Professional Documents

Culture Documents

A5.01-Recommended Use of Trench Boxes

A5.01-Recommended Use of Trench Boxes

Uploaded by

baltazarpaulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A5.01-Recommended Use of Trench Boxes

A5.01-Recommended Use of Trench Boxes

Uploaded by

baltazarpaulCopyright:

Available Formats

TECHNICAL NOTE

Recommended Use for Trench Boxes

TN 5.01

March 2009

Introduction

Trench boxes provide a safer work area to install pipe in deep trenches, restricted right-of-ways, or in soils that have

insufficient stability. This technical bulletin provides guidelines on how to maximize the structural stability and

alignment of the ADS pipe system while using a trench box. While these guidelines will work for most cohesive and

noncohesive native soils, highly unusual soil conditions may require further investigation or different techniques.

General Considerations

OSHA regulations should be carefully followed for all aspects of pipe installation, including those that involve trench

boxes. If information contained in this document conflicts in any way with OSHA or other safety regulations, those

requirements must take precedence.

Some installations may not require trench boxes if the trench sidewall can be sloped adequately. The design engineer

should provide specific guidance on acceptable slopes, but in no case should the trench wall slope be greater than the

angle of repose of the native soil.

The length of the trench box should be suitable for the pipe length. Standard length for ADS N-12® IB is19.7 ft (6m)

although it may be possible to supply shorter lengths for use in shorter trench boxes.

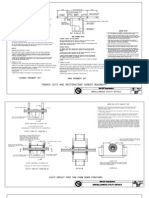

Subtrench Installations

The most effective way to maintain a sound system is to provide a ‘subtrench’ within which to place the pipe and

backfill. The bottom of the trench box should be placed no more than 24” from the bottom of the work surface, in

accordance with OSHA regulation 1926.652(g)(2). This may require the trench box be raised during pipe installation to

conform with both OSHA requirements and to properly backfill and compact the soil around the pipe. Backfill and

compact according to the design specifications within the subtrench. When possible, without disturbing the pipe or

backfill, the trench box can be pulled along the top edge of the subtrench. In some cases, it may be necessary to move

the trench box multiple times to obtain the required compaction of the material in the soil envelope. In either case, it is

paramount to achieve the necessary backfill placement and compaction for a quality installation. Refer to Figure 1 for a

typical subtrench installation.

6.09

4640 TRUEMAN BLVD. HILLIARD, OH 43026 (800) 821-6710 www.ads-pipe.com 1

ATN501 © ADS 2009

Figure 1

Subtrench Installation

Subtrench installations also make it easier to use a geotextile around the backfill if it is required by the project

specifications. Line the subtrench with the geotextile, place the pipe and backfill over the geotextile, and wrap the

geotextile over the top of the pipe/backfill system.

Regular Trench Installations

In installations not involving a subtrench situation, dragging a trench box should only be done if it does not damage the

pipe or disrupt the backfill; otherwise, the box should be lifted vertically into its new position. If it is necessary for a

trench box to be dragged through a trench, do not raise the box more than 24” above the work surface.

Another alternative for when the box will be dragged is to use a well-graded granular backfill material at least two

diameters on either side of the pipe and compact it to a minimum of 90% standard Proctor density before moving the

box. After the trench box is moved, immediately fill the area between the pipe/backfill structure and the trench wall with

a granular material.

If the project requires a geotextile around the backfill, use a well-graded granular backfill material and6.09

compact it to at

least 90% standard Proctor density. Do not drag the box; instead, lift it vertically. After the trench box is removed,

immediately fill the area between the pipe/backfill structure and the trench wall with a granular material and compact

according to project requirements. The geotextile manufacturer may be able to provide additional information

regarding the suitability of specific geotextiles for use with trench boxes.

Summary

While trench boxes increase worker safety in difficult site conditions, their use requires some precautions be taken to

ensure a structurally sound finished installation.

Construction of a subtrench is the most effective means of maintaining a sound system; the trench box can simply be

pulled along the top edge of the subtrench. When a regular trench is used, techniques such as lifting the box, keeping

the box about three-fourths the nominal pipe diameter up from the trench bottom, and providing a wide granular backfill

envelope will help provide a quality installation.

