Professional Documents

Culture Documents

MAX31913

MAX31913

Uploaded by

Phan ToanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MAX31913

MAX31913

Uploaded by

Phan ToanCopyright:

Available Formats

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

General Description Benefits and Features

The MAX31913 industrial interface serializer translates, ●● Very Low Power and Heat Dissipation

conditions, and serializes the 24V digital output of sensors • Low Quiescent Current (1.6mA typ)

and switches used in industrial, process, and building • Highly Accurate and Stable Input Current Limiters,

automation to 5V CMOS-compatible signals required Adjustable from 0.5mA to 6mA

by microcontrollers. It provides the front-end interface • Energy-Less Field-Side LED Drivers

circuit of a programmable logic controller (PLC) digital ●● High Integration Reduces BOM Count, Board Size,

input module. and System Cost

The device features integrated current limiting, lowpass • 8 High-Voltage Input Channels (36V max)

filtering, and channel serialization. Input current limiting • On-Chip 8-1 Serialization with SPI Interface

allows a significant reduction in power consumed from • On-Chip 5V Regulator

the field voltage supply as compared to traditional • On-Chip Overtemperature Indicator

discrete resistor-divider implementations. Selectable on- • Dual On-Chip Field Supply Voltage Monitor

chip lowpass filters allow flexible debouncing and filter- • Integrated Debounce Filters, Selectable From 0 to 3ms

ing of sensor outputs based on the application. ●● Robust Features and Performance for Industrial

Environments

On-chip serialization allows a drastic reduction in the • Multibit CRC Code Generation and Transmission for

number of optocouplers used for isolation. The device Error Detection and More Reliable Data Transmission

serializer is stackable so that any number of input channels • High ESD Immunity on All Field Input Pins

can be serialized and output through only one SPI-

●● Accepts Industry Standard Input Types

compatible port. This reduces the number of optocou-

• Configurable for IEC 61131-2 Input Types 1, 2, and 3

plers needed to only three, regardless of the number of

●● Flexible Power Supply Capability Enables Usage

input channels.

in 5V, 12V, 24V, and Higher Voltage Systems

For enhanced robustness with respect to high-frequency • Wide Operating Field Supply Range of 7V to 36V

noise and fast electrical transients, a multibit CRC code • Can Be Powered From the Logic-Side Using a 5V

is generated and transmitted through the SPI port for Supply

each 8 bits of data. The on-chip 5V voltage regulator

can be used to power external optocouplers, digital isola- Applications

tors, or other external 5V circuitry. Field-side LED drivers • Digital Input Modules for PLCs

recycle the current from the eight inputs to provide visual • Industrial, Building, and Process Automation

input status indication without any additional current or • Motor Control

power consumption.

For ultra-low-power applications, and for the lowest

possible heat dissipation, Maxim Integrated offers a

pin-compatible version of this device, the MAX31912.

The MAX31912 uses patent-pending circuit techniques

to achieve further reduction of power beyond what is

possible by input current limiting alone. Contact the

factory for availability.

Ordering Information appears at end of data sheet.

19-6641; Rev 3; 4/15

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

Block Diagram

24V 5V

VCC24V 5V REGULATOR 5VOUT

VREF MAX31913

SUPPLY

FAULTB

MONITOR

TEMP

MONITOR DB0

DB1

RIREF

CURRENT CRC GEN.

RT1

LIMITER

IN1 µCONTROLLER

LP

SENSORS SIN OR

FILTER

ISOLATION

VOLTAGE MODESEL

VREF COMPARATOR

CLK

SERIALIZER CS

INPUT CHANNEL 0

RT8

INPUT CHANNEL 7 SOUT

IN8

GND

www.maximintegrated.com Maxim Integrated │ 2

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

Absolute Maximum Ratings

(Voltages relative to GND.) Operating Temperature Range

Voltage Range on VCC24V.............................. -0.3V to +45V Ambient Temperature............................... -40NC to +125NC

