Professional Documents

Culture Documents

Pool Fire Surface Emissive Power

Pool Fire Surface Emissive Power

Uploaded by

manishk1234Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pool Fire Surface Emissive Power

Pool Fire Surface Emissive Power

Uploaded by

manishk1234Copyright:

Available Formats

0957±5820

q Institution of Chemical Engineers

Open access under CC BY-NC-ND license.

MODELLING OF THERMAL RADIATION FROM

EXTERNAL HYDROCARBON POOL FIRES

P. J. REW, W. G. HULBERT and D. M. DEAVES

WS Atkins Safety and Reliability, Epsom, Surrey, UK

A

review of literature and published full-scale measurements has been undertaken in

order to assess the current status of the modelling of thermal radiation from

hydrocarbon pool ® res. Based on the review, a semi-empirical model was developed,

in which the pool ® re is assumed to radiate in two layers; a high emissive power, clean burning

zone, at the base, with a smoky, obscured layer above. The choice and development of model

correlations was made through comparison against a wide range of ® eld-trial data, which was

drawn together to form a validation database. The review also enabled a property database to

be produced, containing burning rate and surface emissive power data for a broad range of

liquid hydrocarbon fuels. The uncertainty in the application of semi-empirical pool ® re

modelling is discussed with regard to its use in assessing thermal radiation effects and

estimating ¯ ame dimensions.

Keywords: hydrocarbon pool ® re; thermal radiation; safety assessment.

INTRODUCTION ¯ ame’ s radiative power. The intensity of thermal radiation

When a hydrocarbon liquid is accidentally released, for emitted from a pool ® re is highly dependent on the level of

example due to the rupture of a process plant storage tank or obscuration of the incandescent soot particles within the

a transportation incident, there is a possibility of ignition, ¯ ame by cold soot particles, or smoke, ejected from the

resulting in a pool ® re. A pool ® re is a type of buoyancy- ¯ ame. The quantity of smoke released depends on a number

controlled turbulent diffusion ¯ ame which burns above a of effects including the air entrainment rate (controlling

pool of vaporizing fuel, where the fuel vapour has negligible the fuel mass fraction within the ¯ ame), the turbulence

initial momentum. The consequences of such a ® re may be generated in the ¯ ame (affecting the mixing rate and move-

immediate, if personnel are exposed to the incident ment of smoke to the ® re surface) and fuel type (unsaturated,

radiation, or may be delayed, forming part of an escalation large fuel molecules tend to last longer within the ® re,

train leading to events of greater severity. resulting in heavily sooting ¯ ames).

Consequently, the modelling of the hazards posed by pool The structure of an idealized, well-ventilated, hydro-

® res is an important aspect of both onshore and offshore carbon pool ® re is outlined by Bull and Strachan2 and illus-

safety assessments. An extensive review1 of literature and trated in Figure 1, where the ® re development is divided into

full-scale measurements has been undertaken in order to four phases. Firstly, fuel vaporizes from the surface of the

assess the current status of the modelling of thermal liquid pool, with energy provided by feedback of thermal

radiation from pool ® res. As a result of this review, a radiation from the combustion zones above. Immediately

semi-empirical pool ® re model, POOLFIRE6, was devel- above the fuel surface, a clean burning luminous ¯ ame layer

oped. This is a solid ¯ ame surface emitter model which uses can be observed, characterized by a high mean radiative

a selection of sub-model correlations to derive a ¯ ame shape ¯ ux. Above this layer, an obscured ¯ ame zone develops,

and the ® re’ s radiation characteristics, as functions of where smoke is ejected from the ¯ ame surface, masking the

factors such as fuel type and wind speed. The pool ® re is clean burning ¯ ame below. The clean burning ¯ ame

assumed to radiate in two layers; a high emissive power, intermittently appears in packets or `blumes’ . As the

clean burning zone, at the base, with a smoky, obscured height within the ¯ ame increases, the smoke obscuration

layer above. gradually increases until no ¯ ame is visible, the combustion

As a result of the review of full-scale measurements, a has ceased, and a plume of combustion products and

validation dataset was produced and used in the assessment unburned fuel is produced. Although this plume still con-

of the POOLFIRE6 model. The review also led to the tains heat generated by combustion lower down in the ® re, it

production of a property database containing burning rate has a negligible contribution to the total radiative ¯ ux to

and surface emissive power data for a broad range of liquid external objects.

hydrocarbon fuels.

TYPES OF POOL FIRE MODEL

POOL FIRE CHARACTE RISTICS Two approaches are currently used in the assessment of

All luminous ¯ ames contain soot particles and it is their hydrocarbon pool ® res; ® eld models and semi-empirical

subsequent oxidation that produces a high proportion of the models. Field models (commonly known as Computational

81

82 REW et al.

from 1.8 m in diameter (Shell ® eld trials4 ), to the 35 m

diameter Montoir ® eld trials7 . Experimental pool ® re data

are also available for LNG releases on water, such as the

China Lake ® eld trials8 .

LPG pool ® res

There is a reasonable quantity of data available for

lique® ed petroleum gas pool ® res (propane and/or butane).

Five series of trials have been identi® ed, three of which

provide incident heat ¯ ux data. The scale of the ® res ranges

from 2.7 m by 2.7 m square (Uehara et al.9 ) to 28 m in

Figure 1. Structure of a well-ventilated hydrocarbon pool ® re.

diameter for the Shell Maplin Sands trials1 0 . In the latter

trials, and in a series of trials conducted at China Lake1 1 , of

Fluid Dynamics, or CFD, models) solve the Navier-Stokes approximately 10±20 m in diameter, the LPG was released

equations of ¯ uid ¯ ow and, in order for them to predict ® re onto water.

behaviour, they must incorporate sub-models which

describe the chemical and physical processes occurring in Heavy hydrocarbons (hexane, heptane and crude oil)

® res. Many of these sub-models are empirical and therefore The heat ¯ ux data collected for this class of hydrocarbons

validation of CFD codes is as important as it is for more are limited, with the maximum pool size under controlled

simple modelling techniques. The advantage of ® eld models experimental conditions being 6 m in a trial undertaken by the

is that they provide a more rigorous and ¯ exible framework Japan FRI1 2 . However, limited data are available for a 52 m

for solving combustion problems than semi-empirical diameter iso-hexane tank ® re incident (Lautkaski1 3 ) and a

models. Thus, once validated against data for typical pool 31 m diameter crude oil pool ® re experiment (Koseki1 4 ).

® re con® gurations, more con® dence can be attached to their

results for less idealized scenarios. However, the dis- Commercial fuels (gasoline, aviation fuels, kerosene and

advantage in using ® eld models is that their use requires diesel)

signi® cant effort and expertise. Semi-empirical models are There is a large quantity of large-scale data for this class

more frequently used in risk assessments due to their of fuel, but many of the data sets are incomplete; for

relative ease of use, and it is this level of modelling which example, incident heat ¯ ux levels are given, but, since no

this paper addresses. values of relative humidity are recorded, calculation of

Semi-empirical models characterize the geometry and atmospheric transmissivity is not possible. The scale of the

radiative characteristics of a pool ® re using correlations ® res ranges from 0.6 m (Yumoto1 5 ) to 28 m in diameter

based on dimensionless modelling. They only incorporate (China Lake ® eld trials1 1 ). Note that further trials of up

simple descriptions of the physical processes which are to 75 m equivalent diameter are identi® ed by Alger and

required to describe the phenomena of interest and thus a Capener1 6 but insuf® cient data are supplied for their

semi-empirical model developed for predicting heat radia- inclusion in the validation dataset.

tion from a ® re is not designed to be used for predicting

other phenomena. The correlations used in semi-empirical Other fuels (toluene, methanol, lique® ed ethylene gas and

models are derived from a wide range of experimental data benzene)

and give reasonable predictions provided that they are A limited amount of data is available for these fuels. One

not used outside their range of validation. Various or two datasets were identi® ed for each, with the maximum

examples3 ,4 ,5 ,6 of semi-empirical models exist in the lit- pool size being 2.7 m by 2.7 m square.

erature and this paper reviews such models and compares

their correlations for ¯ ame shape and radiative power with The datasets encompass a wide range of input parameters

full-scale data. and vary both in quality and in quantity of measurements. In

order to produce a workable validation subset for incident

FULL-SCALE DATA

Validation Data Table 1. Parameters covered by validation dataset.

