STANDARD OPERATING PROCEDURE No Doc SOP-SHE-001

Revisio

0

n

PT AKBAR MAULANA ABADI QUALITY CONTROL Date 21 Feb 24

Page Page 6

STANDARD OPERATING PROCEDURE

QUALITY CONTROL

SOP – SHE – 006

Revision ① ② ③ ④ ⑤ ⑥

Date

Prepared By

Reviewed By

Approved By

Page 1 of 15

� STANDARD OPERATING PROCEDURE No Doc SOP-SHE-001

Revisio

0

n

PT AKBAR MAULANA ABADI QUALITY CONTROL Date 21 Feb 24

Page Page 6

LEMBARAN REVISI

Halaman ini memuat catatan semua revisi terhadap panduan SOP ini dan berikut ini adalah

revisi yang telah dilakukan pada panduan SOP ini :

REV. DATE BRIEF OF REVISION

0 April 12,2020 New Issued

Page 2 of 15

� STANDARD OPERATING PROCEDURE No Doc SOP-SHE-001

Revisio

0

n

PT AKBAR MAULANA ABADI QUALITY CONTROL Date 21 Feb 24

Page Page 6

DAFTAR ISI

QUALITY CONTROL..............................................................................................................1

LEMBARAN REVISI...............................................................................................................2

DAFTAR ISI..............................................................................................................................3

1. SCOPE................................................................................................................................5

2. TERMINOLOGY...............................................................................................................5

2.1 COMPANY.................................................................................................................5

2.2 PT AKBARA MAULANA ABADI............................................................................5

2.3 SERVICES...................................................................................................................5

2.4 QUALITY...................................................................................................................5

2.5 QUALITY ASSURANCE...........................................................................................5

2.6 QA PLAN....................................................................................................................5

2.7 WA SYSTEM..............................................................................................................6

3. QUALITY ASSURANCE POLICY...................................................................................6

4. ORGANlSATlON...............................................................................................................6

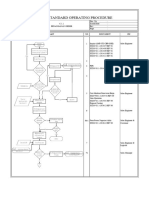

4.1 Organisational Chart....................................................................................................6

4.2 Delegation of Authority...............................................................................................6

5. CONTRACT REVIEW......................................................................................................6

6. DESIGN CONTROL..........................................................................................................7

6.1 General........................................................................................................................7

6.2 Establishment of Design Interface...............................................................................7

6.3 Design Process Control...............................................................................................7

7. DOCUMENT......................................................................................................................9

7.1 General........................................................................................................................9

7.2 Control of Documents.................................................................................................9

7.3 Identification and Control of Documents....................................................................9

8. PROCUREMENT CONTROL...........................................................................................9

8.1 General........................................................................................................................9

8.2 Preparation of Requesition..........................................................................................9

Page 3 of 15

� STANDARD OPERATING PROCEDURE No Doc SOP-SHE-001

Revisio

0

n

PT AKBAR MAULANA ABADI QUALITY CONTROL Date 21 Feb 24

Page Page 6

8.3 Review of Requisition...............................................................................................10

8.4 Selection of Vendor...................................................................................................10

8.5 Evaluation and Verification of Vendor's Performance...............................................10

9. MATERIAL INSPECTION..............................................................................................11

10. SHOP FABRICATION AND INSTALLATION CONTROL.......................................11

10.1 General Control of Fabrication and installation........................................................11

10.2 Environmental Control..............................................................................................11

10.3 Fabrication and InStaIlation Planning.......................................................................11

10.4 Special Proses Control...............................................................................................11

11. INSPECTION AND TESTING PLAN.........................................................................12

12. HANDLING, STORAGE AND SHIPPING.................................................................12

12.1 General......................................................................................................................12

12.2 Planning, Controling General....................................................................................12

12.3 Handling and Storage................................................................................................12

12.4 Packing and Delivery................................................................................................12

13. PRECOMMISIONING CONTROL.............................................................................13

13.1 General......................................................................................................................13

