Professional Documents

Culture Documents

778 08da SD 001 Rev0

Uploaded by

Nguyễn Xuân TrườngOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

778 08da SD 001 Rev0

Uploaded by

Nguyễn Xuân TrườngCopyright:

Available Formats

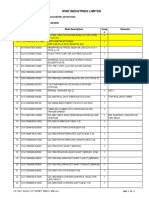

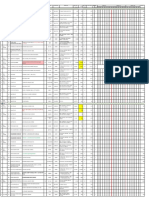

A B C D E F G H I J

MATERIAL FOR ASSEMBLY MK'D 778-08DA 1 T2-P32 FB10X100 1195 1 SS400/A36 9.30 BOM SHOWN FOR 1 UNIT.3 UNITS REQUIRED

LENGTH

WEIGHT(kg)

T2-P33 FB10X100 1036 1 SS400/A36 8.0 1 OFF REQUIRED AS DRAWN FOR WHRU EBN-3520A

PART NO. DESCRIPTION QTY MATERIAL

(mm)

T2-P34 PL12X100 3815 2 SS400/A36 71.90 1 OFF REQUIRED AS DRAWN FOR WHRU EBN-3520B

T2-C1 C-150X75X6.5X10 5042 3 SS400/A36 281.50

T2-P35 PL12X100 2265 2 SS400/A36 42.70 1 OFF REQUIRED AS DRAWN FOR WHRU EBN-3520C

1 T2-C2 C-150X75X6.5X10 5042 1 SS400/A36 93.80

T2-P36 FB10X100 1075 1 SS400/A36 8.40

*ADD MARK NO. FOR 3 UNITS FOLLOW: A C/L B 1

T2-C3 C-150X75X6.5X10 5042 2 SS400/A36 187.70 778-M1-T1-XXX FOR WHRU EBN-3520A

T2-P37 FB10X100 957 1 SS400/A36 7.40 778-M2-T1-XXX FOR WHRU EBN-3520B

T2-C4 C-150X75X6.5X10 418 7 SS400/A36 54.50

T2-P38 C

FB10X100 1160 1 SS400/A36 9.0 778-M3-T1-XXX FOR WHRU EBN-3520C

T2-C5 C-150X75X6.5X10 3815 2 SS400/A36 142.0

T2-P39 FB10X100 1415 1 SS400/A36 11.0

T2-C6 C-150X75X6.5X10 2265 2 SS400/A36 84.30

T2-P40 FB10X100 1755 1 SS400/A36 13.70

T2-C7 C-150X75X6.5X10 4104 1 SS400/A36 76.40

T2-P41 FB10X100 1364 1 SS400/A36 10.60

1

T2-C8 C-150X75X6.5X10 4104 1 SS400/A36 76.40

T2-P42 FB10X100 1401 1 SS400/A36 11.0

T2-C9 C-150X75X6.5X10 3043 1 SS400/A36 56.60

T2-P43 FB10X100 1522 1 SS400/A36 11.90

T2-C10 C-150X75X6.5X10 3043 1 SS400/A36 56.60

T2-P44 FB10X100 1494 1 SS400/A36 11.70

2 2

T2-C11 C-125X65X6X8 418 3 SS400/A36 16.90

T2-P45 FB10X100 1122 1 SS400/A36 8.70

T2-C12 C-125X65X6X8 2803 1 SS400/A36 37.70

T2-P46 FB10X100 782 1 SS400/A36 6.0

T2-C13 C-125X65X6X8 418 2 SS400/A36 11.20

T2-P47 FB10X100 130 2 SS400/A36 2.0

T2-C14 C-125X65X6X8 419 1 SS400/A36 5.60

T2-P48 FB10X100 1462 1 SS400/A36 11.40

T2-C15 C-125X65X6X8 68 4 SS400/A36 3.70

T2-P49 FB10X100 793 1 SS400/A36 6.10

T2-C16 C-125X65X6X8 3565 1 SS400/A36 47.90

T2-P50 PLT12x223 222 2 S355J2 6.50

T2-C17 C-125X65X6X8 3002 1 SS400/A36 40.30

T2-P51 PLT10x90 90 12 S355J2 5.90

