Professional Documents

Culture Documents

Reebol WB

Uploaded by

m.elsanee.cubicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reebol WB

Uploaded by

m.elsanee.cubicCopyright:

Available Formats

Reebol WB* constructive solutions

Water based chemical mould release agent

Uses Instructions for use

To provide quick, clean and easy stripping of moulds and Mould preparation

formwork and ensure high quality, fair faced and stain free

Steel moulds require no special treatment other than the

concrete.

removal of rust or oil, wetting out may be improved by lightly

abrading the surface.

Advantages

Preparation of used moulds

! Ensures easy release, reducing damage and improving

efficiency of production. Moulds previously treated with Reebol WB will require only

! Minimises surface blemishes and staining, promoting light brushing as the presence of fine dust will improve

high quality fair-faced concrete even with white cement. absorption of Reebol WB into the mould surface. This will

usually result in improved release properties on the second

! Reduces opportunity of damage to formwork, extending

and subsequent uses of the mould.

usable life.

! Minimises cleaning of formwork before re-use. Application

! Suitable for use with virtually all types of formwork. Reebol WB may be applied by brush or conventional mould

! Inhibits corrosion of steel formwork. oil sprayer. If a mould oil sprayer is used, it is important that a

fine nozzle is fitted as Reebol WB should be applied in a light

Description continuous film. If Reebol WB is over applied, excess material

should be allowed to drain and then be carefully removed

Reebol WB an emulsified blend of mineral oils and non-

from the bottom of the mould by means of a sponge or cloth.

hazardous chemicals is specially formulated to produce

Pools of Reebol WB should not be allowed to dry otherwise

release properties which are superior to those of conventional

surface retardation of the concrete will occur.

mould oils.

Unlike conventional mould oils Reebol WB does not possess

Reebol WB is supplied as a sprayable white liquid, ready for

residual release properties, so it is important that prior to

direct application on site.

each occasion of use, all areas of the mould are re-coated.

The chemically reactive components in Reebol WB provide Particular attention should be paid to coating mould rims in

a water repellent interface which protects formwork and order to avoid adhesion of overspill cement slurry.

ensures an even colour and texture in the cast concrete.

After stripping or demoulding

In addition to preventing adhesion of concrete to formwork,

After use, the formwork or mould should be brushed or wiped

Reebol WB will allow air to escape from the interface during

clean of any excess dust prior to re-application of Reebol WB

concrete placing and vibration. The release of air minimises

for the next use of the mould. The use of Reebol WB

surface blemishes and blow holes resulting in a substantial

minimises the amount of time and effort required for this

reduction in remedial costs.

process.

Properties Repair of moulds

If, after extended use, mould surfaces require repair or re-

Colour : White

coating with polyurethane sealer, all residual traces of Reebol

Specific gravity at 20°C : 0.995

WB must be removed to ensure complete adhesion. This is

Viscosity at 20°C

best effected by using a strong industrial detergent together

(Ford cup A4) : 10 secs

with stiff brushing, followed by thorough rinsing with clean

Formwork Surfaces: Reebol WB is compatible with timber, water.

steel, GRP and resinous formwork surfaces.

Non-Staining: Does not stain concrete and can be used

safely with white cement.

Reebol WB*

Steam Curing: Reebol WB is effective at elevated

temperatures and can be used for steam curing at 75°C.

Reebol WB*

Estimating Additional Information

Supply Fosroc manufactures a wide range of complementary

Reebol WB : 210 litre drums products which include :

Coverage ! waterproofing membranes & waterstops

Reebol WB : 20 - 75 m2/litre ! joint sealants & filler boards

Note : Depends on substrate e.g. for high quality ! cementitious & epoxy grouts

smooth steel 75m²/ litre. For fair faced plywood ! specialised flooring materials

20m²/ litre.