There is a considerable volume of published data relating Wind Diameter, m Shape

to the burning characteristics of pool ® res; 81 datasets, from

36 separate trial series, were identi® ed, full details of which Fuel type Land Water 0 > 0 < 3 3±10 > 10 circ. rect.

are given by Rew and Hulbert1 . Although not all experi- LNG d d d d d d d d h

ments provide complete sets of incident heat ¯ ux data, LPG d d d d d h d d d

incomplete sets still provide a means of validating the ¯ ame JP5/kerosine d h h d h h d d h

shape correlations used within the pool ® re model. The key Gasoline/petrol d d d d d d d d h

JP4 d h d d d d h d d

data included in the validation dataset are summarized Hexane/heptane d h h d d d h d h

below: Crude d h d h d h d d h

Methanol d h d h h d h d h

LNG pool ® res Toluene d h d h d h h d d

LEG d h h d d h h h d

Approximately 50% of the identi® ed trial series include Benzene d h d h d h h d h

LNG ® res. The scale of LNG pool ® res conducted ranges

Trans IChemE, Vol 75, Part B, May 1997

MODELLING OF THERMAL RADIATION FROM POOL FIRES 83

Table 2. POOLFIRE6 fuel property data.

UR, m2 m- 2

m 9 9,

Ç ¥ kb , E¥ , km,

Fuel kg m- 2 s- 1 m- 1 kW m- 2 m- 1 C/H D < 10 m 10 m < D < 20 m D > 20 m

Acetone 0.038 2.238 130 0.500 0.02 0.02 0.02

Benzene 0.085 2.700 130 1.000 0.02 0.02 0.02

Butane 0.110 0.852 225 0.937 0.400 0.23 0.12 0.08

Crude oil 0.051 1.301 130 0.540 0.05 0.05 0.05

Diesel 0.054 1.301 130 0.530 0.02 0.02 0.02

Ethane 0.141 0.136 250 0.149 0.330 0.77 0.69 0.55

Ethanol 0.020 130 0.330 1.00 1.00 1.00

Fuel oil 0.034 1.670 130 0.610 0.02 0.02 0.02

Gasoline/petrol 0.067 1.480 130 0.430 0.02 0.02 0.02

Heptane 0.081 1.394 200 0.438 0.23 0.12 0.08

Hexane 0.075 1.394 200 0.429 0.23 0.12 0.08

Hydrogen (lique® ed) 0.161 6.741 70 7.415 0.000 1.00 1.00 1.00

JP4 0.056 1.962 130 0.460 0.02 0.02 0.02

JL5/kerosine 0.063 1.296 130 0.450 0.02 0.02 0.02

LEG 0.140 265 0.500 1.00 1.00 1.00

LNG/methane 0.141 0.136 265 0.149 0.250 0.77 0.69 0.55

LNG/methane (water) 0.282 265 0.250 0.77 0.69 0.55

LPG/propane 0.118 0.500 250 0.550 0.375 0.55 0.23 0.16

LPG/propane (water) 0.256 250 0.375 0.55 0.23 0.16

Methanol 0.020 70 0.250 1.00 1.00 1.00

Naptha/pentane 0.095 200 0.417 0.23 0.12 0.08

Octane 0.081 1.394 200 0.444 0.23 0.12 0.08

Toluene 0.066 3.370 130 0.875 0.02 0.02 0.02

Xylene 0.090 1.400 130 0.800 0.02 0.02 0.02

thermal radiation, datasets with fewer than two radiation rarely used, as they do not allow accurate prediction of

measurements were rejected. The single exception to this radiation levels close to the ¯ ame surface. Correlations

was one source1 4 which presented single-point data for a available for the prediction of ¯ ame shape and radiative

wide range of parameters, some of which ® lled gaps in the properties of pool ® res are reviewed below, with the choice of

validation programme. The validation subset covered, as far correlations for the POOLFIRE6 model being made through

as possible, the expected ranges of all the key input comparison against the validation data summarized above.

parameters and included 31 datasets. Table 1 demonstrates The statistical measures used in the comparison (NMSE, FB

the coverage of the validation subset for the key parameters and FTS) are de® ned in Appendix A.

of interest, in which shading indicates at least one validation

test for those conditions. The validation subset includes pool

diameters ranging from 0.6 m to 35 m, wind speeds up to Flame Envelope

9.6 ms- 1 and relative humidities from 23% to 87%.

The two most common ¯ ame shapes used in semi-

empirical pool ® re models are a sheared elliptical cylinder

Fuel Property Data and a tilted circular cylinder. A sheared elliptical cylinder

The review of full-scale data also allowed a fuel property tends to describe the real ¯ ame shape more accurately and

database to be de® ned, giving parameters required as input can be used to give predictions of incident radiation to

to the model correlations discussed below. Although based targets positioned laterally as well as downwind of the

on fuel properties presented by authors such as Mudan1 7 and ¯ ame. Experimental work at Montoir on 35 m diameter

Babrauskas1 8 , it has been enlarged to cover a wider range of LNG pool ® res7 has shown that ground level radiation

hydrocarbon fuels and updated to encompass results of contours are egg-shaped rather than elliptical. Johnson4 has

recent pool ® re experiments. Table 2 gives the necessary used the sheared elliptical ¯ ame shape to predict success-

properties for the fuels contained within the POOLFIRE6 fully the incident heat ¯ ux for these experiments. The

database, noting that, where data is unavailable, conserva- disadvantage of a sheared elliptical cylinder ¯ ame shape is

tive values have been used. For example, for LEG (lique® ed that computation of the view factors between target and

ethylene gas), the only available data are for a 2.7 m by ¯ ame cannot be done analytically and must therefore be

2.7 m square pool ® re, for which there was little smoke performed numerically. However, contour integral tech-

obscuration. Thus for LEG, UR is set to 1.0 for all ® re niques can be used to simplify the calculations, as outlined

diameters. by Sparrow and Cess1 9 . Davis and Bagster2 0 present a

method for identifying the area viewed by the receiver and

Johnson4 has found that using the contour integral approach,

SEMI-EMPIRICAL POOL FIRE MODELLING rather than an area integral approach, reduces computation

Most semi-empirical pool ® re models are solid ¯ ame time by a factor of 10. Therefore, the POOLFIRE6 model

surface emitters, where various correlations are used to de® ne uses a sheared elliptical cylinder envelope, split into two

the dimensions of a simpli® ed ¯ ame envelope and the mean layers, with view factors calculated using contour integration.

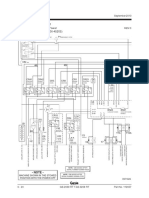

emissive power of the ¯ ame surface. Point source models are Figure 2 shows the ¯ ame shape parameters which are

Trans IChemE, Vol 75, Part B, May 1997

84 REW et al.

increase in size does not produce an increase in emitted

radiation. The pool diameter at which this occurs varies with

fuel type and thus kb values are also fuel dependent.

Flame Length

Flame length can be de® ned in a number of ways.

Cowley and Johnson6 make a distinction between maximum

visible ¯ ame length and the average experimental value.

