Professional Documents

Culture Documents

Pressure Reducing Valve IR-420-R 6 A 16 PULG

Uploaded by

AsesorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Reducing Valve IR-420-R 6 A 16 PULG

Uploaded by

AsesorCopyright:

Available Formats

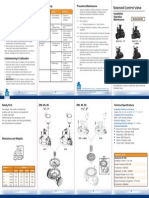

IOM

IR-420-R

Pressure Reducing Valve

(Sizes 6''- 16"; DN150-400)

Description:

The BERMAD IR-420-R Pressure Reducing Valve is a

hydraulically operated diaphragm actuated control valve

that reduces higher upstream pressure to lower constant

downstream pressure, regardless of varying demand or

upstream pressure.

Installation:

1. Ensure enough space around the valve assembly for future maintenance and adjustments.

2. Prior to valve installation, flush the pipeline to insure flow of clean fluid through the valve.

3. For future maintenance, install Isolation gate valves upstream and downstream from Bermad control valve.

4. Install the valve in the pipeline with the valve flow direction arrow in the actual flow direction.

5. For best performance, it is recommended to install the valve horizontally and upright.

6. After installation carefully inspect/correct any damaged accessories, piping, tubing, or fittings.

Commissioning & Calibration:

1. Confirm that the In-line filter arrow direction is in the valve flow direction.

2. Confirm that cock valves (1+2) are open (handles is parallel to valve body).

3. Open fully the upstream isolating valve and slowly open the downstream isolating valve, to fill-up, carefully, the consumers'

line downstream from the Valve.

4. Vent air from the valve's control loop by loosening cover tube fitting at the highest point, allowing all air to bleed. Then

Retighten the tube fitting.

5. The IR-420-R is factory set according to the design. The set pressure is marked on the pilot label, If the set pressure is either

different from the design or the requirements have been changed, change settings according to the following:

5.1. Unlock the pilot locking nut and slowly turn the pilot adjusting screw Clock-Wise to increase set pressure and Counter

Clock-Wise to decrease it. Allow the 420-R- to react and the downstream pressure to stabilize.

5.2. After the pressure is stabilized lock the pilot nut.

6. Open fully the downstream isolating valve.

IOM

IR-420-R

Trouble-Shooting:

Symptoms Cause Remedy

1. Cock valves (1+2) are closed. 1. Check Cock valves (1+2) status.

Valve fails to open 2. Not sufficient inlet pressure 2. Check for sufficient inlet pressure.

3. Not sufficient flow 3. Create demand/flow, confirm pilot setting.

4. Adjusting screws 4. Check that the Pilot adjusting screw is not loose.

1. Cock valve (1) is opened. 1. Check Cock valve (1) status.

2. Control circuit is clogged. 2. Check for any debris trapped in the valve control circuit.

Valve fails to 3. Debris. 3. Check for any debris trapped in the valve body.

close 4. Diaphragm. 4. Check diaphragm is not leaking.

1. Not sufficient inlet pressure 1. Check for sufficient inlet pressure

2. Not sufficient flow 2. Create demand/flow, confirm pilot setting

Valve fails to

3. Pilots setting. 3. Check Pilot setting.

regulate

4. Air trapped in the control chamber. 4. Release air trapped in the control chamber by loosening cover tube

fitting at the highest point.

Preventive Maintenance:

1. System operating conditions that effect on the valve should be checked periodically to determent the required preventative

maintenance schedule.

2. Maintenance instructions:

2.1. Tools required:

2.1.1. Metric and imperial wrenches

2.1.2. Anti-seize grease

2.1.3. Visual inspection to locate leaks and external damages

2.2. Functional inspection including: closing, opening and regulation.

2.3. Close upstream and downstream isolating valves (and external operating pressure when used)

2.4. Once the valve is fully isolated vent pressure by loosening a plug or a fitting.

2.5. Open the screw nuts and remove the cover unit from the valve body. Disassemble necessary control tubs.

2.6. It is highly recommended to stock a reserve parts assembly for each size. This allows minimum system field work.

And system down time.

2.7. Disassemble the cover and examine the inside parts carefully for signs of wear, corrosion, or any other abnormal conditions.

2.8. Replace worn parts and all the Elastomers. Lubricate the bolts and screws threads with Anti seize grease.

2.9. Winterizing /freezing prevention: drain the valve & the valve accessories (pilot, solenoid) on time.

Spare Parts

Bermad has a convenient and easy to use ordering guide for valve spare-parts and control system components.

For solenoid valves refer to model and S/N on solenoid tags.