Voltage Range on IN1–IN8............................. -0.3V to +45V Junction Temperature.............................. -40NC to +150NC

Voltage Range on IN1–IN8 Storage Temperature Range....................... -55NC to +125NC

(through 2.2kω resistors).............................. -45V to +45V Lead Temperature (soldering, 10s)..........................+300NC

Voltage Range on DB0/DB1, CLK, SIN, Soldering Temperature (reflow)................................+260NC

CS, MODESEL........................... -0.3V to (V5VOUT + 0.3V)

Continuous Power Dissipation (TA = +70NC)

TSSOP (derate 27mW/NC above +70NC)........... 2162.2mW

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional opera-

tion of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

Package Thermal Characteristics (Note 1)

TSSOP

Junction-to-Ambient Thermal Resistance (qJA)...........37°C/W

Junction-to-Case Thermal Resistance (qJC)..................2°C/W

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-layer

board. For detailed information on package thermal considerations, refer to www.maximintegrated.com/thermal-tutorial.

Recommended Operating Conditions (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Field Supply Voltage VCC24V (Note 3) 7 36 V

Field Inputs Voltage VINn (Note 4) -0.3 36 V

Logic Inputs Voltage VLOGIC 0 5.5 V

Current-Limit Setting Resistor RREF 15 kI

Field Input Data Rate fIN (Note 5) 200 kHz

www.maximintegrated.com Maxim Integrated │ 3

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

DC Electrical Characteristics

(VCC24V = 7V to 36V, TJ = -40NC to +150NC, unless otherwise noted.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

IN1–IN8 = 24V, 5VOUT = open,

Field-Supply Current ICC24V 1.6 2.3 mA

RT1–RT8 = GND, all logic inputs open

Field-Supply UV1 Alarm Off/On VONUV1 9 10 V

Field-Supply UV1 Alarm On/Off VOFFUV1 7 8 V

Field-Supply UV2 Alarm Off/On VONUV2 16.5 18 V

Field-Supply UV2 Alarm On/Off VOFFUV2 14 15.5 V

LED On-State Current IRT-ON RREF = 15kI, VCC24V = 18V to 30V 2.2 mA

Field Input Threshold High-to-

VIN-(INF) 2.2kI external series resistor 7 8.4 V

Low

Field Input Threshold Low-to-

VIN+(INF) 2.2kI external series resistor 9.4 10.2 V

High

Field Input Hysteresis VHYS(INF) 2.2kI external series resistor 1 V

Input Threshold High-to-Low

VTH-(INP) 3 3.4 V

(at IC pin)

Input Threshold Low-to-High

VTH+(INP) 4.4 5 V

(at IC pin)

Input Threshold Hysteresis

VHYS(INP) 1 V

(at IC pin)

Field Input Pin Resistance RINP 0.8 kI

RREF = 15kI, VCC24V = 18V to 30V,

Field Input Current Limit IINLIM 2.2 2.4 2.7 mA

TA = +25°C to +125°C (Note 6)

DB1/DB0 = 0/0: no filtering 0

DB1/DB0 = 0/1 0.008 0.025 0.038

Filter Time Constant tFILTER ms

DB1/DB0 = 1/0 0.25 0.75 1.1

DB1/DB0 = 1/1 1.0 3 4.5

Linear Regulator Output V5VOUT Max ILOAD = 50mA 4.75 5.0 5.25 V

Regulator Line Regulation dVREGLINE ILOAD = 50mA 10 20 mV

Regulator Load Regulation dVREGLOAD ILOAD = 1mA to 50mA 20 50 mV

Logic-Low Output Voltage VOL IOL = 4mA 0.4 1.0 V

Logic-High Output Voltage VOH IOH = -4mA 4.0 V

0.3 x 0.5 x 0.7 x

Logic-Input Trip Point VIH-IL V

V5VOUT V5VOUT V5VOUT

Logic-Input Leakage Current IIL -50 -30 -15 FA

Overtemperature Alarm TALRM 135 NC

www.maximintegrated.com Maxim Integrated │ 4

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

AC Electrical Characteristics

(VCC24V = 7V to 36V, TJ = -40NC to +150NC, unless otherwise noted.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