The maximum visible ¯ ame length is the distance from the

base of the ¯ ame to the highest point at which blumes of

¯ ame can be seen to emerge from the upper section of the

¯ ame. The average experimental value is the time-averaged

height of these blumes of visible ¯ ame. As the soot

production and obscuration of the ¯ ame increases, then the

Figure 2. Model ¯ ame envelope for hydrocarbon tank/pool ® re.

difference between the ¯ ame lengths measured in these two

ways increases.

required to de® ne the ¯ ame envelope. The incident heat ¯ ux The Thomas2 2 correlation is widely used for models

at a target is then calculated as follows: which use a mean surface emissive power over the entire

envelope and is based on the dimensionless mass burning

q = qL + qU = s L F L EL + s U FU EU (1) rate, Çm* , of the ® re under quiescent conditions:

Atmospheric transmissivity is determined using the L

D=

method given by Wayne2 1 , which assumes that the ¯ ame 42[Çm* ]0.61 (3)

can be modelled as a grey or black body emitter with a 6

source temperature of 1500 K. Although this temperature is Cowley and Johnson showed that, for the benchmark

higher than that of the smoke which may obscure parts of ® res studied, models using the correlation gave good

the ¯ ame, most of the emitted radiation from a pool ® re maximum ¯ ame length predictions for ® res with little

comes from the unobscured ¯ ame, which typically has a smoke obscuration, such as LNG or small ¯ ames, although

temperature of between 1200 K and 1500 K. This method the correlation tended to underpredict the maximum ¯ ame

requires the path length between the radiating body and the length for smoky ¯ ames. Pritchard and Binding3 have

target to be de® ned. In the POOLFIRE6 model the path produced a two-layer surface emitter model, with a realistic

length is conservatively assumed to be equal to the ¯ ame shape, to be used for a wide range of hydrocarbons.

minimum distance between the target and the pool ® re This includes a new correlation to predict the maximum

envelope. ¯ ame length:

Other ¯ ame shapes have been used in the modelling of L

D=

10.615(Çm* )0.305 (U9* )- 0.03 (4)

pool ® res, such as a sheared conical ellipse or the realistic,

normalized ¯ ame shape used in the British Gas FIRE2 This correlation takes into account the effect of wind

model3 . The latter ¯ ame shape, combined with a two-layer causing improved air entrainment into the ® re and thus

surface emissive power model, has been used to predict heat lower ¯ ame heights, although the effect appears to be

¯ ux from a wide range of fuel types. However, view factor secondary as is evident by the small exponent of - 0.03 for

calculations must be undertaken using an area integral U9* . It should also be noted that the correlation has been

method which is more time-consuming than the contour- developed for predicting the ¯ ame length for a model using

integral or analytical methods which are available for simpler a realistic normalized ¯ ame shape, as might be given by

¯ ame shapes, and the bene® t of using a realistic ¯ ame shape the dotted outline in Figure 2. Figure 3 compares the

is likely to be small in comparison with uncertainties in the

surface radiative properties of the pool ® re.

Mass Burning Rate

The parameters describing the ¯ ame geometry are

dependent on both fuel type and ambient conditions. The

key property used to characterize the fuel is its mass burning

rate per unit area of pool surface, Çm9 .9 The mass burning rate

for a particular fuel varies with pool diameter, as given by

Babrauskas1 8 :

Çm9 9 = Çm9¥9 (1 - e- kb D ) (2)

It can be seen that the burning rate asymptotes to a

maximum mass burning rate at large diameters. This can be

explained by assuming that vaporization of fuel from the

pool surface is due predominantly to radiation from the ® re.

As the ¯ ame grows, it reaches a characteristic size at which

it is said to have become optically thick, and any further Figure 3. Comparison of ¯ ame length correlations with full-scale data.

Trans IChemE, Vol 75, Part B, May 1997

MODELLING OF THERMAL RADIATION FROM POOL FIRES 85

Thomas2 2 and the Pritchard and Binding6 correlations with Table 4. Comparison of ¯ ame drag correlations.

a least squares ® t to large-scale pool ® re data. The

Correlation NMSE FB

® gure shows that the ¯ ame length data is very scattered,

re¯ ecting both the dif® culty of measuring ¯ ame length and Moorhouse25 0.003 - 0.01

the different de® nitions of ¯ ame length used in different Johnson4 0.004 0.02

trials. Neither the Pritchard and Binding6 correlation nor Mudan and Croce5 0.02 - 0.04

the least squares ® t provide signi® cant improvement over Pritchard and Binding3 0.02 - 0.12

the Thomas2 2 correlation, which is widely used in

conjunction with cylindrical ¯ ame shapes and is therefore

used in POOLFIRE6. by adding a density ratio term:

D9 0.48

Flame Tilt D = 1.25(Fr10)0.069 ( )

q

q

v

a

(9)

A commonly used correlation for ¯ ame tilt is that given Pritchard and Binding3 give a correlation for ¯ ame drag

by the American Gas Association2 3 : with a reduced dependence on the density ratio:

For U1*.6 < 1.0: cos h =1 D9 0.145

( )

(5) q

= 2.506(Fr9 )0.067(Re9 )- 0.03

v

(10)

1 D q

For U1*.6 > 1.0: cos h = -------- (6) a

ÖU1*.6 Table 4 compares the normalized mean square error

(NMSE) and fractional bias (FB) values for the above

This correlation has been criticized due to its predic-

tion of zero tilt at low wind speeds, when experiments correlations when compared against the full-scale pool ® re

have shown that signi® cant tilt may still occur. More dataset. It can be seen that, for drag ratio, the Moorhouse2 5

recent studies3 ,4 have shown that ¯ ame tilt can be predicted correlation represents the best ® t to the data, although it

using a correlation with a form given by Welker and should be noted that approximately half of the experimental

Sliepcevich2 4 : data used in the comparison is that used by Moorhouse to

develop his correlation. However, the additional data has

tan h

cos h =

c(Fr)a (Re)b (7) been obtained from mainly non-LNG pool ® re tests which

implies that the density ratio term is not as signi® cant as

The use of Froude, Fr, and Reynolds, Re, numbers in suggested by the Mudan and Croce5 modi® cation. There-

the modelling of ¯ ame tilt comes from consideration of the fore, in the absence of further experimental data, the density

forces acting on the gases within the ¯ ame envelope. The ratio term is omitted in the POOLFIRE6 model and the

Froude number can be considered to be the ratio of inertia to Moorhouse correlation is used.

buoyancy forces and the Reynolds number the ratio of

inertia to viscous forces, assuming that the inertia of the gas

is dependent on the wind. The constants a, b and c and the Flame Surface Emissive Power

NMSE and FB values are summarized in Table 3 for The radiative output of a ® re can be calculated either by

correlations given by Johnson4 and Pritchard and Binding3 , assuming that a certain fraction of the combustion energy is

as well as a least squares ® t against the validation dataset. released as radiation, or alternatively by using correlations

The Welker and Sleipcevich2 4 form appears to be to de® ne the surface emissive power of the ¯ ame. Although

insensitive to the Reynolds number of the pool ® re; the latter approach is that most commonly used for pool

POOLFIRE6 uses the least squares ® t, which is consistent ® res, care is required in its application. Different assump-

with this lack of variation with Re. tions about the ¯ ame geometry can produce signi® cant

variations in ¯ ame surface area and therefore the surface

emissive power of the ¯ ame needs to be matched to its

Flame Drag surface area in order for its total radiative output to be

25 modelled correctly.

Moorhouse gives the following correlation for ¯ ame

drag for LNG ® res, which is similar to that developed by The surface emissive power of a pool ® re depends on the

Johnson4 , also derived from LNG data. fuel type and the pool diameter. For LNG and LPG pool

® res, a correlation of the following form is generally used:

D9

D = 1.5(Fr10 )0.069 (8) E = E¥(1 - e- k D )

m

(11)

For heavy hydrocarbon fuels, a smoky ¯ ame correlation

The Moorhouse correlation has been adapted by Mudan is often used, as given by Mudan and Croce5 :

and Croce5 to model ¯ ame drag for other hydrocarbon fuels,

E = EM e- sD + ES (1 - e- sD) (12)

Table 3. Constants for ¯ ame tilt correlations.

