Professional Documents

Culture Documents

Rear Suspension: Section

Uploaded by

Nestor RosalesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rear Suspension: Section

Uploaded by

Nestor RosalesCopyright:

Available Formats

SUSPENSION

SECTION RSU

REAR SUSPENSION

B

RSU

CONTENTS

PRECAUTION ............................................... 2 ON-VEHICLE REPAIR ................................. 10 F

PRECAUTIONS ................................................... 2 REAR LOWER LINK & COIL SPRING ............. 10

Precaution for Supplemental Restraint System Removal and Installation .........................................10 G

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ................................................................... 2 SHOCK ABSORBER ........................................ 11

General Precautions ................................................. 2 Removal and Installation .........................................11

Disassembly and Assembly .....................................11 H

SYMPTOM DIAGNOSIS ............................... 3 Disposal ...................................................................12

NOISE, VIBRATION AND HARSHNESS FRONT LOWER LINK ....................................... 13 I

(NVH) TROUBLESHOOTING ............................. 3 Removal and Installation .........................................13

NVH Troubleshooting Chart ...................................... 3

RADIUS ROD .................................................... 14

PREPARATION ............................................ 4 Removal and Installation .........................................14 J

PREPARATION ................................................... 4 REAR STABILIZER .......................................... 15

Special Service Tool ................................................. 4 Removal and Installation .........................................15

K

Commercial Service Tool .......................................... 4

SUSPENSION ARM .......................................... 16

ON-VEHICLE MAINTENANCE ..................... 5 Removal and Installation .........................................16

L

REAR SUSPENSION ASSEMBLY ..................... 5 SERVICE DATA AND SPECIFICATIONS

On-vehicle Service .................................................... 5 (SDS) ............................................................ 17

Inspection .................................................................. 5 M

Inspection and Adjustment ........................................ 6 SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................. 17

REMOVAL AND INSTALLATION ................ 8 General Specification (Rear) ...................................17

Rear Wheel Alignment (Unladen*) ..........................17 N

REAR SUSPENSION ASSEMBLY ..................... 8 Ball Joint ..................................................................17

Exploded View .......................................................... 8 Wheelarch Height (Unladen*) ..................................18

Removal and Installation ........................................... 9 O

Revision: September 2009 RSU-1 2010 Altima HEV

PRECAUTIONS

< PRECAUTION >

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000005817067

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

General Precautions INFOID:0000000005440820

• When installing rubber bushings, the final tightening must be carried out under unladen conditions with tires

on ground. Oil might shorten the life of rubber bushings. Be sure to wipe off any spilled oil.

- Unladen conditions mean that fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

• After servicing suspension parts, be sure to check wheel alignment.

• Self-lock nuts are not reusable. Always use new ones when installing. Since new self-lock nuts are pre-oiled,

tighten as they are.

Revision: September 2009 RSU-2 2010 Altima HEV

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

< SYMPTOM DIAGNOSIS >

SYMPTOM DIAGNOSIS A

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

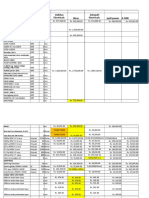

NVH Troubleshooting Chart INFOID:0000000005440817

B

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

C

RAX-3, "NVH Troubleshooting Chart", RSU-3, "NVH Troubleshooting Chart"

D

WT-55, "NVH Troubleshooting Chart"

WT-55, "NVH Troubleshooting Chart"

RAX-3, "NVH Troubleshooting Chart"

RSU

BR-6, "NVH Troubleshooting Chart"

ST-3, "NVH Troubleshooting Chart"

F

RSU-18

RSU-11

RSU-5

RSU-8

RSU-6

RSU-5

—

—

Reference page

G

J

Shock absorber deformation, damage or deflection

K

REAR AXLE AND REAR SUSPENSION

L

Bushing or mounting deterioration

Improper installation, looseness

Possible cause and SUSPECTED PARTS

Incorrect wheel alignment

M

Suspension looseness

Stabilizer bar fatigue

Parts interference

ROAD WHEEL

Spring fatigue

N

WHEEL HUB

STEERING

BRAKES

TIRES

O

Noise × × × × × × × × × × × ×

Shake × × × × × × × × × × ×

P

Vibration × × × × × × × × ×

Symptom REAR SUSPENSION Shimmy × × × × × × × × × ×

Shudder × × × × × × × ×

Poor quality ride or

× × × × × × × × × ×

handling

×: Applicable

Revision: September 2009 RSU-3 2010 Altima HEV

PREPARATION

< PREPARATION >

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000005817081

Tool number

Description

Tool name

HT72520000 Removing upper ball joint

(J-25730-A)

