Professional Documents

Culture Documents

Jis H 5302 Adc12

Uploaded by

Hazem MahmoudOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jis H 5302 Adc12

Uploaded by

Hazem MahmoudCopyright:

Available Formats

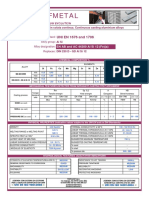

Material ‐ JIS H 5302 ADC12

Standard Specification for Aluminium Alloy Casting

Group ‐ Non‐Ferrous Alumium Alloy

Sub Group ‐ JIS H 5302 Aluminium Alloy Casting

Application ‐ Intended for Valve, Pump, General Engineering, Automotive and Other Industries

Grade Belongs to the Industry ‐ Casting

Chemical Composition Heat Treatment

Copper Cu % 1.500 ‐ 3.500

Magnesium Mg % 0.300 max.

Silicon Si % 9.600 ‐ 12.000

Iron Fe % 1.300 max. As‐Cast

Manganese Mn % 0.500 max.

Nickel Ni % 0.500 max.

Tin Sn % 0.200 max.

Lead Pb % 0.200 max.

Titanium Ti % 0.300 max. Mechanical Properties

Zinc Zn % 1.000 max. Tensile Strength in Mpa 225 min.

Aluminium Al % Balance Yield Strength in Mpa ‐

‐ ‐ ‐ Elongation in % 1.5 min.

‐ ‐ ‐ Reduction of Area in % ‐

‐ ‐ ‐ Hardness in BHN ‐

‐ ‐ ‐ Impact in Joule ‐

Cross Reference Table

Material Standard Country Grade Belong to the Industry

AS401 AS Australia Ingot and Casting

DA401 AS Australia Ingot and Casting

AlSi12 (Fe) ISO International Casting

A413.0 NMX Maxico Ingot and Casting

LM20 BS British Ingot and Casting

A413.0 AA USA Ingot and Casting

A413.0 NBR Brazil Ingot and Casting

Further any inquiry to discuss with Gravity Cast Pvt. Ltd. – Gravity Group of Companies team member Call

on +918469160029, or email marketing@gravitycastindia.com

All information in our data sheets and website is indicative only and is not intended to be a substitute for the full specification from which it is extracted. It is intended to

provide typical values to allow comparison between metal alloy option rather than a definitive statement of mechanical performance or suitability for a particular

application as these will vary with temperature, product type and product application. It is presented apart from contractual obligations and does not constitute any

guarantee of properties or of processing or application possibilities in individual cases. Our warranties and liabilities are stated exclusively in our terms of business.

ONE STOP SOLUTION FOR METAL PARTS

You might also like

- D2360 - 11 Standard Test Method For Trace Impurities in Monocyclic Aromatic Hydrocarbons by Gas Chromatography PDFDocument6 pagesD2360 - 11 Standard Test Method For Trace Impurities in Monocyclic Aromatic Hydrocarbons by Gas Chromatography PDFJacques BlueqNo ratings yet

- API Valve Trim ChartDocument2 pagesAPI Valve Trim ChartkhaireddinNo ratings yet

- ASTM A297 Grade HHDocument1 pageASTM A297 Grade HHinfo.nulyproNo ratings yet

- Sae 1022Document1 pageSae 1022talebimahdi924No ratings yet

- Astm B62 C83600Document1 pageAstm B62 C83600hemant skNo ratings yet

- Astm A743 Cf8mDocument1 pageAstm A743 Cf8makdrnlNo ratings yet

- Astm A351 CF8MDocument1 pageAstm A351 CF8MnadeemNo ratings yet

- Material - IS 2062 E 350: Standard Specification For Hot Rolled Medium and High Tensile Structural SteelDocument1 pageMaterial - IS 2062 E 350: Standard Specification For Hot Rolled Medium and High Tensile Structural Steelaniketgupta05No ratings yet

- BS 970 En8dDocument1 pageBS 970 En8djobseekerarulkumarNo ratings yet

- Technical Specifications - ASTM A27 Grade 70-40Document1 pageTechnical Specifications - ASTM A27 Grade 70-40S.Mohsin AliNo ratings yet

- Din 1.0619Document1 pageDin 1.0619aniketNo ratings yet

- ASTM A128 Grade B-3 PDFDocument1 pageASTM A128 Grade B-3 PDFEko PrasetyoNo ratings yet

- DIN G S 17 CrMo 5-5Document1 pageDIN G S 17 CrMo 5-5kaushal sagarNo ratings yet

- Astm A216 WCBDocument1 pageAstm A216 WCBAkshay ValaNo ratings yet

- Din en 1706 Ac - 71100Document1 pageDin en 1706 Ac - 71100Anudeep NittalaNo ratings yet

