welding Engin or sczepiance prea Snplomoning the epatite cp. The repo sha

‘be supported by the radiograty Vac that shows the fect at locaton win the waded

jou

‘When ts rocossry tore-cap a wale joint forthe purpose of coreg minor misalignment

botweonmatng tages, the Weld Repa Aurora Rept shal show te proposed eea>

‘ocaten via a derstoned ad oroteddlgrarm Tho opr shal alo sits he snout oF

‘movement rineeee) rue to achiev the Gosred oleae.

4. ARDC Welding Superiserinspecter shal be esposibl fo making the location ofthe ele

‘res en the weldea ers bared onthe loan roves ty NDE Contactor,

5, Defoctve wel sha be repaied win 48 hous frecaving he Weng Engines aceptonce

ote pepoead reat method,

6. Nomoto than two waldepaa shal be paritadinthe samelocaton of th agnl vad. he

‘second rept atmo ot susoasl, he complete veld and te heat-fected Zone shale

‘utaut anda ew veld made ni lsc,

7. Welds fund to be craced atthe Heat Afleced Zone (HAZ) shal be ut ut entey an a ne

‘tld made nt pce The new woven sol be numbered as pe Secvon 53.4 TABLE

8, Recapsig f wel shal a be peed mae tha on ine in any one er fthojolnt in

‘ston ifthe capping pocass hak hol achieved ie deste faults thoi halle ct,

felted, welded era Now Destuive Tested in scosdancs wi H3s24a2 OD00-07-123-0008~

‘ectned Spechealon Metals Pipag Fabreston,Tesing ard insslaton,

‘8. Heating he weld jit by runing the GTAW toro ober hesting device ever he expo! any

‘ld sal ee perio,

{0 Re capped wolds shal be non decwucvely examined to th same exerts the orga wo

‘Tha examination shal le He i langtva ha wal, even tboagh ony pt the Wed ay

have been r-capped

‘1-At weds tat have been re-capped sal be euteced wo pressure et using ho same

‘edu and els pressure on apc fr tat system. Ay deviaion om

Shall be subject 0 approval ram ABDC,

Page oid

‘Adoide Aqua DBC Constuction Execution Procedure

Super Duplex Piping Wetting & NDE CaP No, Vioasoo-zeTs

[Adelaide Dessinaion Project ADP D&C vision ¢

SA wiater Date: #7 dune 240

When approvals given fo re-cap welds fr the purpose of corectng minor agrment anomalies, he

{atoning nomenclature sal be ute,

+ Ro-capping of welds performed by others (wel Dat war al made by AA-DEC 25

parol the scope of work) shal be deed 3 "Ax" where "x" fea sequential number

Ungue wo each tn he ome ag AT AZ, AB

‘+ Recapping of fold welis performed by AADAC, shall be Weifed a5 "FsAx” where

ra sequel urbe que fo each Joint onthe mete, eg, PWSAT, FAG,

Fuiaase.

537. _ Weld reporting NDE requesting

1. The Daly Welding Repot F134017-2074 shall be the avanua by veich af welding on the

ec ul be cated and val accepted. The Wang epoca shal Sequel Panber

StDaly Weling Reports,

2, eendnentso Sly wong reports all be recorded en searate DWR wit ofrences 0

‘ho oreinal document. The ona acumen shal aot beached.

“The Wing Supenielnpectr shal seers prosara a DVR ol welding performed

the proigu twenty fou (4) hors, and suit a copy fo the AA-DEC Weldng Engineer ona

daly basa, Every eft il be made lo caput al eomrlates welds Wein he previous 24

fours

4 Alwar es ein pats pce geal by cetmetecen

5, The Welding Inspector shall oly include weidments onthe Dally Wsig Report thats

‘compaia and have boon apie Sod aly aceape

1538 Inspection and tas status

+. Each weldorldng operatr shal lace @ "YELLOW" rsbon ates the complet poducion

eld reat at is ead or vival inspection.