2 4640 TRUEMAN BLVD. HILLIARD, OH 43026 (800) 821-6710 www.ads-pipe.com

ATN501 © ADS 2009

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- 3 - Chapter Two-Company ProfileDocument10 pages3 - Chapter Two-Company ProfileJohnson Mobolaji100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Design A Pressure Safety Valve at The Centrifugal Pump DischargeDocument2 pagesDesign A Pressure Safety Valve at The Centrifugal Pump Dischargeroberdani12No ratings yet

- FLOLINE 3-W Manual & Technical SpecsDocument39 pagesFLOLINE 3-W Manual & Technical SpecsChen YishengNo ratings yet

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- Beardsley Later Work of Aubrey Beardsley 1930Document204 pagesBeardsley Later Work of Aubrey Beardsley 1930baltazarpaul100% (7)

- Calculating Financial Impact of Lean Six Sigma ProjectsDocument4 pagesCalculating Financial Impact of Lean Six Sigma ProjectskbobhateNo ratings yet

- Excavation For NATURAL GASDocument8 pagesExcavation For NATURAL GASottoNo ratings yet

- Installation Procedure For Gre PipeDocument14 pagesInstallation Procedure For Gre PipeNithin Mathai100% (1)

- Culvert ThicknessDocument23 pagesCulvert ThicknessNilaAbubakarNo ratings yet

- Special Conditions of Contract For Supply Installation and Commissioning of Temporary and Permanent Cathodic Protection SystemDocument12 pagesSpecial Conditions of Contract For Supply Installation and Commissioning of Temporary and Permanent Cathodic Protection SystemsudeepjosephNo ratings yet

- Trench Cuts and Restorations Across Roadways: Flexible Pavement Cut Rigid Pavement CutDocument3 pagesTrench Cuts and Restorations Across Roadways: Flexible Pavement Cut Rigid Pavement CutIqueline JacqelineNo ratings yet

- Buried Pipe: A. Trench Design and Burial DepthsDocument6 pagesBuried Pipe: A. Trench Design and Burial DepthsjosethompsonNo ratings yet

- PVC Pressure InstallationDocument6 pagesPVC Pressure InstallationkkkhattabbbNo ratings yet

- Long Form Specification For Underground Installation of Plastic Drainage Pipe 1Document1 pageLong Form Specification For Underground Installation of Plastic Drainage Pipe 1Bruce DoyaoenNo ratings yet

- Instalación de Tuberías EnterradasDocument4 pagesInstalación de Tuberías EnterradasYana ParravanoNo ratings yet

- CH9 Inst and Const ProceduresDocument65 pagesCH9 Inst and Const ProceduresSaad AliNo ratings yet

- Guide For Installing RTR Pipe Courtesy Bondstrand For InfoDocument4 pagesGuide For Installing RTR Pipe Courtesy Bondstrand For InfoHafiz Ali Alvi100% (1)

- Direct Buried Cable Installation PDFDocument8 pagesDirect Buried Cable Installation PDFnecmettinsengunNo ratings yet

- Hollow Core Slab DetailsDocument19 pagesHollow Core Slab DetailsMediks Ferrer100% (1)

- Install at in CablesDocument20 pagesInstall at in Cableshashimkolan100% (2)

- Trenches: Executive SummaryDocument5 pagesTrenches: Executive SummaryvictorNo ratings yet

- Innovative Through-Tubing Cement Packer Technique: Cementing TechnologyDocument2 pagesInnovative Through-Tubing Cement Packer Technique: Cementing TechnologyPak Rio100% (1)

- HDPE Pipe InstallationDocument7 pagesHDPE Pipe InstallationJeferson Binay-an100% (1)

- Box Jacking Paper PDFDocument5 pagesBox Jacking Paper PDFFerdi Aparat100% (1)

- Indicator Posts To Pressure MainsDocument2 pagesIndicator Posts To Pressure MainsganmosesNo ratings yet

- Understanding ASTM D2321Document2 pagesUnderstanding ASTM D2321aorobioqNo ratings yet

- Manhole InstallationDocument2 pagesManhole Installationrealchic100% (1)

- c3813 - Manhole Grounding DetailsDocument9 pagesc3813 - Manhole Grounding DetailsgemotorresNo ratings yet

- ADS Single Wall HDPE Pipe - Min-Max Cover HeightsDocument2 pagesADS Single Wall HDPE Pipe - Min-Max Cover HeightsAnonymous 9SbW7hl7zaNo ratings yet

- Trench PreparationDocument4 pagesTrench PreparationHenry Wa Phwane100% (1)

- Installation Guidance For Cable Troughs and Service Ducts PD84Document7 pagesInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020No ratings yet