No external capacitors on pins

Field Input Pulse Width tPW 1 µs

IN1-IN8

HBM, all pins ±2

ESD kV

HBM, IN1-IN8 with respect to GND ±15

AC Electrical Characteristics: SPI Interface

(VCC24V = 7V to 36V, TJ = -40NC to +150NC, unless otherwise noted.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CLK Pulse Duration tCLKPW (Note 7) 20 ns

CS Pulse Duration tCSPW (Note 8) 20 ns

SIN to CLK Setup Time tSU1 (Note 9) 5 ns

SIN to CLK Hold Time tH1 (Note 9) 8 ns

CS to CLK Setup Time tSU2 (Note 10) 8 ns

CS to CLK Recovery Time tREC (Note 10) 12 ns

Clock Pulse Frequency fCLK (Notes 7, 11) 25 MHz

Propagation Delay, CLK to SOUT tP1 (Note 7) 20 ns

Propagation Delay, CS to SOUT tP2 (Note 8) 20 ns

Rise/Fall Time SOUT/FAULT tR/F (Note 7) 40 ns

Note 2: Limits are 100% production tested at TA = +25°C and/or TA = +125°C. Limits over the operating temperature range and

relevant supply voltage range are guaranteed by design and characterization. Typical values are not guaranteed.

Note 3: If a 24V supply is not available, the device can be powered through V5VOUT. In this mode of operation, the VCC24V

supply must be left unconnected. All other specifications remain identical. The field-supply UV1 and UV2 alarms will be

activated (set to 1), indicating the absence of the 24V supply in this mode of operation.

Note 4: When using suggested external 2.2kω series resistors, limits of -3V to +36V apply.

Note 5: fIN refers to the maximum pulse frequency (1/fIN = shortest pulse width) that can be detected from the field sensors and

switches.

Note 6: External resistor RREF can be adjusted to set any desired current limit between 0.5mA and 6mA.

Note 7: See Figure 8.

Note 8: See Figure 5.

Note 9: See Figure 7.

Note 10: See Figure 6.

Note 11: This is the maximum bit transfer rate through the serializer interface.

www.maximintegrated.com Maxim Integrated │ 5

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

Typical Operating Characteristics

(TA = +25°C, RREF = 15kω, unless otherwise noted.)

SUPPLY CURRENT

vs. VCC24V FIELD SUPPLY SUPPLY CURRENT vs. TEMPERATURE CURRENT LIMIT vs. RREF

1.90 2.3

MAX31913 toc03

MAX31913 toc01

MAX31913 toc02

5.5

1.85 2.2

2.1 4.5

SUPPLY CURRENT (mA)

SUPPLY CURRENT (mA)

1.80

CURRENT LIMIT (mA)

2.0

1.75 3.5

1.9

1.70

1.8 2.5

1.65

1.7

1.5

1.60

1.6

1.55 1.5 0.5

5 15 25 35 -40 10 60 110 0 10 20 30 40 50

SUPPLY VOLTAGE (V) TEMPERATURE (°C) RREF (kI)

INPUT CURRENT LIMIT INPUT-VOLTAGE HYSTERESIS

INPUT CURRENT LIMIT vs. TEMPERATURE vs. FIELD-INPUT VOLTAGE vs. TEMPERATURE

3.0 3.0 5.0

MAX31913 toc05

MAX31913 toc06

MAX31913 toc04

RIN = 0I

2.9 4.8

VIN = 24V

2.5 4.6

INPUT-VOLTAGE HYSTERESIS (V)

2.8

4.4

CURRENT LIMIT (mA)

2.7

CURRENT LIMIT (mA)