2. The Wilding apoctor sal via inept all weldmenis sod ineate visual acceptance by

femoving the yellow ribbon and act's "GREEN" ribbon soured the weld nd ntling the

Din elu proved tale shal be entered for each mul wa.

‘3. Ech wad omincted for NDE shal be iagged With "PINK cloud ribbon, Upon completion

(fall NDE, the NOE Corieact shal emave the pink on Kan he jn

‘Was hi do rot coma tthe pected requlement chal be dened wth a "RED" cxlowod

"bon wich cal romain In lca unl such me eal ecossry rod work has been

computed ad accepted,

«5, Tha geen ron sll not be removed fom the Jot unt al asocnad stv: have been

coated and acepted, eg pressure testing ec

6, Alibbons sha be secutl staced io prevent migration along pipe ue to wind.

80 WORK METHODOLOGY - NON DESTRUCTIVE EXAMINATION (NDE)

GENERAL

‘Extent of NOE on process pprg stall boas flows

[AINDE eae examina an oprte os por he roqurerant f ASNE SectonV.

isu 10%

RE 10%

DPE 100%

ANFllst WeeDPE 10%

‘Al completed wolé hal let in th “ae wala state and sha ot be evarked porto

oe.

‘The reauremns fer NOE a sled io the AB-DEC Speen H32402-0000-07-128

(bos Teemicl Specfeston Mesto Ping fatreaton, Tesing an lstasain Append A

Page ot20

‘Adelaide Aqua D&C Construction Execution Procedsre

Super Duplex Piping Welding & NOE ‘CEP No. Vio2600.2974

‘Adelaide Desalination Project ADP D&C Revision &

SaWater Date: 17une 2070

“The AADAC Welding Eainer shal obtain copes of qualifications ofthe NOE technicians

ftom the Contac Names end quaifeaton cal ba Fecrded an ARDC sppaves NOE

regi.

When veld defects ae cevsied by any of te NDE methods to he extent tte we has

taped ie NOE rb sal ace ya pepe Bt esd

“more NDE revels non comtiyng wos, adiona weliments sal be made alate for

INDE. Adatinal wnicmoris nominated shal bo sutfect fo agreement wit Uno AADEC

‘king Engen or nemnatedropresersave,

[Nacional NOE chal boiled whin 48 hours ofl Now-campying NDE resi

‘AL welds subjected to NOE shall be Ideried on a master oat of vaceabily

ravingstocmeaics

‘An electors NOE aching system shal be implemented that capable of producing the

fotouing tttes oso miner,

8) Welders rea se wibn esc atlooaohy percenage group

1b) Welders vera rpse ae al percontagesrus combined

12) Pescontag of raography pertarmed fo aach piping dastinspection oval

8) Weld ropa foreach lass oad

©) Over we rpair rate

1) Outstanging ecto) recor for each radiogreshic percentage oup

5) Summary repr of NDE parormed on ech omic drawing

1) Summary reat of ll NDE performed for each "NDE Unique Numb”

62 RADIOGRAPHY SPECIFIC

1. seh ralograph shal contin te flowing petmsrent marin. = contact nanbet,

‘Gnue NOE number, date of radiography, wader derifcaion number. eg 2074

Pogot 02 oe woot

2 When a wold nas undircone ropa, the racooraph shall contin the designators

eaetedin "Tale" secon 5.34 of weld tepare selon, above.

3. When a wold restoot i requied e to Identiasion enor or poor qulty the

radiograph shal cary te designate RS (shoo)

4. The radiograph shal lz contain the methods of sstosing rasooraphic quality. Te

‘Genteaton shal val be by means of lead letering held ono pipe wrap o sar

eh. approved by AMDEC. ins provides an unaleatle record curing Ihe

‘asiogahie exposure. The meted of tenifeaton (ora ots shat be prt of he

Sppred raseraphi procedure.