The above correlations tend to be used within models

which assume a constant mean surface emissive power over

a b c NMSE FB the full ¯ ame surface. However, a model which uses

multiple layers of surface emissive power will give more

- 0.03

4

Johnson 0.428 0.109 0.700 0.05 accurate predictions of near-® eld incident radiation, espe-

Pritchard and Binding3 0.333 0.117 0.666 0.07 - 0.12 cially downwind of the ¯ ame where the single-layer model

Least squares ® t 0.431 0.0 3.13 0.05 - 0.03

can underpredict incident heat ¯ uxes at ground level. The

Trans IChemE, Vol 75, Part B, May 1997

86 REW et al.

use of a multi-layer model arises from observations of large

smoke-producing hydrocarbon ® res, where a distinct base

layer to the ¯ ame, which is almost unobscured by smoke

and is emitting radiation at the maximum level for the fuel,

can be seen. Above this layer, smoke is released from the

® re, thereby obscuring the ¯ ame surface from the ® eld of

view of the target and heat is radiated in `blumes’ .

POOLFIRE6 uses a two-layer model. The base layer is

assumed to emit thermal radiation at the maximum level for

the fuel at the pool diameter, i.e. it is assumed that there is

no obscuration of this layer by smoke, and its surface

emissive power, EL , is calculated using equation (11). The

upper layer is assumed to be obscured by smoke; the level of

obscuration being de® ned for each pool ® re using an

unobscured ratio. Considine2 6 assumes that the portion of

¯ ame visible at any one time (unobscured ratio) is 30% and

Pritchard and Binding3 use a database of values that depend Figure 4. Comparison of Pritchard and Binding3 clear ¯ ame length

on fuel type and pool diameter. In the absence of a suitable correlation with full-scale data.

correlation for predicting obscuration, POOLFIRE6 also

uses a database of unobscured ratios based on photographic

data, mean surface emissive power data and on conversion Comparison of both correlations with clear ¯ ame data

of the Pritchard and Binding3 data to correct for ¯ ame length shows that the Pritchard and Binding correlation provides a

and ¯ ame shape. The surface emissive power of the upper better prediction than the Ditali et al. correlation, although

layer, EU , is calculated from the unobscured ratio, UR , as the scatter of results is large for both models. The Pritchard

follows: and Binding correlation tends to be weakest for small

diameter (less than 1.5 m) heavy hydrocarbon ® res, for

EU = UR EL + (1 - UR )ES (13) which the clear ¯ ame length is underpredicted, as illustrated

in Figure 4. At present, the Pritchard and Binding3 cor-

relation seems to represent the best available method for

Clear Flame Length predicting clear ¯ ame length and is therefore used in

The modelling of the clear ¯ ame length has been POOLFIRE6. It should be noted that the NMSE for this

addressed by Considine2 6 , Pritchard and Binding3 , and correlation, when compared with full-scale data, is 0.57.

Ditali et al.2 7 . Considine suggested that it varied from This is far higher than for the other ¯ ame shape parameters

approximately 30% of the maximum ¯ ame length for ® res and re¯ ects both the uncertainty in the measurement of clear

up to 25 m in diameter to 0% for ® re diameters of 50 m or ¯ ame length and the modelling of obscuration.

more. As discussed above, the hydrocarbon fuel type has a

large in¯ uence on the production of smoke within the ® re, Tank Fires

and, therefore, the clear ¯ ame length. The (C/H) ratio can be

In the absence of full-scale tank ® re data, it has been

used to describe the saturation of a hydrocarbon fuel and

assumed in the POOLFIRE6 model that the correlations for

hence its tendency to produce soot. This ratio is the one used

¯ ame shape and ¯ ame radiative power for ground level pool

by Pritchard and Binding3 to characterize the effect of fuel

® res described above can also be used for tank ® res. This

type in their correlation for clear ¯ ame length:

seems a reasonable assumption provided that the level of the

C - 2.49 liquid is close to the top of the tank. If the liquid level is

LC

D = 11.404(Çm* )1.13 (U9* )0.179 ()

H

(14) signi® cantly lower than the tank rim then the mass burning

rate and ¯ ame characteristics may be affected.

The air entrainment rate into a pool ® re has a strong effect A ¯ ame shape parameter peculiar to tank ® res is ¯ ame

on the production of soot particles as is evident by the sag; the ¯ ame from a tank ® re `spills’ over the edge of the

increase in soot production with increasing pool diameter tank and drops, or sags, to a level below the tank lip, as

(when the air entrainment rate to the centre of the pool is illustrated in Figure 2. Observations suggest that the ¯ ame

reduced). As discussed by Thomas2 2 , the ratio of air sag is approximately one third of the extension of the ¯ ame

entrained to fuel burned is characterized by the dimension- base due to ¯ ame drag. This is con® rmed by the measure-

less mass burning rate of a pool ® re, Çm* , which accounts for ments by Lautkaski1 3 of a 52 m diameter iso-hexane tank

its presence in the Pritchard and Binding3 clear ¯ ame length ® re; ¯ ame sag varied from 2.6 m to 6.8 m with correspond-

correlation. Increased wind speed also aids air entrainment ing ¯ ame drag extensions of 7.8 m to 20.8 m, i.e.

into the pool ® re and in the Pritchard and Binding approximately three times the ¯ ame sag. Therefore, in

correlation this is characterized using the dimensionless POOLFIRE6, it is simply assumed that ¯ ame sag, HS , is

wind speed, U9* . Ditali et al.2 7 have produced a similar calculated as follows:

correlation, based on a separate set of experiments, with a HS / D = 13 (D 9 / D - 1) (16)

lower dependence on (C/H) ratio:

C - 0.15

LC

D = 12.4(Çm9 )9 0.61 D- 0.6 ( )

H

(15) MODEL VALIDATION AND UNCERTAINTY

The full validation of the POOLFIRE6 model has been

Trans IChemE, Vol 75, Part B, May 1997

MODELLING OF THERMAL RADIATION FROM POOL FIRES 87

Figure 5. Comparison of POOLFIRE6 model with validation dataset.

Figure 6. Comparison with 10 m by 10 m square JP4 pool ® re data31.

detailed elsewhere1 ,2 8 . Figure 5 and Table 5 summarize the

results of the validation exercise, from which the following

for land-based ® res, possibly due to uncertainties in de® ning

key conclusions can be drawn:

the exact location of the ® re centre with respect to receiver

1. Figure 5 shows that the POOLFIRE6 model predicts the locations for fuel releases onto water. Although the statistics

measured thermal radiation to within a factor of two for appear to suggest that the quality of the model is poorest for

90% of the validation dataset, the obvious exceptions being a large diameter ® res, it should be noted that this large

methanol trial2 9 at 3 m and LNG trials3 0 at 6.1 m. POOL- diameter range is dominated by the water-based pool ® re

FIRE6, and similar semi-empirical models, will severely trials.

overpredict radiation from fuels which are non-sooting,

such as methanol, where the majority of radiation comes The breadth of the validation undertaken for the POOL-

from hot, gaseous combustion products, rather than from FIRE6 model allows the model uncertainty to be de® ned for

incandescent soot, for which the model has been developed. different fuel types and substrate conditions and for a range

The LNG trials showed a wide variation between mean and of ambient conditions and ® re sizes. This uncertainty

maximum incident radiation and the pool ® re model ® tted to encompasses the stochastic nature of the problem, experi-

the trial data showed similar overprediction. mental errors and the inaccuracy of the model itself. In a

2. The POOLFIRE6 model tends to overpredict incident semi-empirical model, the inaccuracy may arise from a lack

thermal radiation for diameters of greater than 3 m. of consideration of parameters such as substrate temperature

Although no validation was undertaken for pool diameters (and its effect on mass burning rate) or over-simpli® cation

greater than 35 m, the model is likely to be conservative for of the modelling of effects such as obscuration of the target

these scenarios, as the obscuration of the ¯ ame surface from the ¯ ame by smoke. It should be noted that the

increases with pool diameter. validation has been undertaken for `ideal’ scenarios (well-

3. The model performed better for heavy hydrocarbon fuels ventilated, circular or low aspect ratio rectangular pool ® res)

than for LNG/LPG. Figure 6 illustrates the prediction of the only and further uncertainty may be introduced when

model for a smoky, 10 m by 10 m square JP4 pool ® re3 1 . attempting to use it for more realistic scenarios. Examples

4. The model predictions improve as the distance from the of `non-ideal’ conditions that may affect the radiation levels

® re increases, as illustrated in Figure 7 for LNG/LPG pool around a pool ® re include reduced ventilation, obstructions

® res. This suggests that predictions of semi-empirical within and around the pool, pool aspect ratio and tempera-

models of this type, which use idealized time-averaged ture of the substrate. Uncertainty in experimental data may

¯ ame envelopes, are uncertain at locations close to the

¯ ame.

