Professional Documents

Culture Documents

Leandro - 2024

Uploaded by

brunobitencortesdasilvaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Leandro - 2024

Uploaded by

brunobitencortesdasilvaCopyright:

Available Formats

RESEARCH ARTICLE

www.starch-journal.com

Morphological and Physicochemical Properties of Pine Seed

Starch Nanoparticles

Gabriel Coelho Leandro, Karina Cesca, Alcilene Rodrigues Monteiro,

and Germán Ayala Valencia*

formulations are constantly searching for

This study aims to characterize pine starch (PS) and pine starch nanoparticles new sources of natural starches, as well as

(PSNPs) produced by anti-solvent precipitation (ASP). PS and PSNPs are new technologies that may lead to products

characterized by particle size, surface charge, morphology, crystalline with better stability under their shelf life. In

structure, chemical bonds, thermal properties, moisture content (MC), water this way, new starches isolated from uncon-

ventional sources as well as new technolo-

activity, solubility in water (SW), swelling factor (SF), water and oil absorption,

gies used to modified starch properties have

and stability in water. PS shows typical starch particle size distribution, while been investigated in recent years.[2,9]

PSNPs display a size distribution varying between 230 and 1300 nm. The The Araucaria angustifolia conifer is a

crystalline structure is modified from A-type structure (native starch) to V6h pine tree widely distributed in the native

structure (PSNPs) after ASP. PSNPs SW at 25 and 90 °C, as well as oil and forests in the southern and southeastern

Brazil.[10,11] Pine seeds are harvested from

water absorption capacities are greatly improved when compared with PS.

April to August, and they are considered a

Furthermore, PSNPs have high stability in water at 25 °C, forming rich source of starch which is isolated from

homogeneous dispersions. This research provides information about the the endosperm of this seed (Figure 1). In

valorization of pine seed as a possible starch source to produce nanoparticles this way, some research studies have been

carried out to isolate and characterize the

physicochemical properties of pine starch

(PS), being concluded that PS has compara-

1. Introduction ble thermal and rheological properties that

those informed in conventional starches,

Starch is a natural carbohydrate considered one of the most as well as low tendency to retrogradation when used in food

abundant in the nature, this macromolecule is most common in formulations.[10–14] Furthermore, the valorization of pine seeds

tubers, roots, and grains.[1,2] Starches are frequently used in food has been considered an alternative to add value to this uncon-

formulations as thickener and bulking ingredients, as well as ventional starch source and reduce its deforestation.[11]

gelling agents, since starches can generate viscous dispersions, In recent years, the production of starch nanomaterials has

solutions, or gels, depending on their botanical origin, concen- been explored due to the different physicochemical proper-

tration, and temperature conditions.[3] The food industry mainly ties of these nanostructures when compared with their native

has focused on the application of starches isolated from corn, counterparts.[15–18] In this way, starch nanoparticles produced

cassava, potato, wheat, and rice due to their physicochemical by anti-solvent precipitation (ASP) have unique physicochemical

properties such as low temperature gelatinization, high peak properties, since these nanomaterials have amorphous structure,

viscosity, and excellent gelling properties.[4–8] no thermal transition associated with starch gelatinization, and

Although starches are broadly used in the food industry, this high water solubility and stability at 25 °C.[15,19] To date, no study

macromolecule is not soluble in water at room temperature. In has produce PS nanoparticles by ASP, the use of PS to produce

addition, many starches produce weak-bodied and undesirable starch nanoparticles by ASP could be an alternative to add value

gels when cooked which are impacted negatively by temperature, to this seed, as well as to increase the food applications of this

relative humidity (RH), and storage time as a consequence of unconventional starch. Hence, this research aims to produce and

the retrogradation process.[9] Industries that use starch in food characterize pine starch nanoparticles (PSNPs) obtained by ASP.

G. C. Leandro, K. Cesca, A. R. Monteiro, G. A. Valencia

2. Results and Discussions

Department of Chemical and Food Engineering 2.1. Nanoparticle Production Yield (NPY)

Federal University of Santa Catarina

Florianópolis, SC Brazil

E-mail: g.ayala.valencia@ufsc.br NPY was 84.44% ± 2.12%, value comparable to those informed

in nanoparticles produced with cassava (90.35% ± 3.93%)

The ORCID identification number(s) for the author(s) of this article and potato (83.96% ± 3.81%) starches.[16] Based on the NPY

can be found under https://doi.org/10.1002/star.202200225 value, it is possible to suggest PS as a starch source to produce

DOI: 10.1002/star.202200225 nanomaterials by ASP. However, the reduced harvest season

Starch - Stärke 2024, 76, 2200225 2200225 (1 of 7) © 2023 Wiley-VCH GmbH

www.advancedsciencenews.com www.starch-journal.com

Figure 1. Illustration of pine seed.

Figure 2. Scanning electron micrographs of pine starch (PS) and pine starch nanoparticles (PSNPs).

(between April and August) is the main factor limiting its food

application.[10,11]

2.2. Morphology, Particle Size Distribution, and Surface Charge

Scanning electron micrographs (SEM) of PS revealed the pres-

ence of starch granules with rounded and oval shapes (Figure 2a).

These PS granules have smooth surfaces without fractures and

irregularities which could be a consequence of the use of mild

physical operations such as slicing, grinding, drying, and siev-

ing, not capable of causing changes on the starch granule during

the production process.[28] The same morphology was informed

in the literature for PS.[10,29] In contrast, PSNPs showed aggre-

gates at the microscale with particle shape and size not defined at

5000× magnification (Figure 2b). Aggregates of starch nanopar-

ticles with similar morphology were observed in SEM images by Figure 3. Particle size distribution of pine starch (PS) and pine starch

Chacon et al.[19] nanoparticles (PSNPs).