- Jis G 3539 SWCH 10aDocument1 pageJis G 3539 SWCH 10asujiyopptsrNo ratings yet

- Astm A487 4 (A)Document1 pageAstm A487 4 (A)baladiroyaNo ratings yet

- Uns S44800Document1 pageUns S44800Mohammad TaherNo ratings yet

- ASTM A 108 Grade 1020Document1 pageASTM A 108 Grade 1020juan ormacheaNo ratings yet

- Astm A351 Cf8Document1 pageAstm A351 Cf8akdrnlNo ratings yet

- Astm b176 Uns c86500Document1 pageAstm b176 Uns c86500Kashif MohiuddinNo ratings yet

- Ref TC - ANSI - AA B390Document1 pageRef TC - ANSI - AA B390Abhilash BaranwalNo ratings yet

- Ficha Tecnica - BS EN 1982 CuSn7Zn4Pb7-C (CC493K)Document1 pageFicha Tecnica - BS EN 1982 CuSn7Zn4Pb7-C (CC493K)freddy benavidesNo ratings yet

- Sae J403 Uns G10050Document1 pageSae J403 Uns G10050Shrikar KuradeNo ratings yet

- Sae 1080Document1 pageSae 1080bharathi_pmNo ratings yet

- Key Facts Typical Wire Analysis: - Bossweld 316LSIDocument1 pageKey Facts Typical Wire Analysis: - Bossweld 316LSIAli TalebiNo ratings yet

- Astm B 491 6063Document1 pageAstm B 491 6063جبر البرحNo ratings yet

- Zincalume G550 Steel: Metallic Coated - MC Structural - SDocument1 pageZincalume G550 Steel: Metallic Coated - MC Structural - SEwo50 New0% (1)

- Stainless Steel Stick Electrodes: Aws E309-16 Aws E309Mo-16 Aws E309Mol-16Document10 pagesStainless Steel Stick Electrodes: Aws E309-16 Aws E309Mo-16 Aws E309Mol-16ManuelNo ratings yet

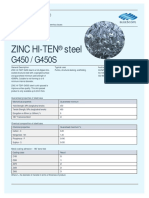

- Galvaspan G450Document2 pagesGalvaspan G450khurshedlakhoNo ratings yet

- ASTM A516 Gr.70Document2 pagesASTM A516 Gr.70Irpan PurnamansyahNo ratings yet

- ASTM A148 Grade 135-125Document1 pageASTM A148 Grade 135-125pranab kumar ghoshNo ratings yet

- Carbide ToolingDocument90 pagesCarbide ToolingHuron Industrial SupplyNo ratings yet

- Cold Rolled CR Structural S CM350-G® Steel: General Description Typical UsesDocument2 pagesCold Rolled CR Structural S CM350-G® Steel: General Description Typical UsesBaziNo ratings yet

- OK Tigrod 19.49Document1 pageOK Tigrod 19.49Ali VarmazyarNo ratings yet

- ZINCALUME® G300 Steel With Activate™ Technology: Structural - S Metallic Coated - MCDocument3 pagesZINCALUME® G300 Steel With Activate™ Technology: Structural - S Metallic Coated - MCEwo50 NewNo ratings yet

- Zincalume® G550 Technical Datasheet MalaysiaDocument2 pagesZincalume® G550 Technical Datasheet MalaysiaJeffrey RonquilloNo ratings yet

- Cw008a Cu-Of Version1Document1 pageCw008a Cu-Of Version1Gaka RtaNo ratings yet

- Silicon Bronze PDFDocument1 pageSilicon Bronze PDFFabian Andres Pinilla CarballoNo ratings yet

- Trim Number Chart API Valve PDFDocument2 pagesTrim Number Chart API Valve PDFtungxuanbrNo ratings yet

- AISI 4140 Chrome Molybdenum High Tensile Steel: Topics CoveredDocument6 pagesAISI 4140 Chrome Molybdenum High Tensile Steel: Topics CoveredCristina NicheNo ratings yet

- Aços Comp Aços Inox Torques (A1, A2, A4)Document3 pagesAços Comp Aços Inox Torques (A1, A2, A4)Paulo Henrique NascimentoNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Jonathan Getial CruzNo ratings yet

- BS2789 Grade 420-12 SG Iron: Form of SupplyDocument2 pagesBS2789 Grade 420-12 SG Iron: Form of SupplySama UmateNo ratings yet

- 320LR StainlessSteel 73Document1 page320LR StainlessSteel 73Cristóbal cardenasNo ratings yet

- LM6 Casting Alloy PDFDocument2 pagesLM6 Casting Alloy PDFSankarNo ratings yet

- Zinc Hi-Ten g450-450s SteelDocument2 pagesZinc Hi-Ten g450-450s SteelPurnomo MbangunNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Anodos MartyDocument2 pagesAnodos MartyEmilsa EsturbanNo ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Agung SulisNo ratings yet

- Material Astm A516 Grade 70Document2 pagesMaterial Astm A516 Grade 70ramdikaNo ratings yet