T2-C18 C-150X75X6.5X10 5975 1 SS400/A36 111.20

T2-P52 PLT12x130 200 8 SS400/A36 13.40

3 T2-C19 C-150X75X6.5X10 5975 2 SS400/A36 222.40 3

T2-P53 PLT10x105 105.0 16.0 SS400/A36 10.90

T2-C20 C-150X75X6.5X10 5975 1 SS400/A36 111.20

T2-P54 FB10X100 1029.0 1.0 SS400/A36 8.0

T2-C21 C-150X75X6.5X10 418 1 SS400/A36 7.80

T2-P55 FB10X100 860.0 1.0 SS400/A36 6.70

T2-C22 C-125X65X6X8 120 2 SS400/A36 3.20

T2-P56 FB10X100 1029.0 1.0 SS400/A36 8.0

T2-C23 C-125X65X6X8 68 2 SS400/A36 1.80

T2-P57 FB10X100 1198.0 1.0 SS400/A36 9.30

T2-C24 C-125X65X6X8 419 2 SS400/A36 11.20

T2-P58 FB10X100 840.0 1.0 SS400/A36 6.60

T2-C25 C-125X65X6X8 3947 1 SS400/A36 53.0

T2-P59 FB10X100 1186.0 1.0 SS400/A36 9.30

T2-C26 C-125X65X6X8 3949 1 SS400/A36 53.0

T2-P60 FB10X100 1348.0 1.0 SS400/A36 10.60

4 T2-C27 C-125X65X6X8 120 1 SS400/A36 1.60

T2-P61 FB10X100 821.0 1.0 SS400/A36 6.40 4

T2-C28 C-125X65X6X8 3947 1 SS400/A36 53.0 B B

T2-P62 FB10X100 1360.0 1.0 SS400/A36 10.60

T2-C29 C-125X65X6X8 418 2 SS400/A36 11.20

T2-P63 FB10X100 1356.0 1.0 SS400/A36 10.50

T2-C30 C-125X65X6X8 2792 1 SS400/A36 37.50

T2-P64 FB10X100 1190.0 1.0 SS400/A36 9.30

T2-C31 C-125X65X6X8 2791 1 SS400/A36 37.50

T2-P65 PLT6x50 50.0 3.0 SS316L 0.40

T2-C32 C-125X65X6X8 2924 1 SS400/A36 39.30

T2-P66 FB10X100 1033.0 1.0 SS400/A36 8.0

T2-C33 C-125X65X6X8 3299 1 SS400/A36 44.30

T2-P67 FB10X100 819.0 1.0 SS400/A36 6.40

T2-C34 C-125X65X6X8 89 1 SS400/A36 1.20

T2-P68 FB10X100 839.0 1.0 SS400/A36 6.60

5 T2-C35 PLT6x50 50 1 SS316L 0.10

T2-P69 FB10X100 859.0 1.0 SS400/A36 6.70

4 5

T2-L1 L-90X90X10 870 2 SS400/A36 23.20

T2-L2 L-90X90X10 600 1 SS400/A36 8.0

T2-P70 FB10X100 1354.0 1.0 SS400/A36 10.50 MARK NO.778-08DA C

T2-P71 FB10X100 1196.0 1.0 SS400/A36 9.30

T2-O1 PIPE 2 INCH SCH80 286 3 ASTM A312 TP316 6.40

T2-P1 PLT6x1433 5030 1 SS400/A36 339.80

T2-P72 FB10X100 1036.0 1.0 SS400/A36 8.10

PLAN VIEW

T2-P73 PLT12x129 240.0 4.0 S355J2 7.70

T2-P2 PLT6x400 4942 2 SS400/A36 186.20

T2-P74 PLT50X10 128.0 2.0 SS400/A36 1.0

SCALE 1:30

T2-P3 PLT6x400 5674 1 SS400/A36 106.80

T2-P65 PLT6x50 50.0 2.0 SS316L 0.20

T2-P4 PLT6x400 5675 1 SS400/A36 106.80

TOTAL WEIGHT 5833.0

T2-P5 PLT6x2776 5042 1 SS400/A36 491.50

6 6

T2-P6 PLT6x2800 5425 1 SS400/A36 830.80

T2-P7 PL6x25 5042 1 SS400/A36 5.80

T2-P8 PLT6x25 2065 2 SS400/A36 4.90