PS displayed monomodal distribution with particle sizes os-

cillating between 8 and 27 μm (Figure 3). According to the liter-

ature, the average particle size of PS oscillates between 11 and

17 μm.[10,14] After ASP, the obtained materials also showed a

monomodal distribution with particle sizes varying between 230

and 1300 nm (Figure 3), confirming the nanometric scale of the Finally, the surface charge of PS and PSNPs was analyzed aim-

materials obtained by ASP. In the literature, starch nanoparticles ing to understand the stability of these materials when dispersed

obtained by ASP have a similar particle size, however, bimodal in water at pH 6. PS has a negative charge (−33.73 ± 2.78 mV) typ-

particle size distributions have been informed.[15,16,30] Discrep- ical of native starches.[30] A reduction in the surface charge was

ancies in the particle size distribution could be credited to the constated in PSNPs (−9.25 ± 0.83 mV) due to the remotion of

constant velocity of the antisolvent used in the current research negative charges in PS during ASP.[16,30] Therefore, dispersions

(see Section 2.1), allowing to obtain PSNPs with monomodal dis- of PS and PSNPs, both at pH 6, can be classified as moderately

tribution. and low stables in water at pH 6, respectively.

Starch - Stärke 2024, 76, 2200225 2200225 (2 of 7) © 2023 Wiley-VCH GmbH

www.advancedsciencenews.com www.starch-journal.com

Figure 4. X-ray diffractograms a) and Fourier-transform infrared spectra b) of pine starch (PS) and pine starch nanoparticles (PSNPs).

2.3. Moisture Content and Water Activity differences could be correlated with the RC values in the native

starches, hence, the RC values of cassava (22%) and potato (15%)

PS had a moisture content (MC) of 21.33% ± 1.32% when con- starches were higher when compared with PS (9.2% ± 0.2%).[16]

ditioned under 58% RH, this value is in agreement with MC val- From a technological viewpoint, amorphous starch nanoparti-

ues informed for the same starch stored in similar RH.[31] A re- cles are desired since these materials can be dispersed in water

duction in the MC (15.29% ± 1.48%) was observed in PSNPs at room temperature and they are applied in food formulations

and could be correlated with the amorphization of PS during sensitive to heat.[19] In this way, native PS could be considered

ASP.[30] as a potential source to produce starch nanomaterials since this

PS and PSNPs conditioned at 58% RH had intermediate aw starch has a low RC value.

values, oscillating between 0.61 and 0.62 in both samples, which Images from polarized light confirmed the crystalline struc-

are typical of biological stable materials.[32] Starch nanoparticles ture of PS since the Maltese cross located at the center of each

with lower aw (0.16–0.39) values have been informed in the granule (image inserted in Figure 4a) was observed. PSNPs did

literature, however, these nanomaterials have been conditioned not have a maltase-cross confirming the amorphous structure of

in RH < 10%.[15] Based on MC and aw results, PS and PSNPs these materials (results not shown).

can be classified as products which are not susceptible to Seven peaks typical of amylaceous materials were observed

microorganism growth when stored at 58% RH.[32] in Fourier transform infrared spectra (FTIR) of PS and PSNPs

(Figure 4b). Vibration of –OH and C–H groups were detected at

3440 and 2921 cm−1 , respectively. The vibration of –OH groups

2.4. Crystalline Structure and Chemical Bonds associated to absorbed water molecules on the materials was ob-

served at 1649 cm−1 . Other bands centered at 1158, 1082, 1000,

Diffraction peaks centered at 15° (d = 0.59 nm), 17° (d = and 928 cm−1 were correlated with the CO bonds stretching of

0.52 nm), 18° (d = 0.49 nm), and 23° (d = 0.39 nm) were ob- carbohydrates, stretching of C=O groups, intramolecular hydro-

served in the XRD diffractogram of PS (Figure 4a), and correlated gen bonding of the hydroxyl groups at C-6, and symmetric elon-

with the presence of A-type crystalline structure in the starch gation of C–O–C groups, respectively (Figure 4b).[16] FTIR of

granules. Furthermore, PS has amylose–lipid complex since a PSNPs showed a decrease in the peak centered at 1649 cm−1 , sug-

small peak centered at 20° (d = 0.44 nm) was observed in the gesting that this material has less water molecules hydrating its

same diffractogram (Figure 4a).[28] The relative crystallinity (RC) structure when compared to PS. FTIR results confirmed no for-

value of PS was 9.2% ± 0.2%, suggesting that this starch has mation of new chemical bonds during the production of PSNPs

low crystallinity. XRD results for PS are in accordance with the by ASP.

literature.[10,14]

After ASP, the obtained nanomaterials displayed V6h -type crys-

talline structure with a small diffraction peak at 13° (d = 0.68 nm) 2.5. Thermal Properties

and a halo centered at 20° (d = 0.44 nm) (Figure 4a). The V6h -type

crystalline structure is composed of six glucose units per helical Thermal properties were investigated in the temperature range of

turn and it has been observed in starch nanoparticles produced −30 and 95 °C. PS suspensions in water exhibited an endother-

by ASP.[15,16,30] Furthermore, the RC in PSNPs was 1.6% ± 0.2%, mic peak associated with the starch gelatinization, this thermal

being lower when compared with starch nanoparticles produced transition had onset, peak, and conclusion temperatures of 56.68

from cassava (RC ≥ 5.7%) and potato (RC ≥ 4.8%) starches. These ± 0.76, 60.40 ± 0.15, and 64.34 ± 1.24 °C, respectively, as well as

Starch - Stärke 2024, 76, 2200225 2200225 (3 of 7) © 2023 Wiley-VCH GmbH

www.advancedsciencenews.com www.starch-journal.com

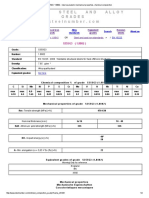

Table 1. Solubility in water (SW), swelling factor (SF), oil absorption capacity (OAC), and water absorption capacity (WAC) of pine starch (PS) and pine

starch nanoparticles (PSNPs).

Sample 25 °C OAC [g g−1 ] WAC [g g−1 ]

SW [%] SF SW [%] SF

PS 4.00 ± 3.61Aa 2.62 ± 0.12Aa 35.50 ± 6.37Ab 39.85 ± 3.11Ab 1.10 ± 0.08A 1.62 ± 0.12A

PSNPs 51.67 ± 4.04Ba 5.21 ± 1.35Aa 83.33 ± 1.53Bb 12.37 ± 1.40Bb 1.82 ± 0.13B 4.21 ± 1.35B

Means within the same column followed by different capital letters are significantly different (p < 0.05) for the same property (SW or SF) and temperature. Means within the

same row followed by different lowercase are significantly different (p < 0.05) for the same material (PS or PSNPs) and same property (SW or SF) at different temperatures.

absorption.[22] Based on SW values, PS can be classified as insol-

uble at 30 °C and slightly soluble at 90 °C.[33] In the literature,

few studies have informed SW and SF of PS. Low SW is a factor

limiting the application of PS in food formulations.

