Professional Documents

Culture Documents

Jhonn Deer Warning Limit

Jhonn Deer Warning Limit

Uploaded by

hugo pinargote0 ratings0% found this document useful (0 votes)

8 views2 pagesOriginal Title

jhonn deer warning limit

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesJhonn Deer Warning Limit

Jhonn Deer Warning Limit

Uploaded by

hugo pinargoteCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

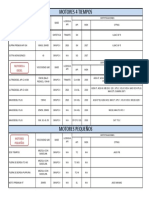

Table2 John Deere “Warning Limits” for Wear Metals and Other Elements

Table 2 contains the ‘warning limits” John Deere apply for wear metals and other elements

based on used lubricant analysis when measured by ICP.

Element ‘Warming Limit - maximum

‘As measured by ICP (ppm)

‘Aluminium 20

Chromium 5

Copper 150 for 7* lubricant drain

20 for subsequent lubricant drains

Tron 125"

Lead 40

Nickel 10

Potassium 30

Tin 25

Silicon 30

‘Sodium 20

™ John Deere waming limitis 05 ppm per hour. This per hour warning mit has been transiated into a limit for 250

lubricant operating hours (due to the field tial actors running for approximately 250 hours for each lubricant

drain)

Review of the used lubricant samples shows

© Total Base Number (TBN by ASTM method 02896) and Total Base Number

(TBN by ASTM method 04739)

Very little reduction in TBN is noted (<10%). This is considered to be a

very small reduction in TBN. This highlights that the engine lubricant is

effectively neutralising the acidic components caused by the combus-

tion process.

o Kinematic Viscosity (tested at 40°C and 100°C by ASTM method D7279)

© Allused lubricant samples fall within the stay in grade specification for

the ACEA E9 2008 specification (note: the stay in grade specifications

for SAE 40 viscosity grade lubricants is between 12.5 to <16.3 mm’is

according to SAE J300). The slight reduction in kinematic viscosity

measured at 100°C for all the used engine lubricant samples is consid-

ered to be normal as has been caused by the shearing of the viscosity

modifier used in the engine lubricant.

© Total Acid Number (TAN by ASTM method D664)

© Very little increase in TAN has been noted. This is combination with the

small reduction in TBN confirms that the engine lubricant is effectivaly

neutralising the acidic components caused by the combustion process.

© Wear metals and engine lubricant additive depletion, measured by Inductive

Coupled Plasma (ICP)

© Wear Metals

Copper (Cu), iron (Fe) and lead (Pb) are typical wear metals. Cu

and Pb are usually found in specific engine parts (e.g. bearings),

whilst Fe is contained in many engine parts. Measurement of ex-

cessively high levels of Cu, Fe or Pb in used engine lubricants

usually indicate that a specific engine component is wearing and

this may become a concem for long term engine durability. It

should be noted however that some low level of wear will be ex-

perienced by all engines and therefore it is not unusual for Cu,

Fe and Pb to be measured in used lubricant samples at low lev-

els.

The maximum measured levels of Cu, Fe and Pb shown in Table

1 are considered to be very low and within normal operating lev-

els for engines operating under the conditions of the field trial.

This is confirmed by the wear metals from each used lubricant

sample being significantly below the John Deere waming limits

shown in Table 2.

© The measured additive metals, calcium (Ca), phosphorus (P), sulphur

(S) and zine (Zn) highlight no change compared to the fresh oil.

© High Temperature High Shear viscosity (as measured by CEC Test method L-

36-A-90)

© Very little change in dynamic viscosity is noted between the fresh and

used lubricant samples.

© Percentage soot measured by Thermogravimetic Analysis (TGA)

© The soot levels in all the used lubricant sampies are very low. This

highlights that the combustion process is not producing a high level of

soot species. The level of soot present in the engine lubricant are not

‘expected to cause any problems in terms of soot handling capability of

the engine lubricant.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Article 2 - 2014 F and L - MC - Ver.0211 - JASO Standards RevisionDocument49 pagesArticle 2 - 2014 F and L - MC - Ver.0211 - JASO Standards Revisionhugo pinargoteNo ratings yet

- ServiciosDocument1 pageServicioshugo pinargoteNo ratings yet

- Resumen Lubricantes Industrial PDVDocument1 pageResumen Lubricantes Industrial PDVhugo pinargoteNo ratings yet

- Brugaoil 11744Document1 pageBrugaoil 11744hugo pinargoteNo ratings yet

- Resumen Lubricantes Transmision PDVDocument1 pageResumen Lubricantes Transmision PDVhugo pinargoteNo ratings yet

- Resumen Lubricantes Motor PDVDocument1 pageResumen Lubricantes Motor PDVhugo pinargoteNo ratings yet

- Resumen Grasas PDVDocument1 pageResumen Grasas PDVhugo pinargoteNo ratings yet