13.2 Planning.....................................................................................................................13

13.3 Implementation of Pre-commissioning.....................................................................13

13.4 Records......................................................................................................................13

13.5 Control of Measuring and Test Equipment................................................................14

14. QUALITY RECORDS..................................................................................................14

14.1 General......................................................................................................................14

14.2 Identification, Collecting and Fitting........................................................................14

Page 4 of 15

� STANDARD OPERATING PROCEDURE No Doc SOP-SHE-001

Revisio

0

n

PT AKBAR MAULANA ABADI QUALITY CONTROL Date 21 Feb 24

Page Page 6

1. SCOPE

This procedure covers quality plan is to establish control procedures to be executed

properly and effectively in order the safe and reliable quality in Engineering,

Procurement, Inspection and Construction in compliance with the requirements

Stipulated in the Construction between Company and Contractor/Vendor. If there is

any conflict between this plan and the contract documents, the latest revision of the

contract documents shall take precedence.

2. TERMINOLOGY

COMPANY

Which is representative user and owner.

PT AKBAR MAULANA ABADI

which is responsible for the detail design, material and equipment procurement

and construction for the mechanical, electric and instrument equipment.

SERVICES

The performance of activities; such as design, fabrication, inspection, non

destructive, repair, or installation.

QUALITY

Fitness for use; meets intended purpose, performs satisfactory in service for

specified time.

QUALITY ASSURANCE

Planned, systematic procedures and actions to assure that the engineering design,

materials, equipment, structures and systems comprising a facility will, on

completion, conform to specified requirements and meet intended purposed.

2.6 QUALITY CONTROL

That part of quality assurance which, through checks, reviews, measurements,

test, inspections, determine that specifications are met.

g) QA PLAN

A detailed scheme developed and documented beforehand, for achieving the

desired level Of quality in a completed facility.

WA SYSTEM

The procedures, equipment, activities, organization and personnel used to

Implement quality assurance plan.

Page 5 of 15

� STANDARD OPERATING PROCEDURE No Doc SOP-SHE-001

Revisio

0

n

PT AKBAR MAULANA ABADI QUALITY CONTROL Date 21 Feb 24

Page Page 6

3. QUALITY ASSURANCE POLICY

PT AMA quality assurance policy shall be formulated to achieve the product and service,

which are defined as on time schedule. competitive project cost, safely execution and

operation, are compliance with the COMPANY requirements. As part of quality assurance is

to satisfy the COMPANY at all stage of project, from design until commissioning. PT AMA

executing management shall be required to confirm their commitments to implement this plan

by signing the Quaijty Assurance Policy Statement.

Project Manager and each relevant manager are responsible for assuring that all phases of the

program for which he is responsible are operating strictly in accordance with the quality

assurance. The QA/QC Manager and his delegates have organizational freedom from

disciplines, being directly responsible for performing the work, and have the Authorities to

conduct audit, identify quality problems and to guide solutions.

4. ORGANlSATlON

This section covers the organization and its authority and responsibility in the

performance of activities affecting quality related to the Project, PT AMA shall

establish a Project Organization, which shall satisfy COMPANY's requirements. The

level of the responsibility and assigned authority of these personnel shall be clearly

indicated.

Organisational Chart

The overall project organization charts is available in contract document between

COMPANY and PT AMA

Delegation of Authority

Each Manager has the responsjbility for the functions assigned to him. Thé

Manager may delegate his taks to the designed personnel. However, this does not

relieve him of his responsibility.

5. CONTRACT REVIEW

At the award of the contract as applicable; PT AMA shall arrange and conduct a

preliminary review of the contract package to ensure that

Project requirements are adequately defined and documented

Any requirements are in compliance with any applicable codes and Standards.

When incomplete, ambiguous or conflicting inputs are found in the course of the contract

review, PT AMA's Project Manager will discuss With COMPANY to draw up the

requirements and result shall be recorded for confirmation.