In contrast, PSNPs showed intermediate and high SW at 25

and 90 °C, respectively (Table 1). However, the same nanomate-

rial had low SF due to the chain modification during ASP. In this

way, PSNPs did not swell because these samples had high SW.

SW and SF of PSNPs are in concordance with those informed by

Alves et al.[16] and Chacon et al.[19] SW and SF are important pa-

rameters aiming the starch food applications. Therefore, PSNPs

can be considered a promissory ingredient in food formulations

since this nanomaterial has better SW than PS.

2.7. Oil (OAC) and Water Absorption (WAC) Capacities

Figure 5. Differential scanning calorimetry thermograms (between 30 and

70 °C) of hydrated pine starch (PS) and hydrated pine starch nanoparticles OAC and WAC were investigated at 25 °C due to the acceptable

(PSNPs). SW values of PSNPs at the same temperature. OAC and WAC

represent the ability of PS and PSNPs to associate with oil and

an enthalpy of gelatinization (ΔHgel ) oscillating between 5.17 and water under limited availability of these fluids. In general, PS had

9.96 J g−1 of dry PS (Figure 5). No thermal event associated to the low retention of oil and water molecules at 25 °C due to the in-

starch phase transition were observed in the temperature range termolecular hydrogen bonds between amylose and amylopectin

of −30 and 30 °C, as well as between 80 and 95 °C (not shown). in the starch granule (Table 1).[37] However, OAC and WAC in-

In the current research, all values correlated with the starch gela- creased in 259% and 165% in PSNPs when compared with PS

tinization are in concordance with those informed in the liter- due to the amorphization of the starch granules during ASP. To

ature for PS.[10,33] Comparing with conventional starches, corn, date, no study has informed OAC and WAC values for PS and

cassava, and potato starches have thermal transition oscillating starch nanomaterials.

between 52 and 80 °C, and ΔHgel values varying between 11 and

18 J g−1 .[34–36] Low ΔHgel values suggest that less energy is neces-

2.8. Stability in Water

sary to gelatinized starch granules during heating. Hence, pine

seeds can be considered a promissory starch source to produce

Dispersions of PS displayed clear precipitation in the first 30 min

nanomaterials.

of analysis (Figure 6), with some particles remaining suspended

PSNPs suspensions did not have any thermal transition con-

in the supernatant. All the dispersed PS was decanted after 5 h

firming the amorphous structure of this nanomaterial.[16] The ab-

(300 min) to the bottom of the test tube. This behavior is due

sence of thermal transition associated to the starch gelatinization

to the starch retrogradation which takes place when starches are

in PSNPs indicates that this material does not need to be heated

stored below its gelatinization temperature. Starch retrograda-

to solubilize in water.

tion is a serious problem in the food industry because it is asso-

ciated which phase separation and syneresis in food products.[19]

2.6. Solubility in Water (SW) and Swelling Factor (SF) No precipitation was observed during 5 h at room temperature

for PSNPs, with dispersions remaining homogenous when com-

PS had low SW and SF values at 25 °C indicating that this ma- pared to PS dispersions (Figure 6). A similar result was observed

terial is not water soluble at this temperature. The insolubility of by Chacon et al.[19] in starch nanoparticles produced with potato

native PS granules in cold water has been previously reported.[33] starch by ASP. The high stability in water of PSNPs can be due

SW and SF values of PS increased with heating at 90 °C due to to the small particle size and the high proportion of hydroxyl

the breaking of intermolecular hydrogen bonds in amorphous ar- groups in PSNPs which allow its solubility and stability in water

eas (Table 1), thus permitting irreversible and progressive water at 25 °C. Based on stability in water values, PSNPs could be

Starch - Stärke 2024, 76, 2200225 2200225 (4 of 7) © 2023 Wiley-VCH GmbH

www.advancedsciencenews.com www.starch-journal.com

Figure 6. Stability in water of pine starch (PS) and pine starch nanoparticles (PSNPs) as a function of time.

applied as an ingredient in food formulations which are prepared mechanical agitator (300 rpm). In sequence, acidified ethanol (100:1 v/v,

at room temperature (e.g., soups and sauces) in the food industry. ethanol to HCl) was added dropwise to the gelatinized starch at a rate of

0.77 mL min−1 while being kept under agitation at 300 rpm.

The resulting mixture was kept under agitation by means of a mag-

netic stirrer for 12 h before being centrifuged at 4000 rpm for 15 min.

3. Conclusions Then, PSNPs were kept at 30 °C for 24 h in order to evaporate the ethanol

and afterwards freeze dried (Liotop L101, Brazil) for 24 h. The result-

In this research, PS was used to produce nanomaterials by ASP. ing PSNPs were macerated and stored in desiccators with silica gel until

The transformation of PS to PSNPs had a high production yield analysis (RH ≤ 0%). The NPY (%) was calculated using Equation (1):

(84.44% ± 2.12%). PSNPs displayed monomodal particle size dis-

tribution with particle sizes oscillating between 230 and 1300 nm, mf

NPY = 100 × (1)

surface charge of −9.25 ± 0.83 mV, and amorphous structure. mi

Furthermore, PSNPs showed a higher SW at 25 and 90 °C, as where mf is the final mass obtained after freeze drying (g) and mi is the

well as higher oil and water absorption capacities at 25 °C when mass of starch at the beginning of the process (g).

compared with PS. Although PSNPs had low surface charge, Starch extraction from pine seeds and the production of PSNPs were

this nanomaterial had a high stability when dispersed in water carried out in triplicate.

(30% w/v) at 25 °C. Thus, PSNPs could be used as an additive in Morphology, Particle Size Distribution, and Surface Charge: The mor-

food formulations and as an adsorbent for both hydrophilic and phology of PS and PSNPs was analyzed using scanning electron mi-

croscopy (SEM, JSM-6390LV, JEOL, Japan) at accelerating voltage of 10 kV.

hydrophobic molecules.