2.0 4.2

2.6 4.0 OFF-ON THRESHOLD

2.5 1.5 3.8

2.4 3.6

1.0 3.4

2.3

VCC24V = 24V 3.2

2.2 0.5 3.0 ON-OFF THRESHOLD

2.1 2.8

2.0 0 2.6

-40 10 60 110 5 15 25 35 -40 10 60 110

TEMPERATURE (°C) FIELD-INPUT VOLTAGE (V) TEMPERATURE (°C)

INPUT-VOLTAGE HYSTERESIS

vs. TEMPERATURE LDO LOAD REGULATION LDO LINE REGULATION

10.0 5.10 5.10

MAX31913 toc07

MAX31913 toc08

MAX31913 toc09

9.8 RIN = 2.2I I5VOUT = 5mA

5.08 5.08

9.6

5.06 5.06

INPUT-VOLTAGE HYSTERESIS

9.4

5.04 5.04

5VOUT VOLTAGE (V)

5VOUT VOLTAGE (V)

9.2

9.0 OFF-ON THRESHOLD 5.02 5.02

8.8 5.00 5.00

8.6 4.98 4.98

8.4

4.96 4.96

8.2

ON-OFF THRESHOLD 4.94 4.94

8.0

7.8 4.92 4.92

7.6 4.90 4.90

-40 10 60 110 0 10 20 30 40 50 6 11 16 21 26 31 36

TEMPERATURE (°C) 5VOUT OUTPUT CURRENT (mA) SUPPLY VOLTAGE (V)

www.maximintegrated.com Maxim Integrated │ 6

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

Typical Operating Characteristics (continued)

(TA = +25°C, RREF = 15kω, unless otherwise noted.)

LDO OUTPUT

LDO LINE REGULATION vs. VCC24V FIELD SUPPLY

5.10 5.5

MAX31913 toc11

MAX31913 toc10

5.08 I5VOUT = 50mA 5.4 I5VOUT = 50mA

5.06 5.3

5VOUT OTPUT VOLTAGE (V)

5.04 5.2

5VOUT VOLTAGE (V)

5.02 5.1

5.00 5.0

4.98 4.9

4.96 4.8

4.94 4.7

4.92 4.6

4.90 4.5

6 11 16 21 26 31 36 4 14 24 34

SUPPLY VOLTAGE (V) SUPPLY VOLTAGE (V)

LDO OUTPUT VOLTAGE LDO OUTPUT VOLTAGE

vs. TEMPERATURE vs. TEMPERATURE

5.10 5.10

MAX31913 toc12

MAX31913 toc13

5.08 I5VOUT = 0mA 5.08 I5VOUT = 5mA

5.06 5.06

5.04 5.04

5VOUT VOLTAGE (V)

5VOUT VOLTAGE (V)

5.02 5.02

5.00 5.00

4.98 4.98

4.96 4.96

4.94 4.94

4.92 4.92

4.90 4.90

-40 10 60 110 -40 10 60 110

AMBIENT TEMPERATURE (°C) AMBIENT TEMPERATURE (°C)

www.maximintegrated.com Maxim Integrated │ 7

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

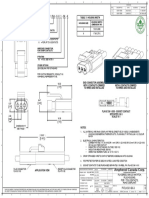

Pin Configuration

TOP VIEW

DB0 1 + 28 GND

DB1 2 27 SIN

IN1 3 26 MODESEL

RT1 4 25 CLK

IN2 5 24 CS

RT2 6 23 SOUT

MAX31913

IN3 7 22 IN8

RT3 8 21 RT8

IN4 9 20 IN7

RT4 10 19 RT7

IN5 11 18 IN6

RT5 12 17 RT6

RIREF 13 EP 16 FAULT

VCC24V 14 15 5VOUT

Pin Description

PIN NAME FUNCTION

1, 2 DB0, DB1 Debounce (Filtering) Time Select Inputs

3, 5, 7, 9, 11, 18,

IN1–IN8 Field Inputs

20, 22

4, 6, 8, 10, 12,

RT1–RT8 Energyless LED Driver Outputs. Connect to GND if LEDs are not required.