Ball joint remover

NT146

ST3127S000 Measuring ball joint rotating torque

(J-25765-A)

Preload gauge

ZZA0806D

Commercial Service Tool INFOID:0000000005440822

Tool name Description

Power tool Loosening bolts and nuts

PBIC0190E

Revision: September 2009 RSU-4 2010 Altima HEV

REAR SUSPENSION ASSEMBLY

< ON-VEHICLE MAINTENANCE >

ON-VEHICLE MAINTENANCE A

REAR SUSPENSION ASSEMBLY

On-vehicle Service INFOID:0000000005440823

B

• Check the suspension parts for excessive play, cracks, wear or damage. Shake each rear wheel to check for

excessive play.

• Retighten all nuts and bolts to the specified torque. C

• Make sure that the cotter pin is installed.

• Check the shock absorber for oil leakage or other damage.

• Check the wheelarch height. Refer to RSU-18, "Wheelarch Height D

(Unladen*)".

• Check the suspension ball joint for grease leakage and the ball

joint dust cover for cracks or other damage.

RSU

SMA113

G

Inspection INFOID:0000000005817083

SHOCK ABSORBER ASSEMBLY

H

• Check for smooth operation through a full stroke for both compression and extension.

• Check for oil leakage on the welded or gland packing portions.

• Check the shock absorber piston rod for cracks, deformation, or other damage and replace if necessary.

I

SUSPENSION ARM

• Check the suspension arm for damage, cracks, deformation and replace if necessary.

• Check the rubber bushings for damage, cracks and deformation. Replace suspension arm if necessary.

• Check the ball joint. Replace the suspension arm assembly if any J

of the following conditions exist:

- Ball stud is worn.

- Joint is hard to swing. K

- Check if the swinging force (A), rotating torque (B), or vertical end

play (C) is out of specification using Tool.

L

Tool number : ST3127S000 (J-25765-A)

NOTE:

Before checking specifications, turn the ball joint at least 10 revolu- M

tions so the ball joint is properly broken in. SFA858A

Swinging force (A) : Refer to RSU-17, "Ball Joint".

N

Rotating torque (B) : Refer to RSU-17, "Ball Joint".

Vertical end play (C) : Refer to RSU-17, "Ball Joint".

RADIUS ROD O

• Check the radius rod for any deformation, cracks, or damage and replace if necessary.

• After installing the radius rod, check the wheel alignment and adjust if necessary. Refer to RSU-17, "Rear

Wheel Alignment (Unladen*)". P

FRONT LOWER LINK

• Check the front lower link for any deformation, cracks, or damage and replace if necessary.

UPPER AND LOWER RUBBER SEATS

• Check the upper and lower rubber seats for deterioration, or cracks and replace if necessary.

REAR LOWER LINK AND COIL SPRING

Revision: September 2009 RSU-5 2010 Altima HEV

REAR SUSPENSION ASSEMBLY

< ON-VEHICLE MAINTENANCE >

• Check the rear lower link and coil spring for any deformation, cracks, or other damage and replace if neces-

sary.

STABILIZER BAR

• Check the stabilizer bar and clamps for any deformation, cracks, or damage and replace if necessary.

• Check the rubber bushings for deterioration, or cracks and replace if necessary.

Inspection and Adjustment INFOID:0000000005817084

Before checking the rear wheel alignment, make a preliminary inspection.

• Measure the wheel alignment under unladen conditions.

NOTE:

Unladen conditions mean that fuel, engine coolant, and lubricants are full. That the spare tire, jack, hand

tools, and mats are in their designated positions.

PRELIMINARY INSPECTION

• Check the tires for wear and for improper inflation.

• Check the wheels for deformation, cracks, and other damage. Remove the wheel and check the wheel

runout. Refer to WT-58, "Inspection".

• Check the rear wheel bearings for looseness.

• Check the rear suspension for looseness.

• Check that the rear shock absorbers work properly.

• Check the wheelarch height in the unladen condition. Refer to RSU-18, "Wheelarch Height (Unladen*)".

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is recommended for any NISSAN vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be capable of accepting any NISSAN vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated.

• Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific alignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to RSU-18,

"Wheelarch Height (Unladen*)".

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators

may not be correct.

• This may result in an ERROR.

2. Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). Do NOT use this “Rolling Compensation”

method.

• Use the “Jacking Compensation” method. After installing the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn both ways.

• See Instructions in the alignment machine you are using for more information.