5. The model predictions are poorer for water-based than

Table 5. Results of POOLFIRE6 validation.

Validation subset NMSE FB FTS

LNG/LPG 0.26 - 0.42 0.79

Non-LNG/LPG 0.08 - 0.06 0.98

Land-based circular 0.18 - 0.29 0.90

Land-based rectangular 0.05 + 0.04 1

Water-based 0.30 - 0.33 0.75

D < 3m 0.12 + 0.06 0.95

3 m < D < 10 m 0.10 - 0.16 1

D > 10 m 0.23 - 0.36 0.83

Overall 0.17 - 0.18 0.90

Figure 7. Comparison with LNG/LPG circular land-based data.

Trans IChemE, Vol 75, Part B, May 1997

88 REW et al.

relate to variation in ambient conditions (especially wind APPENDIX AÐ VALIDATION METHODOLOGY

speed and direction) during a trial and the averaging time There are various methods available for evaluating the

and ® eld of view of radiometers. Generally, the low number quality of consequence models, including, for example,

of measurements taken for each trial precludes authors from those used in the comparison of dense gas dispersion models

de® ning the accuracy of their measurements. However, against appropriate validation data (Hanna et al.3 2 ). Britter3 3

there are exceptions and, for example, Johnson4 provides has reviewed methods used to assess the ® tness for purpose

standard deviations of measured ¯ ux data for a range of of technical models and suggests that two statistics used by

highly instrumented and well controlled LNG pool ® re Hanna et al.3 2 , fractional bias and normalized mean square

trials. For the trials given, this standard deviation is error, provide a useful comparison between models. If a

approximately 10 to 25% of the average values and is quantity X has N predicted values, XP , corresponding to

related to both experimental uncertainty and the stochastic observations, XO , then these statistics can be calculated as

and ¯ uctuating nature of the ® re event. follows:

The primary purpose of the POOLFIRE6 model is to

predict the thermal radiation which is incident on targets Fractional Bias (FB):

external to the ¯ ame envelope. Thus, although the ¯ ame

S

N

shape correlations have been compared against full-scale 1 XO - XP

FB = 2

data, care is required in using semi-empirical pool ® re N 1

XO + XP

models to predict ¯ ame impingement. Pool ® res are

unsteady and solid surface emitter models predict the

visible steady-state dimensions of idealized ¯ ame envel- Normalized Mean Square Error (NMSE):

opes. Additionally, the model does not allow prediction of N

(XO - XP )2

S

1

heat ¯ uxes to objects within the ¯ ame, where heat transfer is NMSE =

due to convection as well as radiation. N 1

XO XP

Fractional bias (FB) is a measure of the over- or

underprediction of a model; a negative fractional bias

CONCLUSIONS indicates that a correlation is overpredicting experimental

data. The normalized mean square error (NMSE) is a

The review of pool ® re modelling and full-scale data has

measure of the relative ® t of a model to data and can be used

allowed the production and validation of a semi-empirical

in the comparison of correlations. Both the FB and NMSE

pool ® re model, POOLFIRE6. The review showed that there

measures have been used to assist in the process of choosing

is a large quantity of published large-scale data (especially

the correlations for the POOLFIRE6 sub-models and also in

for incident external radiation) which is of suf® cient quality

assessing the quality of the model for the prediction of

to be used to validate pool ® re models, of whatever

thermal radiation for different fuel types and a range of

complexity. The validation dataset covers the majority of

input parameters.

fuels, pool sizes and ambient conditions considered within

A further statistical function used by Hanna et al.3 2 in the

risk assessments. However, two de® ciencies that were

evaluation of hazardous gas models is the factor of two

identi® ed are the lack of large-scale wind-blown tank ® re

statistic.

data and measurements of incident radiation at locations

close to the ¯ ame surface.

The validation exercise has de® ned the uncertainty in Factor of Two Statistic (FTS):

modelling thermal radiation from pool ® res. The POOL- FTS = n/ N

FIRE6 model predicts thermal radiation within a factor of

two for 90% of the validation subset, with better con® dence where n is the number of predictions within a factor of two

for certain fuel types and sets of input parameters. The of the corresponding observations. The FTS is an absolute

uncertainty in the modelling is likely to consist of two measure of the quality of ® t of a model and has been used to

components; experimental error and model inaccuracy. assess the POOLFIRE6 model predictions of incident

Model inaccuracy may be reduced by improved modelling thermal radiation.

of smoke obscuration. There will also be uncertainty

related to the use of the model within a hazard assessment

which results from its use for non-ideal incidents, e.g. for NOMENCLA TURE

obstructed pools, or where it is used outside its range of a, b, c constants used in ¯ ame tilt correlation

validation. C/H carbon to hydrogen atomic ratio in fuel

D pool ® re diameter, m

An alternative to semi-empirical modelling of pool ® res is D9 ¯ ame dragged diameter of pool ® re, m

the use of ® eld (CFD) models. However, these require sub- E surface emissive power of ¯ ame, kW m- 2

models for combustion, soot-production and radiative heat EL surface emissive power of lower clean burning ¯ ame zone, kW m- 2

transfer. These sub-models will contain some level of Em maximum emissive power of luminous spots, approximately

140 kW m- 2

empiricism and therefore CFD models also require valida- E¥ maximum surface emissive power for the fuel, kW m- 2

tion. Once validated, CFD models have the potential to ES emissive power of smoke, approximately 20 kW m- 2

address effects such as enclosure of the ® re and obstructions EU surface emissive power of upper ¯ ame zone corrected for

within the ¯ ame. These bene® ts must be balanced against obscuration, kW m- 2

the relative ease of use of semi-empirical models, which, FL view factor between lower zone of ¯ ame and receiver

Fr U 2 / gD = Froude number of pool ® re

within their range of validation, provide an ef® cient method Fr9 Froude number of the pool ® re based on wind speed at a height of

of calculating heat ¯ uxes for hazard assessment purposes. 9m

Trans IChemE, Vol 75, Part B, May 1997

MODELLING OF THERMAL RADIATION FROM POOL FIRES 89

Fr10 Froude number of the pool ® re based on wind speed at a height of 11. Mudan, K. S., 1984, Hydrocarbon Pool and Vapour Fire Data

10 m Analysis, USDOE Report DE-AC01-83EP16008.

FU view factor between upper zone of ¯ ame and receiver 12. Koseki, H. and Mulholland, G. W., 1991, The effect of diameter on the

g acceleration due to gravity, m s- 2 burning of crude oil pool ® res, Fire Technology, February, 54±65.

HS vertical sag of tank ® re ¯ ame below tank top, m 13. Lautkaski, R., 1992, Validation of ¯ ame drag correlations with data

kb mean beam length corrector extinction coef® cient product, m- 1 from large scale pool ® res, J Loss Prev Pro Ind, 5 (3): 175±180

km extinction coef® cient for fuel, m- 1 14. Koseki, H., 1989, Combustion properties of large liquid pool ® res, Fire

L ¯ ame length, m Technology, August, 241±255.