T2-P9 PLT6x25 3498 1 SS400/A36 4.10

T2-P10 PLT6x25 5358 1 SS400/A36 6.30

T2-P11 FB10X100 543 1 SS400/A36 4.10

T2-P12 FB10X100 1203 1 SS400/A36 9.30

T2-P13 FB10X100 1038 1 SS400/A36 8.0

7 T2-P14 FB10X100 1340 1 SS400/A36 10.50 7

T2-P15 FB10X100 1139 1 SS400/A36 8.90 1

T2-P16 FB10X100 938 1 SS400/A36 7.30

T2-P17 PLT10x93 131 18 SS400/A36 14.50

T2-P18 PLT10x69 141 6 SS400/A36 4.30

0 05.07.2023 ISSUED FOR CONSTRUCTION VTA NVT NVH

T2-P19 PLT10x68 138 6 SS400/A36 4.20

REV DATE REVISION DESCRIPTION DRAWN CHECKED APPROVED

T2-P20 PLT600x90 123 1 SS400/A36 8.30

T2-P21 FB10X100 144 4 SS400/A36 3.60

8 T2-P22 FB10X100 212 4 SS400/A36 5.40 8

A

B.I.H

T2-P23 FB10X100 800 2 SS400/A36 11.80

T2-P24 PLT10x188 286 2 SS400/A36 5.30

T2-P25 PLT15x69 139 4 SS400/A36 4.20

C/L 4

T2-P26 PLT10x69 137 4 SS400/A36 2.80 BOUSTEAD INTERNATIONAL HEATERS Ltd.

T2-P27 PLT10x120 129 4 SS400/A36 4.80 DRAWING TITLE

T2-P28 PLT6x2904 5042 1 SS400/A36 466.90 B INLET TRANSITION

T2-P29 PLT6x2760 5358 1 SS400/A36 575.70

SERVICE WASTE HEAT RECOVERY UNIT (WHRU)

T2-P30 FB10X100 1368 1 SS400/A36 10.60 EBN-3520 A/B/C

9 9

T2-P31 FB10X100 1364 1 SS400/A36 10.60 ISOMETRIC VIEW FOR UARU F.P.S.O. PROJECT

SHEET SCALE: 1:1 ORIGINAL SIZE: A1 DO NOT SCALE NOTE: THIS DRAWING IS THE PROPERTY OF BOUSTEAD

REV. 3 BY DATE CHECKED DATE DESIGN REVIEW DATE APPROVED DATE REV. 2 BY DATE CHECKED DATE DESIGN REVIEW DATE APPROVEDDATE REV. 1 BY DATE CHECKED DATE DESIGN REVIEW DATE APPROVED DATE INTERNATIONAL HEATERS LTD. BURGESS HILL, SUSSEX, U.K.

AND SHALL NOT BE TRACED, PHOTOGRAPHED,

PHOTOSTATED OR REPRODUCED IN ANY MANNER NOR

USED FOR ANY PURPOSE WHATSOEVER EXCEPT BY WRITTEN

PERMISSION OF BOUSTEAD INTERNATIONAL HEATERS LTD.

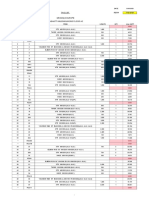

NOTES

1. THIS DOCUMENT IS TO BE READ IN CONJUNCTION WITH 3. ALL SHARP EDGES SHALL BE GROUND SMOOTH AND ALL 6. ALL DIMENSIONS SHALL BE VERIFIED AND ANY

B.I.H DOCUMENT ETD-089 9. ALL SECONDARY STEEL AND STIFFENING TO BE PROFILED 11. ALL MATERIALS GRADE SHALL BE DESIGNED &

10 SHARP CORNERS ROUNDED PRIOR TO PAINTING. DISCREPANCIES SHALL BE REFERRED TO BIH FOR 10

"ENGINEERING STANDARD FOR FABRICATION AND INTO PRIMARY STEEL UNLESS OTHERWISE STATED. FABRICATED USING LOCALLY AVAILABLE MATERIAL PER: TITLE:

WELDING FOR PROCESS FIRED HEATER STEELWORK".