Fosroc additionally offers a comprehensive package of

Storage products specifically designed for the repair and

refurbishment of damaged concrete. Fosroc’s ‘Systematic

Reebol has a minimum shelf life of 12 months when stored Approach’ to concrete repair features the following :

in the original unopened containers under normal warehouse

conditions, below 40°C. ! hand-placed repair mortars

Fire ! spray grade repair mortars

Reebol WB is water based and is therefore non-flammable. ! fluid micro-concretes

! chemically resistant epoxy mortars

Precautions

! anti-carbonation/anti-chloride protective coatings

Health and safety

! chemical and abrasion resistant coatings

Reebol WB is non-toxic, however it is advisable to wear

goggles when spraying. Inhalation of spray should be For further information on any of the above, please consult

avoided. In the case of excessive skin contact wash with soap your local Fosroc office - as below.

and water and apply skin conditioning cream. Should contact

with eyes occur, flush with clean water for 10 minutes. If Technical support

irritation persists obtain medical advise, if product is Fosroc offers a comprehensive technical support service to

swallowed - do not induce vomiting, obtain medical attention specifiers, end users and contractors. It is also able to offer

immediately. on-site technical assistance, an AutoCAD facility and

Cleaning and disposal dedicated specification assistance in locations all over the

world

Spillages of Reebol WB should be absorbed onto sand, earth

or vermiculite and transferred to suitable containers.

Contaminated areas will become slippery therefore care must

be exercised.

The disposal of excess or waste material should be carried

out in accordance with local legislation under the guidance of * Denotes the trademark of Fosroc International Limited

the local waste regulatory authority. †

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard

Conditions for the Supply of Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s

responsibility to obtain the recent version. Refer to www.fosroc.com.

Head Office

Al Gurg Fosroc telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

LLC Regional offices

Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

Post Box 657, Dubai Bahrain, YBA Kanoo telephone: 17735454 fax: 17732828 email: bahrain@fosroc.com

United Arab Emirates Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

www.fosroc.com

Qatar, Tadmur telephone: 4500607 fax: 4500543 email: qatar@fosroc.com

UAE/0301/07/B

You might also like

- Fosroc Reebol WB: Constructive SolutionsDocument2 pagesFosroc Reebol WB: Constructive SolutionsVincent JavateNo ratings yet

- Reebol: High Performance Environmental Friendly Mould Release AgentDocument2 pagesReebol: High Performance Environmental Friendly Mould Release AgentKrishna PrakashNo ratings yet

- Reebol PDFDocument2 pagesReebol PDFBhupendra Singh RajputNo ratings yet

- Reebol ConcentrateDocument2 pagesReebol Concentratem.elsanee.cubicNo ratings yet

- Reebol: High Performance Environmental Friendly Mould Release AgentDocument2 pagesReebol: High Performance Environmental Friendly Mould Release AgentpankajsinghNo ratings yet

- Reebol WBDocument2 pagesReebol WBVenkata RaoNo ratings yet

- Reebol: Chemical Mould Release AgentDocument3 pagesReebol: Chemical Mould Release Agentyoga pratamaNo ratings yet

- Reebol 3Document2 pagesReebol 3MayankNo ratings yet

- ReebolDocument2 pagesReebolm.elsanee.cubicNo ratings yet

- Fosroc Reebol: Constructive SolutionsDocument2 pagesFosroc Reebol: Constructive SolutionsVincent JavateNo ratings yet

- REEBOLDocument2 pagesREEBOLathulraj sbNo ratings yet

- REEBOLDocument2 pagesREEBOLadilabad newsNo ratings yet

- Concure RB90Document4 pagesConcure RB90m.elsanee.cubicNo ratings yet

- Reebol Emulsion: Concentrated and Emulsified Chemical Mould Release AgentDocument3 pagesReebol Emulsion: Concentrated and Emulsified Chemical Mould Release AgentSHAIK ASIMUDDINNo ratings yet

- Fosroc Concure RB90: High Quality, Resin Based, Concrete Curing CompoundDocument4 pagesFosroc Concure RB90: High Quality, Resin Based, Concrete Curing CompoundBrian MbathaNo ratings yet

- Concure RB90Document4 pagesConcure RB90m.basim.technitalNo ratings yet

- Reebol Emulsion Xtra: Constructive SolutionsDocument4 pagesReebol Emulsion Xtra: Constructive SolutionsDeven PatleNo ratings yet