Powders were fixed on aluminum stubs by carbon tape and then coated

with a thin gold layer before SEM analyses. Five micrographs were taken

at random sample spots with 1000× and 5000× magnification.[19]

4. Experimental Section Particle size distribution and mean particle size of PS was calculated

by dispersing samples in glycerol 50% (w/w, glycerol to H2 O) over mi-

Production of Starch Nanoparticles and Nanoparticle Production Yield: croscope slides and covering with coverslips. The diameter of 145 starch

Starch was isolated from pine seeds following Costa et al.[20] methodology granules were measured using a light microscope (L-2000a , Bioval, Brazil)

with slight modifications. Seeds were cut longitudinally and transversally with the aid of the software Image J, v1.53k (National Institute Health,

in order to remove the exterior peel and then mixed with distilled water in Bethesda, MD, USA).[21]

a 1:2 (w/w, peeled seed to H2 O) proportion using a blender. The formed PSNPs size distribution was carried out using a LUMiSizer (LUM

slurry was filtered using a cloth filter followed and afterwards mixed with GmbH, Germany). PSNPs (0.01 g) were dispersed in 10 mL of ethanol

distilled water in a 1:1 (w/w slurry to H2 O) proportion before being filtered and sonicated for 5 min prior to analysis.[22]

again. The permeate of both filtrations was kept in a refrigerator at 4 °C Surface charge of samples was analyzed using a Zetasizer Nano ZS

for 24 h in order to precipitate the starch. The decanted material was later (Malvern, England). PS and PSNPs were dispersed in deionized water

separated from the supernatant and washed with distilled water once be- (0.01% w/v) and then their pH were adjusted to 6 and sonicated for 30 min

fore being one more time decanted, separated, and dried in a convective prior to analysis.[23]

oven at 30 °C. The dried starch was then milled and stored in desiccators Moisture Content and Water Activity: PS and PSNPs were kept in desic-

until analysis. cators with RH of 58% during 7 days prior to analysis. MC (g of water g−1

PSNPs were produced by ASP as described by Alves et al.[15] with slight of sample) was measured by heating samples to 120 °C using a moisture

modifications. Firstly, 2.5 g of PS were dispersed in 50 mL of distilled wa- analyzer (MOC63u, Shimadzu, Japan). Water activity (aw , dimensionless)

ter and hydrated for 30 min before being agitated with a mechanical ag- was analyzed using a water activity analyzer (AquaLab 4TE, METER Group,

itator (300 rpm) at 90 °C for 30 min to achieve the starch gelatinization. USA).[19]

Afterwards, the evaporated water was added to the slurry to guarantee the Crystalline Structure and Chemical Bonds: The crystalline structure of

starch concentration and then cooled to room temperature using the same PS and PSNPs was analyzed using an X-ray diffractometer (XRD, Rigaku

Starch - Stärke 2024, 76, 2200225 2200225 (5 of 7) © 2023 Wiley-VCH GmbH

www.advancedsciencenews.com www.starch-journal.com

MiniFlex600, Japan), operating at 40 kV and 15 mA (CuK𝛼 1 𝜆 = 1.54056 Å WAC (g of water g−1 of sample, d.b.) was performed similarly to OAC,

radiation). The diffractograms were recorded at 20 °C, between 2𝜃 = 5° with water being used in place of oil.[27] However, the WAC was calculated

and 50°, at 1° min−1 with a step size of 0.02°.[24] The interplanar distance d using Equation (7):

(nm) was calculated from the diffraction angle at the maximum intensity of

the peak found in the XRD diffractograms and using Equation (2) (Brag’s Sd − (Si − Sr )

WAC = (7)

law): S i − Sr

where Sr is the mass of sample that was solubilized (g).

N𝜆 = 2dsin (𝜃) (2)

Stability in Water: The stability of PS and PSNPs in water was studied

by dispersing samples in distilled water (30% w/v) at 25 ± 1 °C. Disper-

where 𝜆 is the wavelength (nm), and N is the reflection order (N = 1, sions were mixed in a vortex for 5 min, and then the sedimentation process

dimensionless). was studied during 5 h at the same temperature.[19]

The RC (%) of PS and PSNPs was calculated by measuring the crys- Statistical Analyses: All the tests were performed at least in triplicate

talline and total area of the X-ray diffractograms obtained for samples by for each sample, and the results were expressed as means ± standard de-

means of Equation (3)[25] : viation (n ≥ 3). Analysis of variance (ANOVA) and Tukey test of multiple

comparisons were accomplished at 5% significance level using the soft-

ware OriginPro 2018® .

Ac

RC = 100 × (3)

At

Acknowledgements

where Ac is the peak area, or crystalline area, and At is the total area.

The crystallinity of the samples was also analyzed under polarized light. The authors are grateful to the Fundação de Amparo à Pesquisa e In-

Samples of PS and PSNPs were dispersed in glycerol 50% (w/w, glycerol ovação do Estado de Santa Catarina (FAPESC) for the MsC fellowship

to H2 O) over microscope slides and covered with a coverslip. Samples (48/2021) of the first author. G. A. V. would like to thank the FAPESC

were photographed using a polarizing light microscope (ML-9400, Meiji, (grants 2021TR000418 and 2021TR001887) and National Council for Sci-

Japan) with 100× and 200× magnification.[21] entific and Technological Development (CNPq) (grant 302434/2022-4) for

The chemical bonds of PS and PSNPs were analyzed by means of financial support. Furthermore, the authors gratefully acknowledge the

Fourier-Transform Infrared Spectroscopy (FTIR, Cary 660, Agilent, USA). Federal University of Santa Catarina for its support, as well as to the Central

Analyses were performed in the infrared region between 4000 and Laboratory of Electronic Microscopy (LCME) and Interdisciplinary Labora-

400 cm−1 using 4 cm−1 resolution with 20 scans and KBr pellets.[26] tory for Nanostructures Development (LINDEN) for the analyses.

