Professional Documents

Culture Documents

B-05 Standard Roll Groove-RevG

Uploaded by

DeniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B-05 Standard Roll Groove-RevG

Uploaded by

DeniCopyright:

Available Formats

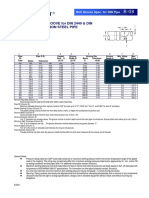

Roll Groove Specification B-05

Roll Grooving Dimensions for ANSI B36.10, BS 1387 (M) & AS 1074 (M)

Pipe

Basic roll groove dimensions conform to

ANSI/AWWA C606-06 Table 5 with slightly

adjusted tolerances to incorporate

international standards including CSA B242,

ISO/FDIS 6182-12, VdS 2100-6en and JPF

MP-006.

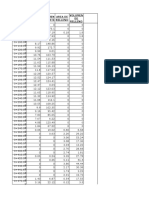

Pipe O.D. d F

A B C t Groove Max.

Nominal Basic Tolerance ±0.030 ±0.030 +0.000 Min. Depth Allowed

Size ±0.76 ±0.76 +0.00 Wall (ref.) Flare Dia.

in in in in in in in in in in

mm mm mm mm mm mm mm mm mm mm

¾ 1.050 +0.010 -0.010 0.625 0.281 0.938-0.015 0.065 0.056 1.15

20 26.7 +0.25 -0.25 15.88 7.14 23.83-0.38 1.65 1.42 29.21

1 1.315 +0.013 -0.013 0.625 0.281 1.190-0.015 0.065 0.063 1.43

25 33.4 +0.33 -0.33 15.88 7.14 30.23-0.38 1.65 1.60 36.30

1¼ 1.660 +0.016 -0.016 0.625 0.281 1.535-0.015 0.065 0.063 1.77

32 42.2 +0.41 -0.41 15.88 7.14 38.99-0.38 1.65 1.60 44.96

1½ 1.900 +0.019 -0.019 0.625 0.281 1.775-0.015 0.065 0.063 2.01

40 48.3 +0.48 -0.48 15.88 7.14 45.09-0.38 1.65 1.60 51.05

2 2.375 +0.024 -0.024 0.625 0.344 2.250-0.015 0.065 0.063 2.48

50 60.3 +0.61 -0.61 15.88 8.74 57.15-0.38 1.65 1.60 62.99

2½ 2.875 +0.029 -0.029 0.625 0.344 2.720-0.018 0.083 0.078 2.98

65 73.0 +0.74 -0.74 15.88 8.74 69.09-0.46 2.11 1.98 75.69

3.000 +0.030 -0.030 0.625 0.344 2.844-0.018 0.090 0.075 3.10

76.1mm 76.1 +0.76 -0.76 15.88 8.74 72.24-0.46 2.30 1.93 78.74

3 3.500 +0.035 -0.031 0.625 0.344 3.344-0.018 0.083 0.078 3.60

80 88.9 +0.89 -0.79 15.88 8.74 84.94-0.46 2.11 1.98 91.44

101.6mm 4.000 +0.040 -0.031 0.625 0.344 3.834-0.020 0.083 0.083 4.10

101.6 +1.02 -0.79 15.88 8.74 97.38-0.51 2.11 2.11 104.10

108.0mm 4.250 +0.042 -0.031 0.625 0.344 4.084-0.020 0.083 0.083 4.35

108.0 +1.07 -0.79 15.88 8.74 103.73-0.51 2.11 2.11 110.49

4 4.500 +0.040 -0.031 0.625 0.344 4.334-0.020 0.083 0.083 4.60

100 114.3 +1.02 -0.79 15.88 8.74 110.08-0.51 2.11 2.11 116.84

133.0mm 5.250 +0.051 -0.031 0.625 0.344 5.084-0.020 0.109 0.083 5.35

133.0 +1.32 -0.79 15.88 8.74 129.13-0.51 2.77 2.11 135.89

5.500 +0.050 -0.031 0.625 0.344 5.333-0.020 0.109 0.083 5.60

139.7mm

139.7 +1.40 -0.79 15.88 8.74 135.46-0.51 2.77 2.11 142.24

5 5.563 +0.056 -0.031 0.625 0.344 5.395-0.022 0.109 0.083 5.66

