Professional Documents

Culture Documents

KWR 5CA007 110 Installation Recommendation

KWR 5CA007 110 Installation Recommendation

Uploaded by

oscar trasladinoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KWR 5CA007 110 Installation Recommendation

KWR 5CA007 110 Installation Recommendation

Uploaded by

oscar trasladinoCopyright:

Available Formats

Datasheet 110 - Installation recommendation

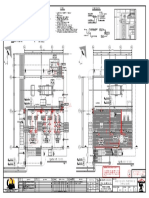

For the density and flow sensor it is important that the slurry is very well mixed and that there is

good contact between the particles and the sensors. Below table will show the ranking (1 to 5, 1 is

the higher ranking) of importance for the installation of the density and flow sensor.

The density sensor needs a turbulent flow, while the flowmeter needs a “laminar” flow. Due to

budget reasons we fix them together in one spool piece or wafer cell, but separate mounting would

be much better.

When considering mounting both sensors apart from each other, then follow these rules:

1) The ultrasonic density probe shall be a full ceramic QP015, as it is in turbulent area.

2) The slurry composition at both locations shall be the same, as well as the temperature and

massflow.

3) The density sensor is mounted upstream, the flow sensor downstream.

4) The preferred distance between them is 5xD, without any obstruction. After the flowmeter, a

minimum of 3xD shall be clear of any obstruction.

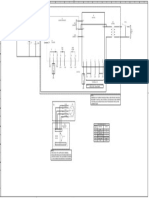

5) The cable connection between the transmitters of each sensor is a 2x2 twisted pair cable,

readily available at Arenal.

Sensor position Density Flow

Rank rank

Just after the pump in a vertical section. The slurry is well mixed and has a high 1 4

pressure *)

Just after the pump in a horizontal section. Position the sensor at 4:30 o’clock *) 2 5

In the middle of a vertical section. The flow profile and also the slurry concentration 3 1

at the outside of the pipe will change after a flow change. It means that the density

reading will change as well. It is not predictable, but it is reproducible.

In the middle of a horizontal section. The solids will settle after a few meter. Solids 4 2

will settle, unless the density is high enough to form a good mixture. Never place the

sensor at the bottom or top of the pipe. The best location is 4:30 or 7:30 o’clock.

Increase the moving average. Take samples at the same height as the sensor, not

from the top or bottom.

Just before or after a bend or obstruction. The flow and density profile is not 5 3

predictable. If this position cannot be avoided, place the sensors at the outer part of

the pipe at 3 am position.

*) At this point the slurry is very abrasive: check the insertion of the sensor in the pipe if the pipe is

eroding fast. The sensors are made from Sintered Silicon Carbide, the toughest ceramic material on

earth and they do not wear when installed correctly. But they can chip off when inserted too much in

the slurry (about 5 mm) by the side impact of the solids.

In any installation, make sure first to select the highest ranking for density, then for flow.

Arenal Process Control Solutions BV, Boezemweg 23E, NL-2642KG, Pijnacker, The Netherlands

Tel: +31.153.010.071, www.arenal-pcs.com, info@arenal-pcs.com

©2020, Arenal PCS BV KWR-5CA007-110

You might also like

- 4900 80 11 0Document1 page4900 80 11 0oscar trasladinoNo ratings yet

- KWR 7QA03 901 201124 EN User ManualDocument92 pagesKWR 7QA03 901 201124 EN User Manualoscar trasladinoNo ratings yet

- 4900 80 09 0Document1 page4900 80 09 0oscar trasladinoNo ratings yet

- S. A. de C. V.: REV. 1 REV. 2Document1 pageS. A. de C. V.: REV. 1 REV. 2oscar trasladinoNo ratings yet

- 4900 80 08 0Document1 page4900 80 08 0oscar trasladinoNo ratings yet

- 4800 80 04 1Document1 page4800 80 04 1oscar trasladinoNo ratings yet

- 4900 80 10 0Document1 page4900 80 10 0oscar trasladinoNo ratings yet

- 4900 80 06 0Document1 page4900 80 06 0oscar trasladinoNo ratings yet

- 4900 80 05 1Document1 page4900 80 05 1oscar trasladinoNo ratings yet

- Diagrama 1Document1 pageDiagrama 1oscar trasladinoNo ratings yet

- 4900 80 04 1Document1 page4900 80 04 1oscar trasladinoNo ratings yet

- Diagrama 3Document1 pageDiagrama 3oscar trasladinoNo ratings yet

- Diagrama 4Document1 pageDiagrama 4oscar trasladinoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)