LC clear ¯ ame length, m 15. Yumoto, T., 1971, An Experimental Study on Heat Radiation from

Ç

m mass release rate of fuel, kg s- 1 Oil Tank Fire, Report of Fire Research Institute of Japan, No. 33.

m Ç * mÇ 9 / 9 q a (gD)1/ 2 = dimensionless mass burning rate of fuel 16. Alger, R. S. and Capener, E. L., 1975, Aircraft Ground Fire

m Ç 9 9 mass burning rate of fuel, kg m- 2 s- 1 Suppression and Rescue Systems, Phases III,V,VI and VII, Report

m 99

Ç ¥ maximum mass burning of fuel, kg m- 2 s- 1 DOD-AGFSRS-75-4 (DOD Aircraft Ground Fire Suppression and

n number of data points for which 0.5 XO < XP < 2 XO Rescue Systems Of® ce).

N number of predictions, XP, corresponding to observations, XO 17. Mudan, K. S., 1984, Thermal radiation hazards from hydrocarbon pool

q total incident heat ¯ ux at the receiver, kW m- 2 ® res, Prog Energy Comb Sci, 10: 59±80.

qL incident heat ¯ ux at the receiver from lower ¯ ame, kW m- 2 18. Babrauskas, V., 1983, Estimating large pool ® re burning rates, Fire

qU incident heat ¯ ux at the receiver from upper ¯ ame, kW m- 2 Technology, 19: 251±261

Re UD/ t = Reynolds number of ® re source 19. Sparrow, E. M. and Cess, R. D., 1978, Radiation Heat Transfer

Re9 Reynolds number of ® re source based on wind speed at a height of (McGraw Hill Book Company, New York, USA).

9m 20. Davis, B. C. and Bagster, D. F., 1989, The computation of view factors

s 0.12 m- 1 = experimentally determined parameter of ® re models, J Loss Prev Proc Ind, 2, Oct, 224±234.

U wind speed, m s- 1 21. Wayne, F. D., 1991, An economical formula for calculating atmo-

U* U / (g Çm9 D 9 / q a )1/ 3 = dimensionless wind speed spheric infrared transmissivities, J Loss Prev Proc Ind, 4 (2): 86±92.

U1*.6 dimensionless wind speed measured at a height of 1.6 m 22. Thomas, P. H., 1963, The size of ¯ ames from natural ® res, 9th Int

U9* dimensionless wind speed measured at a height of 9 m Combustion Symp, 844±859 (Combustion Institute, Pittsburgh, Pa,

UR unobscured ratio of upper ¯ ame zone USA).

XO observed value of data point 23. American Gas Association (AGA), 1974, LNG Safety Research

XP predicted value of data point Program, Report IS 3-1.

24. Welker, J. R. and Sliepcevich, C. M., 1966, Fire Technology, 2: 127.

Greek letters 25. Moorhouse, J., 1982, Scaling laws for pool ® res determined from large

t kinematic viscosity of air, m2 s- 1 scale experiments, IChemE Symposium Series No. 71, 165±179.

q a density of air at ambient conditions, kg m- 3 26. Considine, M., 1984, Thermal Radiation Hazard Ranges from Large

q v vapour density of fuel at its boiling point, kg m- 3 Hydrocarbon Pool Fires, UKAEA Report No. SRD R297.

h tilt of ¯ ame from vertical, degrees 27. Ditali, S., Rovati, A. and Rubino, F., 1992, Experimental model to

s L atmospheric transmissivity for lower zone assess thermal radiation from hydrocarbon pool ® res, 7th Int Symp on

s U atmospheric transmissivity for upper zone Loss Prevention and Safety Promotion in the Process Industries,

Taormina, Italy.

28. Rew, P. J. and Deaves, D. M., 1995, The validation and application of

REFERENCES pool ® re models, SERA-Vol 4, Safety and Risk Analysis (ASME).

29. Alger, R. S., Corlett, R. C., Gordon, A. S. and Williams, F. A., 1979,

1. Rew, P. J. and Hulbert, W. G., 1995, Development of Pool Fire Some aspects of structures of turbulent pool ® res, Fire Technology 15:

Thermal Radiation Model, HSE Contractor Report WSA/RSU8000/018 142±156.

(HSE Books, UK). 30. Atallah, S. and Raj, P. P. K., 1974, Radiation from LNG Fires, AGA

2. Bull, D. and Strachan, D., 1992, Liqui® ed natural gas safety research, report IS 3-1, Section G.

Selected Papers (Shell International Petroleum Company Ltd). 31. Hagglund, B. and Persson, L., 1976, The heat radiation from petroleum

3. Pritchard, M. J. and Binding, T. M., 1992, FIRE2: A new approach for ® res, FOA Report (Forvarets, Forskningsanstalt, Stockholm, Sweden).

predicting thermal radiation levels from hydrocarbon pool ® res, 32. Hanna, S. R., Strimaitis, D. G. and Chang, J. C., 1991, Evaluation of

IChemE Symposium Series No. 130, 491±505. fourteen hazardous gas models with ammonia and hydrogen ¯ uoride

4. Johnson, A. D., 1992, A model for predicting thermal radiation hazards data, J Haz Mat, 26: 127±158.

from large-scale LNG pool ® res, IChemE Symposium Series No.130, 33. Britter, R. E., 1994, The evaluation of technical models used for major-

507±524. accident hazard installations, EUR 14774 EN (Commission of the

5. Mudan, K. S. and Croce, P. A., 1988, Fire hazard calculations for large European Communities (CEC)).

open hydrocarbon ® res, The SFPE Handbook of Fire Protection

Engineering, First edition, Section 2, Chapter 4 (NFPA, Quincy, MA,

USA).

6. Cowley, L. T. and Johnson, A. D., 1991, Oil and Gas Fires;

ACKNOWLEDGEMENT

Characteristics and Impact, Work Package FLI, Blast and Fire The work described in this paper has been undertaken on behalf of the

Engineering Project for Topside Structures (Joint Industry Project, UK Health and Safety Executive. However, the views expressed in this

SCI). paper are those of the authors and are not, except where the context

7. Nedelka, D., Moorhouse. J. and Tucker, T. F., 1989, The Montoir 35 m indicates, necessarily those of the HSE.

diameter LNG pool ® re experiments, TRCP.3148R, 9th Int Congress

and Exposition of Liqui® ed Natural Gas, `LNG9’ , Nice, France.

8. Raj, P. P. K., Moussa, A. N. and Aravamudan, K., 1979, Experiments ADDRESS

Involving Pool and Vapour Fires from Spills of Liqui® ed Natural Gas

on Water, NTIS Report No. CG-D-55-79. Correspondence concerning this paper should be addressed to Mr P. J. Rew,

9. Uehara, Y., Yumoto, T. and Nakagawa, S., 1973, Burning Character- WS Atkins Safety & Reliability, Woodcote Grove, Ashley Road, Epsom,

istics of Cryogenic Fuels, Report of Fire Research Institute of Japan, Surrey KT18 5BW, UK.

No. 37.

10. Mizner, G. A. and Eyre, J. A., 1983, Radiation from lique® ed gas ® res The manuscript was received 18 November 1996 and accepted for

on water, Combust Sci Technology, 35: 33±57. publication after revision 11 March 1997.