- Installation Guidance For Cable Troughs and Service Ducts PD84Document7 pagesInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020No ratings yet

- Installation Guidance For Cable Troughs and Service Ducts PD84Document7 pagesInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020No ratings yet

- OSP DataDocument6 pagesOSP DataHemanth KumarNo ratings yet

- 333913Document4 pages333913AyiNo ratings yet

- Construction Specification Cs-Ut-202, Pipeline Through EmbankmentsDocument3 pagesConstruction Specification Cs-Ut-202, Pipeline Through EmbankmentsPaola Paternina PadrónNo ratings yet

- Inflatable Packers and Grouting Procedures Injection GroutingDocument7 pagesInflatable Packers and Grouting Procedures Injection GroutingRipe PackersNo ratings yet

- Note On PVC Pipe LayingDocument2 pagesNote On PVC Pipe LayingNitin S JogNo ratings yet

- Installation Guide For Solvent-Welded PVC Pipe: HandlingDocument3 pagesInstallation Guide For Solvent-Welded PVC Pipe: HandlingKPHMXNo ratings yet

- Probe DrillingDocument5 pagesProbe Drillinghosam_arafatNo ratings yet

- Manual FOR Underground Installation of GRP Pipes in The TrenchesDocument37 pagesManual FOR Underground Installation of GRP Pipes in The TrenchesGanesh ThakurNo ratings yet

- OTC 23923 Plug and Abandonment Applications For Inflatable Packers in The Gulf of MexicoDocument5 pagesOTC 23923 Plug and Abandonment Applications For Inflatable Packers in The Gulf of Mexicomoh kadNo ratings yet

- Sec 06 - Process VesselsDocument4 pagesSec 06 - Process VesselseujualNo ratings yet

- HDDDocument6 pagesHDDRon Cyl100% (1)

- Almacenamiento de TuberiaDocument4 pagesAlmacenamiento de TuberiaYesid Cruz Yesid CruzNo ratings yet

- Ection: Underground SystemsDocument19 pagesEction: Underground SystemsPhel FloresNo ratings yet

- PIL 181 Package Tie-Down Options Rev 4Document7 pagesPIL 181 Package Tie-Down Options Rev 4ganesh100% (1)

- General Installation Smart DitchDocument8 pagesGeneral Installation Smart Ditchanon_49687612No ratings yet

- Grasscrete: Cast Insitu Paving System Design and Specification GuideDocument23 pagesGrasscrete: Cast Insitu Paving System Design and Specification Guidemssrao1977No ratings yet

- Pad Transformer Concrete Found SpecsDocument15 pagesPad Transformer Concrete Found SpecsSatya100% (1)

- How To Backfill Foundations and Trenches Backfill Is The Key To A Solid and Stable Grading Share Flip Pin EmailDocument4 pagesHow To Backfill Foundations and Trenches Backfill Is The Key To A Solid and Stable Grading Share Flip Pin Emailram_babu_59No ratings yet

- Storm and Sewerage Pipe Installation Guide, VinidexDocument16 pagesStorm and Sewerage Pipe Installation Guide, VinidexMiroslav AleksicNo ratings yet

- Manhole NasscoDocument9 pagesManhole NasscoAsmara KanthiNo ratings yet

- HDD GP Guidelines 2-1 Chapter 2: HDD Applications and ProcessDocument6 pagesHDD GP Guidelines 2-1 Chapter 2: HDD Applications and ProcessEnri05No ratings yet

- Tank Manual2 Of2Document195 pagesTank Manual2 Of2AlbertNo ratings yet

- Dike and Spill Protection: Diked AreaDocument6 pagesDike and Spill Protection: Diked AreamniarunNo ratings yet

- Slope ProtectionDocument3 pagesSlope Protectionshima2727No ratings yet

- SPE 87282 Innovative Completion Technology, Preparation, and Contingency Planning Simplifies Baltim Completions While Increasing Reliability and Reducing Remedial CostDocument9 pagesSPE 87282 Innovative Completion Technology, Preparation, and Contingency Planning Simplifies Baltim Completions While Increasing Reliability and Reducing Remedial Costmoh kadNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Cap 15 - 17Document66 pagesCap 15 - 17baltazarpaulNo ratings yet

