Professional Documents

Culture Documents

Itwitwe00246 1 2

Uploaded by

wise6comeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Itwitwe00246 1 2

Uploaded by

wise6comeCopyright:

Available Formats

Toll Free: 87 PERMATEX

(877-376-2839) Technical Data Sheet

10 Columbus Blvd., Hartford,

Permatex® Ultra Blue® RTV

Connecticut 06106

6875 Parkland Boulevard, Solon

Ohio 44139 Silicone Gasket Maker

INDUSTRIAL

PRODUCT DESCRIPTION S.I.N.: 834-300

Permatex® Ultra Blue® RTV Silicone Gasket is a single 6. Assemble parts immediately while silicone is still wet.

component, room temperature vulcanizing gasketing 7. Finger tighten flange only until material begins to seep

compound designed to provide reliable “formed-in-place” out the sides of the flange.

gaskets for mechanical assemblies. This material cures on 8. Allow to set for at least two hours and re-torque at lease

exposure to moisture in the air to form a tough, flexible, one quarter to one half turn.

silicone rubber gasket. The product resists aging, weathering 9. For best results, allow to cure overnight.

and thermal cycling without hardening, shrinking or cracking.

Designed for superior bonding properties to oil contaminated For assembly as gasket dressing

metals as compared to other formed-in-place gaskets, and 1. Repeat steps 1 thru 4 as in previous section.

maintains outstanding oil resistance. NSF White Book 2. Apply a thin film of silicone to one surface to be sealed.

registered. 3. Place the pre-cut gasket onto silicone film.

4. Apply a second thin film to pre-cut gasket surface.

PRODUCT BENEFITS 5. Remove any excess and assemble parts immediately.

• Sensor safe, non-corrosive Note: Product not recommended for use as a cylinder

• Superior adhesion and flexibility head gasket or head gasket sealant.

• Improved oil resistance

• Replaces most cut gaskets Instructions for PowerBead™

• Low odor 1. Clean and dry all flange surfaces to be sealed.

• Can be used as a gasket maker or dressing 2. Remove black cap from top of extension nozzle.

• Non-flammable, Non-toxic 3. Turn nozzle extension one complete turn (360°)

counterclockwise.

TYPICAL APPLICATIONS 4. Depress finger trigger and apply a continuous 1/16 inch

• Pump housings to 1/8 inch PowerBead to one surface.

• Machine tools 5. Assemble parts immediately while silicone is still wet.

• Compressors 6. Finger tighten flange only until material begins to seep

• Gearboxes out the sides of the flange.

• Transmission pans 7. Allow to set for at least two hours and re-torque at least

• Valve covers one quarter to one half turn.

• Oil pans 8. For best results, allow to cure overnight.

9. To close, turn extension nozzle clockwise until tight

DIRECTIONS FOR USE (about one full turn). Wipe off excess material from

For assembly as form-in-place gasket nozzle and replace black cap.

1. Remove all previous material from mating surfaces.

For Cleanup

Permatex® Gasket Remover or Silicone Stripper is

1. Remove uncured product from parts and hand-tools with

recommended for most materials.

Permatex® Envirosafe® ODC Free Cleaner/Degreaser.

2. For best results, clean and dry all surfaces with a

If skinned over, break film with a dry cloth to remove as

residue-free solvent, such as Permatex® Brake and

much as possible. Remove the remaining material with

Parts Cleaner. ®

Permatex Gasket Remover.

3. Cut nozzle to desired bead size, 1/16“ to 1/4“ in

2. Clean hands with a dry cloth or Permatex® Fast Orange®

diameter. A 1/8” bead is usually sufficient for most

hand cleaner.

applications.

4. Remove cap, puncture tube or cartridge seal and attach

Storage of Unused Product

extension nozzle.

1. Create a “Silicone Plug” by allowing excess material to

5. Apply a continuous 1/16 inch to 1/8 inch bead of silicone

extend beyond the extension nozzle or aerosol tip to

to one surface, first tracing the internal areas of the

cure, sealing and protecting the remaining product from

gasket configuration, then all surrounding bolt holes.

moisture. For reuse, simply remove the cured product

from the tip.