Thermal Properties: Thermal properties of the samples were analyzed

by differential scanning calorimetry (DSC, Jade, Perkin Elmer, USA). Ap-

proximately 3 mg (d.w.) of the samples were dispersed in distilled in a

1:2 (w/w, sample to H2 O) proportion in aluminum pans, sealed with alu-

Conflict of Interest

minum caps and kept hydrating in for 1 h.[16] Afterwards, hydrated sam- The authors declare no conflict of interest.

ples were heated from −30 to 95 °C at 10°C min−1 in two-cycle mode.

Nitrogen (N2 ) was used as flushing gas at 45 mL min−1 and an empty

aluminum pan was used as reference.

Solubility in Water and Swelling Factor: For solubility (SW, %) and SF Data Availability Statement

(dimensionless), samples of PS and PSNPs (W) were dispersed in distilled The data that support the findings of this study are available from the cor-

water (1% w/v, sample to H2 O, d.b.), heated at 25 and 90 °C for 30 min and responding author upon reasonable request.

mixed for 10 s in a vortex every 10 min. Samples were cooled down to room

temperature and centrifuged at 4000 rpm for 15 min. The supernatant was

separated and dried at 105 °C in order to obtain the dry mass (Wr ). The

slurry that remained in the tubes was weighted (Wt ) and then SP and S Keywords

were calculated using Equations (4) and (5), respectively.[22]

alternative starch sources, anti-solvent precipitation method, carbohy-

drate nanoparticles, physicochemical properties

Wt

SF = (4)

W − Wr Received: October 13, 2022

Revised: January 30, 2023

Wr Published online: April 29, 2023

S = 100 × (5)

W

Oil and Water Absorption Capacities: OAC (g of oil g−1 of sample, d.b.)

essays were performed by dispersing samples in soybean oil (1% w/v, sam- [1] W. D. C. Chacon, G. A. Valencia, G. M. A. Rojas, A. C. A. Henao,

ple to oil, d.b.) followed by heating at 25 °C for 30 min. The samples were Starch/Stärke 2019, 1800081.

mixed for 10 s in a vortex every 10 min. Samples were cooled down to [2] H. A. Makroo, S. Naqash, J. Saxena, S. Sharma, D. Majid, B. N. Dar,

room temperature and centrifuged at 4000 rpm for 15 min. The super- Appl. Food Res. 2021, 1, 100001.

natant was separated and samples were left draining for 25 min and then [3] C. G. Luciano, G. A. Valencia, O. H. Campanella, P. J. D.oA. Sobral, I.

weighted (Sd , g).[27] The OAC was calculated using Equation (6): C. F. Moraes, Food Biophys. 2018, 13, 155.

[4] J. Chen, Y. Chen, H. Ge, C. Wu, J. Pang, S. Miao, Food Hydrocoll. 2019,

89, 885.

Sd − S i

OAC = (6) [5] A. K. Siroha, S. Punia, M. Kaur, K. S. Sandhu, Int. J. Biol. Macromol.

Si 2020, 143, 984.

[6] S. A. Mir, S. J. D. Bosco, M. Bashir, M. A. Shah, M. M. Mir, Int. J. Food

where Si is the initial sample mass (g, d.w.). Prop. 2017, 20, 821.

Starch - Stärke 2024, 76, 2200225 2200225 (6 of 7) © 2023 Wiley-VCH GmbH

www.advancedsciencenews.com www.starch-journal.com

[7] S. Li, H. Liu, Q. Zheng, N. Hu, M. Zheng, J. Liu, Starch/Stärke 2022, [22] G. Ayala Valencia, I. C. Freitas Moraes, R. Vinicius Lourenço, A. M. Q.

74, 2100254. Barbosa Bittante, P. J. Do Amaral Sobral, Int. J. Food Prop. 2015, 18,

[8] C. E. Chinma, C. C. Ariahu, J. O. Abu, J. Food Sci. Technol. 2013, 50, 1990.

1179. [23] M. Ahmad, P. Mudgil, A. Gani, F. Hamed, F. A. Masoodi, S. Maqsood,

[9] M. J. D. S. Alves, W. D. C. Chacon, T. R. Gagliardi, A. C. Agudelo Food Chem. 2019, 270, 95.

Henao, A. R. Monteiro, G. Ayala Valencia, Starch/Stärke 2021, 73, [24] L. Do Prado Cordoba, L. S. Ribeiro, L. S. Rosa, L. G. Lacerda, E. Schnit-

2100046. zler, Thermochim. Acta 2016, 642, 45.

[10] P. S. Hornung, S. Rosa Da Silveira Lazzarotto, M. B. Bellettini, M. [25] S. Nara, T. Komiya, Starch/Stärke 1983, 35, 407.

Lazzarotto, T. Beta, R. H. Ribani, E. Schnitzler, Starch/Stärke 2019, [26] G. Coelho Leandro, C. Capello, B. Luiza Koop, J. Garcez, A. R. Mon-

71, 1800140. teiro, G. A. Valencia, Food Res. Int. 2021, 109903, 109903.

[11] V. Z. Pinto, N. L. Vanier, B. Klein, E. d. R. Zavareze, M. C. Elias, L. C. [27] M. J. Y. Lin, E. S. Humbert, F. W. Sosulski, J. Food Sci. 1974, 39,

Gutkoski, E. Helbig, A. R. G. Dias, Starch–Stärke 2012, 64, 855. 368.

[12] L. Costa De Conto, M. S. V. Plata-Oviedo, C. Joy Steel, Y. K. Chang, [28] G. A. Valencia, I. C. F. Moraes, R. V. Lourenço, A. M. Q. B. Bittante, P.

Starch–Stärke 2011, 63, 198. J. d. A. Sobral, Starch/Stärke 2015, 67, 163.

[13] M. E. B. Zortéa-Guidolin, I. M. Demiate, R. C. B. de Godoy, A. d. P. [29] P. M. Gonçalves, C. P. Z. Noreña, N. P. Da Silveira, A. Brandelli, LWT

Scheer, D. Grewell, J. L. Jane, S. Food Hydrocoll. 2017, 63, 19. – Food Sci. Technol. 2014, 58, 21.