125 141.3 +1.42 -0.79 15.88 8.74 137.03-0.56 2.77 2.11 143.76

159.0mm 6.250 +0.063 -0.031 0.625 0.344 6.084-0.030 0.109 0.083 6.35

159.0 +1.60 -0.79 15.88 8.74 154.53-0.76 2.77 2.11 161.29

6.500 +0.063 -0.031 0.625 0.344 6.334-0.022 0.109 0.085 6.60

165.1mm

165.1 +1.60 -0.79 15.88 8.74 160.88-0.56 2.77 2.16 167.64

6 6.625 +0.063 -0.031 0.625 0.344 6.455-0.022 0.109 0.085 6.73

150 168.3 +1.60 -0.79 15.88 8.74 163.96-0.56 2.77 2.16 170.94

216.3mm 8.516 +0.063 -0.031 0.750 0.469 8.331-0.025 0.109 0.092 8.69

216.3 +1.60 -0.79 19.05 11.91 211.61-0.64 2.77 2.34 220.73

8 8.625 +0.063 -0.031 0.750 0.469 8.441-0.025 0.109 0.092 8.80

200 219.1 +1.60 -0.79 19.05 11.91 214.40-0.64 2.77 2.34 223.52

10 10.750 +0.063 -0.031 0.750 0.469 10.562-0.027 0.134 0.094 10.92

250 273.0 +1.60 -0.79 19.05 11.91 268.27-0.69 3.40 2.39 277.37

12 12.750 +0.063 -0.031 0.750 0.469 12.531-0.030 0.156 0.109 12.92

300 323.9 +1.60 -0.79 19.05 11.91 318.29-0.76 3.96 2.77 328.17

14 14.000 +0.063 -0.031 0.938 0.469 13.781-0.030 0.156 0.109 14.10

350 355.6 +1.60 -0.79 23.83 11.91 350.04-0.76 3.96 2.77 358.14

16 16.000 +0.063 -0.031 0.938 0.469 15.781-0.030 0.165 0.109 16.10

400 406.4 +1.60 -0.79 23.83 11.91 400.84-0.76 4.19 2.77 408.94

18 18.000 +0.063 -0.031 1.000 0.469 17.781-0.030 0.165 0.109 18.16

450 457.2 +1.60 -0.79 25.40 11.91 451.64-0.76 4.19 2.77 461.26

20 20.000 +0.063 -0.031 1.000 0.469 19.781-0.030 0.188 0.109 20.16

500 508.0 +1.60 -0.79 25.40 11.91 502.44-0.76 4.78 2.77 512.06

B-05-1/2 Rev.G 20180601

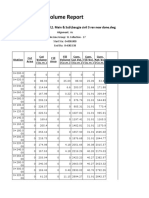

Roll Groove Specification B-05

Pipe O.D. d F

A B C t Groove Max.

Nominal Basic Tolerance ±0.030 ±0.030 +0.000 Min. Depth Allowed

Size ±0.76 ±0.76 +0.00 Wall (ref.) Flare Dia.

in in in in in in in in in in

mm mm mm mm mm mm mm mm mm mm

22 22.000 +0.063 -0.031 1.000 0.469 21.656-0.030 0.188 0.172 22.20

550 558.8 +1.60 -0.79 25.40 11.91 550.06-0.76 4.78 4.37 563.88

24 24.000 +0.063 -0.031 1.000 0.500 23.656-0.030 0.218 0.172 24.20

600 609.6 +1.60 -0.79 25.40 12.70 600.86-0.76 5.54 4.37 614.68

1. Pipe ends must be square cut. See above table for maximum allowable tolerances from square cut ends

Pipe Size G (max)

~3½ " 0.030" (0.8mm)

4 ~ 6" 0.045" (1.2mm)

8" ~ 0.060" (1.6mm)

2. The gasket seating surface `A' shall be free from deep scores, marks, or ridges that would prevent a positive seal.

3. The `C' dimensions are average values. The groove must be of uniform depth around the entire circumference. Use a Shurjoint

groove gage or rule to check the groove diameter.