- Reebol Emulsion Xtra: Constructive SolutionsDocument3 pagesReebol Emulsion Xtra: Constructive SolutionssbnCNo ratings yet

- 2511 Data She e Tree BolDocument2 pages2511 Data She e Tree BolAjay SharmaNo ratings yet

- MS For Honeycomb rectification-RFMS 010Document17 pagesMS For Honeycomb rectification-RFMS 010Chamux skalNo ratings yet

- TDS Concure WB Saudi ArabiaDocument2 pagesTDS Concure WB Saudi ArabiaAstc AfaqNo ratings yet

- CONSOL Form Oil WBDocument3 pagesCONSOL Form Oil WBimmanuel lumbantobingNo ratings yet

- Concure WB : Water Based Concrete Curing CompoundDocument2 pagesConcure WB : Water Based Concrete Curing CompoundVenkat Eswarlu BNo ratings yet

- Cure Tec EngDocument2 pagesCure Tec EngPedroNo ratings yet

- Concure WB White: Water Based Concrete Curing CompoundDocument2 pagesConcure WB White: Water Based Concrete Curing CompoundSure Tech Trivandrum100% (1)

- Reebol Emulsion ConcentrateDocument2 pagesReebol Emulsion ConcentrateJA WPKNo ratings yet

- TDS VETOBOND pb434Document4 pagesTDS VETOBOND pb434PeshteenNo ratings yet

- TDS Concure AB White India PDFDocument4 pagesTDS Concure AB White India PDFAarish KhanNo ratings yet

- Concure WBDocument2 pagesConcure WBR.ThangarajNo ratings yet

- Fosroc Concure A: (Formerly Cureseal)Document4 pagesFosroc Concure A: (Formerly Cureseal)Shaik QutubuddinNo ratings yet

- Fosroc Concure WB: Water Based Concrete Curing CompoundDocument2 pagesFosroc Concure WB: Water Based Concrete Curing CompoundShaik QutubuddinNo ratings yet

- Pactofinish WBDocument2 pagesPactofinish WBNNo ratings yet

- TDS Concure WB IndiaDocument2 pagesTDS Concure WB IndiaipoNo ratings yet

- Concure ADocument4 pagesConcure Am.basim.technitalNo ratings yet

- Concure WBDocument2 pagesConcure WBm.basim.technitalNo ratings yet

- Abecote 341: Concrete Dust Proofer and Surface Hardening CompoundDocument2 pagesAbecote 341: Concrete Dust Proofer and Surface Hardening Compoundengramir07No ratings yet

- Nitobond SBR TDSDocument3 pagesNitobond SBR TDSHariom GuptaNo ratings yet

- Release Agent ComparisonDocument1 pageRelease Agent ComparisonsulingNo ratings yet

- Brushbond RFX PDFDocument2 pagesBrushbond RFX PDFDeep GandhiNo ratings yet

- Arkifloor SLE 2MDocument2 pagesArkifloor SLE 2MChristinaNo ratings yet

- Water ProofDocument3 pagesWater ProofMohamed KhanNo ratings yet

- Fosroc Concure A: (Formerly Cureseal)Document4 pagesFosroc Concure A: (Formerly Cureseal)Vincent JavateNo ratings yet

- Polybit Ma Polybond SBR Tds LeedDocument2 pagesPolybit Ma Polybond SBR Tds LeedMuhammad hussainNo ratings yet

- Supreme Silicones: Technical Data SheetDocument1 pageSupreme Silicones: Technical Data SheetSukhwinder SinghNo ratings yet

- Masterkure 100WBDocument2 pagesMasterkure 100WBDoby YuniardiNo ratings yet

- Datasheet of Al Form Oil CDocument3 pagesDatasheet of Al Form Oil CSunil75% (4)

- 6 2 3 6 1 Polybond SBR PDFDocument2 pages6 2 3 6 1 Polybond SBR PDFHtun ZarniNo ratings yet

- Nitoflor HardtopDocument4 pagesNitoflor HardtopArunashish Mazumdar100% (1)