2. For PowerBead™ dispensers, you may store remaining

product using either the above “silicone plug” method or

using the included plastic cap.

NOT FOR PRODUCT SPECIFICATIONS.

THE TECHNICAL DATA CONTAINED HEREIN ARE INTENDED AS REFERENCE ONLY.

PLEASE CONTACT PERMATEX, INC., TECHNICAL SERVICE DEPARTMENT FOR ASSISTANCE AND RECOMMENDATIONS FOR YOUR SPECIFIC APPLICATION.

PERMATEX, INC., HARTFORD SQUARE NORTH, 10 COLUMBUS BOULEVARD, HARTFORD, CT 06106 PHONE – (1-87PERMATEX) Revised 07/04

Technical Data Sheet Ultra Blue® RTV Silicone Gasket Maker

PROPERTIES OF UNCURED MATERIAL NOTE

Typical Value The data contained herein are furnished for information only

Chemical Type Oxime silicone rubber and are believed to be reliable. We cannot assume

Appearance Blue non-sag paste responsibility for the results obtained by others over whose

Odor Low odor

methods we have no control. Permatex, Inc. specifically

Specific Gravity 1.3

Viscosity Thixotropic paste disclaims all warranties expressed or implied, including

Extrusion rate @ 25°C, (grams/min) 880 warranties of merchantability or fitness for a particular

Flash Point °C (°F) >93 (>200) purpose, arising from sale or use of Permatex, Inc.

products and disclaims any liability for consequential or

TYPICAL CURING PERFORMANCE incidental damages of any kind, including lost profits.

Permatex® Ultra Blue® No-Leak RTV Silicone Gasket cures on This product may be covered by one or more United States or

exposure to moisture in the air. The product dries tack free in foreign patents or patent applications.

two hours and fully cures in 24 hours. Cure times will vary

with temperature, humidity and gap.

PERFORMANCE OF CURED MATERIAL

After 7 days at 25°C (77°F), 50% Relative Humidity

Typical Values

Hardness (Shore A) 30

Elongation, %* 360

2

Tensile Strength, N/mm (psi)** 1.7 (240)

Gap Fill, inch 0.25

*Material will stretch 3.6 times its original length before breaking.

**Amount of force required to break material.

TYPICAL ENVIRONMENTAL RESISTANCE

Temperature Resistance Typical Values

Continuous, °C (°F) -54 to 204 (-65 to 400)

Intermittent, °C (°F) -54 to 260 (-65 to 500)

Chemical / Solvent Resistance

The product retains effective properties in contact with

automotive fluids, such as motor oil, transmission fluids,

alcohol and antifreeze solutions. Note: Not recommended for

parts in contact with gasoline.

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected as

a sealant for chlorine or other strong oxidizing materials.

For safe handling information on this product, consult the

Material Safety Data Sheet, (MSDS).

ORDERING INFORMATION

Part Number Container Size

81724 (77BR) 3.35 oz. tube, carded

81725 (77C) 13 oz. Cartridge

85519 9.5 oz. PowerBead

STORAGE

Products shall be ideally stored in a cool, dry location in

unopened containers at a temperature between 8 to 28°C

(46 to 82°F) unless otherwise labeled. Optimal storage is at

the lower half of this temperature range. To prevent

contamination of unused product, do not return any material to

its original container.

Permatex, Ultra Blue, PowerBead and Fast Orange are trademarks of Permatex, Inc. © 2004 All rights reserved

You might also like

- Permatex Optium Red Gasket 750 TDSDocument2 pagesPermatex Optium Red Gasket 750 TDSVio AmarieiNo ratings yet

- Section Cutting and Staining: A practical introduction to histological methods for students and practitionersFrom EverandSection Cutting and Staining: A practical introduction to histological methods for students and practitionersNo ratings yet

- Ultra Black Gasket Maker TDSDocument2 pagesUltra Black Gasket Maker TDSAmal ChinthakaNo ratings yet

- Permatex Grey Ultra Bond Datasheet 82194Document2 pagesPermatex Grey Ultra Bond Datasheet 82194DeddyNo ratings yet