4. The `t' is the minimum allowable wall thickness that may be roll-grooved.

5. The `d' is for reference use only. The groove depth shall be determined by the groove diameter `C'.

6. Flare Diameter: The pipe end that may flare when the groove is rolled shall be within this limit when measured at the extreme end of

the pipe.

.

Note:

⚫ Shurjoint reserves the right to change specifications, designs and or standard equipment without notice and without incurring any obligations.

B-05-2/2 Rev.G 20180601

You might also like

- B-05 Standard Roll Groove-RevFDocument2 pagesB-05 Standard Roll Groove-RevFAgreen AnggadaNo ratings yet

- VOLUMENDocument8 pagesVOLUMENnelson molianes doriaNo ratings yet

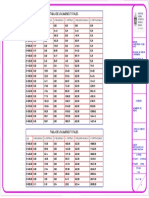

- Station Cut Area (SQ.M.) Cut (Cu.m.) Reusable (Cu.m.) Fill Area (SQ.M.) Fill (Cu.m.) Cum. Cut Vol. (Cu.m.) Cum. Reusable Vol. (Cu.m.)Document4 pagesStation Cut Area (SQ.M.) Cut (Cu.m.) Reusable (Cu.m.) Fill Area (SQ.M.) Fill (Cu.m.) Cum. Cut Vol. (Cu.m.) Cum. Reusable Vol. (Cu.m.)Juan Carlos Perez JulcaNo ratings yet

- Volumenes Canal Mazac - 03Document5 pagesVolumenes Canal Mazac - 03RicardoPrietoNo ratings yet

- Quantities ReportDocument5 pagesQuantities ReportAlfredo Huerta ZoluagaNo ratings yet

- METRADOSDocument22 pagesMETRADOSFelmo SondorNo ratings yet

- Movimiento de Tierra-KM10-15 OKDocument7 pagesMovimiento de Tierra-KM10-15 OKherosley cercadoNo ratings yet

- 2.0. - Calculo Hidraulico Tubería.0Document1 page2.0. - Calculo Hidraulico Tubería.0johann arceNo ratings yet

- SDOF Damped Forced Vibration - NewmarkDocument5 pagesSDOF Damped Forced Vibration - NewmarkAbu Hadiyd Al-IkhwanNo ratings yet

- Volume Report: Station Area de Corte M2 Volumen de Corte Area de Relleno Volumen DE RellenoDocument4 pagesVolume Report: Station Area de Corte M2 Volumen de Corte Area de Relleno Volumen DE RellenoEddy ARNo ratings yet

- 25.03 - Vitaulic RanuradoDocument3 pages25.03 - Vitaulic RanuradoABAD ALEXANDER MORENO ZÁRATENo ratings yet

- Station Area de Corte Volumen de Corte Area de Relleno Volumen DE RellenoDocument5 pagesStation Area de Corte Volumen de Corte Area de Relleno Volumen DE RellenopuchamonNo ratings yet

- Volumen de ReporteDocument6 pagesVolumen de ReporteRider R. Damian ChipanaNo ratings yet

- Total Volume Table Total Volume Table Total Volume Table Total Volume Table Total Volume Table Total Volume TableDocument1 pageTotal Volume Table Total Volume Table Total Volume Table Total Volume Table Total Volume Table Total Volume TableteddyNo ratings yet

- TAREA Diagrama de Masas 2021Document23 pagesTAREA Diagrama de Masas 2021Joaquin Fernando Vilte PeralesNo ratings yet

- Geometric Toll Road Analisys Alignment Vertical Calculation Links: Pemalang - BatangDocument8 pagesGeometric Toll Road Analisys Alignment Vertical Calculation Links: Pemalang - BatangJennifer HudsonNo ratings yet

- Standard Gauge For Sheet and Plate Iron & SteelDocument3 pagesStandard Gauge For Sheet and Plate Iron & Steelnelson121No ratings yet

- Tabla de Volumen CompuertasDocument6 pagesTabla de Volumen CompuertasGerardo Puño espinozaNo ratings yet

