Professional Documents

Culture Documents

Sealing - HC Company Product

Sealing - HC Company Product

Uploaded by

t.cardoso.verion0 ratings0% found this document useful (0 votes)

8 views59 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views59 pagesSealing - HC Company Product

Sealing - HC Company Product

Uploaded by

t.cardoso.verionCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 59

Tel

PROFESSIONAL

PARTNER IN SEALING AND FLUID CONTROL

®

‘TheHe Company

FC

Ma i

SEALING AND FLUID CONTROL

—

® > The HC Company is a professional company producing high-

cwalty process hole sealing and fio contol procucts. With a

> complete range of prosicts, the HC Company provides olopa

tustorers wih solifane for compieheraive and pratessional

sealing and tui contol

‘The HC Company > No matter whethor it is the automotive industry, transportation

industry, hydraulic industry, energy industry, construction

industry, electronic industry, high-precision industry or medical

devica industry, where highly reliable and safe sealing and fluid

control technology is needed, there are high-performance

solutions of the HC Company, providing the most reliable solution

for the details and key points of your product

> The HC Company does not only provide you with standardized

products and components, but also pays more attention to

providing the best solution through close cooperation with

‘customers and solutions especially when customers have special

requirements.

Pate

OU neste LL

Ta RY

02. www.heplug.cn

Cc

Dea SITAR

‘As a professional manufacturer of process hole sealing technology, the HC Company

produces H

lug sealing product with the mos! efficient and reliable plugging scheme

‘or process holes, which can be flexibly and reliably applied to various workpieces of

different materials, and provide rated beating capacity up to 600 BAR. In the automotive

industry, the HC Plug sealing products are widely used in engine, gearbox. transmission

system, suspension system, braking system, steering system and fuel injection system: for

uid technology modules used in machinery industry, engineering machinery

ransmissian facilities and mold equipment, HC plug

ing products can perfectly meet

all design and application requiremonts. At tne samo time, in adaition to a wide range of

standardized products, HC always provides efficient and reliable customized solutions for

Dy

wivwheplug.en 03

DUTT Ma tL HB

® Combining our leading flow control and sealing expertise, HC

The precise orifice flow control solution provides reliable

‘The HC Company performance for @ wide range ot applications ang makes the

products easy to install. Moreover, our engineers can develop

custom dasigns for your special flaw control needs.

04 www.heplug.cn

> HC Plug sealing products

27-12 |B) rcanneemsionrivcs

19-14 RS EXPANSION PLUGS

a7-19 (CLW SEALING PLUGS

20-25 CLYO-RING/ED RING PLUGS

iS

NS

HC Valve fluid control products

27-31 RT RESTRICTORS

s2-33 RERESTRICTORS

34-36 CVH CHECK VALVES

39 HVO CHECK VALVES

40 (CVPS.5 CHECK VALVES

a SHVS S SHUTTLE VALVES

of

44-47 Pressure performance

48 Bearing capacity test

49 HC plugs installation Bar

50 HC plugs Air Hammer Bar

51 HC plugs installation tool

51 RS Plugs Installation Tool (Hydraulic Pneumatic Too!)

52-54 Design Guide (HCIRS Products)

58 Hardness conversion table

56 ___HC,s quali

assurance

05

DL anh

Maximum rated withstand pressure 450BAR

06. www.heplug.cn

HCQD Plugs

Material

Sleeve: hard stai

st

stec!, passivated surfac

| ball: bearing steel, heat treatment

Unit: mm

Ce 5

wosooroen power ke

nosso qnome Tet

wosooioen aoe TT

woswioen — Qoime tt eo

is TDA 4 TNE a NN TE

Bearing capacity

er2-t6 2e00AR 2s00AR

eae 010mm

pa ate, Riess

%, Rated beating capaci

°%. For dota, please rater to the bearing capacity test page

‘maximum allowable working pressure

wwwheplug.cn 07

HC Plugs

Material

hard stainless steel, passivated surface 4]