CAMBER

• Measure the camber of both the right and left wheels using a suitable alignment gauge and adjust using the

following procedure.

Revision: September 2009 RSU-6 2010 Altima HEV

REAR SUSPENSION ASSEMBLY

< ON-VEHICLE MAINTENANCE >

Camber : Refer to RSU-17, "Rear Wheel Alignment A

(Unladen*)".

• If the camber is not within specification, adjust the camber by turn-

ing the adjusting bolts in the same direction. B

SFA948A

D

1. Turn the adjusting bolts in the same direction to calibrate.

NOTE:

Camber changes about 0° 5’ with each graduation of the adjust- RSU

ing bolt.

G

LEIA0008E

LEIA0009E K

2. Tighten the adjusting bolt nuts to the specified torque.

Adjusting bolt nuts : Refer to RSU-8, "Exploded View". L

TOE-IN

• Measure the toe-in of the rear wheels. If out of specification, inspect and replace any damaged or worn rear M

suspension parts before adjusting.

Total toe-in : Refer to RSU-17, "Rear Wheel Alignment (Unladen*)".

N

• Adjust toe-in by turning adjusting bolt on rear lower link.

NOTE:

Toe changes about 1.5 mm (0.059 in) [one side] with each gradua-

tion of the adjusting bolt. O

• After adjusting, tighten the adjusting bolt nut to the specified

torque.

P

Adjusting bolt nut : Refer to RSU-8, "Exploded View".

LEIA0009E

Revision: September 2009 RSU-7 2010 Altima HEV

REAR SUSPENSION ASSEMBLY

< REMOVAL AND INSTALLATION >

REMOVAL AND INSTALLATION

REAR SUSPENSION ASSEMBLY

Exploded View INFOID:0000000005440826

AWEIA0162GB

1. Cap 2. Washer 3. Upper shock bushing

4. Distance tube 5. Shock absorber mount bracket 6. Lower shock bushing

7. Bound bumper cover 8. Bound bumper 9. Suspension arm

10. Suspension arm bushing 11. Connecting rod mount bracket 12. Connecting rod

13. Suspension arm bushing 14. Rear suspension member 15. Bushing

Revision: September 2009 RSU-8 2010 Altima HEV

REAR SUSPENSION ASSEMBLY

< REMOVAL AND INSTALLATION >

16. Stabilizer bar clamp (RH) 17. Front member stay (RH) 18. Stabilizer bar

19. Bushing 20. Stabilizer bar clamp (LH) 21. Front member stay (LH) A

22. Radius rod 23. Front lower link 24. Member stopper

25. Knuckle 26. Knuckle bushing 27. Knuckle bushing

28. Knuckle bushing 29. Rear lower link 30. Lower rubber seat B

31. Coil spring 32. Shock absorber 33. Ball seat

34. Upper ruber seat 35. Rear member stay Front

C

Removal and Installation INFOID:0000000005440827

Removal D

CAUTION:

Before removing the rear suspension assembly, disconnect the ABS wheel sensor from the assembly.

Failure to do so may result in damage to the sensor wires and the sensor becoming inoperative. RSU

1. Remove the center exhaust tube with muffler. Refer to EX-6, "Removal and Installation".

2. Remove brake caliper assembly and reposition aside, without disconnecting the hydraulic hose, using

power tools. Refer to BR-34, "BRAKE CALIPER ASSEMBLY : Removal and Installation". F

• Leave the brake hydraulic hose connected to the brake caliper.

• Do not depress the brake pedal, or the caliper piston will pop out.

• Do not pull or twist the brake hydraulic hose.

G

3. Remove brake rotor. Refer to BR-34, "BRAKE CALIPER ASSEMBLY : Removal and Installation".

4. Disconnect parking brake wire from knuckle. Refer to PB-7, "Exploded View".

5. Remove rear wheel sensors. Refer to BRC-198, "Removal and Installation". H

6. Remove lower shock absorber nuts using power tools.

7. Remove rear lower link. Refer to RSU-10, "Removal and Installation".

8. Remove upper ball joint nut and cotter pin. Refer to RSU-8, "Exploded View". I

• Discard the cotter pin. Use a new cotter pin for installation.

9. Disconnect radius rod member side. Refer to RSU-14, "Removal and Installation".

10. Remove front lower link. Refer to RSU-13, "Removal and Installation". J

11. Remove knuckle from the suspension arm using Tool. Refer to RSU-8, "Exploded View".

Tool number : HT72520000 (J-25730-A) K

CAUTION:

• Do not damage ball joint when removing.