Pub # : IOMIR-420-R-6'' 16''' By : YG 4/12 Rev: YG 4/12 File name : IOMIR420-R-6"-16''- 4/12 PT1AE08-01

You might also like

- Pressure Reducing Valve GuideDocument2 pagesPressure Reducing Valve GuideOscar RhenalsNo ratings yet

- Operating InstructionDocument2 pagesOperating InstructionÖmer KarahanNo ratings yet

- Bermad PHA Preventative Maintenance InstructionsDocument8 pagesBermad PHA Preventative Maintenance InstructionsimeizuNo ratings yet

- TM 90 21 PDFDocument22 pagesTM 90 21 PDFJuan MateNo ratings yet

- TM 90 21Document21 pagesTM 90 21enrique RiosNo ratings yet

- 1.Cooling Tower Operation & Maintenance manual 冷却塔操作维护手册-ENDocument15 pages1.Cooling Tower Operation & Maintenance manual 冷却塔操作维护手册-ENNissar Hussain100% (2)

- IOM-FIG1320 Pressure Reducing ValveDocument6 pagesIOM-FIG1320 Pressure Reducing ValveChhomNo ratings yet

- WW 83q Iom EnglishDocument5 pagesWW 83q Iom EnglishmecanicoNo ratings yet

- 90G-21/90A-21 UL: UL Listed Pilot-Operated Pressure ControlDocument2 pages90G-21/90A-21 UL: UL Listed Pilot-Operated Pressure ControllesterNo ratings yet

- INSTALACION Valvula Reguladora de PresionDocument2 pagesINSTALACION Valvula Reguladora de Presionfabian cardenasNo ratings yet

- PRM FRDocument7 pagesPRM FRGelber Norberto Gutierrez PalaciosNo ratings yet

- Tm-90-21-Ul (R-03/30/22)Document20 pagesTm-90-21-Ul (R-03/30/22)Mohamed Abou El hassanNo ratings yet

- I & M 6800HP Series: Ideal Installation SchematicDocument4 pagesI & M 6800HP Series: Ideal Installation SchematicMultilibros VillamontesNo ratings yet

- Control Valve Norriseal - Series2200 O&MDocument16 pagesControl Valve Norriseal - Series2200 O&MJairo AlonsoNo ratings yet

- 1) Pyro Section: Blending Silo 340 BS1Document5 pages1) Pyro Section: Blending Silo 340 BS1SSAC PVT.LTD.No ratings yet

- Pressure Reducing Valve: ModelDocument2 pagesPressure Reducing Valve: Modeljuliancardona77No ratings yet

- SD-425 SEHI InstallationDocument4 pagesSD-425 SEHI InstallationSampoerna MildNo ratings yet

- Installation & Maintenance Instructions: Motorised Ball ValveDocument9 pagesInstallation & Maintenance Instructions: Motorised Ball ValvemeoNo ratings yet

- Valtek MK1 IOMDocument12 pagesValtek MK1 IOMJuan HernandezNo ratings yet

- Thermo scuba valve maintenance guideDocument24 pagesThermo scuba valve maintenance guideCarlos Arturo Martinez SalcedoNo ratings yet

- IBHCVDocument71 pagesIBHCVdvmahiidaNo ratings yet

- Bendix TC-2 Trailer Control Brake Valve: DescriptionDocument4 pagesBendix TC-2 Trailer Control Brake Valve: Descriptionjorge chavarriaNo ratings yet

- Pneumatic Solenoid Control Box - 2Document4 pagesPneumatic Solenoid Control Box - 2Jose luis ConsuegraNo ratings yet

- I & M Mark V-100 Series: NtroductionDocument16 pagesI & M Mark V-100 Series: Ntroductionwagner machado de moraesNo ratings yet

- Forged Floating & Trunnion-Mounted Ball Valves: Installation, Operation & Maintenance ManualDocument66 pagesForged Floating & Trunnion-Mounted Ball Valves: Installation, Operation & Maintenance ManualKYAWNo ratings yet

- Air Inlet and Exhaust Valve Lash AdjustmentDocument3 pagesAir Inlet and Exhaust Valve Lash Adjustmentnolram23No ratings yet

- Proceso de Mantenimiento Maquina AnestesiaDocument20 pagesProceso de Mantenimiento Maquina AnestesiaSHIRLEY GIRALDONo ratings yet

- 50B-4KG1/2050B-4KG1: Pressure Relief ValveDocument2 pages50B-4KG1/2050B-4KG1: Pressure Relief ValveEduardo CastilloNo ratings yet