17, 19, 21

13 RIREF Current-Limiter Reference Resistor

14 VCC24V Field-Supply Voltage

15 5VOUT 5V Regulator Output

16 FAULT Active-Low Undervoltage Alarm

23 SOUT Serial-Data Out

24 CS Active-Low Chip-Select Input

25 CLK Serial-Clock Input

Mode-Select Input

26 MODESEL MODESEL = 1: Selects 8-bit shift register

MODESEL = 0: Selects 16-bit shift register

27 SIN Serial-Data Input

28 GND Field Ground

— EP Exposed Pad. Must be connected to the PCB ground plane.

www.maximintegrated.com Maxim Integrated │ 8

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

Basic Application Circuit

JUMPERS TO

5VOUT

AND GND

R1

24V VCC24V 5VOUT

C1 DB0

DB1 C3

MODESEL VDD_LOGIC

SIN

MAX31913

RINX

fIN1–8 IN1–8 CLK CLK

CS CS

ISOLATION

SOUT SOUT

RT1–8

FAULT FAULT

LED 1–8 RIREF GND

RREF

NOTE: SEE FIGURE 1 FOR ADDITIONAL COMPONENTS NEEDED FOR EMC.

Detailed Description the IN1–IN8 input pins are compared against internal-

ly set references to determine whether the sensor is

Input Current Clamp

on (logic 1) or off (logic 0). The trip points determining

The MAX31913 industrial interface serializer inputs the on/off status of the sensor satisfy the requirements

(IN1–IN8) sense the state (on vs. off) of field sen- of IEC 61131-2 Type 1 and 3 switches. The device can

sors by monitoring both voltage and current flowing also be configured to work as a Type 2 switch.

through the sensor output. The current sinking through

these input pins rises linearly with input voltage until Glitch Filter

the limit set by the current clamp is reached. Any volt- A digital glitch filter provides debouncing and filtering

age increase beyond this point does not increase the of noisy sensor signals. The time constant of this filter

input current any further. is programmable from 0ms to 3ms through the DB0

The value of the current clamp is adjustable through and DB1 pins. See Table 1 for debounce settings.

an external resistor connected between the RIREF To provide the digital glitch filter, the device checks

pin and GND. Pins RT1—RT8 are connected through that an input is stable for at least three clock cycles.

LEDs which recycle the current from the eight inputs The duration of a clock cycle is 1/3 of the selected

to provide visual status indication, without consuming debounce time. If the input is not stable for at least

additional current. If LEDs are not used, these pins three clock cycles, the input change is not sent to the

must be connected directly to GND to provide a return internal shift register.

path for the input current. The voltage and current at

www.maximintegrated.com Maxim Integrated │ 9

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

Reading Serial Data The shift register contents are read only (no write

The filtered outputs of the input comparators are capability exists) through the SPI-compatible

latched into a shift register at the falling edge of CS. interface.

Clocking the CLK pin, while CS is held low, shifts the For higher input counts than 8, multiple devices can

latched data out of SOUT 1 bit at a time. be cascaded. In this case, the SOUT pin of one

The internal data serializer comprises a 16-bit shift device should be connected to the SIN pin of the next

register, containing 8 bits of data corresponding to device, effectively cascading the internal shift regis-

the eight field inputs, as well as an 8-bit status byte ters. The CLK and CS pins of all the devices should be

containing supplementary status and CRC informa- connected together in this configuration. See the

tion. The status byte contains 1 bit representing the Serial-Port Operation section for more detailed

status of the field-supply voltage (UV1), 1 bit repre- information on operating the SPI interface.

senting the status of the internal temperature monitor

(OT), a 5-bit CRC code internally calculated and gen-

Temperature Monitoring

erated, and 1 bit representing a secondary voltage The internal junction temperature of the device is

supply monitor (UV2). constantly monitored. An alarm is raised, by asserting the

OT bit to a 1.