- Back Up Cut and Fill 2Document2 pagesBack Up Cut and Fill 2Yerry PayapoNo ratings yet

- Volume Report: Project: D:/Documents/ALAT KERJA/Project 2019/data Ukur Laonti Konsel/Gambar Jalan Laonti - DWGDocument7 pagesVolume Report: Project: D:/Documents/ALAT KERJA/Project 2019/data Ukur Laonti Konsel/Gambar Jalan Laonti - DWGAdji PriwantaraNo ratings yet

- Din 2448Document1 pageDin 2448IsaacNo ratings yet

- Cuadro de Volumen Total (Sal)Document2 pagesCuadro de Volumen Total (Sal)HERMOGENES BERMUDO POMANo ratings yet

- Volume Report: Client: Prepared byDocument48 pagesVolume Report: Client: Prepared byjaretd martinezNo ratings yet

- Diagrama de Masa I KMDocument6 pagesDiagrama de Masa I KMenwarNo ratings yet

- Tabla Diagrama de MasasDocument4 pagesTabla Diagrama de MasasLuis Alejandro Feliz PeñaNo ratings yet

- Curva Masa HDocument3 pagesCurva Masa HErick De Jesus PalemonNo ratings yet

- 3 - Cuadro de Calculo Volumetrico Tramo 3Document12 pages3 - Cuadro de Calculo Volumetrico Tramo 3ojoramarioNo ratings yet

- Earthwork VolumeDocument12 pagesEarthwork VolumeDaniel AnuchaNo ratings yet

- Volume Report: Project: E:/PROJECT/wika/2. Main & Sub/baugia Civil 3 Rev New Done - DWGDocument17 pagesVolume Report: Project: E:/PROJECT/wika/2. Main & Sub/baugia Civil 3 Rev New Done - DWGBismo AnggoroNo ratings yet

- Station Cut Area (SQ.M.) Cut (Cu.m.) Reusable (Cu.m.) Fill Area (SQ.M.) Fill (Cu.m.) Cum. Cut Vol. (Cu.m.) Cum. Reusable Vol. (Cu.m.)Document7 pagesStation Cut Area (SQ.M.) Cut (Cu.m.) Reusable (Cu.m.) Fill Area (SQ.M.) Fill (Cu.m.) Cum. Cut Vol. (Cu.m.) Cum. Reusable Vol. (Cu.m.)Anonymous 5CbAVb8No ratings yet

- Vol - Ancho CARRIL DERECHO 4.20Document8 pagesVol - Ancho CARRIL DERECHO 4.20Junior Josue Julca SicchaNo ratings yet

- Drawing 101Document1 pageDrawing 101grovercip27No ratings yet

- Tabla de Volumen TotalDocument8 pagesTabla de Volumen TotalMarco Antonio Cardenas RevattaNo ratings yet

- Criterios de DiseñoDocument8 pagesCriterios de DiseñoKARITO SUAREZNo ratings yet

- Aignment: EJE DE ACCESO Sample Line Group: EMSAMBLE 01 Start Sta: 0+000.00 End Sta: 1+989.69Document8 pagesAignment: EJE DE ACCESO Sample Line Group: EMSAMBLE 01 Start Sta: 0+000.00 End Sta: 1+989.69Pablo Cesar Leon LeguiaNo ratings yet

- Mov Tieras Reservorio ChunchangaDocument1 pageMov Tieras Reservorio ChunchangaGabriel Arias TabrajNo ratings yet

- 01.movimiento de Tierra VerificarDocument14 pages01.movimiento de Tierra VerificarFredi BPNo ratings yet

- ACAD-CARRETERA MARIO..original-VOLUMENESDocument1 pageACAD-CARRETERA MARIO..original-VOLUMENESAnonymous 72QTPMNo ratings yet

- Banqueta 2 - 1Document6 pagesBanqueta 2 - 1alan arcaNo ratings yet

- 1 - Cuadro de Calculo Volumetrico Tramo 1Document8 pages1 - Cuadro de Calculo Volumetrico Tramo 1ojoramarioNo ratings yet