- Galvaspan G550Document2 pagesGalvaspan G550eli abdul rohimNo ratings yet

- Bolts and Nuts Stainless SteelDocument2 pagesBolts and Nuts Stainless SteelfedemochileroNo ratings yet

- Alluminium GradesDocument4 pagesAlluminium GradesAnjani kumarNo ratings yet

- Datasheet Zincalume G550Document2 pagesDatasheet Zincalume G550adihindNo ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)UmerNo ratings yet

- 1.4401 1.4404 316 316L X2Crnimo17-12-2 S31603: en Designation Astm DesignationDocument2 pages1.4401 1.4404 316 316L X2Crnimo17-12-2 S31603: en Designation Astm Designation池边树No ratings yet

- Zincalume G300 Steel: Metallic Coated - MC Structural - SDocument2 pagesZincalume G300 Steel: Metallic Coated - MC Structural - SPranatia Wisnu HeryudaNo ratings yet

- Stainless Steel Data - Fuller Metric Parts LTDDocument2 pagesStainless Steel Data - Fuller Metric Parts LTDGoNo ratings yet

- M1226e Peristaltic Pump Compact b19b PDFDocument12 pagesM1226e Peristaltic Pump Compact b19b PDFRenatoNo ratings yet

- DactylosDocument50 pagesDactylosRed Snow75% (4)

- L&T Ball ValveDocument12 pagesL&T Ball ValvecdsenthilNo ratings yet

- How To Perform Intradermal InjectionsDocument2 pagesHow To Perform Intradermal InjectionsDennis LunaNo ratings yet

- Radon-222 Exhalation From Danish Building Material PDFDocument63 pagesRadon-222 Exhalation From Danish Building Material PDFdanpalaciosNo ratings yet

- Permabond Adhesive Guide: - Our Science... Your SuccessDocument28 pagesPermabond Adhesive Guide: - Our Science... Your SuccessU4 CreationZNo ratings yet

- Sheet Metal - WikipediaDocument10 pagesSheet Metal - WikipediaDhamo_55No ratings yet

- Hot Tears in CastingDocument15 pagesHot Tears in CastingRafdi Abdul MajidNo ratings yet

- Soap FormsDocument6 pagesSoap FormsJunJieNo ratings yet

- Maraging Steel - WikipediaDocument5 pagesMaraging Steel - WikipediaVysakh VasudevanNo ratings yet

- Rocks PDFDocument5 pagesRocks PDFfatwa27No ratings yet

- Basics On Piping LayoutDocument11 pagesBasics On Piping Layoutpuru55980No ratings yet

- Quiz 1.1 2021 LectureDocument4 pagesQuiz 1.1 2021 LectureSupia NazmaNo ratings yet

- Skema Jawapan Bagi Peperiksaan Percubaan SPM 2011Document7 pagesSkema Jawapan Bagi Peperiksaan Percubaan SPM 2011Joe Lidy50% (4)

- EN-Genano-350 Datasheet LowresDocument2 pagesEN-Genano-350 Datasheet LowresLeader Healthcare Power CafeNo ratings yet

- Mil PRF 8565kDocument39 pagesMil PRF 8565kgustavojorge12No ratings yet

- Case StudyDocument2 pagesCase StudyArtee Aggrawal100% (1)

- Fda Q&aDocument17 pagesFda Q&ablackcholoNo ratings yet

- 8 2 7Document19 pages8 2 7Hussain AbouelkhairNo ratings yet

- Defi Making 2011Document41 pagesDefi Making 2011JonardoNo ratings yet

- CBSE Class X Science Acids Bases and Salts Important Questions Paper 2012Document5 pagesCBSE Class X Science Acids Bases and Salts Important Questions Paper 2012MahenderGoelNo ratings yet

- Impacted Notch Bend Specimens: A. S. KobayashiDocument6 pagesImpacted Notch Bend Specimens: A. S. KobayashiVishnu VNo ratings yet

- CND 4.medication & Dispensing ErrorDocument32 pagesCND 4.medication & Dispensing Errorlisnawati farmasicbthNo ratings yet

- Steam and Water Analysis SystemDocument4 pagesSteam and Water Analysis SystemJASWANT ADILENo ratings yet

- Magnet Recycling: Rethinking Scrap Collection and SeparationDocument16 pagesMagnet Recycling: Rethinking Scrap Collection and SeparationBerk GülörtenNo ratings yet

- ChmistryDocument27 pagesChmistryChooi YingNo ratings yet

- Ball ValvesDocument20 pagesBall Valvesनिखिल बायवारNo ratings yet

- A Handbook of Infection Control For The Asian Healthcare Worker PDFDocument17 pagesA Handbook of Infection Control For The Asian Healthcare Worker PDFSanti utamiNo ratings yet

- Klübersynth GH 6 Oils: Synthetic Gear and High Temperature OilsDocument8 pagesKlübersynth GH 6 Oils: Synthetic Gear and High Temperature OilsFabrizzio_ValerNo ratings yet