4. ALL HOLES Ø22mm FOR M20 BOLTS UNLESS OTHERS

STATED. 7.

RESOLUTION.

FABRICATOR SHALL AT NO ACCOUNT BE RELEASED FROM

10. FABRICATOR TO PROVIDE ADEQUATE Ø24mm DRAIN - EN 10025 S355 J2 (TYPE 1) (LIFTING LUGS & LIFTING BEAMS) INLET TRANSITION

2. ALL WELDS TO BE CONTINUOUS FILLET WELD. WELD HOLES WHERE REQUIRED. - EN 10025 S355 J2 (TYPE 2) (FOR MAIN W.H.R.U. RAFT)

5. ALL BOLTS TO BE ASTM A325M WITH 1 OFF WASHER, HIS RESPONSIBILITY OF OVERALL EQUIPMENT FIT UP.

EQUAL TO THINNEST PIECE JOINED, BUT NO GREATER - TIS 1227 SS400/ASTM A36 (TYPE 3M) (FOR ALL OTHER REV:

1 OFF HEX NUT & 1 OFF LOCK NUT AS 1 OFF BOLT 8. ALL DIMENSIONS IN MILLIMETERS UNLESS OTHERWISE JOB DRAWING

THAN 6mm, UNLESS OTHERWISE NOTED. ASSEMBLY SET. STATED. BEAMS, COLUMNS, SECONDARY STEEL & CASING) NUMBER 778 NO. 778-08DA-SD-001 0

A B C D E F G H I J

You might also like

- 778 07ea SD 001 Rev0Document1 page778 07ea SD 001 Rev0Nguyễn Xuân TrườngNo ratings yet

- 1014 Graha Paramita II Bintaro, Tangerang (r.12) Jaga - Citra - Inti Fans Mar21 250321Document3 pages1014 Graha Paramita II Bintaro, Tangerang (r.12) Jaga - Citra - Inti Fans Mar21 250321imam wardhanaNo ratings yet

- Ca 50 50Document2 pagesCa 50 50Adrian MartinNo ratings yet

- 2HS - 008 Bushings in FuserDocument3 pages2HS - 008 Bushings in FuserJose Luis Caceres SeverinoNo ratings yet

- Item Qty Reference Part Description Manufacture / Part # Kit Qty PKG Qty BalDocument4 pagesItem Qty Reference Part Description Manufacture / Part # Kit Qty PKG Qty BalZesiee LuphNo ratings yet

- JCB Parts Catalogue PDFDocument629 pagesJCB Parts Catalogue PDFДмитрий100% (1)

- EON Power15 - P-1 Exploded ViewDocument1 pageEON Power15 - P-1 Exploded ViewDaniel FloresNo ratings yet

- TK-3107 (M6) Supplement - B51-8641-00Document22 pagesTK-3107 (M6) Supplement - B51-8641-00David PalashNo ratings yet

- Wiwi Industries Limited: Product Code K02-CCD7601-261018-00ADocument21 pagesWiwi Industries Limited: Product Code K02-CCD7601-261018-00AGaspar GarciaNo ratings yet

- No. Maker Exd No. Reference No. Vehicle Eng/Model (An Example) P/YDocument18 pagesNo. Maker Exd No. Reference No. Vehicle Eng/Model (An Example) P/YDevin ZhangNo ratings yet

- VX-351PMR446 SM EC083U90C With Spares LDocument32 pagesVX-351PMR446 SM EC083U90C With Spares Lvjt.radioNo ratings yet

- Subbu DAC SE V3 BOMDocument1 pageSubbu DAC SE V3 BOMcristi289No ratings yet

- VP3455DDocument11 pagesVP3455DSteni MoaiNo ratings yet

- 3359 Pmjland Tower Totalindo Eka Persada Fans Nov23 071123Document2 pages3359 Pmjland Tower Totalindo Eka Persada Fans Nov23 071123Deden MardiansyahNo ratings yet

- KC Sore 26+27 Juni 2023Document4 pagesKC Sore 26+27 Juni 2023PintoNo ratings yet

- Yz15177 2826KRB PDFDocument7 pagesYz15177 2826KRB PDFeduardo yauriNo ratings yet

- Wharfedale SVP 12PMDocument13 pagesWharfedale SVP 12PMrdbasses100% (1)