Trans IChemE, Vol 75, Part B, May 1997

You might also like

- Uxv500i 500se 500ile Service ManualDocument43 pagesUxv500i 500se 500ile Service ManualIvan Escudero Bedmar50% (4)

- Mixing and Chemical Reaction in Steady Confined Turbulent FlamesDocument9 pagesMixing and Chemical Reaction in Steady Confined Turbulent Flamesmohamadhosein mohamadiNo ratings yet

- Flamability of High Flash Point Liquid Fuels: Peter J Kay, Andrew P. Crayford, Philip J. Bowen James LuxfordDocument8 pagesFlamability of High Flash Point Liquid Fuels: Peter J Kay, Andrew P. Crayford, Philip J. Bowen James LuxfordEfari BahcevanNo ratings yet

- Controlling LOI From Coal Reburning in A Coal-Fired Boiler: Hou-Peng Wan, Chyh-Sen Yang, B.R. Adams, S.L. ChenDocument7 pagesControlling LOI From Coal Reburning in A Coal-Fired Boiler: Hou-Peng Wan, Chyh-Sen Yang, B.R. Adams, S.L. ChenJayanath Nuwan SameeraNo ratings yet

- Japan Servo CatalogDocument39 pagesJapan Servo CatalogKofaKing100% (1)

- An Attempt at Large Eddy Simulation For Combustor Modeling: Leiyong Jiang and Ian CampbellDocument10 pagesAn Attempt at Large Eddy Simulation For Combustor Modeling: Leiyong Jiang and Ian CampbellWVNicholsonNo ratings yet

- 10 1021@ef700545jDocument9 pages10 1021@ef700545jHangie Cristina Montoya PeñalozaNo ratings yet

- A Non-Premixed Combustion Model Based On Flame STRDocument59 pagesA Non-Premixed Combustion Model Based On Flame STRCarlos AlarconNo ratings yet

- Computational Evaluation of Emissions For Non-Premixed Natural Gas CombustionDocument3 pagesComputational Evaluation of Emissions For Non-Premixed Natural Gas CombustionijsretNo ratings yet

- In-Situ Combustion Model: Intercomp Resource Development and Engineering IncDocument22 pagesIn-Situ Combustion Model: Intercomp Resource Development and Engineering IncAliNo ratings yet

- Boilng CFDDocument23 pagesBoilng CFDjawed ahmedNo ratings yet

- Monitoring and Modelling Gas Side Fouling Biomass BoilerDocument7 pagesMonitoring and Modelling Gas Side Fouling Biomass BoilermsoyoralNo ratings yet

- Combustion and Flame: Yu Hu, Sriram Bharath Hariharan, Haiying Qi, Michael J. Gollner, Elaine S. OranDocument7 pagesCombustion and Flame: Yu Hu, Sriram Bharath Hariharan, Haiying Qi, Michael J. Gollner, Elaine S. OranSidharth K PillaiNo ratings yet

- Combustion and Flame: K. Kumaran, V. BabuDocument8 pagesCombustion and Flame: K. Kumaran, V. BabuaruntnjNo ratings yet

- 2009 ISH Jovalekic Vukovic Dissolved - Gas Analysis of Natural EsterDocument6 pages2009 ISH Jovalekic Vukovic Dissolved - Gas Analysis of Natural EsterMohamedHussein MohamedHusseinNo ratings yet

- 1 s2.0 S0894177721000625 MainDocument27 pages1 s2.0 S0894177721000625 MainShelly BiswasNo ratings yet

- Caldeira-Pires - 2000 - Experimental Characterization of Non-Premixed Turbulent Jet Propane FlamesDocument18 pagesCaldeira-Pires - 2000 - Experimental Characterization of Non-Premixed Turbulent Jet Propane FlamesArmando Caldeira PiresNo ratings yet

- Absorber Intercooling Configurations Using Aqueous Piperazine For Capture From Sources With 4 To 27% CODocument20 pagesAbsorber Intercooling Configurations Using Aqueous Piperazine For Capture From Sources With 4 To 27% COasmaa aliNo ratings yet

- Experimental Investigation and Numerical Simulation of Secondary Combustor Flow in Boron-Based Propellant Ducted RocketDocument8 pagesExperimental Investigation and Numerical Simulation of Secondary Combustor Flow in Boron-Based Propellant Ducted RocketAzeem KhanNo ratings yet

- Combustion Chamber of Small Capacity Gas TurbineDocument10 pagesCombustion Chamber of Small Capacity Gas TurbineDevangMarvaniaNo ratings yet

- Spe12247 Coats Some Observations On Field Scale Simulation of The in Situ Combustion ProcessDocument10 pagesSpe12247 Coats Some Observations On Field Scale Simulation of The in Situ Combustion ProcessBruceNo ratings yet

- Bermudez2011 PulverizedCoalDocument14 pagesBermudez2011 PulverizedCoalKhadeeja NicyNo ratings yet

- Pool Fire Mass Burning Rate and Flame Tilt Angle Under Crosswind in Open Space (2016)Document14 pagesPool Fire Mass Burning Rate and Flame Tilt Angle Under Crosswind in Open Space (2016)Torero02No ratings yet

- Applied Energy: Medhat A. Nemitallah, Mohamed A. HabibDocument15 pagesApplied Energy: Medhat A. Nemitallah, Mohamed A. HabibsoroushNo ratings yet

- Cabra Chen Dibble Karpetis BarlowDocument16 pagesCabra Chen Dibble Karpetis BarlowJulio Andrés Casal RamosNo ratings yet

- A111526 PDFDocument9 pagesA111526 PDFalexNo ratings yet

- Large Eddy Simulation of Ethanol-Gasoline Fire: SciencedirectDocument6 pagesLarge Eddy Simulation of Ethanol-Gasoline Fire: SciencedirectjanainaNo ratings yet

- Berglund, M., & Fureby, C. (2007) - LES of Supersonic Combustion in A Scramjet Engine Model. Proceedings of The Combustion InstituteDocument8 pagesBerglund, M., & Fureby, C. (2007) - LES of Supersonic Combustion in A Scramjet Engine Model. Proceedings of The Combustion InstituteViet LeNo ratings yet

- Ebullated Bed Reactor Modeling For Residue Conversion PDFDocument9 pagesEbullated Bed Reactor Modeling For Residue Conversion PDFMohmmed Abdullah Sanam100% (1)

- Liquid H2 Jet Revised 080409xDocument11 pagesLiquid H2 Jet Revised 080409xAghajaniNo ratings yet

- Approximation of Flammability Region For Natural Gas-Air-Diluent MixtureDocument6 pagesApproximation of Flammability Region For Natural Gas-Air-Diluent Mixtureg_marianiNo ratings yet

- Large Eddy Simulation of Low Reynolds Number Turbulent Hydrogen Jets - Modelling Considerations and Comparison With Detailed ExperimentsDocument15 pagesLarge Eddy Simulation of Low Reynolds Number Turbulent Hydrogen Jets - Modelling Considerations and Comparison With Detailed Experimentsxaviera07No ratings yet

- Bali Metal Focusing EffectDocument8 pagesBali Metal Focusing EffectABNo ratings yet

- Fu2015 - From Determination of The Fugacity Coefficients To Estimation of Hydrogen Storage Capacity - A Convenient Theoretical MethodDocument10 pagesFu2015 - From Determination of The Fugacity Coefficients To Estimation of Hydrogen Storage Capacity - A Convenient Theoretical MethodSteven BosscherNo ratings yet

- Ying Wang (2020) CFD Simulation of Propane Combustion in A PorousDocument9 pagesYing Wang (2020) CFD Simulation of Propane Combustion in A PorousmadadmrdNo ratings yet

- Abstracts of The Papers Presented at The Thirteenth National Vacuum SymposiumDocument1 pageAbstracts of The Papers Presented at The Thirteenth National Vacuum SymposiumgfpeezyNo ratings yet

- 1 s2.0 S1359431122000813 MainDocument21 pages1 s2.0 S1359431122000813 MainNimble NimbleNo ratings yet

- Shsan Foolafgar - 2019 - C&F - Characterization of Flameless Combustion in A Model Gas Turbine Combustor Using A Novel Post Processing ToolDocument12 pagesShsan Foolafgar - 2019 - C&F - Characterization of Flameless Combustion in A Model Gas Turbine Combustor Using A Novel Post Processing TooljayakrishnatejaNo ratings yet

- Flame QuenchingDocument10 pagesFlame QuenchingSufian KhalidNo ratings yet

- Starkloff Et Al. - 2016 - Investigation Into Gas Dynamics in An Oxyfuel CoalDocument9 pagesStarkloff Et Al. - 2016 - Investigation Into Gas Dynamics in An Oxyfuel CoalZhouNo ratings yet