5. The ANDEC Welding Engingor or nominated rpresrtave stall te given tho

pparuniy te review all redzraphe Toloing Inepelation and review by the

nracor! Repairs shot not be aries et ntl ADAG have gen clesance Toc

5. Ropaks shall be record on approved documenistion (RECO of rpals) nd

‘ibm daly to An-D8C Weng Engineer for even

7. Project Ropar Rate sha be calniated on But welds racioraphed ely a shal be

‘ested 8 lon

2 100% = Reps Rate

‘ola No of Wage Radoraphed

8. Where walars and projet vert raconrphy reps rate wxceads 5%, The A-DEC

Wilcng Engineer shel review the par fo ently vequred conecve acon,

Page t0 020

‘Adoaide Aqua 086 ‘Construction Execution Procedure

Super Duplex Piping Welding & NOE ‘CEP No. Vioz-000-2574

‘Adellde Desslinaton Project ADP D&C ‘Revision 4

SaWator te: 47 June 2010

8. Al radiogaohs shal te boxed and stored by the ion unicue number. These

Boxeropot nonbere sal be inde, and form part of he nl hand over package

fom ARDEC to SA Wal

10. Alradiogaphs and NDE reports shal be sored win fre ret eis un wnover

AnORcRSAnaer

63° TRACEABILITY

1. Welding wacoabityrquromont chal be 0 pec

2. Al peemaranty welded piping mae, ning welded ves and any aschments,

(erorcng pads pipe sxpoar, lugs et) welded drecy io pin and oer presse

‘eising ates sal be ecrde by het suber adc Ot ety

umber, a6 cece by AADC.

3. Prior to cating of any fly aceatle mati, hest runes andor other vacesbity

rumbars shal bo tensfred end independently wneased ty ARDEC. Tho winese

al lace nor ital and dla agalal the Uorsfared numbers fo very De

sccuacy ofthe Wann.

‘Ihe ARBRE Weleng Inepecor andor Welding Supervisor shall be given the

opportunity to verly te secaracy of tha enstr pore cutin.

‘5. Arya toncmucton and moseatone to pressure retain sabonay and rtatng

‘pment anal be hy vaceabe

Unique mmboring NOE

At weds rquting non-dectucive examination sal be allocated unique reference rumba. For the

purpose of is aocument unique rumoaing shall op) to RT, UT, MT and PT.

|AK-DAC shal mainlana"Weld Unique Number Regi fer Gah cine (ne table 2 below)

= m Nambering

Dlecptine Descriptor rng

Pi “i piping and moaienions Bereio P| Po00t, P02 es.

nea | Sutil repair t rosare 1" oe

Misc ‘ata pari to. Mono, 0002

Unique reference numbers shal belie nan ascending rumeical sequence on tha Weld Unique

urbe Regie:

[ADC Wielding nspectr cr Welding Superior shal larly ark the unique reference number

‘ajoor tothe waa ruing NOE

‘Te unique reference number shall cont ofthe contact umber flowed by the approntite unique

‘ymbaleauerl ruber Gesebed In Tale? above, 9, 237% POOD"

For raring aposes, the unigue sibosecvont umber canbe wien wihaut ne preceding

‘onveet rue proving thet te coitcl pumoet is specified onthe document blog Pesan

Note: Projct Number Is 2874

‘Traceability Records

‘ne master st of wacalilty ravings (mata maps, weld maps atc.) stall be markad up bythe

‘Wong Supa Inspecler wih sequentl uber alocated o ppg mars os spproprate and

swale iin the scope of work

“Tho weld numbers sal bo aocated ard marked onto the fame in alia sequence that lows

‘no Row econ wherever racial Cantnuly welds at somatic aca shal be dudes on re

Upeteam somatic fe. fs! weld f each seme chal be weld amber 1

‘As a micu, veces drawings al contain the olowieg waceabity data enclosed winin a ok

cua ose shape,

Page 020

‘Adelaide Aqua D&C ‘Construction Execution Proceaure

‘Super Dupex Piping Woking & NDE ‘CoP No. Vinz. cop 2174

[Adelaise Destination Proest DP D&C ‘Revision §

Sa vistar Date: a7 dune 2010

+ Shop Wald Swi, swW2ee.

+ Fils Welds FAS, FW? ee.