• While using Tool, temporarily tighten the nut so as not to damage screw threads. L

12. Remove stabilizer bar. Refer to RSU-15, "Removal and Installation".

13. Disconnect member harness.

M

14. Support the rear suspension assembly using a suitable jack.

15. Remove the suspension member nuts and member stay bolts using power tools.

16. Use the jack to support and lower the rear suspension assembly for removal. N

Installation

Installation is in the reverse order of removal.

• Check the rear wheel alignment and adjust if necessary. Refer to RSU-17, "Rear Wheel Alignment O

(Unladen*)".

Revision: September 2009 RSU-9 2010 Altima HEV

REAR LOWER LINK & COIL SPRING

< ON-VEHICLE REPAIR >

ON-VEHICLE REPAIR

REAR LOWER LINK & COIL SPRING

Removal and Installation INFOID:0000000005440828

Removal

1. Loosen the rear lower link bolt and nut from the suspension member side.

2. Support the rear lower link by placing a suitable jack under the knuckle.

3. Remove the rear lower link adjusting bolt and nut from the

knuckle side using power tool.

4. Slowly lower the jack to lower the rear lower link and coil spring.

5. Remove the upper rubber seat, coil spring, and lower rubber

seat from the rear lower link.

6. Remove rear lower link bolt and nut from the suspension mem-

ber side using power tool.

• Do not reuse the adjusting nut, use a new adjusting nut for

installation.

7. Remove the rear lower link. LEIA0009E

Installation

Installation is in the reverse order of removal.

• Do not reuse the adjusting nut, use a new adjusting nut for installation.

• Check that the projecting part inside the upper rubber seat and the

bracket flange are attached as shown.

• Check that the projection part outside the upper rubber seat is

directed toward the front of the vehicle.

• Position the hollow of the lower rubber seat with the groove part of

the rear lower link.

• Install the coil spring so that the side with the two paint markers is

directed toward the lower side.

• Check the rear wheel alignment and adjust if necessary. Refer to

RSU-17, "Rear Wheel Alignment (Unladen*)".

LEIA0011E

Revision: September 2009 RSU-10 2010 Altima HEV

SHOCK ABSORBER

< ON-VEHICLE REPAIR >

SHOCK ABSORBER

A

Removal and Installation INFOID:0000000005817068

REMOVAL B

1. Remove tires from vehicle with a power tool.

2. Set a jack under rear lower link to relieve the coil spring tension.

C

3. Remove shock absorber lower end bolt with a power tool.

4. Gradually lower the jack to remove it from rear lower link.

5. Remove shock absorber assembly upper end nuts ( ) with a D

power tool, and then remove shock absorber assembly from

vehicle.

RSU

FA-0274D

G

INSPECTION AFTER REMOVAL

• Check shock absorber assembly for deformation, cracks, damage, and replace if there are.

• Check welded and sealed areas for oil leakage, and replace if there are. H

INSTALLATION

• Installation is the reverse order of removal. For tightening torque. Refer to RSU-8, "Exploded View".

CAUTION: I

Do not reuse non-reusable parts.

• Perform final tightening of shock absorber assembly lower side (rubber bushing) under unladen condition

with tires on level ground. Check wheel alignment. Refer to RSU-6, "Inspection and Adjustment". J

• Adjust neutral position of steering angle sensor after checking the wheel alignment. Refer to BRC-9, "PER-

FORM ZERO POINT OF STEERING ANGLE SENSOR : Special Repair Requirement".

Disassembly and Assembly INFOID:0000000005817069 K

DISASSEMBLY

CAUTION: L

Make sure piston rod on shock absorber is not damaged when removing components from shock

absorber.

1. Remove mounting seal from mounting bracket. M

2. Wrap a shop cloth around lower side of shock absorber and secure it in a vise.

CAUTION:

Do not set the cylindrical part of shock absorber in a vise.

N

3. Secure the piston rod tip so that piston rod does not turn, and

remove piston rod lock nut.

4. Remove washer, distance tube, bushing, bound bumper cover

O

and bound bumper from shock absorber.

SEIA0218J

INSPECTION AFTER DISASSEMBLY

Bound Bumper and Bushing

Revision: September 2009 RSU-11 2010 Altima HEV

SHOCK ABSORBER

< ON-VEHICLE REPAIR >

Check bound bumper cover and bushing for cracks and damage. Replace if there are.

Shock Absorber

Check the following:

• Shock absorber for deformation, cracks, and other damage. Replace if there are.

• Piston rod for damage, uneven wear, and distortion. Replace if there are.