- Catalogo Regulador Mooney Product00288 Manual Slam Shut 2 PLG y 4plgDocument20 pagesCatalogo Regulador Mooney Product00288 Manual Slam Shut 2 PLG y 4plgluis_d_mNo ratings yet

- Dia-Flo & Pure-Flo Diaphragm Valves Instruction Manual With Dia-Flo ActuatorDocument16 pagesDia-Flo & Pure-Flo Diaphragm Valves Instruction Manual With Dia-Flo Actuatorabdul rehmanNo ratings yet

- 7 - Quick Closing ValveDocument4 pages7 - Quick Closing ValveRanjan DiptanshuNo ratings yet

- Test Bench For Safety ValveDocument8 pagesTest Bench For Safety ValvekhairurNo ratings yet

- Two Pieces Older Ball Valve I OmDocument1 pageTwo Pieces Older Ball Valve I OmYoucefGMANo ratings yet

- Needle Valve Maintenance Instructions - Alco Valves PM-221Document5 pagesNeedle Valve Maintenance Instructions - Alco Valves PM-221AzaelNo ratings yet

- Install, Operate and Maintain High Flow Gas Pressure RegulatorDocument11 pagesInstall, Operate and Maintain High Flow Gas Pressure RegulatorgffNo ratings yet

- IOM Manual For CAMAROON Ball ValvesDocument20 pagesIOM Manual For CAMAROON Ball ValvesSathish Kumar Pt100% (2)

- 08-Conv Valves Product InfoDocument18 pages08-Conv Valves Product Infoakrk777No ratings yet

- Maintenance Procedures for Modulus II VentilatorDocument31 pagesMaintenance Procedures for Modulus II VentilatorEng. Edelson MartinsNo ratings yet

- Troubleshooting: System Shuts Down During OperationDocument8 pagesTroubleshooting: System Shuts Down During Operationdollahyong69No ratings yet

- Control Valves MaintenanceDocument78 pagesControl Valves MaintenanceRisimic NebojsaNo ratings yet

- Butterfly Valve User ManualDocument10 pagesButterfly Valve User ManualEduardoAscencioNo ratings yet

- Conventional Valves GuideDocument23 pagesConventional Valves GuidePower PlantNo ratings yet

- Model N18-4.9 (470 ) 18Mw Condensing Steam TurbineDocument20 pagesModel N18-4.9 (470 ) 18Mw Condensing Steam TurbineFajarnurjamanNo ratings yet

- Maintenance Procedures of Electrical EquipmentDocument4 pagesMaintenance Procedures of Electrical EquipmentEdwin Cob GuriNo ratings yet

- Safety ValvesDocument11 pagesSafety Valvesravindra_jivaniNo ratings yet

- Installation & Maintenance Instructions for Mark 57 Pressure RegulatorsDocument4 pagesInstallation & Maintenance Instructions for Mark 57 Pressure Regulatorsbenzerga karimNo ratings yet

- Maintain Pneumatic Diverter ValvesDocument18 pagesMaintain Pneumatic Diverter ValvesmehtahemalNo ratings yet

- Maintain Gate Valves EffectivelyDocument33 pagesMaintain Gate Valves EffectivelyTrushar GhosalkarNo ratings yet

- Drilling Note BookDocument100 pagesDrilling Note Booksalcedopozas100% (2)

- Instructions On Installation, Operation and Maintenance For Kirloskar Kinetic Air ValvesDocument15 pagesInstructions On Installation, Operation and Maintenance For Kirloskar Kinetic Air Valvessure_iitdNo ratings yet

- WW 73Q 4-20-Inch IOM EnglishDocument2 pagesWW 73Q 4-20-Inch IOM EnglishwawanNo ratings yet

- DLT Cooling Tower MaintenanceDocument9 pagesDLT Cooling Tower MaintenanceleeNo ratings yet

- TroubleshootingDocument11 pagesTroubleshootingMaxwell Carrasco SantiNo ratings yet

- ReferenceDocument2 pagesReferenceToan VanNo ratings yet

- ZSFM Deluge Valve PDFDocument7 pagesZSFM Deluge Valve PDFkhalidwy6342No ratings yet

- T&C of Pressurization UnitDocument6 pagesT&C of Pressurization UnitMohamed YousufNo ratings yet

- IBOP MaintenanceDocument3 pagesIBOP MaintenanceSasan AbbasiNo ratings yet

- BR33 Rotary Valve ManualDocument20 pagesBR33 Rotary Valve ManualHimozaesNo ratings yet