- Technical Data Sheet Permatex Optimum Grey RTV Silicone GasketDocument2 pagesTechnical Data Sheet Permatex Optimum Grey RTV Silicone GasketKhalifa-Assil BaoucheNo ratings yet

- Technical Data Sheet Permatex Water Pump & Thermostat RTV Silicone GasketDocument2 pagesTechnical Data Sheet Permatex Water Pump & Thermostat RTV Silicone GasketΧρήστος πορηςNo ratings yet

- TDS - R FlexDocument2 pagesTDS - R FlexDivyanshu GuptaNo ratings yet

- Permatex 81158 TDSDocument2 pagesPermatex 81158 TDSRenato AbalosNo ratings yet

- Mục 64 Keo dán nguội băng tải Devcon R flex 15565Document2 pagesMục 64 Keo dán nguội băng tải Devcon R flex 15565Việt Hùng NghiêmNo ratings yet

- B680 BulkDocument3 pagesB680 BulkJM ArcillaNo ratings yet

- T2 Global-CP03-C&S-MSB-XX-019941-B - W0 - T0 - 12974-3Document7 pagesT2 Global-CP03-C&S-MSB-XX-019941-B - W0 - T0 - 12974-3Areaya mahetemNo ratings yet

- Supreme Wall-Base Adhesive: BasebondDocument2 pagesSupreme Wall-Base Adhesive: BasebondYASHICA VAITTIANATHANNo ratings yet

- D A T A Install: Submerseal SystemDocument4 pagesD A T A Install: Submerseal SystemJHARPA NHYNHANo ratings yet

- PermatexDocument1 pagePermatexFREDY JOEL HURACCAHUA LLAMOCANo ratings yet

- Estoseal c500PF - Cold Applied SealantDocument2 pagesEstoseal c500PF - Cold Applied SealantjoshepNo ratings yet

- Arlon Installation Guide SLX PlusDocument5 pagesArlon Installation Guide SLX PlusMarek KamenickyNo ratings yet

- Wrb-Air Barrier - Parex Usa Weatherseal Spray and Roll OnDocument3 pagesWrb-Air Barrier - Parex Usa Weatherseal Spray and Roll Onsaffronbuilders9No ratings yet

- Technical Data Sheet Medium Strength Threadlocker BlueDocument3 pagesTechnical Data Sheet Medium Strength Threadlocker BlueVictorNo ratings yet

- Classic VW Carpet InstallationDocument6 pagesClassic VW Carpet InstallationInma VianaNo ratings yet

- Silicona Gris Permatex 599 Ultra-GreyDocument2 pagesSilicona Gris Permatex 599 Ultra-GreyjotapinzonNo ratings yet

- Pro98 InstructionsDocument6 pagesPro98 InstructionsFrederick KepnerNo ratings yet

- Sikadur AnchorFix-1Document3 pagesSikadur AnchorFix-1Adam GreenlawNo ratings yet

- Expangrout AGDocument2 pagesExpangrout AGPMG04 EKLNo ratings yet

- Flexeasy: Product BenefitsDocument2 pagesFlexeasy: Product BenefitsmanishaliveNo ratings yet

- Cerakote Firearm Training Manual7 10 13Document28 pagesCerakote Firearm Training Manual7 10 13Miguel KalizskyNo ratings yet

- C-Series Application Guide - Piston Coat C-186Document1 pageC-Series Application Guide - Piston Coat C-186claudioNo ratings yet

- 005 PowerPatch EPCTDocument3 pages005 PowerPatch EPCTChristian Leal CantuNo ratings yet

- TDS00456 Timebond AdhesiveDocument3 pagesTDS00456 Timebond AdhesiveBismech EngineeringNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Super Glue GelDocument2 pagesSuper Glue GelGökhan IŞIKNo ratings yet

- Smartcare AkrylmaxDocument2 pagesSmartcare AkrylmaxsouptikguptaNo ratings yet

- Zoom Pet Upright: User GuideDocument26 pagesZoom Pet Upright: User GuideUKNo ratings yet