Mates, M2 ete

NDE unique number Le PO0ot

“Wher hare has neon no welding pafomes on dang, the drawing sha be mos No Welding

Performed on this Drawing"

Tho Convair sal main a “Traceably Record She (TRS) Foon No: F135.017.2574 foreach

Incveal voces drew, Ths shat inde crawngs where wring snot vaceaby are nak

appleate

Inaticn to the above fs the TRS shal lo contain oevew acceptance lack forthe AADAC

feprosriatve anda certo ofaclal the nll any sora moles appcabie ae

‘resistor

‘Wire ther sno waceaiy eats to eco tbe TRS sal be marked aceon.

{GA Enginger hall ensure tat ne relevant recon lsometis and TRS are comolte and

Inforatn seovatt recrsed poo Meet, Prauratin, save visu Examineon AA: OBC

Shal ret a egal deeamentaton fr omplaton ino Neracurrs Dela Repart

“Traceability Test Packs

SterDedpine Engroar shal comple Traceabily end NDE Teet Pack representing pling eaters

{hat are complete ar fom pat oa resure ot Stem.

[ADAC dicing erginoe sal cori tho "Tacoablty and NDE Test Pac Ino least flier

‘early mares wth tee pack ramet

‘The content eft trcoabily et pack sal be as allows:

8) Copy of he test pack "Lasd Shoo (costing a at fal aploatie cravings associated wth

the os and revensccaplance sire och)

») Cony ore corrasponding an completed Tacacbiy droning wth ait icates

©} Copy of eorespanng and conplatod TRS,

4) Copy ofretvant Urigue Number Register.

©) Capy at NOE Raped, where spncaio.

1) Copy comsleted punch it

‘The AMOR Welcng Engineer shel check the “Traced and NDE Tet Pack’ ane sgn the gl

"oe Shost auhering te examination ofthe png set o proceed

No tesing stall be peared un he ARDEC Weldrg Engineer InspecerSignatire has bean

‘sind on th "Lead Shee

4 DOCUMENTATION

1. Nor Destructive Examination (NDE) contractor shal eomaet all NDE eps fr submission

anes

2, Contactor shal submit ll NOE reports lo AADEC Welding Engieer or nominated

reprecalatve for ravraw ard apprors. AM-DEC Waldng Engine’ sta eh copes f at

“proved NDE rpore end olur heoigala to GA Engineer fr usin is Menufacrers

aa Report

8. Form No, F140.0172974 chal be usad to report rxiaraphy. Each radiographic ropor hat

conan oly weds fom ane somatic Wels fom varaue tometrce evant be reported en

‘one single ep.

4. Fm No, £196.17-2974 shal bo used to repat both MT and PT etaminalons. MT & PT

‘eports shal not be mad on the same report Welds for varus lsorettes hal not be

reported on om sng rapa.

8, Form Ne. F14-017-2074 shall be used to tepatall ultazonie examination (UT). A separate

Fopars egutedtor eoch wats Oaly one wel shallb apate em any UT rosa

Page 12a

‘Adelaide Aqua D8C ‘Construction Execution Proc

‘Super Duplex Piping Wolsng & NDE ‘CEP ho. Vil2.600-2378

‘Adelige Desalination Project ADP D&C Revision §

SAMiator Dates 17 ne 2010

1. Form We, F133.0172978 Summary of soprored waders sall bo lesved to the AADAC

Waldag Enginer fr appro proto walang ‘abzston, of feld weld carmencing. Thi

Summary ex be reve end fesuomag whenever thre fe change i wagers older

odtaing easton euaistons

7. rk pak shal be prepared by AA DEC wk pack coordinator and submiled fo Welling

Engine fo review porto eld aso. Upon competion of was the AA DAC work fork

‘nora sal run Te wrk pack tothe Weldng Engines: or Nera Ropresoratve for

raven art conplton of Tracabilty Resod Sheet (TRS). When sesfes, te Woling

EEnginer cal sign he pisng ts pack ane tan over o Site Engines for elease ote eng

', The wacng and NOE ooumeriaton shal ronsin fled and be retorale by amet, This

‘Sooumentton shal ot be nsued in ay piping fst pace

65 REPORTING

‘The Wielcng Suncor shal come ach week thor Weders Wooly Pafrmance Recor. These

Sl be separate reports er

2) Pofabricaon of Pipe werk

) Field Erection of Pipe work

‘Ropar salt on separate reports: -

2) But Wave

1) Socket Wels

ach rport sal sae:

2) Tota Number of oats Welded

9) Toa ameter miners Welded

Total Diameter Miners to Date, sccumsed

4) Tota Nomber of Joints Wekead, acura.