- Fosroc Concure WB30 TDSDocument2 pagesFosroc Concure WB30 TDSmrameshceNo ratings yet

- Carboguard 703Document2 pagesCarboguard 703Achraf BoudayaNo ratings yet

- Arkifloor AWDocument2 pagesArkifloor AWChristinaNo ratings yet

- Rheobuild 1000Document2 pagesRheobuild 1000Mcr KumaraNo ratings yet

- Abecote 341: Concrete Dust Proofer and Surface Hardening CompoundDocument2 pagesAbecote 341: Concrete Dust Proofer and Surface Hardening CompoundAshvin ParmessurNo ratings yet

- Antisol - WB PDFDocument2 pagesAntisol - WB PDFAshraf ELsherbeneyNo ratings yet

- Cico Plast Super C804Document2 pagesCico Plast Super C804ASRAR AHMED KHANNo ratings yet

- Carboguard 954 HB PDS 7-10Document2 pagesCarboguard 954 HB PDS 7-10raja020No ratings yet

- Concure ADocument4 pagesConcure AtalatzahoorNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Ceramic Tiles Rev.1Document2 pagesCeramic Tiles Rev.1m.elsanee.cubicNo ratings yet

- Emortar FC200Document2 pagesEmortar FC200m.elsanee.cubicNo ratings yet

- Conbextra EP300Document4 pagesConbextra EP300m.elsanee.cubicNo ratings yet

- Nitoflor Lithurin 2Document2 pagesNitoflor Lithurin 2m.elsanee.cubicNo ratings yet

- Nitoflor LVBGDocument4 pagesNitoflor LVBGm.elsanee.cubicNo ratings yet

- Fosroc Nukote BGIIDocument4 pagesFosroc Nukote BGIIm.elsanee.cubicNo ratings yet

- Conbextra UWDocument2 pagesConbextra UWm.elsanee.cubicNo ratings yet

- Galvashield FMADocument2 pagesGalvashield FMAm.elsanee.cubicNo ratings yet

- Nitoflor RoctopDocument2 pagesNitoflor Roctopm.elsanee.cubicNo ratings yet

- Galvashield CCDocument4 pagesGalvashield CCm.elsanee.cubicNo ratings yet

- Egrout S50Document2 pagesEgrout S50m.elsanee.cubicNo ratings yet

- Galvashield LJDocument2 pagesGalvashield LJm.elsanee.cubicNo ratings yet

- Fosroc Nitogard MA210Document2 pagesFosroc Nitogard MA210m.elsanee.cubicNo ratings yet

- Fosroc Trowel EZDocument2 pagesFosroc Trowel EZm.elsanee.cubicNo ratings yet

- Conbextra GPDocument4 pagesConbextra GPm.elsanee.cubicNo ratings yet

- Galva FroidDocument2 pagesGalva Froidm.elsanee.cubicNo ratings yet

- Dekguard E2000Document4 pagesDekguard E2000m.elsanee.cubicNo ratings yet

- Supercast Synkoflex and Synkoflex FR Jun06Document2 pagesSupercast Synkoflex and Synkoflex FR Jun06m.elsanee.cubicNo ratings yet

- Conbextra BB80Document4 pagesConbextra BB80m.elsanee.cubicNo ratings yet

- Nitoflor TSR5000Document4 pagesNitoflor TSR5000m.elsanee.cubicNo ratings yet

- Cemtop 250TDocument4 pagesCemtop 250Tm.elsanee.cubicNo ratings yet

- Structuro 340Document2 pagesStructuro 340m.elsanee.cubicNo ratings yet

- Assignment2 SolutionDocument19 pagesAssignment2 Solutionm.elsanee.cubicNo ratings yet

- Conbextra PDocument4 pagesConbextra Pm.elsanee.cubicNo ratings yet

- 16 Ganesh DDocument16 pages16 Ganesh DGanesh DhobaleNo ratings yet

- VW 276 - Action PlanDocument9 pagesVW 276 - Action PlanbenindalsiNo ratings yet