- Cap 10 - 14Document102 pagesCap 10 - 14baltazarpaulNo ratings yet

- APENDICEDocument58 pagesAPENDICEbaltazarpaulNo ratings yet

- A4.03 Abrasion Resistance of PolypropyleneDocument3 pagesA4.03 Abrasion Resistance of PolypropylenebaltazarpaulNo ratings yet

- Handbook Kurvers PipingDocument208 pagesHandbook Kurvers PipingbaltazarpaulNo ratings yet

- A2.02-Min Max Burial Depth F2648 PipeDocument3 pagesA2.02-Min Max Burial Depth F2648 PipebaltazarpaulNo ratings yet

- 12 Pipes and CisternDocument40 pages12 Pipes and Cisternhemanth kumarNo ratings yet

- Safety Science: Riccardo TommasiniDocument6 pagesSafety Science: Riccardo TommasiniSanaNo ratings yet

- ADDENDUM Fall ProtectionDocument27 pagesADDENDUM Fall ProtectionNala A.No ratings yet

- Sulfur Removal Product BulletinDocument12 pagesSulfur Removal Product BulletinMali NkunziNo ratings yet

- 4. HSG ANH 9 TỈNH PHÚ THỌ (2010-2011)Document7 pages4. HSG ANH 9 TỈNH PHÚ THỌ (2010-2011)32.Nguyễn Thị Minh Trang - 8ANo ratings yet

- Prologis Logistics Park Galanta Gan EngDocument4 pagesPrologis Logistics Park Galanta Gan Engmutton moonswamiNo ratings yet

- Astm A-252Document9 pagesAstm A-252Dayana HernandezNo ratings yet

- Equivalent Stabilizing Force of Direct Method For TrussesDocument16 pagesEquivalent Stabilizing Force of Direct Method For TrussesYu PiNo ratings yet

- Detect Soft Foot With Vibration AnalysisDocument4 pagesDetect Soft Foot With Vibration AnalysisJaime BerryNo ratings yet

- 1concrete TechnologyDocument9 pages1concrete TechnologySamarjyoti RayNo ratings yet

- NetMaster Installation GuideDocument105 pagesNetMaster Installation GuideAtanda Babatunde MutiuNo ratings yet

- Manual Slot MachinesDocument4 pagesManual Slot MachinesScribdTranslationsNo ratings yet

- Installing Shower PumpDocument4 pagesInstalling Shower PumpFree_Beating_HeartNo ratings yet

- 3E AND 110H/210H SERIES Canned Motor Pumps: R S P W C I MDocument16 pages3E AND 110H/210H SERIES Canned Motor Pumps: R S P W C I Mari_prasNo ratings yet

- What Sank The Kursk Nuclear Submarine?: Which Catalyst? Decomposing Hydrogen PeroxideDocument4 pagesWhat Sank The Kursk Nuclear Submarine?: Which Catalyst? Decomposing Hydrogen PeroxideEddy RichardsNo ratings yet

- Dual Fuel Genset - Heat Recovery-1-2Document2 pagesDual Fuel Genset - Heat Recovery-1-2Ab Sami100% (1)

- Analog Input Digital Panel Meters-Www - Ucontrol.com - AuDocument12 pagesAnalog Input Digital Panel Meters-Www - Ucontrol.com - AuPREVISTONo ratings yet

- QAQC Resume Review Checklist - UpdatedDocument12 pagesQAQC Resume Review Checklist - Updatedh_aldhwyainNo ratings yet

- Ce 479 Reinforced Masonry Fall 2004Document9 pagesCe 479 Reinforced Masonry Fall 2004Reinaldo Andrei SalazarNo ratings yet

- Constantin Carathéodory and The Axiomatic ThermodynamicsDocument12 pagesConstantin Carathéodory and The Axiomatic ThermodynamicsajejeyNo ratings yet

- Muratec MFX-C3400 User ManualDocument188 pagesMuratec MFX-C3400 User Manualbill3759No ratings yet

- DUNGS - Data SheetDocument12 pagesDUNGS - Data SheethamzadarbarNo ratings yet

- McamX4 NCI Parameter RefDocument432 pagesMcamX4 NCI Parameter Refp12385612No ratings yet

- Electrical Drives Lab 2: Speed Control of DC Shunt MotorsDocument12 pagesElectrical Drives Lab 2: Speed Control of DC Shunt MotorsDastan KhanNo ratings yet

- Eurotiles PDFDocument7 pagesEurotiles PDFYoungman ChiewNo ratings yet

- Sample Project ProposalDocument37 pagesSample Project ProposalAminul Sarker100% (1)