ASSEMBLY

• Installation is the reverse order of removal. For tightening torque, refer to RSU-8, "Exploded View".

CAUTION:

Do not reuse non-reusable parts.

• Make sure piston rod on shock absorber is not damaged when attaching components to shock absorber.

Disposal INFOID:0000000005817070

1. Set shock absorber horizontally with the piston rod fully extended.

2. Drill 2 – 3 mm (0.08 – 0.12 in) hole at the position ( ) from top

as shown in the figure to release gas gradually.

CAUTION:

• Wear eye protection (safety glasses).

• Wear gloves.

• Be careful with metal chips or oil blown out by the com-

pressed gas.

NOTE:

• Drill vertically in this direction ( ).

• Directly to the outer tube avoiding brackets.

• The gas is clear, colorless, odorless, and harmless. NNEIB0021ZZ

(A) : 20 – 30 mm (0.79 – 1.18 in)

3. Position the drilled hole downward and drain oil by moving the piston rod several times.

CAUTION:

Dispose of drained oil according to the law and local regulations.

Revision: September 2009 RSU-12 2010 Altima HEV

FRONT LOWER LINK

< ON-VEHICLE REPAIR >

FRONT LOWER LINK

A

Removal and Installation INFOID:0000000005440829

Removal B

1. Remove the front lower link nut and bolt from the knuckle side

and the adjusting bolt and nut from the suspension member side

using power tools. C

• Do not reuse the adjusting nut, use a new adjusting nut for

installation.

2. Remove the front lower link. D

RSU

LEIA0008E

Installation F

Installation is in the reverse order of removal.

• Do not reuse the adjusting nut, use a new adjusting nut for installation.

• Check the rear wheel alignment and adjust if necessary. Refer to RSU-17, "Rear Wheel Alignment

(Unladen*)". G

Revision: September 2009 RSU-13 2010 Altima HEV

RADIUS ROD

< ON-VEHICLE REPAIR >

RADIUS ROD

Removal and Installation INFOID:0000000005817071

Removal

1. Remove wheel and tire.

2. Remove radius rod from knuckle using power tools. Refer to RSU-8, "Exploded View".

3. Remove radius rod from rear suspension member.

Installation

Installation is in the reverse order of removal.

• Check the rear wheel alignment and adjust if necessary. Refer to RSU-17, "Rear Wheel Alignment

(Unladen*)".

Revision: September 2009 RSU-14 2010 Altima HEV

REAR STABILIZER

< ON-VEHICLE REPAIR >

REAR STABILIZER

A

Removal and Installation INFOID:0000000005440831

Removal B

1. Disconnect the stabilizer bar from connecting rod, using power tools.

2. Remove the stabilizer bar clamps and bushings using power

tools. C

3. Remove the stabilizer bar.

RSU

LEIA0050E

F

Installation

Installation is in the reverse order of removal.

G

Revision: September 2009 RSU-15 2010 Altima HEV

SUSPENSION ARM

< ON-VEHICLE REPAIR >

SUSPENSION ARM

Removal and Installation INFOID:0000000005817079

Removal

1. Remove the rear suspension assembly. Refer to RSU-9, "Removal and Installation".

2. Remove the connecting rod bracket from the suspension arm using power tools.

3. Remove the two suspension arm bolts and nuts from the suspension member side of the suspension arm

using power tools.

Installation

Installation is in the reverse order of removal.

• Discard the cotter pin, use a new cotter pin for installation.

• Check the rear wheel alignment and adjust if necessary. Refer to RSU-17, "Rear Wheel Alignment

(Unladen*)".

Revision: September 2009 RSU-16 2010 Altima HEV

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS) A

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specification (Rear) INFOID:0000000005440833

B

Suspension type Multi-link independent suspension

C

Shock absorber type Double-acting hydraulic

Rear Wheel Alignment (Unladen*) INFOID:0000000005440834

Minimum −0° 45′ (−0.749°)

Camber

Nominal −0° 15′ (−0.249°) RSU

Degree minute (Decimal degree)

Maximum 0° 15′ (0.251°)

ALEIA0059ZZ

I

Distance difference between RH and LH Minimum −2 (−0.08)

side

Nominal 0 (0)

(AR - BR) - (AL - BL)

: Front

J

Maximum 2 (0.08)

mm (in)

Total toe-in Minimum −0° 5′ (−0.08°)

Angle difference between RH and LH side K

Nominal 0° 0′ (0°)

Degree minute (decimal degree)

Maximum 0° 5′ (0.08°)