- ColumnasDocument2 pagesColumnasroryvaz597No ratings yet

- How To Use Fogger.Document3 pagesHow To Use Fogger.maruti jadhavNo ratings yet

- Intergard 774Document4 pagesIntergard 774Doby YuniardiNo ratings yet

- MSDS - ASMACO RTV GasketDocument2 pagesMSDS - ASMACO RTV GasketadminNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Conley Corporation Fabrication Seminar Trainee Sign-Off SheetDocument3 pagesConley Corporation Fabrication Seminar Trainee Sign-Off SheetDieguitoOmarMoralesNo ratings yet

- Applying Appropriate SealantDocument64 pagesApplying Appropriate SealantShina AbieraNo ratings yet

- Positest: Pull-Off Adhesion TesterDocument12 pagesPositest: Pull-Off Adhesion TesterASESORIAS SOLDADURASNo ratings yet

- Expanseal 105: Construction ChemistryDocument2 pagesExpanseal 105: Construction Chemistrymuhammad aliNo ratings yet

- Crack RepairDocument11 pagesCrack RepairMuhammed Shafeek K TNo ratings yet

- 3m Dms Fine General Purpose Body Filler 51004 Technical Datasheet en Eu 0820Document6 pages3m Dms Fine General Purpose Body Filler 51004 Technical Datasheet en Eu 0820Remon T.HNo ratings yet

- Sonneborn 400adhesiveDocument2 pagesSonneborn 400adhesiveRam Marthi100% (1)

- PHCT400 DataDocument14 pagesPHCT400 DataGabriel AguerNo ratings yet

- Application Guide - Aerospace Sealants PDFDocument4 pagesApplication Guide - Aerospace Sealants PDFRiki NurzamanNo ratings yet

- Basf Masterseal NP 474 TdsDocument3 pagesBasf Masterseal NP 474 Tdstally3tallyNo ratings yet

- Retreading of TyresDocument3 pagesRetreading of TyresLucky TraderNo ratings yet

- Sikaflex ConcretefixDocument3 pagesSikaflex ConcretefixMichael A FarinNo ratings yet

- ARMUS-Hull Pro - TDS - 07122023Document3 pagesARMUS-Hull Pro - TDS - 07122023aleo.latam.ingenieriaNo ratings yet

- Permatex - 80036Document1 pagePermatex - 80036David Martinez VillarroelNo ratings yet

- Martini Absorb Installation Guide - 0421Document3 pagesMartini Absorb Installation Guide - 0421lac ngoNo ratings yet

- d3) Epilux4 2763Document2 pagesd3) Epilux4 2763Salman KhanNo ratings yet

- Hydroloc SmartcareDocument2 pagesHydroloc SmartcareNikhil PatilNo ratings yet

- Bissell Vacuum ManuelDocument12 pagesBissell Vacuum ManuelMarlene VotawNo ratings yet

- Bostick Liquid NailsDocument3 pagesBostick Liquid NailsNozzre Villanueva LucasNo ratings yet

- Managing Adhesive Ooze PDFDocument3 pagesManaging Adhesive Ooze PDFkapasariNo ratings yet

- TDS Araldite Standard 2016 enDocument2 pagesTDS Araldite Standard 2016 endantewow1No ratings yet

- Expanseal PJS: Construction ChemistryDocument3 pagesExpanseal PJS: Construction ChemistryRey BanriNo ratings yet

- Research 9: Activity 4: Background of The StudyDocument7 pagesResearch 9: Activity 4: Background of The StudyPhilip AmelingNo ratings yet

- Thursday / January 2019 Thursday / January 2019Document572 pagesThursday / January 2019 Thursday / January 2019Zie EikinNo ratings yet

- PP in Ii 001Document15 pagesPP in Ii 001Dav EipNo ratings yet

- THE INDIAN NAVY - Artificer Apprentice & Senior Secondary Recruit PDFDocument3 pagesTHE INDIAN NAVY - Artificer Apprentice & Senior Secondary Recruit PDFUjjwalNo ratings yet

- G20 SolutionDocument11 pagesG20 SolutionAbidemi Benjamen AttehNo ratings yet

- 3-Storeyed 31-3-2015-Schedule PDFDocument1 page3-Storeyed 31-3-2015-Schedule PDFSi Thu AungNo ratings yet