- Converter Thrust Bearings: Image Alto# Tri Components # Sonnax # DescriptionDocument4 pagesConverter Thrust Bearings: Image Alto# Tri Components # Sonnax # DescriptionJosue Eli Carreon VillaseñorNo ratings yet

- Ms DD 4250 STR DWG 0202 - Rev0Document21 pagesMs DD 4250 STR DWG 0202 - Rev0harijoesantosNo ratings yet

- Engenharia: 1EG-3000-001 1/94 12 Tubulação 0652 11/01/07Document3 pagesEngenharia: 1EG-3000-001 1/94 12 Tubulação 0652 11/01/07MatheusNo ratings yet

- Product Information Packet: 20HP, 1765RPM, 3PH, 60HZ, 256T, 0952M, TEFC, F1Document10 pagesProduct Information Packet: 20HP, 1765RPM, 3PH, 60HZ, 256T, 0952M, TEFC, F1pavanreguNo ratings yet

- Parts Manual: Customer Support ServicesDocument20 pagesParts Manual: Customer Support ServicesEduardo Javier Valenzuela CelisNo ratings yet

- BinaryDocument4,188 pagesBinaryJivendra KumarNo ratings yet

- Mackie 1202-vlz Pro Service ManualDocument12 pagesMackie 1202-vlz Pro Service ManualdimasarenasgonzalezNo ratings yet

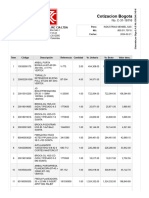

- Cotizacion Bogota: Ferreteria JRC Cia LtdaDocument3 pagesCotizacion Bogota: Ferreteria JRC Cia LtdaDISEÑO Y PRODUCCIÓNNo ratings yet

- Kma26 Sa 103 601-10140-0030Document14 pagesKma26 Sa 103 601-10140-0030jet100% (1)

- ACS800 MultiDriveDocument104 pagesACS800 MultiDriveYasir AbdooNo ratings yet

- Catálago Chines DongDocument5 pagesCatálago Chines DongEmerson SouzzaNo ratings yet

- Spare Mech 811 R0Document2 pagesSpare Mech 811 R0Ivan MaltsevNo ratings yet

- 11th Faa CMM Record Ms ExcelDocument12 pages11th Faa CMM Record Ms Excelajaydce05No ratings yet

- Hertz Ep4 SCHDocument11 pagesHertz Ep4 SCHMantasPuskoriusNo ratings yet

- Material With Electrode SelectionDocument2 pagesMaterial With Electrode SelectionAhmadiBinAhmadNo ratings yet

- 12th Faa CMM Record Ms ExcelDocument12 pages12th Faa CMM Record Ms Excelajaydce05No ratings yet

- VT23 - Workshop Laundry Swb. - 20.10Document6 pagesVT23 - Workshop Laundry Swb. - 20.10TamNo ratings yet

- OEL Recommended Spare Parts List: Revision 8Document3 pagesOEL Recommended Spare Parts List: Revision 8belinha1234No ratings yet

- Ref# TFE-6791 Granada Europe Binghatti Milennium 2Nd Floor Ac Project Tag List CustomerDocument2 pagesRef# TFE-6791 Granada Europe Binghatti Milennium 2Nd Floor Ac Project Tag List Customeraneeshm91No ratings yet

- 3259262Document4 pages3259262M Iqbal AdmanNo ratings yet

- n'Rocky Клапана и Направляющие2012Document242 pagesn'Rocky Клапана и Направляющие2012Валерий Герасимов73% (15)

- Asif WorkDocument2 pagesAsif WorkkrishanNo ratings yet

- CompDocument17 pagesCompTran Anh TuanNo ratings yet

- Liftena Pcba GVZN 20220404 KartiDocument4 pagesLiftena Pcba GVZN 20220404 Karti??????No ratings yet

- Lfpolfpg PDF 1708877289Document35 pagesLfpolfpg PDF 1708877289shiaviation1No ratings yet

- USEM 2speed Amps ModelsDocument2 pagesUSEM 2speed Amps Modelspetronila66No ratings yet

- Mangueras de Tanque de RefrigeranteDocument3 pagesMangueras de Tanque de RefrigeranteAlvaro Escalona GtzNo ratings yet