Angle (left or right) L

0° 6′ (0.109°)

Degree minute (decimal degree)

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Ball Joint INFOID:0000000005440835

M

SFA858A

Swinging force (A)

7.8 - 54.9 (0.8 - 5.6, 1.8 - 12.3)

(Measuring point: cotter pin hole of ball stud) N (kg-f, lb-f)

Revision: September 2009 RSU-17 2010 Altima HEV

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE DATA AND SPECIFICATIONS (SDS)

Turning torque (B) N·m (kg-cm, in-lb) 0.49 - 3.43 (5.0 - 35.0, 4.3 - 30.4)

Vertical end play (C) mm (in) 0 (0)

Wheelarch Height (Unladen*) INFOID:0000000005817080

Unit: mm (in)

SFA818A

Destination USA Canada

Tire size 215/60R16 215/60R16

Front (Hf)* 727 (28.62) 728 (28.66)

Rear (Hr)* 719 (28.31) 719 (28.31)

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Revision: September 2009 RSU-18 2010 Altima HEV

You might also like

- 2016 Nissan Rogue Service Repair Workshop Manual PDFDocument25 pages2016 Nissan Rogue Service Repair Workshop Manual PDFpecno1100% (1)

- Rear Suspension: SectionDocument23 pagesRear Suspension: SectionederengNo ratings yet

- 41 Manual Nissan Sentra 2013Document16 pages41 Manual Nissan Sentra 2013DavidNo ratings yet

- Fsu PDFDocument22 pagesFsu PDFMaiChiVuNo ratings yet

- Rear Suspension: SectionDocument14 pagesRear Suspension: SectiontecnicofigueroaNo ratings yet

- Rsu PDFDocument15 pagesRsu PDFMisha KulibaevNo ratings yet

- REAR SUSPENSION RsuDocument27 pagesREAR SUSPENSION Rsuciro_svNo ratings yet

- Fsu PDFDocument25 pagesFsu PDFronaldNo ratings yet

- PS STEERING SYSTEM GUIDEDocument36 pagesPS STEERING SYSTEM GUIDEAnonymous 64HDY7IiN0No ratings yet

- Restraint system component removal guideDocument25 pagesRestraint system component removal guidecesarNo ratings yet

- Steering System: SectionDocument34 pagesSteering System: SectionederengNo ratings yet

- FSU FRONT SUSPENSION Nissan Pathfinder R52Document22 pagesFSU FRONT SUSPENSION Nissan Pathfinder R52Pablo Marchese HuertaNo ratings yet

- Front Suspension: SectionDocument24 pagesFront Suspension: SectionJumadi AlkutsNo ratings yet

- Front Suspension: SectionDocument21 pagesFront Suspension: SectionWilmer Elias Quiñonez HualpaNo ratings yet

- Manual de Servicio Motor 1600 Nissan Versa 2014Document21 pagesManual de Servicio Motor 1600 Nissan Versa 2014iohammorilloNo ratings yet

- Srs Airbag: SectionDocument23 pagesSrs Airbag: SectionMaiChiVuNo ratings yet

- AIR BAG Frontier 08Document20 pagesAIR BAG Frontier 08Denílson M. GarciaNo ratings yet

- Parking Brake System: SectionDocument16 pagesParking Brake System: SectionEngr Ko VictorNo ratings yet

- Rear Suspension: SectionDocument12 pagesRear Suspension: SectionDudu RodriguesNo ratings yet

- 9194 2014 Nissan Leaf Service RepairDocument16 pages9194 2014 Nissan Leaf Service RepairEngr Ko VictorNo ratings yet

- Brake System: SectionDocument32 pagesBrake System: SectionDorusNo ratings yet

- Front Suspension: SectionDocument22 pagesFront Suspension: SectioncesarNo ratings yet

- Mirrors: SectionDocument20 pagesMirrors: SectiontecnicofigueroaNo ratings yet

- Front Axle: SectionDocument26 pagesFront Axle: SectionNestor RosalesNo ratings yet

- FRONT SUSPENSION OVERVIEWDocument24 pagesFRONT SUSPENSION OVERVIEWgiancarlo sanchezNo ratings yet

- Rear Suspension: SectionDocument22 pagesRear Suspension: SectionLino Bello RezamanoNo ratings yet

- Clutch: SectionDocument19 pagesClutch: SectionAnonymous 64HDY7IiN0No ratings yet

- Bomba HidraulicoDocument38 pagesBomba HidraulicomayestrikNo ratings yet

- RSU suspension guideDocument23 pagesRSU suspension guideАндрей НадточийNo ratings yet