[14] C. Beninca, R. A. Barboza, C. S. De Oliveira, C. D. Bet, R. Z. B. [30] K. T. Dos Santos Lima, J. Garcez, M. J. Dos Santos Alves, A. R. Mon-

Bisinella, E. Schnitzler, Starch/Stärke 2019, 71, 1800290. teiro, G. A. Valencia, M. Jaízia dos Santos Alves, Starch–Stärke 2021,

[15] M. Jaízia dos Santos Alves, A. Rodrigues Monteiro, G. Ayala Valencia, 2000221. https://doi.org/10.1002/star.202000221

Starch/Stärke 2022, 2100289. [31] R. C. S. Thys, C. P. Z. Noreña, L. D. F. Marczak, A. G. Aires, F. Cladera-

[16] M. J. Dos Santos Alves, P. M. Calvo Torres De Freitas, A. R. Monteiro, Olivera, J. Food Eng. 2010, 100, 468.

G. Ayala Valencia, Starch–Stärke 2021, 73, 2100034. [32] A. H. Al-Muhtaseb, W. A. M. McMinn, T. R. A. Magee, Food Bioprod.

[17] Q. Sun, Starch Nanoparticles, Elsevier Ltd. Netherlands 2018. Process 2002, 80.

[18] M. Ahmad, A. Gani, I. Hassan, Q. Huang, H. Shabbir, Sci. Rep. 2020, [33] R. M. Daudt, I. C. Külkamp-Guerreiro, F. Cladera-Olivera, R. C. S.

10, 3533. Thys, L. D. F. Marczak, Ind. Crops Prod. 2014, 52, 420.

[19] W. D. C. Chacon, K. T. Dos Santos Lima, G. A. Valencia, A. C. A. [34] K. Alvani, X. Qi, R. F. Tester, C. E. Snape, Food Chem. 2011, 125, 958.

Henao, Starch–Stärke 2021, 73, 2000086. [35] C. Chatpapamon, Y. Wandee, D. Uttapap, C. Puttanlek, V.

[20] F. J. O. G. Costa, J. M. C. Couto, N. Waszczynskyj, R. C. B. Godoy, C. Rungsardthong, Carbohydr. Polym. 2019, 215, 338.

W. P. Carvalho, E. H. M. Walter, Comun Técnico, Embrapa 2014, 4p. [36] G. Ayala Valencia, M. Djabourov, P. J. Do Amaral Sobral, Carbohydr.

[21] D. Perez-Rea, C. Rojas, S. Carballo, W. Aguilar, B. Bergenståhl, L. Nils- Polym. 2016, 147, 533.

son, Starch–Stärke 2013, 65, 151. [37] S. Baraheng, T. Karrila, Food Biosci. 2019, 30, 100412.

Starch - Stärke 2024, 76, 2200225 2200225 (7 of 7) © 2023 Wiley-VCH GmbH

You might also like

- Naming Chemical Compounds WorksheetDocument4 pagesNaming Chemical Compounds WorksheetSam Jo100% (1)

- Industrial Waste Water TreatmentDocument303 pagesIndustrial Waste Water Treatmentharis_penaberkarya100% (19)

- EPA Corrosion ManualDocument141 pagesEPA Corrosion Manualnert100% (1)

- Peter The Penguin Rattle Pattern by Yarn WaveDocument5 pagesPeter The Penguin Rattle Pattern by Yarn WaveArnaud Gdn100% (3)

- BQ - Pedestrian BridgeDocument25 pagesBQ - Pedestrian Bridgemarzuki0202No ratings yet

- Fischer Tropsch SynthesisDocument18 pagesFischer Tropsch Synthesisdeion29No ratings yet

- 2023-Mejo-Encapsulation of Rutin in Pickering Emulsions StabilizedDocument14 pages2023-Mejo-Encapsulation of Rutin in Pickering Emulsions StabilizedDelfina FariasNo ratings yet

- Zhang2017 PDFDocument7 pagesZhang2017 PDFEsther N. NinaNo ratings yet

- Xiao 2020Document9 pagesXiao 2020Joluis CcanahuireNo ratings yet

- Food Research International: Yun Wang, Genyi ZhangDocument12 pagesFood Research International: Yun Wang, Genyi Zhangyoiber jimenezNo ratings yet

- Lafuente 2019Document8 pagesLafuente 2019..........................No ratings yet

- 10 1016@j Foodhyd 2015 01 026Document12 pages10 1016@j Foodhyd 2015 01 026Linda Flor De Maria Cuevas PalenciaNo ratings yet

- Barros Et Al., 2020Document8 pagesBarros Et Al., 2020Ousadia VendasNo ratings yet

- Foods 11 01966 PDFDocument13 pagesFoods 11 01966 PDFKibangula BusiboNo ratings yet

- Gupta 2011Document9 pagesGupta 2011Métodos Modernos SensorialesNo ratings yet

- Properties of Baked Foams From Citric Acid Modified Cassava Starchand Native Cassava Starch BlendsDocument6 pagesProperties of Baked Foams From Citric Acid Modified Cassava Starchand Native Cassava Starch BlendsShamir Jose ContrerasNo ratings yet

- Modification of Cassava Starch For Industrial Uses: ArticleDocument8 pagesModification of Cassava Starch For Industrial Uses: ArticleAnnisa Rizki SesariNo ratings yet

- Compozitie Chimica Faian de ArorutDocument5 pagesCompozitie Chimica Faian de ArorutDana StoinNo ratings yet

- Nanostructure Morphology and Functionality of Cassava Starch 2016 Food HydrDocument12 pagesNanostructure Morphology and Functionality of Cassava Starch 2016 Food HydrLICET VANESSA DURANGO CASTILLANo ratings yet

- 10 1016@j Ijbiomac 2019 07 074Document9 pages10 1016@j Ijbiomac 2019 07 074Sthefany OteroNo ratings yet

- J.ijbiomac.2021.05.144 Musaparadisica 2021Document9 pagesJ.ijbiomac.2021.05.144 Musaparadisica 2021deepan kumarNo ratings yet

- Emulsifying Properties of Chickpea, Faba Bean, Lentil and Pea Proteins Produced by Isoelectric Precipitation and Salt ExtractionDocument9 pagesEmulsifying Properties of Chickpea, Faba Bean, Lentil and Pea Proteins Produced by Isoelectric Precipitation and Salt ExtractionMinh DuyNo ratings yet