The undervoltage (UV1) bit is normally 1. If the supply

voltage falls below VOFFUVLO, the UV1 becomes a 0. Supply Voltage Monitoring

The UV1 bit returns to 1 once the supply voltage has A primary supply voltage monitor circuit constantly

returned above VONUVLO. monitors the field-supply voltage. If this voltage falls

The overtemperature (OT) bit is normally 0. If the junction below a threshold (VOFFUV1), an alarm is raised by

temperature increases to above TALRM, the OT bit asserting the FAULT pin, indicating that the part is expe-

becomes a 1. The bit returns to 0 once the junction riencing a fault condition and the data in the serializer is

temperature has returned below TALRM. not to be trusted. In addition, the device resets the UV1

The CRC code can be used to check data integrity during bit to a 0. Once the field-supply voltage has recovered

transfer from the device to an external microcontroller. In and goes above VONUV1, the FAULT pin is released. A

applications where the integrity of data transferred is not secondary supply voltage monitor circuit also monitors

of concern, the CRC bits can be ignored. The CRC uses the field-supply voltage. This secondary monitor only

the following polynomial: raises a flag in the serializer, by resetting the UV2 bit to

0 (it does not assert the FAULT pin), if the field supply

P(x) = x5 + x4 + x2 + x0 drops below VOFFUV2. Once the supply voltage goes

The number of bits in the internal serializer can be back above VONUV2, the UV2 bit is set to 1. The second-

selected between 8 bits or 16 bits. The MODESEL ary supply monitor has higher trip points and its purpose

pin is used to configure the serializer as an 8-bit is to warn the system that the supply voltage is below

(disabling the status byte) or 16-bit shift register. specifications (approximately 24V - 20%). Whereas the

In 8-bit mode, only the eight field input states are purpose of the primary supply monitor is to warn that

transferred through the SPI port and the status byte is the supply voltage has dropped to a value close to the

ignored. Therefore, in multiple IC applications (input minimum operating voltage of the IC.

channels greater than 8), if desired, only a single

status byte can be generated and transmitted for any

number of input channels.

Table 1. Debounce Settings

DB1 DB0 BINARY VALUE DEBOUNCE TIME

0 0 0 0

0 1 1 25Fs

1 0 2 0.75ms

1 1 3 3ms

www.maximintegrated.com Maxim Integrated │ 10

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

Applications Information ments. Table 2 lists an example device for each com-

ponent in Figure 1. The system shown in Figure 1,

EMC Standards Compliance

using the components shown in Table 2, is designed

The external components shown in Figure 1 allow the to be robust against IEC fast transient burst, surge,

device to operate in harsh industrial environments. RFI specifications, and ESD specifications (IEC

Components were chosen to assist in suppression 61000-4-4, -5, -6, and -2).

of voltage burst and surge transients, allowing the

system to meet or exceed international EMC require-

Table 2. Recommended Components

COMPONENT DESCRIPTION REQUIRED/RECOMMENDED/OPTIONAL

C0 4.7nF, 2kV polypropylene capacitor Recommended

C1 10FF, 60V ceramic capacitor Required

C3 100nF, 10V ceramic capacitor Recommended

C4 4.7µF, 10V low ESR ceramic capacitor Required

C5 100nF, 100V ceramic capacitor Recommended

D0 36V fast zener diode (ZSMB36) Recommended

D1 General-purpose rectifier (IN4007) Optional: For reverse-polarity protection.

LED1–LED8 LEDs for visual input status indication Optional

R1 150I, 1/3W MELF resistor Required

RINX 2.2kI, 1/4W MELF resistor Required

RREF 15kI, 1/8W resistor Required

Note: For higher EFT performance, a minimum 1nF, 1000V capacitor can be added from nodes fIN1–fIN8 to Earth or Ground. For

additional methods to improve EFT robustness, please check the Maxim website regularly for upcoming application notes currently

being developed.

JUMPERS TO

24V 5VOUT

R1 D1 AND GND

VCC24V 5VOUT

C0 D0 C1 C5 DB0

DB1 C3 C4

EARTH

MODESEL VDD_LOGIC

SIN

MAX31913

RINX

fIN1–8 IN1–8 CLK CLK

CS CS

ISOLATION

SOUT SOUT

RT1–8

FAULT FAULT

LED 1–8*

RIREF GND

RREF

GROUND 0V C0

EARTH

*IF LEDS ARE NOT USED, USER MUST GROUND THE RT PINS.