- Evaluation of Supersonic SeparatorDocument6 pagesEvaluation of Supersonic SeparatorNelson PalenciaNo ratings yet

- Separation and Purification TechnologyDocument10 pagesSeparation and Purification TechnologyPedro Henrique MagachoNo ratings yet

- Model-Based Evaluation of A Chemical Looping Combustion Plant For Energy Generation at A Pre-Commercial Scale of 100 MWTHDocument9 pagesModel-Based Evaluation of A Chemical Looping Combustion Plant For Energy Generation at A Pre-Commercial Scale of 100 MWTHDaniel Z JucaNo ratings yet

- Thesis FtirDocument8 pagesThesis Ftirdnqkxm09100% (2)

- Laminar Flame Speeds of Ethanol, N-Heptane, IsooctaneDocument8 pagesLaminar Flame Speeds of Ethanol, N-Heptane, IsooctaneanilkoleNo ratings yet

- He 2017Document11 pagesHe 2017puspita dwikartikasariNo ratings yet

- 1 s2.0 S1540748912002702 Main - Cetane - NumberDocument7 pages1 s2.0 S1540748912002702 Main - Cetane - NumberEverton Luiz Dias da SilvaNo ratings yet

- Conversion of Coal Particles in Pyrolysis and Gasification: Comparison of Conversions in A Pilot-Scale Gasifier and Bench-Scale Test EquipmentDocument10 pagesConversion of Coal Particles in Pyrolysis and Gasification: Comparison of Conversions in A Pilot-Scale Gasifier and Bench-Scale Test EquipmentRoberto Macias NNo ratings yet

- Energies: Ventilation System Influence On Hydrogen Explosion Hazards in Industrial Lead-Acid Battery RoomsDocument11 pagesEnergies: Ventilation System Influence On Hydrogen Explosion Hazards in Industrial Lead-Acid Battery Roomsigor VladimirovichNo ratings yet

- Three Phase Reactor Model Pilot TrickleDocument11 pagesThree Phase Reactor Model Pilot TrickleThế vũ Đặng vănNo ratings yet

- Energies 15 04816 v2Document15 pagesEnergies 15 04816 v2ORLANDO GONZALEZNo ratings yet

- Experiments of Premixed Hydrogen - Air Flame Propagation in DuctsDocument36 pagesExperiments of Premixed Hydrogen - Air Flame Propagation in DuctsgovindNo ratings yet

- Energy Conversion and Management: H.U. Helvaci, Z.A. KhanDocument12 pagesEnergy Conversion and Management: H.U. Helvaci, Z.A. Khan11751175No ratings yet

- Thermochemical Exploration of Hydrogen Combustion in Generic Scramjet CombustorDocument11 pagesThermochemical Exploration of Hydrogen Combustion in Generic Scramjet CombustorGunvir SinghNo ratings yet

- MW 323Document8 pagesMW 323dio prabowoNo ratings yet

- Efficiency Measurements of Flares in A Cross Flow: M.R. Johnson, O. Zastavniuk, D.J. Wilson and L.W. KostiukDocument9 pagesEfficiency Measurements of Flares in A Cross Flow: M.R. Johnson, O. Zastavniuk, D.J. Wilson and L.W. KostiukAhmed AliNo ratings yet

- Thermal Cracking of Methane in A Liquid Metal Bubble Column Reactor Experiments and Kinetic AnalysisDocument14 pagesThermal Cracking of Methane in A Liquid Metal Bubble Column Reactor Experiments and Kinetic Analysisdavid alendezNo ratings yet

- Numerical Modelling of Hydrodynamics and Gas Dispersion in An Autoclave - Appa Et Al 2013-1Document9 pagesNumerical Modelling of Hydrodynamics and Gas Dispersion in An Autoclave - Appa Et Al 2013-1ninaNo ratings yet

- 10.1515 - Cls 2022 0029Document19 pages10.1515 - Cls 2022 0029Omosekeji TimilehinNo ratings yet

- International Journal of Greenhouse Gas ControlDocument11 pagesInternational Journal of Greenhouse Gas Controlamirali2015No ratings yet

- Outward Propagation Burning Velocities and Chemical Effects of Methane Flames Up To 60ATMDocument10 pagesOutward Propagation Burning Velocities and Chemical Effects of Methane Flames Up To 60ATMMarcos Noboru ArimaNo ratings yet

- Class 12 Physics NotesDocument115 pagesClass 12 Physics NotesAiden Pearce100% (1)

- Diagraama QuantumDocument6 pagesDiagraama QuantumClaudio Rene Silva Hernandez100% (1)

- Te Etc Pe Lab Manual 2017-18Document36 pagesTe Etc Pe Lab Manual 2017-18wondieNo ratings yet

- Transmission LineDocument84 pagesTransmission Linemiguel itsonNo ratings yet

- ELECTROSTATICS HARD Question Paper With SolutionDocument30 pagesELECTROSTATICS HARD Question Paper With SolutionArvita KaurNo ratings yet

- SECTION5940Document13 pagesSECTION5940Franklin Manolo NiveloNo ratings yet

- Serway PSE Quick ch32Document15 pagesSerway PSE Quick ch32Ràhuł MathiasNo ratings yet

- Brochure Gamme MLT MVT (EN)Document44 pagesBrochure Gamme MLT MVT (EN)ManitouNo ratings yet

- Revue Technique Derbi Euro 2Document71 pagesRevue Technique Derbi Euro 2Hellbent BikersNo ratings yet

- Derating of Asymetric PID 117539.PDF JsessionidDocument9 pagesDerating of Asymetric PID 117539.PDF Jsessionidaqaish15No ratings yet

- Value Addition of Apple RevisedDocument76 pagesValue Addition of Apple Revisedmunir HussainNo ratings yet

- O&G - FMS PortfolioDocument10 pagesO&G - FMS PortfoliopablobsNo ratings yet

- Ifm The Right Choice For Your Application Level Sensors From IfmDocument24 pagesIfm The Right Choice For Your Application Level Sensors From Ifmifm electronicNo ratings yet

- Design, Analysis and Development of Improved Hollow Concrete Block Making Machine - IJERTDocument22 pagesDesign, Analysis and Development of Improved Hollow Concrete Block Making Machine - IJERThhNo ratings yet

- Bed 9Document6 pagesBed 9Mary Grace VelitarioNo ratings yet

- Elektrisch Schema - 112657 - 23 - C3Document3 pagesElektrisch Schema - 112657 - 23 - C3Folkwin LapNo ratings yet

- 07 Fluid CouplingDocument18 pages07 Fluid Couplingananttomar80361No ratings yet

- TransformerDocument52 pagesTransformerorangramaiNo ratings yet

- Acetylated Castor Oil - Preparation and Thermal DecompositionDocument7 pagesAcetylated Castor Oil - Preparation and Thermal DecompositionPee Hai NingNo ratings yet

- UPS 30kVA 30minDocument6 pagesUPS 30kVA 30minJosé LuisNo ratings yet

- Mooring EquipmentDocument195 pagesMooring EquipmentVladimirs Arzeninovs100% (4)

- Maytag MHWE301YW Dimensions GuideDocument2 pagesMaytag MHWE301YW Dimensions Guidenxa244No ratings yet

- ICS Series Float & Thermostatic Steam TrapsDocument2 pagesICS Series Float & Thermostatic Steam TrapsWilliam OeyNo ratings yet

- MIT8 02SC Notes16to18Document30 pagesMIT8 02SC Notes16to18GeorgeChangNo ratings yet

- Low Voltage Alternators - 4 Pole: TAL046 - TAL047 - TAL049Document8 pagesLow Voltage Alternators - 4 Pole: TAL046 - TAL047 - TAL049zainahmedscribdNo ratings yet

- 5990 3699enDocument124 pages5990 3699enthichchanthanh7593No ratings yet

- ProfileDocument6 pagesProfilealiNo ratings yet

- Specification Sheet Delmag D12-32Document1 pageSpecification Sheet Delmag D12-32Danny CruzNo ratings yet