- Characterisation of Sago Pith Waste and Its Composites: Industrial Crops and ProductsDocument8 pagesCharacterisation of Sago Pith Waste and Its Composites: Industrial Crops and ProductsHadi Iz'aanNo ratings yet

- 1 s2.0 S0928493116316320 MainDocument9 pages1 s2.0 S0928493116316320 MainJuGuerra86No ratings yet

- Mathematical Tools For Objective Comparison of Microbial Cultures Application To Evaluation of 15 Peptones For Lactic Acid Bacteria ProductionsDocument12 pagesMathematical Tools For Objective Comparison of Microbial Cultures Application To Evaluation of 15 Peptones For Lactic Acid Bacteria ProductionsAlex CárdenasNo ratings yet

- Dias 2010Document7 pagesDias 2010Sol AngelNo ratings yet

- 1 s2.0 S0733521016305471 MainDocument7 pages1 s2.0 S0733521016305471 MainMonicah MarikaNo ratings yet

- 1 s2.0 S0141813021025605 MainDocument11 pages1 s2.0 S0141813021025605 MainHanan AqoubNo ratings yet

- Carbohydrate PolymersDocument9 pagesCarbohydrate PolymersaaronNo ratings yet

- Sri Chu Wong 2012Document5 pagesSri Chu Wong 2012shanifahnNo ratings yet

- Caracterización Reológica de Mezclas de Nanopartículas de Goma y AlmidónDocument28 pagesCaracterización Reológica de Mezclas de Nanopartículas de Goma y AlmidónALBERTO LUIS LIZCANO GONZALEZ ESTUDIANTENo ratings yet

- Polímeros Biodegradáveis - Estudos em FTIRDocument9 pagesPolímeros Biodegradáveis - Estudos em FTIRPedro MaravilhaNo ratings yet

- Ajas 25 9 1248 6Document7 pagesAjas 25 9 1248 6Mariam SharifNo ratings yet

- 1 s2.0 S2238785419308828 MainDocument12 pages1 s2.0 S2238785419308828 MainRio ArrayNo ratings yet

- Papa InvestigaciónDocument11 pagesPapa InvestigaciónChris GuzmanNo ratings yet

- (Jia Et Al., 2022) - Persimmon PectinDocument17 pages(Jia Et Al., 2022) - Persimmon PectinHerda CahyaningrumNo ratings yet

- 2014, Nesterenko Et Al, Encapsulation of Vitamins, SPI, AA, YODIMETRIADocument8 pages2014, Nesterenko Et Al, Encapsulation of Vitamins, SPI, AA, YODIMETRIAGREILIS QUINTERONo ratings yet

- Akpa 1Document7 pagesAkpa 1Whirl BambiNo ratings yet

- Pilot Scale Bioconversion of Rice and SuDocument9 pagesPilot Scale Bioconversion of Rice and SuPrassu SwtyNo ratings yet

- Food Chemistry: Fa-Xing Luo, Qiang Huang, Xiong Fu, Le-Xing Zhang, Shu-Juan YuDocument6 pagesFood Chemistry: Fa-Xing Luo, Qiang Huang, Xiong Fu, Le-Xing Zhang, Shu-Juan YuSamir Eduardo Suarez MendezNo ratings yet

- Timgren 2013Document15 pagesTimgren 2013Cukup BayuNo ratings yet

- Colussi Et Al. (2014) Physical, Mechanical, and Thermal Properties of Biodegradables Films of Rice StarchDocument9 pagesColussi Et Al. (2014) Physical, Mechanical, and Thermal Properties of Biodegradables Films of Rice StarchVania Zanella PintoNo ratings yet

- Potential 3D Filament of Janeng INHAME (Dioscorea Hispida Dennst) Starch 2024Document8 pagesPotential 3D Filament of Janeng INHAME (Dioscorea Hispida Dennst) Starch 2024rjan85No ratings yet

- Israkarn 2007Document9 pagesIsrakarn 2007Pedro MaldonadoNo ratings yet

- LWT - Food Science and TechnologyDocument7 pagesLWT - Food Science and TechnologyKeiidys MartinezNo ratings yet

- Food Hydrocolloids: in Vitro and in Vivo Digestibility From Bionanocomposite Edible Films BasedDocument14 pagesFood Hydrocolloids: in Vitro and in Vivo Digestibility From Bionanocomposite Edible Films BasedWilliam SeniorNo ratings yet

- De Campo 2017 - Microencapsulación Con Mucilago de ChiaDocument9 pagesDe Campo 2017 - Microencapsulación Con Mucilago de ChiaMich MbappéeNo ratings yet

- Solid State PharmaceuticsDocument6 pagesSolid State PharmaceuticsPrajyot SononeNo ratings yet

- Yunus 2014Document10 pagesYunus 2014La Ode Muhamad RusliNo ratings yet

- Dura Dan Rosell, 2016Document7 pagesDura Dan Rosell, 2016Fiyan Maulana RajendraNo ratings yet

- Food Chemistry: Miaomiao Shi, Zhiheng Zhang, Shujuan Yu, Kai Wang, Robert G. Gilbert, Qunyu GaoDocument7 pagesFood Chemistry: Miaomiao Shi, Zhiheng Zhang, Shujuan Yu, Kai Wang, Robert G. Gilbert, Qunyu GaoSNo ratings yet

- Carnauba Wax As A Wall Material For Urea Microencapsulation: Journal of The Science of Food and Agriculture July 2018Document11 pagesCarnauba Wax As A Wall Material For Urea Microencapsulation: Journal of The Science of Food and Agriculture July 2018Sue neklawiNo ratings yet

- Nanoencapsulation of Date Palm Pit Extract in Whey Protein Particles GeneratedDocument6 pagesNanoencapsulation of Date Palm Pit Extract in Whey Protein Particles GeneratedPublicaNo ratings yet

- All Rights Reserved Optimization of Starch Extraction From Amorphophallus PaeoniifoliusDocument19 pagesAll Rights Reserved Optimization of Starch Extraction From Amorphophallus PaeoniifoliusRohit LodhiNo ratings yet

- Physico Chemical Characterization of CheDocument9 pagesPhysico Chemical Characterization of CheNguyễn Thị VươngNo ratings yet