- Reporte de Volumenes Tramo I Start Sta: 0+000.000 End Sta: 3+175.803Document34 pagesReporte de Volumenes Tramo I Start Sta: 0+000.000 End Sta: 3+175.803Rony Wieland GaravitoNo ratings yet

- Cos (X) Ax BDocument10 pagesCos (X) Ax BArt RaNo ratings yet

- Volumenes VialidadesDocument5 pagesVolumenes VialidadesRamon MendozaNo ratings yet

- REPORTEDocument36 pagesREPORTEOscar Aldair Piñín SeclénNo ratings yet

- Volume Report (Alignment 1)Document3 pagesVolume Report (Alignment 1)Yvonne YveNo ratings yet

- Start Sta: 0+020. 000 End Sta: 2+740. 000Document8 pagesStart Sta: 0+020. 000 End Sta: 2+740. 000jhoselinNo ratings yet

- Proyecto: Construccion Sistema de Riego Itau: Ramal Principal Desde Toma 1Document26 pagesProyecto: Construccion Sistema de Riego Itau: Ramal Principal Desde Toma 1Carlos VilteNo ratings yet

- Volume Report: Client: Prepared byDocument11 pagesVolume Report: Client: Prepared byAnonymous 9rlS94No ratings yet

- Reporte de Volumen CanalDocument30 pagesReporte de Volumen CanalIvan Alexander Navarro SilupuNo ratings yet

- Pipe TolerancesDocument1 pagePipe TolerancesPamungkasNo ratings yet

- Volumen ExcelDocument2 pagesVolumen ExcelRicardo RodriguezNo ratings yet

- Volume Report: Project: C:/Users/Rrodriguez/Appdata/Local/Temp/Caminos Y Superficie779 - 1 - 14862 - B90C7174.Sv$Document3 pagesVolume Report: Project: C:/Users/Rrodriguez/Appdata/Local/Temp/Caminos Y Superficie779 - 1 - 14862 - B90C7174.Sv$Rodrigo RodriguezNo ratings yet

- Volume Report: Project: C:/Users/ JUAN/ap Pdata/loc Al/temp/ Camino - SE - 1 - 2 - 8 977.sv$Document12 pagesVolume Report: Project: C:/Users/ JUAN/ap Pdata/loc Al/temp/ Camino - SE - 1 - 2 - 8 977.sv$Richard Calisaya IllacutipaNo ratings yet

- Catalog - Broadcast and Entertainment Connector ProductsDocument32 pagesCatalog - Broadcast and Entertainment Connector ProductsОльга КолчинNo ratings yet

- Volume Report: Project: C:/Users/Roberto/Appdata/Local/Temp/Huabo 3D - 1 - 4522 - E8F48E7D.Sv$Document6 pagesVolume Report: Project: C:/Users/Roberto/Appdata/Local/Temp/Huabo 3D - 1 - 4522 - E8F48E7D.Sv$Aquino C. RobertNo ratings yet

- Pendiente 9.973 DV 35.750 DH 358.46Document2 pagesPendiente 9.973 DV 35.750 DH 358.46YaxsNo ratings yet

- Volume Report: Project: E:/PROJECT/wika/2. Main & Sub/baugia Civil 2 New Rev - DWGDocument10 pagesVolume Report: Project: E:/PROJECT/wika/2. Main & Sub/baugia Civil 2 New Rev - DWGBismo AnggoroNo ratings yet

- Diagrama de MasaDocument7 pagesDiagrama de MasaGladys Huincho LimaNo ratings yet

- Volume Report: Project: C:/Users/ USER/app Data/loca L/temp/p Erfiles - 1 - 1 - 5420.sv $Document8 pagesVolume Report: Project: C:/Users/ USER/app Data/loca L/temp/p Erfiles - 1 - 1 - 5420.sv $daniel quispe mezaNo ratings yet

- PAL v. CIR (GR 198759)Document2 pagesPAL v. CIR (GR 198759)Erica Gana100% (1)

- Mision de Amistad Correspondence, 1986-1988Document9 pagesMision de Amistad Correspondence, 1986-1988david_phsNo ratings yet