- Dipetro Synergy Engineering SDN BHD: Visual Inspection ReportDocument1 pageDipetro Synergy Engineering SDN BHD: Visual Inspection ReportMohd SaffririzalNo ratings yet

- HiltiDocument2 pagesHiltiDon RidzwanilNo ratings yet

- Korg Ax 1000gDocument14 pagesKorg Ax 1000gCélio André RibeiroNo ratings yet

- e-STUDIO5520c 6520c 6530cDocument255 pagese-STUDIO5520c 6520c 6530cWolfgang HedwigNo ratings yet

- Wharfedale Pro-Mp2800 SMDocument10 pagesWharfedale Pro-Mp2800 SMJavierNo ratings yet

- Driver Rack DBX 480 - Power BoardDocument4 pagesDriver Rack DBX 480 - Power BoardWalter CruzNo ratings yet

- Im Supplement Bolt Torque Information Fisher 249 Sensors en 124786Document6 pagesIm Supplement Bolt Torque Information Fisher 249 Sensors en 124786Rachmat MaulanaNo ratings yet

- Service Manual: AmplifierDocument7 pagesService Manual: AmplifierRamon Alejandro Figueredo LinaresNo ratings yet

- Service Manual: AmplifierDocument8 pagesService Manual: AmplifierКирилл ОстапецNo ratings yet

- 10th Faa CMM Record Ms ExcelDocument14 pages10th Faa CMM Record Ms Excelajaydce05No ratings yet

- A1 (2 3 4) F./... D 6905 Af/1Document3 pagesA1 (2 3 4) F./... D 6905 Af/1GERALD SIMONNo ratings yet

- Man ModelDocument83 pagesMan Modelmohammed barghothiNo ratings yet

- A32 Calibration - DFHDocument1 pageA32 Calibration - DFHVictor Julian Ortiz PorrasNo ratings yet

- CM70371 1Document8 pagesCM70371 1Juan UchuyaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- 778 08da SD 004 Rev0Document1 page778 08da SD 004 Rev0Nguyễn Xuân TrườngNo ratings yet

- 778 08da SD 002 Rev0Document1 page778 08da SD 002 Rev0Nguyễn Xuân TrườngNo ratings yet

- 778 08da SD 005 Rev0Document1 page778 08da SD 005 Rev0Nguyễn Xuân TrườngNo ratings yet

- 778 07ea SD 010 Rev0Document1 page778 07ea SD 010 Rev0Nguyễn Xuân TrườngNo ratings yet

- 778 07ea SD 008 Rev0Document1 page778 07ea SD 008 Rev0Nguyễn Xuân TrườngNo ratings yet

- 778 07ea SD 009 Rev0Document1 page778 07ea SD 009 Rev0Nguyễn Xuân TrườngNo ratings yet

- 778 07ea SD 005 Rev0Document1 page778 07ea SD 005 Rev0Nguyễn Xuân TrườngNo ratings yet

- 764 08G SD 006 Rev1Document1 page764 08G SD 006 Rev1Nguyễn Xuân TrườngNo ratings yet

- 778 07ea SD 004 Rev0Document1 page778 07ea SD 004 Rev0Nguyễn Xuân TrườngNo ratings yet

- 778 07ea SD 002 Rev0Document1 page778 07ea SD 002 Rev0Nguyễn Xuân TrườngNo ratings yet

- 764 08H SD 003 Rev0Document1 page764 08H SD 003 Rev0Nguyễn Xuân TrườngNo ratings yet

- 764 08H SD 004 Rev0Document1 page764 08H SD 004 Rev0Nguyễn Xuân TrườngNo ratings yet

- 764 08H SD 005 Rev0Document1 page764 08H SD 005 Rev0Nguyễn Xuân TrườngNo ratings yet

- Norsok M101 Rev.5 2011Document62 pagesNorsok M101 Rev.5 2011Elzo2000No ratings yet

- Super Duplex Stainless Steel PipesDocument3 pagesSuper Duplex Stainless Steel Pipeskumar sandeepNo ratings yet

- Viking Manual 110Document90 pagesViking Manual 110Marcelo RochaNo ratings yet

- CATALOG 4660-Thermoplastic HoseDocument339 pagesCATALOG 4660-Thermoplastic HoseJose Antonio GomezNo ratings yet