- Power Steering System: SectionDocument26 pagesPower Steering System: SectionSilvio ServinNo ratings yet

- Clutch: SectionDocument19 pagesClutch: SectionEduardo ColinNo ratings yet

- Instrument Panel (Section IP)Document23 pagesInstrument Panel (Section IP)Gleydson Bahiense RamosNo ratings yet

- Power Steering System: SectionDocument38 pagesPower Steering System: SectionEduardo ColinNo ratings yet

- Instrument Panel: SectionDocument23 pagesInstrument Panel: Sectionak_adamNo ratings yet

- Instrument PanelDocument24 pagesInstrument PaneldiegoNo ratings yet

- SUSPENSION DISASSEMBLY GUIDEDocument29 pagesSUSPENSION DISASSEMBLY GUIDEciro_svNo ratings yet

- SUSPENSION REPAIR GUIDEDocument13 pagesSUSPENSION REPAIR GUIDEАртем ЛысечкоNo ratings yet

- Front Suspension: SectionDocument22 pagesFront Suspension: SectionLino Bello RezamanoNo ratings yet

- RF Roof TechoDocument30 pagesRF Roof TechoRicardo RaulNo ratings yet

- Engine Cooling System: SectionDocument23 pagesEngine Cooling System: SectionMaiChiVuNo ratings yet

- Mirrors: SectionDocument27 pagesMirrors: SectionProbadorAutomotrizNo ratings yet

- PARKING BRAKE SYSTEM PBDocument15 pagesPARKING BRAKE SYSTEM PBciro_svNo ratings yet

- Rear Suspension: SectionDocument11 pagesRear Suspension: SectionAnonymous 64HDY7IiN0No ratings yet

- 2009 Nissan Sentra 401Document12 pages2009 Nissan Sentra 401rsrsuporteNo ratings yet

- Fax PDFDocument27 pagesFax PDFAnonymous 64HDY7IiN0No ratings yet

- Front Suspension: SectionDocument18 pagesFront Suspension: SectionNestor RosalesNo ratings yet

- Suspension System GuideDocument25 pagesSuspension System GuideАндрей НадточийNo ratings yet

- Front Suspension: SectionDocument19 pagesFront Suspension: SectionemenelikNo ratings yet

- 2014 Nissan Rogue 40846Document24 pages2014 Nissan Rogue 40846ВладиславГолышевNo ratings yet

- 2014 Nissan Rogue 40846Document24 pages2014 Nissan Rogue 40846ВладиславГолышевNo ratings yet

- Brake System: SectionDocument36 pagesBrake System: SectionWilmer QuiñonezNo ratings yet

- Power Steering System: SectionDocument36 pagesPower Steering System: SectionJBNo ratings yet

- (TM) Nissan Manual de Taller Nissan Tiida 2010 en InglesDocument17 pages(TM) Nissan Manual de Taller Nissan Tiida 2010 en InglesLUIS ALFONZONo ratings yet

- Brake System: SectionDocument36 pagesBrake System: Sectionfearimus1No ratings yet

- Power Steering System: SectionDocument28 pagesPower Steering System: SectionLino Bello RezamanoNo ratings yet

- BR PDFDocument34 pagesBR PDFewald51No ratings yet

- Clutch: SectionDocument17 pagesClutch: SectionDagoberto MoralesNo ratings yet

- Front Suspension: SectionDocument21 pagesFront Suspension: SectionHarol CastilloNo ratings yet

- Steering System ManualDocument21 pagesSteering System ManualOscar VillaseñorNo ratings yet

- Exterior Lighting System: SectionDocument158 pagesExterior Lighting System: SectionNestor RosalesNo ratings yet

- Warning Chime System: SectionDocument59 pagesWarning Chime System: SectionNestor RosalesNo ratings yet

- Rear Axle: SectionDocument8 pagesRear Axle: SectionNestor RosalesNo ratings yet

- Glass & Window System: SectionDocument25 pagesGlass & Window System: SectionNestor RosalesNo ratings yet

- Heater & Air Conditioning System: SectionDocument38 pagesHeater & Air Conditioning System: SectionNestor RosalesNo ratings yet

- Door & Lock: SectionDocument228 pagesDoor & Lock: SectionNestor RosalesNo ratings yet

- Body Repair: SectionDocument50 pagesBody Repair: SectionNestor RosalesNo ratings yet