Page 6 of 15

� STANDARD OPERATING PROCEDURE No Doc SOP-SHE-001

Revisio

0

n

PT AKBAR MAULANA ABADI QUALITY CONTROL Date 21 Feb 24

Page Page 6

6. DESIGN CONTROL

General

This section covers the design and engineering control procedure to ensure that

PT AMA’s design is performed in strict compliance with COMPANY's

requirements, applicabie laws and regulations, codes and standards, and that the

quality requirements for equipment and material are properly attained.

Establishment of Design Interface

i) Design Interface between COMPANY and PT AMA

Engineering Manager shall control design interface by identifying

design and engineering responsibilities and establishing the

"Coordination Meeting" The design information transmitted across the

interface between COMPANY and PT AMA shall be incorporated in

such documents as construction drawing, P&lD, Data Sheet, etc for

proper control.

ii) Design Interface within PT AMA.

Engineering Manager shall Plot design activities, identify design input

and outputs, interface flow lines, etc. The internal screening. meeting

Shall be held to resolve interface problems by cross check and collation

between relevant design groups in timely manner Physical design

interfaces are identified by internal coordination meetings of design

groups within the design division.

Design Process Control

iii) Review of Design input from COMPANY

a) Engineering Manager shall conduct a preliminary review of the contract

package to ensure that requirements are adequately defined and

documented and that any requirements differing from those in the tender

documents are resolved.

b) Engineering Manager shall identify the design requirements such as

COMPANY's basic des·ign data, regulatory requirements, applicable

codes and standards, etc. to provide the consistent basis for succeeding

design work.

c) Design input shall be coordinated by Engineering Manager, considering

the past experiences of the similar plants, the feedback etc. who shall

confinn contents.

Page 7 of 15

� STANDARD OPERATING PROCEDURE No Doc SOP-SHE-001

Revisio

0

n

PT AKBAR MAULANA ABADI QUALITY CONTROL Date 21 Feb 24

Page Page 6

d) When incomplete, ambiguous or conflicting inputs are found in the

course of the engineering review, Engineering Manager shall discuss

with COMPANY for drawing up the requirements. The results shall be

documented and immediately informed to Project Manager.

iv) Document Preparation.

a) On the basis of design inputs, Design Engineer shall prepare design and

engineering document, such data sheets, specifications, instructions,

drawings, procedures. etc.

b) The documents shall meet design-input requirements, contain or

reference productand/or acceptance criteria and conform to applicable

statutory requirements.

v) Review and Approval

Documents prepared by Design Engineer shall be reviewed and approved by

Engineering Manager.

vi) Design Verification

a) Design verification shall be conducted to verify, confirm and substantiate

the design, taking the importance to safety, complexity, degree of

standardization, state of art and the similarity to previously proven

design, the assumption, etc into account.

b) The design verification shall be conducted by means of the following

measures such as :

Undertaking demonstration or qualification test (s)

Carrying out alternative calculation.

vii) Control of Design Changes

a) Changes to design documents such as specification, procedures,

drawings, etc. shall be reviewed and approved, in principle by the same

manner as applied to the original.

b) In the event that inconsistening or in adequacy is found, the finder shall

request the originating design group to change the document, using

Engineering revision request and Engineering revision instruction sheet.

c) The proposed change shall be evaluated for the correctness and the

effectiveness including the impact on fabrication, schedule, cost etc.

d) The changed part shall be mar11.ed for easy identification and revis1on

date, revision number and the reason of the change shall be noted on the

document.

Page 8 of 15

� STANDARD OPERATING PROCEDURE No Doc SOP-SHE-001

Revisio

0

n

PT AKBAR MAULANA ABADI QUALITY CONTROL Date 21 Feb 24

Page Page 6

e) The changed document shall be submitted to COMPANY for approval.

The original copy approved documents, including "As Built" drawings,

shall be submitted to COMPANY.

f) Obsolete documents shall be destroyed or withdrawn for disposition.

g) Files containing copies of the latest revision of documents shall be

maintained and easily accessible for use.

viii) Engineering Hold

Design engineering shall identify the Engineering hold. when the design is

uncertainties. The relevant work involved in such engineering hold shall not

proceed without the clear solution given by the responsible Design Engineer.