Figure 1. Typical EMC Protection Circuitry

www.maximintegrated.com Maxim Integrated │ 11

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

Serial-Port Operation external components used to enhance EMC robustness

Serial output of the device functions in one of two do not need to be duplicated for each device of a circuit

modes, depending on the MODESEL setting (Table 3). board. Figure 4 illustrates a 16-input application.

With MODESEL = 0, the device output includes a 5-bit

SPI Waveforms

CRC, an undervoltage alarm, and an overtemperature

alarm. See the Detailed Description for CRC, undervolt- The serial output of the device adheres to the SPI proto-

age, and overtemperature functional descriptions. With col, running with CPHA = 0 and CPOL = 0. Input states

MODESEL = 1, the device outputs only the state of the on IN1–IN8 are latched in on the falling edge of CS. The

IN1–IN8 inputs and omits the CRC, undervoltage alarm, transfer of data out of the slave output, SOUT, starts

and overtemperature alarm. immediately when CS is asserted (i.e., MSB is output

onto SOUT independent of CLK). The remaining data bits

Daisy-Chain Operation are shifted out on the falling edge of CLK. The data bits

For systems with more than eight sensor inputs, multiple are written to the output SOUT with MSB first. When CS

devices can be daisy-chained to allow access to all data is high, SOUT is high impedance. The resultant timing is

inputs through a single serial port. When using a daisy- shown in Figure 5. Note that all bits after IN1 are invalid

chain configuration, connect SOUT of one of the devices if 8-bit operation mode is selected with the MODESEL

to the SIN input of another upstream device. CS and SCK input. Figure 6, Figure 7, Figure 8, and Figure 9 illustrate

of all devices in the chain should be connected together SPI timing specifications.

in parallel (see Figure 2). In a daisy-chain configuration,

SIN SIN SIN

MAX31913 MAX31913 MAX31913

SOUT SOUT SOUT

TO µCONTROLLER

Figure 2. Daisy-Chain Operation

Table 3. MODESEL Settings

MODESEL SETTING FUNCTIONALITY

0 16-bit output; [IN8–IN1][CRC (5 bit)][UV1][OT][UV2]

1 8-bit output; [IN8–IN1]

www.maximintegrated.com Maxim Integrated │ 12

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

Powering the Device Through the 5VOUT Pin

The device can alternatively be powered using a 5V

supply connected to the 5VOUT pin. In this case a 24V

supply is no longer needed and the VCC24V supply must

be kept unconnected. (see Figure 3)

In this configuration, the device will always indicate

a UVFAULT (UV1 and UV2) and the FAULT pin will

always be active (pulled low). Faults due to the Supply

Voltage monitoring will not be available. Faults due to the

Temperature monitor can only be read through the SPI

interface.

This configuration has lower power consumption and

heat dissipation since the on-chip 5V voltage regulator

is disabled.