heat treatment |

i

Unit: mm

reel

No. name

H¢330301M C030 a 3.6 47 3 22 Evy O48

He330302M_ Hc040 4 4 st 4 3.3. 38 o4

H¢330303M Ho050 5 5.5 7A 6 4.3 83 04

He330304M C060 6 65 36 6 5.3. 63 oa

He330305M Hc070 7 7.8 10.1 7 64 7.3 oa

He330306M Ho080 a a5 11.6 8 74 a3 08

He330307M H4c090 8 10 13.5 8 34 98 oa

He330308M Hc100 10 1" 15.1 0 84 108 oa

Hc330300M C120 12 13 17.8 2 10.6 12.8 04

He330310M e140 14 18 20.4 “4127 145 oa

He330311M Ho160 16 7 23.8 1% 147 16.5 06

H0390312M He180 18 19 26.3 1% 167 18.5 06

H1c330319M Ho200 20 2 30 20187 215 06

He330314M_ C220 22 25 34 2220.7 24.5 06

Bearing capacity

23-10 380BAR

o1216 280BAR

Processhole Tolerance 0160-4

Tequirements Stace. R16-64

+, Rated bearing capacity= maximum allowable working pressure

+ For details, please refer to the hearing capacity test page

(08 wwwhoplug.cn

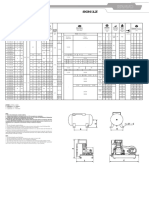

HCS Plugs

Material

Sleeve: hard stai

st

less steel, passivated surface

| ball: stainless steel, passivated Surface

FERS

AL: EK

Serie

fee) im

ae

43

53

6.4

7

8.4

a4

10.6

27

14.7

16.7

18.7

20.7

38

63

63

73

a3

28

108

12.8

165

185

215

245

04

4

os

4

04

04

oa

04

04

06

06

068

06

Hess001m = HCS030 3 3

Hosso4o2m | HESo4O 4 4 84 4

Hessosoam == HESO50 5 5.5 74 5

Hessososm — HES060 6 86 6

He3s0405M =——-HCSO70 7 104 7

Hessososm = HESo80 8 ne 8

Hoss0407M =——-HOS090 9 a)

Hessososm = HEst00 10 " 454 10

Hess0409M —-HOS120 2 ‘3 7.8 12

Heasostom = Hest40 4 15 204 14

Hessoatim = HCS160 16 7 234 16

Hesso412M —— HESt80 18 19 23 18

Hesso#ism = HES200 20 22 30 20

Hoss0414M ——-HOS220 2 25 34 22

Bearing capacity

ea

Cr i

23-10 380BAR

12-416 280BAR

Process hole Tolerance 01+0.1mm

Se) sougincss R164

°%. Rated bearing capacity= maximum allowable working pressure

‘%, For details, please reter to the bearing capacity test page

450BAR

350BAR,

wowheplug.cn 09

HCV Plugs (British specifications)

Material

hard stainless steel, passivated surface 4]

heat treatment |

i

Unit: mm

reel e

No. Tose Gua)

+HC3307011 HY156E 0.156 0.158 021 01862 0.130 0.149.008,

H4¢3307021 HY1e7E 0.187 217 027 0.1875 0.160 © 0.208 0.010

403307031 Hy218E 0.218 27 028 © 02187 0.190 0.208» 0.010

H4¢3307041 Hy250€ 0.250 0.256 034 0.2500 0.220 © 0.247 0.010

14¢3307051 Hy261E. 0.281 0.296 040 0.2812 0.250 0.287 0.010

113307061 HYS12E 0.312 0.335 046 03125 0.281 = 0.926 0.010,

43307071 yaaa. 0.343 0.394 082 03437 0.312 0.985 9.010

43307081 HYS75E 0.375 0.394 054 03750 0.343 0.385 0.010

Hc3307091 Hy406e. 0.406 0.434 059 0.4062 0.875 = 0.425 0.010.

03307101 Hyas7E 0.437 0512 068 0.4375 0.406 0.503 0.010

Ho3307111 Hy468E 0. 468 os12 O71 0.4687 0.837 ~—0.503 0.010.