7. DOCUMENT

General

This section covers the procedure to control all documents affecting quality to

assure that documents are processed properly and that the latest applicable

documents are available to the personnel or organization concerned, on schedute.

Control of Documents

Project Administration shall control all receiving, recording, distributing and

filling by PT AMA Project Administration is responsible for the document control

He directs document control to collect, distribute and totally control documents.

Identification and Control of Documents

ix) Numbering document of Documents prepared by the relevant discipline

shall be System assigned a blished unique in for the accordance with the

Document Numbering system established unique in for the accordance

Project.

x) Listing of Documents

Project of Administration Documents shall list up the documents to be

submitted to COMPANY (DL -Manager Document shall List) and

document approved by the Department Manager shall be sent with a

Document Transmittal sheet.

Page 9 of 15

� STANDARD OPERATING PROCEDURE No Doc SOP-SHE-001

Revisio

0

n

PT AKBAR MAULANA ABADI QUALITY CONTROL Date 21 Feb 24

Page Page 6

2) PROCUREMENT CONTROL

8.1 General

The section covers the procedure to ensure that purchased product and services

conform to specified requirements.

8.2 Preparation of Requesition

Project Engineer shall prepare the requisition on the basis of the COMPANY's Basic

Engineering Data, including the following as deemed necessary.

8.2.1 Scope of Supply.

8.2.2 Deliver Date, Location.

8.2.3 Applicable project codes, Standards, COMPANY'S specification Engineering

Design and QA/QC documents.

8.2.4 Requirements for personnel qualification, inspection and test, and shipping

preparation and reporting.

8.2.5 QA/QC requirement, such as establishment of QA Program, Non

Conformance Control, Inspection requirements, the extension of

8.2.6 8.26 Documents -to be supplied to Vendor-

8.2.7 Vendor's documents required such as : Fabrication procedure, WPS/PQR,

Qualified Personnel List, Inspection and Test Procedure, QA]QC Plan,

inspection and Test Records, Special Process Record Technical Documents,

etc.

8.2.8 Right to access and guarantee description.

8.3 Review of Requisition

A review of requisition and change there to shall be made to assure the adequacy of

specify requirement Review and approval Shali be conducted in the same way as

described in Para. 6.3.5 (c). Procurement Manager shall check the requisition and

attach the necessary documents for the inquiry or for the Purchase Order Project

Manager shall give the final approval

8.4 Selection of Vendor

8.4.1 PT AMA shall selected potenüal Vendor's in principle among "Approval

Vendor List

8.4.2 Procurement Manager shall issue Request for Quotation to potensial

Vendor's

8.4.3 upon request Of Project Manager. Engineering Manager and QA/QC

Manager shall perform QA,/QC surveillance to Vendors in accordance with

Page 10 of 15

� STANDARD OPERATING PROCEDURE No Doc SOP-SHE-001

Revisio

0

n

PT AKBAR MAULANA ABADI QUALITY CONTROL Date 21 Feb 24

Page Page 6

the QA levels of products and service to be made. The results Shall be

reported to Project Manager.

8.4.4 The selection Of Vendor and extend of control shall be dependent upon the

type of product and services. Vendor's demonstrated capacity and past

performance of the similar work. the evaluation of Vendor's quotation, QA

evaluation and the capability on schedule and cost

8.5 Evaluation and Verification of Vendor's Performance

After the Purchase Order, PT AMA exerts the following control.