- Study of Protein Detection and Ultrastructure of Brazilian Rice Starch During Alkaline ExtractionDocument8 pagesStudy of Protein Detection and Ultrastructure of Brazilian Rice Starch During Alkaline ExtractionMatheus FerreiraNo ratings yet

- Physical Properties of Physico-Enzymatically ModifDocument11 pagesPhysical Properties of Physico-Enzymatically Modifatep dianNo ratings yet

- Cow Urine Powder TechnologyDocument8 pagesCow Urine Powder TechnologypriyaNo ratings yet

- Phospate 2Document11 pagesPhospate 2XX GUYNo ratings yet

- LWT - Food Science and TechnologyDocument4 pagesLWT - Food Science and Technologyrudi salamNo ratings yet

- Legumes Seeds Protein Isolates in The Production of Ascorbic Acid MicroparticlesDocument7 pagesLegumes Seeds Protein Isolates in The Production of Ascorbic Acid Microparticlesкатя калайдаNo ratings yet

- FromCelluloseNanospheresNanorodstoNanofibers VariousAspectRatioInducedNucleation ReinforcingEffectsonPolylacticAcidforRobust-BarrierFoodPackagingDocument20 pagesFromCelluloseNanospheresNanorodstoNanofibers VariousAspectRatioInducedNucleation ReinforcingEffectsonPolylacticAcidforRobust-BarrierFoodPackagingJakariya NugrahaNo ratings yet

- Romero-Hernadez 2021Document10 pagesRomero-Hernadez 2021Lorenth ArgüellesNo ratings yet

- Physicochemical and Disintegrant Properties of Sodium Carboxymethyl Starch Derived From Borassus Aethiopum (Arecaceae) ShootDocument9 pagesPhysicochemical and Disintegrant Properties of Sodium Carboxymethyl Starch Derived From Borassus Aethiopum (Arecaceae) ShootSamir Eduardo Suarez MendezNo ratings yet

- 2019-Journal of Applied Polymer ScienceDocument10 pages2019-Journal of Applied Polymer ScienceLarissa CostaNo ratings yet

- A Compilation of Ligno-Cellulose Feedstock and Related Research for Feed, Food and EnergyFrom EverandA Compilation of Ligno-Cellulose Feedstock and Related Research for Feed, Food and EnergyNo ratings yet

- Non - Halogen Flame RetardantsDocument8 pagesNon - Halogen Flame RetardantsJimmy WongNo ratings yet

- An Auditorium Case Study: Veer Savarkar Auditorium, Shivaji ParkDocument15 pagesAn Auditorium Case Study: Veer Savarkar Auditorium, Shivaji Parkram shreevastavNo ratings yet

- PPG Hi-Temp™ 500Document6 pagesPPG Hi-Temp™ 500Marleo MorenoNo ratings yet

- Journal of Applied Polymer Science Volume 98 Issue 2 2005 (Doi 10.1002 - App.22097) Kishore Ravi Shankar S. Sankaran - Short-Beam Three-Point Bend Tests in Syntactic Foams. Part II - Effect of MicroDocument7 pagesJournal of Applied Polymer Science Volume 98 Issue 2 2005 (Doi 10.1002 - App.22097) Kishore Ravi Shankar S. Sankaran - Short-Beam Three-Point Bend Tests in Syntactic Foams. Part II - Effect of MicroPablo OrtegaNo ratings yet

- Solid-Propellant Burning-Rate Modification: M. HumphreyDocument6 pagesSolid-Propellant Burning-Rate Modification: M. Humphreynaren_0015No ratings yet

- tieu chuẩn dri 2045Document4 pagestieu chuẩn dri 2045anhthoNo ratings yet

- Erb West D101 D103: MP Steam Combustion AirDocument3 pagesErb West D101 D103: MP Steam Combustion AirAbdul AzizNo ratings yet

- Tailieuxanh Asn Xuat Etylen 4131Document65 pagesTailieuxanh Asn Xuat Etylen 4131Minh HoàngNo ratings yet

- Main Gate and Boundary Wall PDFDocument13 pagesMain Gate and Boundary Wall PDFwali mustafaNo ratings yet

- Agentes AntiescalaDocument7 pagesAgentes AntiescalaFabian ArboledaNo ratings yet

- Polyprolylene MCQDocument6 pagesPolyprolylene MCQSHUBHRAJITNo ratings yet

- 0657940-60-01 Rev3 Medc Hd1 Heat Detector (HD) - A2 - EnglishDocument1 page0657940-60-01 Rev3 Medc Hd1 Heat Detector (HD) - A2 - EnglishrhomadonaNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10225Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10225farshid KarpasandNo ratings yet

- Surface Treatments For Precifitation-Hardening Stainless SteelsDocument62 pagesSurface Treatments For Precifitation-Hardening Stainless SteelssleonNo ratings yet

- RCBeams DESIGNDocument1 pageRCBeams DESIGNHermogenesGerardoIII OcanaNo ratings yet

- Periodic Classification of ElementsDocument3 pagesPeriodic Classification of Elementsvivek_theeasywaysNo ratings yet

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Kevlar Fiber Fianl Report by ShubhamDocument80 pagesKevlar Fiber Fianl Report by ShubhamShubham KangadeNo ratings yet

- Haldimann Structural Use of Glass Book PDFDocument221 pagesHaldimann Structural Use of Glass Book PDFDAVID LOPES DOS SANTOSNo ratings yet

- Datasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1Document13 pagesDatasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1mauferesNo ratings yet

- Bearing Steel 100Cr6 AUSA - 2Document3 pagesBearing Steel 100Cr6 AUSA - 2suresh kumarNo ratings yet

- Habonim Cryo ValveDocument8 pagesHabonim Cryo ValveashishpearlNo ratings yet

- USP 401 Fats and OilsDocument13 pagesUSP 401 Fats and OilsChandrajeet U. SagarNo ratings yet

- Pasqual Cavaliere - Shaft Furnaces and Beehive Charcoal Kilns - A History of Smelting in The Far West, 1863-1900Document4 pagesPasqual Cavaliere - Shaft Furnaces and Beehive Charcoal Kilns - A History of Smelting in The Far West, 1863-1900HamidBarekatainNo ratings yet