4403307121 Hys02E 0.562 0.591 082 05625 0510 © 0.570 0.010,

43307131 HYy625E 0.625 0.869 0.91 0.6250 0.562 0.649 0.010

He3307141 Hyes7E 0.687 o7as 103068750625 0727 0.010

103307151 HY750E 0.750 0.866 118 07500 0.688 = 0.845.010

Hc3307161 Hva75E 0.875 0.984 1.95 08750 0.813 0.983 0.010

Bearing capacity

iene ue

(sLER/Sea3 5 a or Priore

Es id Ewer G Paice

086-0.375 808A “0548

00406-0878 22088 sos

BE tronce ois0.004n

cee) Ses Riso

3#, Rated bearing capacity maximum allowable working pressure

3, For datails, please refer to the bearing capacity test page

410. www.heplug.cn

HCVS Plugs (British specifications)

Material

Sleeve: hard sta

st

——

Bearing capacity

=

stec|, passivated surface

| ball: stainless steel, passivated surface

0.156

0.187

a.218

0.250

0.281

0.312

0.343

0.375

0.408

0.437

0.468

0.562

0.625

0.687

0.750

0.875

380BAR

2808AR

0.158

o2i7

027

0.256

0.296

0.335

0.294

o.ss4

0.434

0.812

osi2

0.591

0.669

o7a8

0.866

0.984

021 0.162

027 0.1875

028 0.2187

034 0.2500

040 0.2812

0.46 0.3125

082 0.9437

064 0.3750

0.59 0.4062

0.68 0.4375

071 0.4887

082 0.5625

0.91 0.6250

1.03 0.6875

118 0.7500

1.85 0.8750

neue

0/+0.004in

R164

'%. Rated bearing capacity= maximum allowable working prossure

', For dotals, please reter to the bearing capacity test page

450BAR

S50BAR

0.149

0.208

0.208

0.287

0.287

0.326

0.288

0.385

0.425

0.503

0.503

0.870

0.649

over

0.885

0.963

Unit: mm

0.008

0.010

o.o10

o.o10

o.010

0.010

o.o10

0.010

o.o10

0.010

o.o10

o.o10

0.010

0.010

o.010

0.010

woowheplug.en 11

HCE PLUGS

Material {

Sleeve: Aluminum, hard anodized surface 4

Steel ball: stainless steel

Unit: mm

ery E

ce : Ta)

He3307011 T0320 2 3.6 47 3 22 34 4

He3s07021 HTo40 4 4 5A 4 3.3 38 04

3307031 T0850 5 5.5 TA 5 43 583 04

Ho330704) HT060 6 65 86 6 53 63 04

3307051 HT070 7 7.5 10.4 7 6.4 73 04

He3307061 HT080 8 85 ne) 8 14 83 04

He3307071 HT090 ° 10 35 8 a4 a8 04

He3307081 HT010 10 " 154 8a 08 od

Bearing capacity

Aone eae

ob ‘ono

Berens oie

ae area

“Rated beating capacity= maximum allowable working pressure

+. For details, please refer ta the bearing capacity tast page

412. www.heplug.cn

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5809)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bener Volante VK 430i NOVO (Reduzido)Document2 pagesBener Volante VK 430i NOVO (Reduzido)t.cardoso.verionNo ratings yet

- FT ME 2Document2 pagesFT ME 2t.cardoso.verionNo ratings yet

- FT ME 3Document2 pagesFT ME 3t.cardoso.verionNo ratings yet

- Sintético RDocument1 pageSintético Rt.cardoso.verionNo ratings yet

- Catalog Bosch RexrothDocument343 pagesCatalog Bosch RexrothCriminally_Sane100% (1)

- Balanceamento e RPMDocument11 pagesBalanceamento e RPMt.cardoso.verionNo ratings yet

- Ficha Tecnica y Manual Compresor 5hpDocument74 pagesFicha Tecnica y Manual Compresor 5hpJuan Esteban Gallego OrtizNo ratings yet

- A Ovelha Rosa Da Dona RosaDocument17 pagesA Ovelha Rosa Da Dona Rosat.cardoso.verionNo ratings yet

- Engrenagem Cônica 45°Document1 pageEngrenagem Cônica 45°t.cardoso.verionNo ratings yet