8.5.1 Review and Approval of Vendor's Documents

Vendor's documents shall be reviewed by Engineering Manager or QA/QC

Manager and approved by Project Manager for their compliance to the

requisition,

8.5.2 Control and Verification of Vendor/SubcontraCtor Performance

a) A kick-off meeting and pre-inspection meeting will be held between PT

AMA and Vendor for coordination and mutual understanding At the

monthly coordination meeting, the status of progress, schedule of inspection

and major problems are reported, discussed

b) PT AMA or his representative shall be afforded the right to acces Vendor's

facilities for communication and inspection,

c) Procurement Manager shall keep abreast of the current status and expedite

Vendor's Manufacturing and delivery schedule of product and Shali report

to Project Manager.

d) Inspection shall be performed to verify and confirm the compliance of

product to specification.

e) Audit shall be performed on QA activities of Vendor as necessary, taking

the performance to the specification,

9 MATERIAL INSPECTION

This section covers the identification procedure of product the correctness of product to

specified requirements for Material Inspection.

10 SHOP FABRICATION AND INSTALLATION CONTROL

10.1 General Control of Fabrication and installation

1.1.1 Environmental Control

a) Vendor/Subcontractor Shali establish the control measures to keep working area

clean and under suitably controlled condition to prevent product from mixing-in

of foreign materials and not to cause detrimental effects on product.

b) PT AMA shall check the controlled status Of working area at witness inspection

or by patrolling, as appropriate and give recommendation for correction, if any.

Page 11 of 15

� STANDARD OPERATING PROCEDURE No Doc SOP-SHE-001

Revisio

0

n

PT AKBAR MAULANA ABADI QUALITY CONTROL Date 21 Feb 24

Page Page 6

1.1.2 Fabrication and InstaIlation Planning

a) Project Engineer and OC inspector shall identify applicable regulation, codes and

standard for fabrication and intallation, -inspection and monitoring point,

acceptance criteria, etc.

b) QC Inspector shall prepared Inspection and/or monitoring points, acceptance

criteria and process are made clear.

c) PPC Engineer shall prepared travelers. check lists records etc, to monitor and

confirm the compliance of work and product with the requirements.

d) Where qualification is required for specific work, the qualification procedures

and the records shall be maintained.

10.1.3 Special Proses Control

a) Welding Proses Control

Welding Shall be controlled in accordance with the regulation, codes,

standard and Welding Procedure Specification on Procedure.

Other special process such as Non Destructive Examination, cleaning,

special leak test shall be performed by the procedures, equipment and

personnel in accordance with applicable codes.

b) Training

the event that qualification are required are for special process and/or

personnel performing specific work. PT AMA shall establish and

perform necessary training to Obtain the qualification and to maintain the

required skill.

Identification methods for the qualified procedures and/or personnel shall

be established and the appropriate record shall be established and

maintained

PT AMA shall confirm the qualification and monitor the performance and

when any degradation is found, require to do re-training.

11. INSPECTION AND TESTING PLAN

This section covers Procedures for controlling inspection and testing to verify the

conformance of product and setvices to the specified requirements of the contract,

applicable codes, standard and Examination & inspection Procedure

12. HANDLING, STORAGE AND SHIPPING

12.1 General

Page 12 of 15

� STANDARD OPERATING PROCEDURE No Doc SOP-SHE-001

Revisio

0

n

PT AKBAR MAULANA ABADI QUALITY CONTROL Date 21 Feb 24

Page Page 6

This section covers the controlling procedures to be established and carried out for

handling, Storage, shipping and preservation of material and equipmen

11.2 Planning, Controling General

11.2.1 PT AMA will identify the requirements on handling, storage and shipping on the

basis of legal restrictions

11.2.2 Where required, PT AMA Shall submit the procedures for review and approval. PT

AMA shall implement the work in accordance With the approved procedures and

shall generate the work records.

11.3 Handling and Storage

11.3.1 PT AMA shall provide methods and means of handling that prevent damages or

deterioration

11.3.2 Product in stock Shali be clearly identified by marking, tags, label, location etc.

11.3.3 Handling of heavy components shall be performed under controlled conditions.

Operator of special handling and lifting equipment shall be qualified or experience

in the use Of equipgnent.

11.4Packing and Delivery

11.4.1 Prior to packing PT AMA shall confirm the Cleanliness, coating, required records

of the product, materials to be used for packing and the completion of disposition

of Nonconformance, etc.