- Cypermethrin: Environmental Health Criteria 82Document159 pagesCypermethrin: Environmental Health Criteria 82AshishNo ratings yet

- IJRET20140311060Document7 pagesIJRET20140311060ltve20me136No ratings yet

- Process Description Part 1 of 2 32618-196-06-DB-001Document13 pagesProcess Description Part 1 of 2 32618-196-06-DB-001waheedNo ratings yet

- Project On Study of Constituents of AlloyDocument15 pagesProject On Study of Constituents of AlloyBhumit MittalNo ratings yet

- Fibertec M6 User ManualDocument61 pagesFibertec M6 User ManualSpyr TourNo ratings yet

- SepSolve Aroma Profiling of Wine Using Sorptive ExtractionDocument7 pagesSepSolve Aroma Profiling of Wine Using Sorptive ExtractionDanaNo ratings yet

- Distillation CurveDocument9 pagesDistillation CurveAmmar .kNo ratings yet

- SGL Technical Info SIGRATHERM Chemical Resistance ENDocument13 pagesSGL Technical Info SIGRATHERM Chemical Resistance ENTushar LateNo ratings yet

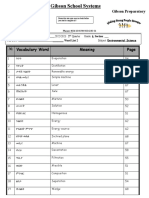

- Grade 6 Env. Scinence Wordlist 2Document2 pagesGrade 6 Env. Scinence Wordlist 2reshid museNo ratings yet

- Protocol Agilent 1100 HPLC ChemstationDocument9 pagesProtocol Agilent 1100 HPLC ChemstationNarongchai PongpanNo ratings yet

- Preparation and Characterisation of Polyaluminium Silicate Chloride CoagualantDocument10 pagesPreparation and Characterisation of Polyaluminium Silicate Chloride CoagualantThu TongNo ratings yet

- Aldehydes and Ketones - JEE Main 2024 January Question Bank - MathonGoDocument6 pagesAldehydes and Ketones - JEE Main 2024 January Question Bank - MathonGoRoshan AhamedNo ratings yet

- Autothermal Reforming of Methane Design and PerforDocument7 pagesAutothermal Reforming of Methane Design and Perforromi moriNo ratings yet

- Ppi CL PDFDocument3 pagesPpi CL PDFMaxflowNo ratings yet

- Acs Energyfuels 7b03733Document12 pagesAcs Energyfuels 7b03733Dinesh JoshiNo ratings yet

- Terrarium 50 Ideas PDFDocument198 pagesTerrarium 50 Ideas PDFdbarrios1985100% (1)

- Chapter 46-51 PDFDocument179 pagesChapter 46-51 PDFHasan RabyNo ratings yet

- Chemistry Btech Lab Manual-CH 202Document17 pagesChemistry Btech Lab Manual-CH 202John HopkinsNo ratings yet

- Concrete Manual 8th Edition (USBR)Document661 pagesConcrete Manual 8th Edition (USBR)great_triskelion100% (10)

- Acidic Strength-Basic StrengthDocument25 pagesAcidic Strength-Basic StrengthrrNo ratings yet

- Electrical Properties FinalDocument7 pagesElectrical Properties FinalMohsin AlamNo ratings yet

- Inorganic ChemistryDocument10 pagesInorganic Chemistrydebraj sethi100% (1)

- Oerlikon Metco FeCrAlYDocument3 pagesOerlikon Metco FeCrAlYMarcin LisNo ratings yet

- Material Brand ListDocument853 pagesMaterial Brand ListJan laporeNo ratings yet

- 2 Structure and Deformation in Material Lecture 1Document79 pages2 Structure and Deformation in Material Lecture 1Hung HimmyNo ratings yet

- Country's Best Online Test PlatformDocument63 pagesCountry's Best Online Test PlatformSubhrasankar RaychaudhuryNo ratings yet

- Drilling Fluid ProgramDocument434 pagesDrilling Fluid ProgramhakoubNo ratings yet

- Combining Chemical and Biological Catalysis For The Conversion of HemicelluloseDocument8 pagesCombining Chemical and Biological Catalysis For The Conversion of Hemicellulosemrsch 1No ratings yet