‘The Waling Supervisor sab sued a eco fa NDE completed win each week,

AADEC Welding Enginer shal iesue © wookY report detling project rep rales to the AADEC

Consrcton Manager

86 DOCUMENT STRUCTURE FOR SUPERDUPLEX PIPING.

The pay documents sssocite wth maining Faceatity ant summarising tha weceabity dats

‘+ Projet tanngslsomaiss ely marked up with the reevanturique atrial ar veld number.

+3 Deewingatomotin fr daly

1+ “Tracey Record Stet” ey competed er each éravinglsometic

“The secondary raceabity documents are ese tal support he primary documents and cons of

RRegetera, Reports ond Geresos,

Page 130120

Adelaide Aqua D&C ‘Construction Execution Procodute

Super Dupex Piping Weng & NOE ‘CeP no, Vinzconzers

‘Adelaide Deselination Projet ADP D&C ‘Rovision

SAviater Date: 7 une 2040

“The diagram bow represent the dosurentation srr as document hierarchy asst with he

raceadiysysion,

TSOMETRICS/ DRAWINGS

£

TRACEABILITY RECORD SHEET

TE

REGISTERS REPORTS: CERTIFICATES | [ MISCELLANEOUS

+ NDE + BWR Materia + WPS Summary

3 Feria Tost * NOeRT 4% Coraumatio | | $ Weider aval

+ Matera Con 4 NbePr Galoraton ‘Summy.

+ Consumabe + Welder Ou. + Werkng Fit

‘Unive Batch woo

70 WORK METHODOLOGY . FLANGES, PIPE SUPPORT AND INLINE ASSEMBLY

74 FLANGESIGASKETS

1. Flange feces hal be cleaned and checked fr mecnanical or earoslon damage tothe gasket

‘const suracee

2, Flange gest srfoes shal be protected rom damage wth uta covers

13. Flanged piss sho be elated and euppertd so that accurate matrig of bolt oles and

‘uslor contact ove In entire gasket surface areas blaine por 0 bs eohanirg ery

anges.

4. Fert eld ines, no mtgnment shal xa eden flanges pio tering the le.

5 Fer nora nes, Ringe shal be fitted win Siem per 1 000 mn across dame

‘eles pote tanerng te Bating. The maxinum msolgrat of feng bl hls shal

be 3mm. Hange balls, when Ughoned sal expose two veads (min) st he rt

6, Flange bats that be ighenad every nd dati oppo impose even posse on

Ihe gastata andi aad dorian or overseding of equipment. Trquevalues or tersonng

‘shal be os por ne manufacturers recommended trash.

17. Alfange bate sallbe ubisied wih a copme bved anil 20 lubicent

1 Wore langed pie spcls re ote to wate fnged conection cal be mec ung &

oration gaska before weldg To ensue hal frais ra misalignment

19, The ade ameter of wai nck fangs and apa eubende shal be sh wth the nego

ameter ofthe pipe rte whic te atacred

‘0¥enge gekat surface potetve covers eal be remaved aft fil ntalation of te plpe ad

ust plo canna

11.Gasets shal be stale 0 that hey do no proud rsd the pipe bore. Te itn lamer

‘ofthe goat shel mate the vera lameta of fangs

12.Gaahae al nat be reused. a Marge jan ust be open, fr axa fr systom pressure

‘ean, ne using, temoval of emorary bias or stlners ee the ot shal be relaced wth

ew gastte ana wih to tak uorean replenished

13 seling compounds shal Se sped lo gatels Hanged faces.