- Defogger: SectionDocument59 pagesDefogger: SectionNestor RosalesNo ratings yet

- AutomovelDocument5 pagesAutomovelCarlos BraiaNo ratings yet

- Eaton SPD Series Product Aid SPD PA01005003EDocument4 pagesEaton SPD Series Product Aid SPD PA01005003EDiego PeñaNo ratings yet

- Plano Electrico 815FDocument2 pagesPlano Electrico 815FAriel Avalos100% (2)

- AV28KT1Document48 pagesAV28KT1Luis MorenoNo ratings yet

- Optocoupler Tutorial: Home Miscellaneous CircuitsDocument5 pagesOptocoupler Tutorial: Home Miscellaneous CircuitsMoh OkoeNo ratings yet

- FM910 4 Manual F SM 138FDocument36 pagesFM910 4 Manual F SM 138FThomas DevlinNo ratings yet

- Streetlight Lum90: Luminaire - Technical InformationDocument3 pagesStreetlight Lum90: Luminaire - Technical InformationIvan ZanzaniNo ratings yet

- Star Delta TrafoDocument6 pagesStar Delta TrafoAries ApriheriantoNo ratings yet

- Ignition System Circuit GuideDocument10 pagesIgnition System Circuit GuideCarlos Awo OsaureNo ratings yet

- MJT314Document4 pagesMJT314eng_zidNo ratings yet

- Euro ConnectorsDocument46 pagesEuro ConnectorsAchyuth ShettigarNo ratings yet

- Schemat CatDocument10 pagesSchemat CatLhsan RajawiNo ratings yet

- 7-Eleven construction cost summary LipataDocument16 pages7-Eleven construction cost summary LipatamogsiNo ratings yet

- Electrical Equipment Quotes ComparisonDocument18 pagesElectrical Equipment Quotes ComparisonSaibabu SaiNo ratings yet

- MV Panels and CCP Proposal from Tehama Trading CoDocument8 pagesMV Panels and CCP Proposal from Tehama Trading Coطربوش التميميNo ratings yet

- Passive Components: Capacitors & Resistors: TopicsDocument24 pagesPassive Components: Capacitors & Resistors: TopicsSaravanan RajendranNo ratings yet

- 19 +ECU+Power+Source+CircuitDocument5 pages19 +ECU+Power+Source+Circuitmoh12109100% (1)

- 3电气与信息系统 L958F英文Document106 pages3电气与信息系统 L958F英文gerallazo29No ratings yet

- UNIT 2: Bipolar Junction TransistorDocument14 pagesUNIT 2: Bipolar Junction TransistorWaleed HåšhįmNo ratings yet

- DES-101B: Multiple of Trip Rating PlugDocument1 pageDES-101B: Multiple of Trip Rating Plugjurica_2006No ratings yet

- Katalia Small Housing BookDocument37 pagesKatalia Small Housing BookrNo ratings yet

- Cree Led Lifecycle WhitepaperDocument8 pagesCree Led Lifecycle WhitepapervipulggNo ratings yet

- 17-ES-0401-04 - ESP Link System Field Installation Guide (English)Document33 pages17-ES-0401-04 - ESP Link System Field Installation Guide (English)Edwin Vitovis TorresNo ratings yet

- Vdocuments - MX Product Information 8408 112 Hyundai 27330 85021 Doosan Na Atech s514008 NoDocument7 pagesVdocuments - MX Product Information 8408 112 Hyundai 27330 85021 Doosan Na Atech s514008 Nothanhhai31No ratings yet

- G7L Omron RelayDocument13 pagesG7L Omron RelayLong NguyễnNo ratings yet

- Versamate Cleanroom Receptacle PR19Document1 pageVersamate Cleanroom Receptacle PR19Anonymous llBSa7No ratings yet

- Manuel MultiPlus II 24V 48V 3k Et 5k 230VDocument156 pagesManuel MultiPlus II 24V 48V 3k Et 5k 230VjackyNo ratings yet

- Model Part No: Sevice PartsDocument18 pagesModel Part No: Sevice PartsthechevronkidNo ratings yet

- Completelamp Catalogue: British Electric Lamps LimitedDocument64 pagesCompletelamp Catalogue: British Electric Lamps LimitedΜαρια ΡοδακοπουλουNo ratings yet

- Ticket Counter, Observation Deck and Viewing Deck at RiverstoneDocument36 pagesTicket Counter, Observation Deck and Viewing Deck at RiverstonebuddikalrNo ratings yet

- Product data sheet for TeSys D contactor with 80A ratingDocument4 pagesProduct data sheet for TeSys D contactor with 80A ratingمحمد اظهرNo ratings yet