- V800 - Ball - Installation & Maintenance ManualDocument15 pagesV800 - Ball - Installation & Maintenance ManualHayderr HassNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Thermo Safety Cabinets MSC-Advantage - User ManualDocument53 pagesThermo Safety Cabinets MSC-Advantage - User ManualAhmed SalamaNo ratings yet

- Scotts S2048 S2554 Operators ManualDocument99 pagesScotts S2048 S2554 Operators ManualobixmtNo ratings yet

- Sony STR Da80esDocument66 pagesSony STR Da80estelstarservicesNo ratings yet

- Engineering Design For A Circular Economy - A List of Design GuidelinesDocument1 pageEngineering Design For A Circular Economy - A List of Design Guidelinesmy oneNo ratings yet

- PDA Technical Documents on Sterilization ProcessesDocument3 pagesPDA Technical Documents on Sterilization ProcessesManas MishraNo ratings yet

- 5.test Report - RFU-C-7Ghz IP10 Extract VersionDocument42 pages5.test Report - RFU-C-7Ghz IP10 Extract Versionminhdung.pham4713No ratings yet

- (Jean Oliver and Alison Middleditch (Auth.) ) Funct (B-Ok - CC)Document332 pages(Jean Oliver and Alison Middleditch (Auth.) ) Funct (B-Ok - CC)Lorena BurdujocNo ratings yet

- DP-10/DP-10T/DP-11/DP-15/DP-18 Digital Ultrasonic Diagnostic Imaging SystemDocument213 pagesDP-10/DP-10T/DP-11/DP-15/DP-18 Digital Ultrasonic Diagnostic Imaging SystemDaniel JuarezNo ratings yet

- EnCORE V13.5 en EnglishDocument138 pagesEnCORE V13.5 en EnglishRommel SaavedraNo ratings yet

- ECOSYS M2030dn M2530dn M2035dn M2535dn SM UKDocument273 pagesECOSYS M2030dn M2530dn M2035dn M2535dn SM UKMaks Prost60% (5)

- Mens Care Active Concepts PDFDocument19 pagesMens Care Active Concepts PDFFredy MendocillaNo ratings yet

- Pediatrics Study ScheduleDocument2 pagesPediatrics Study ScheduleNatnaelNo ratings yet

- Economics of Power GenerationDocument32 pagesEconomics of Power GenerationKimberly Jade VillaganasNo ratings yet

- Sapamine CSN Textile Softener: Technical Data SheetDocument5 pagesSapamine CSN Textile Softener: Technical Data SheetsaskoNo ratings yet

- Course Code Part Sem Paper Code Paper NameDocument3 pagesCourse Code Part Sem Paper Code Paper Nameshiv mishraNo ratings yet

- ANNEX III-Site Components Drawings SetDocument96 pagesANNEX III-Site Components Drawings SetDenice Erika ManzanoNo ratings yet

- Guidelines SLCM BWDocument60 pagesGuidelines SLCM BWpnaarayanNo ratings yet

- RLT-Guideline Certification: Herstellerverband Raumlufttechnische Geräte E. V. AHU Manufacturer AssociationDocument22 pagesRLT-Guideline Certification: Herstellerverband Raumlufttechnische Geräte E. V. AHU Manufacturer AssociationJorge RoblesNo ratings yet

- The Neuroscience of Autism Spectrum DisordersDocument10 pagesThe Neuroscience of Autism Spectrum DisorderssouciNo ratings yet

- Robotics Process AutomationDocument21 pagesRobotics Process Automationbhaskarkiran.pNo ratings yet

- The Secret Science of Shaktipat - Guide To Initiation 13 September 2020Document77 pagesThe Secret Science of Shaktipat - Guide To Initiation 13 September 2020Patrick JenksNo ratings yet

- B.O Blog 6 (Benefits and Hacks of Using Turmeric)Document6 pagesB.O Blog 6 (Benefits and Hacks of Using Turmeric)sanaNo ratings yet

- Examining The Structural Relationships of Destination Image, Tourist Satisfaction PDFDocument13 pagesExamining The Structural Relationships of Destination Image, Tourist Satisfaction PDFAndreea JecuNo ratings yet

- Bee WareDocument49 pagesBee WareJayNo ratings yet

- Agile Spotify - Team - HomeworkDocument8 pagesAgile Spotify - Team - Homeworksp76rjm7dhNo ratings yet

- LogDocument15 pagesLogandrew_hm925635No ratings yet

- Vocabulary Practice 1Document3 pagesVocabulary Practice 1Phuong AnhNo ratings yet

- 1 Catalyst FundamentalsDocument17 pages1 Catalyst FundamentalsSam AnuNo ratings yet