‘Adelaide Aqua D&C Construction Exscition Procedure

‘Super Duplex Piping Welding & NDE ‘CEP No, Vibz-co0 2574

‘Adelaide Dealinaion Projet ADP D&C Revision 4

Aviat Date: 7shane 2040

72 PRESUPPORT

1. Pip spor shal bo ietatadasindeatod on th smo eauing ad Ping sport

sroninae.

2. Weide io pire sping supports as a emgorary suppor measure ding stlaton rot

perme

‘3. Temporary suppor hat bo comes removed upon complain of esting ad prio to

4. Where pe spat ataclmens ae tobe permanently welded tthe poe wor, waldng sha

De nscornce wiht proceaure

5. Galvanized mata shal rtbe welded vo eustorite, duplex, cupor duplex sthioes iel o

‘itl aloysunder any cearstanoss,

7.3 NUNE INSTRUMENTS:

1. Indira nstumonts shal be insaed a pr the related Project Spacteaton or vensor's

Ineructors

2, Wire inating ange kt sr tobe neal, cre shal be akan otto damage te tat

‘hooves and gasket. Th competed Jit sal bo tested wih 3 "Magge” DVOM or silat device

ipanore secre isto

3 Root sto ofthe flanges tre rounded a eacng of creo went oes wl occ. fone of

‘oth ides are not roundes feaing of 1000 more os should accu

4 Con Welcng ftom leads shal rat be sated across elation Ranges

180 HANDLING, STORAGE

‘Al oducts alba hada and stored in aoortance wi "932402.0000.07129-0000~ Techical

Speciation: Nelli Piping Fabreaon, Testing ane ets” Cause 02

80 QUALITY RECORDS

Quatiy rear sha be mensined in acoadaree wth “PEP Atachmont 143.MDR Procedure

9.4 INSPECTION ano TESTING

Inspecton an Tes Pan (TP)

wraeor7-2074

22 FORMS

For No:£132017-2074 Welderslding Operate: Gualifcaton Test Reco

Form Na: FI38017-2074 Summary of Approves Welders,

Form No:FI3e017-2074 Daly Weld Report (ORN)

For No: F135:0172574 Tragsbiliy Record Shel (TRS)

Forti: FI2e-0r7-2574 — Weding Gonaumabi sus Sip

From No: F1a6-017.2978 Fete Tea opert

FomNo: FI3?-17-2978 Heat Inpullerpass Tom. Veeston Lag

Form No: F138017-2574 Maqnsio Parkde(Dye Portant Rp

Foo: F1ab017-2972 Nos Deciucbvebxamiraten Summary

Fom No: FIaD017-2078 Radiogrape Report

FomNo:Fistoir-2are Ulta Sonic apes Repert

Fem No: F142.017 207% Wald Join Un Number Reiter

Farm Ne: F143-017 2574 Weld pak Autatiztion Report,

Ferm No: FO0H-017-2574 Inspecien and Tet Pan (TP)

Fame: Fige07-2074 Weld Procaire Speestion Surry

Page 15 120

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- gb-t8163-1999-1Document11 pagesgb-t8163-1999-1smlvl01No ratings yet

- ISO_22825-2012 Non-destructive testing of welds - Ultrasonic Testing - Testing of welds in austenitic steels and nickel-based alloysDocument31 pagesISO_22825-2012 Non-destructive testing of welds - Ultrasonic Testing - Testing of welds in austenitic steels and nickel-based alloyssmlvl01No ratings yet

- Aws D1.1 - 2008Document566 pagesAws D1.1 - 2008smlvl01No ratings yet

- AWS D10.11-1987 Recommended Practices For Root Pass Welding of Pipe Without BackingDocument20 pagesAWS D10.11-1987 Recommended Practices For Root Pass Welding of Pipe Without Backingsmlvl01No ratings yet

- Aws D18.2Document2 pagesAws D18.2smlvl01No ratings yet

- Sep 70Document33 pagesSep 70smlvl01No ratings yet