JUMPERS TO 5V

5V AND GND

NOT 5VOUT

VCC24V

CONNECTED DB0

DB1 C1

C3

MODESEL

SIN

RINX

MAX31913

FIN1-8 IN1-8

CLK

CS

SOUT

RT1-8

FAULT

RIREF GND

RREF

Figure 3. Basic Application Powered Through 5VOUT

www.maximintegrated.com Maxim Integrated │ 13

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

JUMPERS TO

5VOUT

24V AND GND

R1

VCC24V 5VOUT

C0 D0 C1 DB0

DB1 C3 C4

MODESEL

EARTH

VDD_LOGIC

MAX31913

SIN

RINX

fIN1–8 IN1–8 CLK CLK

CS CS

ISOLATION

SOUT SOUT

RT1–8

FAULT FAULT

RIREF GND

RREF

D1

0V C0

EARTH

VCC24V CLK

C1 CS

SOUT

FAULT

SIN

JUMPERS TO

MAX31913 5VOUT

RINX

AND GND

fIN1–8 IN1–8

5VOUT

DB0

DB1 C3 C4

RT1–8 MODESEL

RIREF GND

RREF

Figure 4. 16-Input Application Circuit

www.maximintegrated.com Maxim Integrated │ 14

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

CLK

SOUT IN8 IN7 IN6 IN5 IN4 IN3 IN2 IN1 CRC4 CRC3 CRC2 CRC1 CRC0 UV1 OT UV2

CS

IN8 –IN1 VALID

Figure 5. SPI Communication Example

tCSPW tP2

tSU1 tH1

CS CLK

SIN SIN VALID

SOUT

Figure 6. SPI Timing Diagram 1 Figure 8. SPI Timing Diagram 3

1/fCLK

tCLKPW

tSU2 tREC

CLK

CS

tR/F

SOUT

CLK

tP1

tR/F

Figure 7. SPI Timing Diagram 2 Figure 9. SPI Timing Diagram 4

www.maximintegrated.com Maxim Integrated │ 15

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

Chip Information Package Information

PROCESS: S45JRS For the latest package outline information and land patterns

(footprints), go to www.maximintegrated.com/packages. Note

that a “+”, “#”, or “-” in the package code indicates RoHS status

only. Package drawings may show a different suffix character,

but the drawing pertains to the package regardless of RoHS status.

Ordering Information

PACKAGE PACKAGE OUTLINE LAND

PIN- TYPE CODE NO. PATTERN NO.

PART TEMP RANGE CARRIER

PACKAGE 28 TSSOP-EP U28E+4 21-0108 90-0146

MAX31913AUI+ -40NC to +125NC 28 TSSOP Bulk

Tape

MAX31913AUI+T -40NC to +125NC 28 TSSOP

and Reel

+Denotes a lead(Pb)-free/RoHS-compliant package.

T = Tape and reel.

www.maximintegrated.com Maxim Integrated │ 16

MAX31913 Industrial, Octal, Digital Input

Translator/Serializer

Revision History

REVISION REVISION PAGES

DESCRIPTION

NUMBER DATE CHANGED

0 3/13 Initial release —

1 7/14 Various typos corrected 2, 6, 9, 11, 13, 14

2 2/15 Updated page 1 content 1

Updated Reading Serial Data section, IEC diagram, and added Powering

3 4/15 10-12, 14

the Device Through the 5VOUT Pin section

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642, or visit Maxim Integrated’s website at www.maximintegrated.com.

Maxim Integrated cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim Integrated product. No circuit patent licenses

are implied. Maxim Integrated reserves the right to change the circuitry and specifications without notice at any time. The parametric values (min and max limits)

shown in the Electrical Characteristics table are guaranteed. Other parametric values quoted in this data sheet are provided for guidance.

Maxim Integrated and the Maxim Integrated logo are trademarks of Maxim Integrated Products, Inc. © 2015 Maxim Integrated Products, Inc. │ 17

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- KC868 A2 SchematicDocument1 pageKC868 A2 SchematicPhan ToanNo ratings yet

- Base 1Document1 pageBase 1Phan ToanNo ratings yet

- Amphenol Canada CorpDocument1 pageAmphenol Canada CorpPhan ToanNo ratings yet

- 2D - FLHS4100 - P FLH sx1 XX XDocument1 page2D - FLHS4100 - P FLH sx1 XX XPhan ToanNo ratings yet

- Quectel EC200U Series Hardware Design V1.0Document95 pagesQuectel EC200U Series Hardware Design V1.0Phan ToanNo ratings yet

- 1Document2 pages1Phan ToanNo ratings yet

- FH26W 25S 0.3SHW (60) - CL0480 0160 8 60 - SpecSheet - 0000428581Document2 pagesFH26W 25S 0.3SHW (60) - CL0480 0160 8 60 - SpecSheet - 0000428581Phan ToanNo ratings yet