- VW Touareg 2 Brake System EngDocument111 pagesVW Touareg 2 Brake System EngCalin GeorgeNo ratings yet

- Finance Management Individual AssDocument33 pagesFinance Management Individual AssDevan MoroganNo ratings yet

- The Achaeans (Also Called The "Argives" or "Danaans")Document3 pagesThe Achaeans (Also Called The "Argives" or "Danaans")Gian Paul JavierNo ratings yet

- Green ConcreteDocument19 pagesGreen ConcreteAnubhav KalNo ratings yet

- TV Ads/Commercials Thread (October-December 2010)Document55 pagesTV Ads/Commercials Thread (October-December 2010)Pcnhs Sal100% (1)

- Medical Professionalism Across Cultures: A Challenge For Medicine and Medical EducationDocument7 pagesMedical Professionalism Across Cultures: A Challenge For Medicine and Medical EducationYoNo ratings yet

- Manual BeefDocument82 pagesManual Beefcmukasauk100% (1)

- 2021 06 WJU Circus Fanfare NOV DECDocument28 pages2021 06 WJU Circus Fanfare NOV DECDwarven SniperNo ratings yet

- ELT Catalog Secondary PDFDocument26 pagesELT Catalog Secondary PDFRafael Cruz IsidoroNo ratings yet

- Loan-Level Price Adjustment (LLPA) MatrixDocument8 pagesLoan-Level Price Adjustment (LLPA) MatrixLashon SpearsNo ratings yet

- Mirage Probationary EmploymentDocument3 pagesMirage Probationary EmploymentIsrael FortoNo ratings yet

- Resolution No. 1433Document2 pagesResolution No. 1433MA. DIVINA LAPURANo ratings yet

- Propulsive PowerDocument13 pagesPropulsive PowerWaleedNo ratings yet

- Law of Torts - Atkt Sem 1 (Internal Assessment)Document15 pagesLaw of Torts - Atkt Sem 1 (Internal Assessment)YASHI JAINNo ratings yet

- Intern CV Pheaktra TiengDocument3 pagesIntern CV Pheaktra TiengTieng PheaktraNo ratings yet

- Arnold Böcklin Was Born in Basel, Switzerland inDocument6 pagesArnold Böcklin Was Born in Basel, Switzerland inDragos PlopNo ratings yet

- Module 6:market Segmentation, Market Targeting, and Product PositioningDocument16 pagesModule 6:market Segmentation, Market Targeting, and Product Positioningjanel anne yvette sorianoNo ratings yet

- Beyond SyncretismDocument27 pagesBeyond Syncretismz miriamNo ratings yet

- Reflection of The Movie Informant - RevisedDocument3 pagesReflection of The Movie Informant - RevisedBhavika BhatiaNo ratings yet

- The New Version of This Sheet Is Available. Item Name Slots FruitDocument6 pagesThe New Version of This Sheet Is Available. Item Name Slots FruitAlex VrankenNo ratings yet

- Make An Acknowledgment Receipt Showing A Full Payment of A Loan (Extinguishment by Payment)Document5 pagesMake An Acknowledgment Receipt Showing A Full Payment of A Loan (Extinguishment by Payment)Kim Cyrah Amor GerianNo ratings yet

- The People Lie, But Numbers Don't Approach To HR AnalyticsDocument8 pagesThe People Lie, But Numbers Don't Approach To HR AnalyticsYour HR BuddyNo ratings yet

- Lesson 5 - 8ae AbsorptionDocument12 pagesLesson 5 - 8ae AbsorptionarnavprajeetNo ratings yet

- Mark Magazine#64Document197 pagesMark Magazine#64Андрей КанищевNo ratings yet

- Aeneid Proem and Book II AnalysisDocument6 pagesAeneid Proem and Book II AnalysisJustin ChangNo ratings yet

- Raising CapitalDocument43 pagesRaising CapitalMuhammad AsifNo ratings yet

- Stop TB Text Only 2012Document30 pagesStop TB Text Only 2012Ga B B OrlonganNo ratings yet

- Email 1Document4 pagesEmail 1Ali AmarNo ratings yet