- 3685 Mir 006 PDFDocument1 page3685 Mir 006 PDFashishpearlNo ratings yet

- Pump DesignDocument23 pagesPump DesignDidi Kurniadi100% (2)

- Fire Rated Counter Doors Standard Cer C 10Document11 pagesFire Rated Counter Doors Standard Cer C 10Valentinas PranskunasNo ratings yet

- 3D Finite Element Analysis of A Complex Excavation: TitleDocument6 pages3D Finite Element Analysis of A Complex Excavation: TitleFaten Abou ShakraNo ratings yet

- Interior Arch Vs DesignDocument9 pagesInterior Arch Vs DesignAyesha MAhmoodNo ratings yet

- Lysaght Bondek User GuideDocument12 pagesLysaght Bondek User GuideSiu SiuNo ratings yet

- T 321-07 2011Document11 pagesT 321-07 2011susanaleNo ratings yet

- Test Methods For Self-Compacting Concrete (SCC)Document56 pagesTest Methods For Self-Compacting Concrete (SCC)MAS_LAGA50% (2)

- ASCE - 'Astoria Tunnel Profile Under The East River'Document109 pagesASCE - 'Astoria Tunnel Profile Under The East River'Colin PearceNo ratings yet

- G K9FB6-40001 HoodDocument6 pagesG K9FB6-40001 HoodGustavo RodriguezNo ratings yet

- Construction and Building Materials: Abhishek Jain, Rajesh Gupta, Sandeep ChaudharyDocument13 pagesConstruction and Building Materials: Abhishek Jain, Rajesh Gupta, Sandeep ChaudharySchool of EngineersNo ratings yet

- Mega-Stop Bell Protection System Aids in Pipe Joint AssemblyDocument2 pagesMega-Stop Bell Protection System Aids in Pipe Joint AssemblyKeaten ClaneyNo ratings yet

- Zap Diy Old School Cable Kit Guide v1Document6 pagesZap Diy Old School Cable Kit Guide v1asdfhwegaNo ratings yet

- Acoustic Emission Source LocationDocument176 pagesAcoustic Emission Source LocationCarlos Quiterio Gomez Muñoz100% (2)

- Lampiran 1 Amandemen-1 Kesepakatan Harga Satuan (KHS)Document5,697 pagesLampiran 1 Amandemen-1 Kesepakatan Harga Satuan (KHS)YeremiaNo ratings yet

- Acoustics Required in A Recording StudioDocument19 pagesAcoustics Required in A Recording StudioRiyaNo ratings yet

- Buildingguide - Co.nz-Construction ChecklistsDocument16 pagesBuildingguide - Co.nz-Construction ChecklistsElla CelineNo ratings yet

- FAS Data-Sheet Vantage-Seal PDFDocument10 pagesFAS Data-Sheet Vantage-Seal PDFVictor Flores ResendizNo ratings yet

- Calex Auto Private LimitedDocument8 pagesCalex Auto Private LimitedVishalNo ratings yet

- Innova M3 New: 3. InstallationDocument8 pagesInnova M3 New: 3. InstallationAndreea DanielaNo ratings yet

- Gen TT Install InstructionsDocument25 pagesGen TT Install Instructionsspsperformance1No ratings yet

- ME 582 F06 - Chapter 5 Failure Analysis and Design of Laminates Part 1Document23 pagesME 582 F06 - Chapter 5 Failure Analysis and Design of Laminates Part 1Ernesto ChagoyenNo ratings yet

- StratosDocument4 pagesStratosCelith Rossy Inga PeñaNo ratings yet

- Excel Tulangan Slab On Pile 3Document2 pagesExcel Tulangan Slab On Pile 3panduNo ratings yet

- CPHEEODocument53 pagesCPHEEOVignesh NadimuthuNo ratings yet

- Operation and Maint Manual Swill Hydraulic PlateformDocument16 pagesOperation and Maint Manual Swill Hydraulic Plateformmicell dieselNo ratings yet

- Workshop Manual Citea DAF Euro-5 EnglezaDocument466 pagesWorkshop Manual Citea DAF Euro-5 EnglezaIgor NistorNo ratings yet