11.4.2 PT AMA Shall control packing, preservation and marking process to satisfy.

11.4.3 All Shipments shall be prepared and transported in conformance to specified

requirements and applicable carrier regulations,

11.4.4 PT AMA shall deliver the cargo to the specified port of loading within the term

delivery

11.4.5 PT AMA Shall supervise or conduct inspection for shipping as necessary.

12 PRECOMMISIONING CONTROL

12.1 General

This section covers the procedures to control pre-commissioning activities,

10.2 Planning

PT AMA shall prepare and arrange the following plans, procedures etc. with the

cooperation of pre-commissioning staffs and relevant Subcontractors.

10.2.1 Pre-commissioning Plan, identifying activity sequences, boundaries Of equipment

to be tested and released, pre-requisition, verification methods and inspection and

test point.

10.2.2 Identification Of acceptance and rejection criteria

Page 13 of 15

� STANDARD OPERATING PROCEDURE No Doc SOP-SHE-001

Revisio

0

n

PT AKBAR MAULANA ABADI QUALITY CONTROL Date 21 Feb 24

Page Page 6

10.2.3 Adequate and appropriate equipment.

10.2.4 Suitable and controlled environmental conditions,

10.2.5 Subcontractor's Cooperation for significant product testing as required

10.2.6 Preparation of record form and checklist.

11 MPLEMENTATION OF PRE-COMMISSIONING

13.1 Pre-commissioning Verification

Pre-installation verification.

Identification check, physical condition cheek.

Installation verification

Equipment verification for commissioning readiness and confirmation of

satisfactory disposition Of pending problem, system check cleaning, pressure

leak-test, flow direction Check, in line instrumentation check, etc.

11.2 Measuring equipment shaft be calibrated and instruments shall be adjusted. Where

temporary items are mounted, they shall be identified and removed after the

completion of test.

11.3 Collection of data and evaluation

Data taken at each stage shan be analysed and evaluated of the. validi , inte ri and

com leteness. Whe.n an incompleteness is found, PT AMA shall fake corrective

actions.

11.4 Records

11.4.1 Records shall be co.Uected and compiled by the relevant engineers with prior

aggrement

11.4.2 Records shall include the result of analysis and evaluation corrective actions,

changes and modifications, calibration records etc.

11.4.3 Records shaU be controlled in accordance with section 15 of this document.

11.5 Control of Measuring and Test Equipment

11.5.1 Records are requested to plan and specify the characteristics to be tested,

measuring method to be employed and the acceptance limits.

11.5.2 PT AMA shall select appropriate measuring and test equipment in

their accuracy and capacity to the specified requirements.

11.5.3 Equipment, gases, jigs or such devices to verify the acceptability of PT AMA

shall select appropriate measuring and test equipment in their accuracy and

capacity to the specified requirements.

11.5.4 The measures shall .include the records and control logs, the identification of

validity to show the calibration status, the handling and storing to prevent

damage and deterioration.

Page 14 of 15

� STANDARD OPERATING PROCEDURE No Doc SOP-SHE-001

Revisio

0

n

PT AKBAR MAULANA ABADI QUALITY CONTROL Date 21 Feb 24

Page Page 6

12 QUALITY RECORDS

14.1 General

This section covers the procedures for the preparation and maintenance of the

evidence of quality.

14.2 Identification, Collecting and Fitting.

14.2.1 Records required to be turned over to COMPANY shall be defined at an early

stage of the work by mutual agreement between COMPANY and PT AMA.

14.2.2 Records shan be classified into following categories

General Documents : QA Documents, Project Documents.

Engineering Documents Design Documents, including vendors

Documents.

Shop Quality RecordS Manufacturing Records, Inspection & Test

Records.

Construction Records Site Construction & Installation Records.

Commisioning Operation recorde

14.2.3 Project Administration shall establish the filling CO-de of documents and

prepare Quality records

14.2.4 Records shall be legible With Approved Signs.

15

Page 15 of 15