- One Plan Student 1Document7 pagesOne Plan Student 1api-465826207No ratings yet

- 02.certificate of Compliance FM UkDocument10 pages02.certificate of Compliance FM Ukmyatthura870No ratings yet

- NCR Supplier PPAP Training PresentationDocument166 pagesNCR Supplier PPAP Training PresentationRajeev ChadhaNo ratings yet

- MT4400 STRG Flo Amp ValveDocument7 pagesMT4400 STRG Flo Amp ValveBrian Careel0% (1)

- Nokia 2690 RM-635 Service ManualDocument18 pagesNokia 2690 RM-635 Service ManualEdgar Jose Aranguibel MorilloNo ratings yet

- Chapter 6 SBLDocument4 pagesChapter 6 SBLbrave manNo ratings yet

- Ground Architecture (Mourad Medhat)Document146 pagesGround Architecture (Mourad Medhat)Aída SousaNo ratings yet

- NEC G266 Quick Reference GuideDocument3 pagesNEC G266 Quick Reference GuideIonut Gabriel DascaluNo ratings yet

- TM 9-1425-429-12-HR - Stinger - Training - Set - 1983 PDFDocument34 pagesTM 9-1425-429-12-HR - Stinger - Training - Set - 1983 PDFWurzel1946No ratings yet

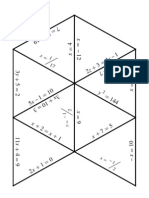

- Algebra1 Review PuzzleDocument3 pagesAlgebra1 Review PuzzleNicholas Yates100% (1)

- An Introduction To EFTDocument24 pagesAn Introduction To EFTkunjammuNo ratings yet

- PASSAGE ONE (Questions 1-4)Document5 pagesPASSAGE ONE (Questions 1-4)Vian LonkzeerNo ratings yet

- Law of DemandDocument16 pagesLaw of DemandARUN KUMARNo ratings yet

- Alignment Technique - The Steam TurbineDocument2 pagesAlignment Technique - The Steam TurbineRajeswar KulanjiNo ratings yet

- (Prestressed Concrete) Lecture 05 Dr. ZubairDocument62 pages(Prestressed Concrete) Lecture 05 Dr. ZubairAhmed RiadNo ratings yet

- Union Metal SemiconductorDocument4 pagesUnion Metal SemiconductorskinhugoNo ratings yet

- (AB-ANI) Program SpecificationDocument8 pages(AB-ANI) Program SpecificationMycah EvangelistaNo ratings yet

- 1991 - Defect Chemistry of BaTiO3Document20 pages1991 - Defect Chemistry of BaTiO3Beh NaatNo ratings yet

- Report Writing: IBS HyderabadDocument35 pagesReport Writing: IBS HyderabadHarita SudhirNo ratings yet

- Summative 1Document4 pagesSummative 1Nean YsabelleNo ratings yet

- ISO 20000-1 Gap Analysis QuestionaireDocument15 pagesISO 20000-1 Gap Analysis QuestionaireUsman Hamid67% (6)

- Animal Defenses TestDocument3 pagesAnimal Defenses TestNermine MouallemNo ratings yet

- Lithospheric Evolution of The Pre-And Early Andean Convergent Margin, ChileDocument29 pagesLithospheric Evolution of The Pre-And Early Andean Convergent Margin, ChileAbdiel MuñozNo ratings yet

- Cocoon 8002 PDFDocument24 pagesCocoon 8002 PDFaxisNo ratings yet

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- Slow Violence and the Environmentalism of the PoorFrom EverandSlow Violence and the Environmentalism of the PoorRating: 4 out of 5 stars4/5 (5)

- Busted!: Drug War Survival Skills and True Dope DFrom EverandBusted!: Drug War Survival Skills and True Dope DRating: 3.5 out of 5 stars3.5/5 (7)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010From EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Rating: 5 out of 5 stars5/5 (2)

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933From EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No ratings yet

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksFrom EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksNo ratings yet

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawFrom EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawRating: 4 out of 5 stars4/5 (334)

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet