Professional Documents

Culture Documents

Service Manuals Silniki Benzynowe

Service Manuals Silniki Benzynowe

Uploaded by

piotre0 ratings0% found this document useful (0 votes)

9 views24 pagesOriginal Title

Service Manuals silniki benzynowe

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views24 pagesService Manuals Silniki Benzynowe

Service Manuals Silniki Benzynowe

Uploaded by

piotreCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 24

2Ae1

Chapter 2 Part A:

Petrol engine in-car repair procedures

Contents

Camshaft covers) - removal and refitting

Camshaft oll sealis)~ renewal...

Camshafts) and followers - removal, inspection and refiting

Engine/tvansmission mountings - inspection and renewal... «18

Fiywheelicriveplate - removal, inspection and refitting 7

General information . .... tei wasn 1

Compression test - aseription and interpretation Gil cooler removal and reftiing 15

Crankshaft ol seals - renewal Gil pump - removal, inspection and refiting 4

Crankshaft pulley - removal and refitting . ‘Sump - removal and refitting . 18

Gyincer head - removal and rafting Timing belt - general information, removal and reiting. 7

Engine assembly/valve timing holes - general information Timing belt covers - removal and refiting 6

Timing bel tensioner and sprockets - removal, inspection and

usage aire

Eine land iter rewal sss ssccssceecceecsee See Ohapter 14 “rfting 18

Engine ollovl check ‘Seo “Week cnachs” Vale clearances = chacking and adjustrent "

Degrees of difficulty

Easy, Suitable for 3s Fairly easy, suitable =), | Fairly difficult, Difficult, suitable for & ‘Very difficult, x

novice with litle SS] forbeginner with < | suitable for competent 4° | experienced DIY S| sutable for expert DIY BS

parce Sy] someerpernce RQ) rv mecnanic S| mechanic Zor proiessna = XN

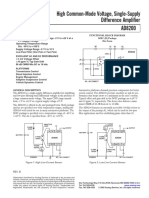

Specifications

Engine (general)

1.6 lira (1880 ee) engine XUS

{kro 76 ce} engine xu?

2o ro 1098 os) engine xuia

Engine codes":

‘eitreengine « FZ US JP»)

1B ire Soave engine SINIIII LZ ou? 482 or XU? uP, or L6A QxU7 UPsA9

{8iive 1e-alve engine try RUT uPA

Zotwee-vaveengne sscsscuscos REX (kU10 12072 0° XL0 J2CILS} or RED UO JEG

Zoe 16-vave engine REV UT0 Ja)

soe

{Olive engine... 29,00 mm

eve engine £3.00 mm

20 tr engine 36,00 mm

sik:

Tere engine 78.00 mm

is 8.40 mm

6.00 mm

2.0 lie engine

Direction of crankshaft rotation |

No‘ oyliner location r

Compression ratio:

Clockwise (viewed from the right-hand side of vehicle)

At the tranemission end of block

W6iitreeagine esse 9.2521

18 litre 8-valve engine : feet 9.25:

1.8iitre 16-valve engine I toa

20 tre B-valve engine 95:1

20 ire 16-valve engine 30.4: 4

“the engine cod is stamped on a plata attached fo the front left-hand end of the cylinder block on early 1.6 and 1.8 fitre engines, and stamped

recy onto the front face of the cylinder block Gustto the left of the ail filter) on 2.0 lire and fater engines. This is the code most often used by

Ctrogn, The code given in brackets 's the factory identification number, and is not often referred to by Citroén or this manual

Camshaft

Drie eee cone cesses Toothed belt

No of baarings oe eon &

Camshaft bearing journal diameter Not available at time of writing

Not available at time of writing

2Ae2 Petrol engine in-car repair procedures

Cylinder head bolts

‘Maximum length for re-use (see text}

1.6 and 1.8 litre 8-valve engines:

Bolt with spacer (right-hand rear bolt)...

Bolts without spacer ........2.+++

Bolts without washer

2.0 litre 8-valve engines:

Bott with spacer (ight-hand reer bolt)

Bolts without spacer

1.Blitra 16-valva engines.

2.0 lire 16-valve engines

Valve clearances (8-valve engines only)

Inlet eet

Exhaust -

Lubrication system

il pump type

Minimum oll prossure at 80°C

Oil pressure waming switch operating pressure

Torque wrench settings

1.6 and 1.8 litre 8-valve engines

‘AMtornator bracket bolts

Big-end bearing eap nits

Stage 1

Stage 2

Camshaft bearing cap nuts

Camshaft cover nuts/oolts .

Gamshalt sprocket retaining belt

M0 boit

M2 bolt an

Grankshaft pully retaining boi.

Gylinder head bolts fhex-head type}

Staged...

Fly stacken each bot in sequence, then tighten to:

Stage?

168 0.5mm

176.5 mm

171.8mm

324.5 mm

122mm

160mm

12mm

0.20 mm # 0.05 mm

0.40 mm « 0.05 mm,

Gear-type, chain-riven off the crankshatt night-hand end

6.0 bars (approx) at 4000 rpm

Tighten all bolls to Stage 2, then warm up engine. Allow to cool for hours, then:

Faliy slacken each bolt in sequence, then lighten to:

StageS .....

Gylinder head bolts (Tork type)

‘Stage 1... .

Fully slacken each bot in sequence, then tighten to

Stage 2

Whon all bolts are

Stages

Stage 4

Engine/transmission left-hand mounting:

Mounting brackat-to-bedy bolts

Mounting stud . ve 3

Centre nut

Engine‘transmission rear mounting

Mounting assembly-to-black bolts

Mounting bracket-lo-mounting bolt

Mounting bracket-to-subframe bolt

Engine/transmission right-hand mounting:

Brackel-lo-engine bolts

‘Mounting bracket retaining nuts

FlywheeVdriveplate retaining bolts”

Front cil seal carter bolts

‘Main bearing cap nuts/bolts:

Retaining nuts/bolts a

Centre bearing cap side bolts

il pump retaining belts

‘Sump retaining bolls

Timing batt cover bolts

‘Timing belt tensioner pulley bot

*Use iocking fluid

htened to Stage 2, tighten all bots in sequence to:

as bars

Nm wort

22 16

20 15

‘Angle-tighten a further 70°

16 12

10 7

35 28

30 59

+90 98

60 a

20+ 120° 15+ 120"

20+ 120° 15+ 120°

60 44

20+ 107° 164107"

‘Ariglo-tighten a further 100°

‘Angle-tighten a further 100°

25 18

50, 37

80 58

45 33

50 37

50 30

48 33

45 33

50 30

16 12

54 40

23 v

16 2

19 14

a 6

a 16

Petrol engine in-car repair procedures 2A*3

Torque wrench settings (continued) Nm lot ft

20litre 8-valve engines

Alernator bracket bolts 20 16

Big-end bearing cap nuts:

Stage 1. eas 40 20

Ful slacken all nuts, than tightan to:

Stage 2. : : 20 18

Stage 3. : sicse Angle-tighten a further 70°

‘Canshatt bearing cap nuts/bolts 16 2

Carshaft cover nuls/bolts . 10 7

Camshatt sprocket retaining bot:

Mid bolt 35 26

M2 bolt 22 80 59

Crankshaft pile reining bolt - 130 96

finder head bolts:

Stage 1. 35 26

Fully slacken each bolt in sequence, than tighten te

Stage 2. : 70 62

Stages - ‘Angle-tighten a further 160°

Enginetranemission left-hand mounting:

Heng ibarorboty eae: 20 16

Mounting stu 1 ercirenaie ot (OO, 37

entre nt = 65 a8

Enginaftransmission rear mounting:

Mounting assembly-to-block bolts 45 33

Mounting link-to-mounting bolt 50 37

Mounting link-to-suibframe bolt 70 52

Engineltransmission right-hand mounting:

Mounting bracket retaining nuts 45 38

Curved retaining piste ven; 20 18

FiywheeVdriveplata retaining bolts” 50 8?

Front el wal eareiar Bats sce c eos e eae teens 18 2

‘Man bearing eap Dots a 8

8 pump retaining bots 6 2

Psion oiljet spray tube bolt 10 7

Sunyprwtaining bots 18 13

Timing belt cover botis SAE UAT 8 6

Timing bel tensioner pulley bolt” fiitctitteseesness TF 13

“Use ocking fluid

Band 2.0 litre 16-valve engines

Big-end bearing cap nuts:

Stage 1... vetinarian 20 15

Stage 2 Angie-tighten through 70°

Camshaft bearing housings:

Stage 1. fa 5 4

Stage 2. 53 FERGIE RETALOE EU 10 7

Ccamehaft cover nuts/bolts 10 7

Camshaft sprockei-to-hub retaining Bolts =... see ceeeceeeeeee 10 7

Camshaft sprocket hub-to-camshatt retaining bolts... 2... 5 55

Crankshatt pullay retaining bolt” 190 26

Gyfinder head bolts:

1.6 lie engines

Siage 1. 60 4a

Fully slacken each bolt in sequerice, then tighten to:

Stage 2 20+ 107° 184107"

When all bolts are tightened to Stage 2, tighten all bo! to:

Stage 3 sesseee+ Angle-tighten a further 100°

Stage ¢ ssa aseRa Siocciecses Angle-tighten a further 100°

20 ire engines:

Stage 1... + c 35 26

Fully slacken each boi in Sequerice, then tighten to:

Stage 2. . 70 52

Stage S ces ciss2 Angie-tighten a further 160°

Dipstick guide tube boll... esse eceeeeeeeeeeseeeeeeees 10 7

Engine-to-transmission fixing boits 45 33

FiywheeVdriveplate retaining bolts’ veces 8 37

2Ae4 Petrol engine in-car repair procedures

Torque wrench settings (continued)

1.8 and 2.0 litre 16-valve engines (continued)

Front ol seal cartier bolts

Ignition coil unit retaining botts

Left-hand engine/transmnission mounting

‘Mounting bracket-to-body

Rubeer mouriting-to-bracket balts

‘Mounting stud-1o-transmission

‘Mounting stud bracket-to-transmission

Centre nut

Main bearing cap bolts:

1 B litre engine:

Bearing bolts

Side securing bolts

2.01itre engine:

Engine code RFS:

Ro 5 cap bolts,

All other bolts

All other engines

ll pump retaining bolts

Piston ol jet spray tube bolt

Right-hand engine/transmission mounting:

1 B litre engines:

Mounting bracket-to-engine nuts

Mounting bracket-to-engine bolts

Mounting bracket-lo-rubber mounting nut

Fubber mounting-to-bocy nut

2.0 litre engines:

Mounting bracket-to-engine nuta/volts

Mounting bracket-to-rubber mounting nut

Fubbor mounting-to-bady nut

Sump retaining batts

Tiening belt cover bolts

Timing bolt ilar paley Belt

Timing belt tansionor pulley bolt

“Use focking ful

54

23

85

70

70

16

10

18

a

21

1 General information

How to use this Chapter

This Part of Chapter 2 describes those repair

pprocectures that can reascnably be carried out

con the XU series petrol engine, while t remains

inthe car. IF the engine has been removed from

the car and is being dismantled as described in

Part C, any preliminary dismanting procedures

‘can be ignored.

Note that, while it may be possible physically

to overhaul items such asthe

piston/connecting rod assemblies while the

engine isin the car, such tasks are not usually

carried out as separate operations. Usually,

several additional procedures (not to mention

the cleaning of components and ollways) have

to be carted out. For this reason, all such tasks

are cassec as major overhaul procedures, and

are desorbed in Part C of this Chapter.

Part G describes the removal of the engine!

reneniesion unk fonvthe vatiioks, ani} the till

‘overhaul procedures that can then be cared

out.

XU series engine description

‘The XU series engine is a well-proven engine

which has been fitted te many previous Croan

‘and Peugeot vehicles. The engine is of the in-

line four-cylinder type, mounted transversely at

the front of the car. Tha clutch and

transmission are attached to its left-hand end.

The crankshaft runs in five main bearings.

Thrustwashers are fitted to No 2 main bearing

cap, to control crankshaft enctloat.

The connecting rods rotate on horizontally-

split bearing shells at their big-ends. The

pistons are attached to the connecting rods

by gudgoon pins. The gudgeon pins are an

Imterterence fit in the connecting rod smal-

fend eyes. The aluminium alloy pistons are

fitted with three piston rings - two

‘compression rings and an oil control ring,

The engine may be an B-valve, single

‘overhead camshaft unit, or a 16-valve, double

overhead camshaft type. The 16-valve

engines were introduced in 1995, and can be

identified by having "/6V" stamped in the

Porsemennbiicesnas.

On the 1.6 and 1.8 litre B-valve engine, th

oylindar block is of the “wat-linar” type. The

cylinder block Is cast in aluminium alloy, an

the bares have replaceable cast-iron lines

that are located from the top of the cylinds

block. Sealing O-rings are fitted at the base 0

each liner, to prevent the escape of coolat

into tho sump.

(On the 2.0 litre B.valve angine, and all 16

valve engines, the engine is of the

conventional “dry-liner" type. The cylinds

block is cast in iron, and no separate bow

liners are fitted.

Cn the -valve engine, the camshaft i

driven by a toothed timing belt, and i

operates the valves via followers’ located

beneath each cam lobe. The vaive clearance

are adjusted by shims, positioned betwee

the followers and the tip of the valve stem.

“The camshafts on 16-velve engines are els

driven by a common toothed timing belt; th

front camshait operates the inlet valves, an

the rear camshait operates the exheus

valves. The vaive clearances are seli-adjustin

bby means of hydraulic tappets.

Each camshaft runs in bearing caps whici

are bolted te the top of the cylinder head:

Petrol engine in-car repair procedures 2A¢5,

‘The inlet end exhaust valves are each closed

by coil springs, and operate in guides

tossed into the cylinder head. Both the

vahe seats and guides can be renewed

separately if worn.

‘The water pump is driven by the timing batt,

{and is locatad! in the right-hand end of the

oynder block,

Lubrication is by means of an oll pump

whichis cvan (via a chain and sprocket) off

the crankshait right-hand end. It draws oll

through a strainer located in the sump, and

then forces if through an externaliy-mounted

fier into galleries in the cylinder

Dlockicrankease. From there, the oil is

Ais buted to the crankshaft (main bearings)

and camshatt. The big-end bearings are

supplied with oll via internal drilings in the

crankshaft; the camshaft bearings also

fective a pressurised supply. The camshaft

lobes and valves are lubricated by splash, as

reall thor engine components. An oll cooler

is fited to some models to keep the oll

temperatura constant uncer severe opereting

Conditions - itis mounted behind the ol fiter.

The oll cooler is supplied with coolant from

the engine cooling system,

Throughout the manual, it is often

necessary to identify the engines not only by

ther cubic capacity, but also by thelr engine

code, The angine core consists of three

laters (09, LF2), On early 1.8 and 1.8 ttre

models, the code ix skamped on a plate

attached to the front, tett-hand endl OF the

tyne block, On 2.0 litre and later medels, t

stamped directly onto the front face of the

oyinder block, on the machined! surlace

located just to the loft of the ci filter (ext to

‘be crankcase vent hose union),

Repair operations possible with

the engine in the car

The following work can be camied out with

the engine inthe car

4) Compression pressure - testing

2) Camshatt covers) - cemoval ad reting,

6) Crankshaft pulley - removal and reiting.

4 Tining bet covers - removal and refitting.

© Tining bot - removal, refiting ancl

sgustment,

1 Tining bet tensioner and sprockets -

temova and refiting.

g) Camshaft oif seal(s) - renewal.

5) Camshan(s) and folomers - removal,

inspection and refiting.

4) Yay clearances ~ checking and

aajustment

2 Cynder ead - removal and reiting.

Cylindier head and pistons -

ecarbonising

4. Sump - removal and refiting.

1/Oi pump - removal, overha! and refitting.

1) Crankshaft of seals = renova

0) Enghnesrensmission mountings ~

‘nspection and renewal.

1) Pywneaferiveptate removal, inspection

‘end refitting.

2 Compression test -

description and interpretation &

We

1 When engine performance is down, or if

misting ocours which cannot be attributed to

the ignition or fuel systems, a compression

test can provide diagnostic clues as to the

engine's condition. If the test is performed

regulary, it can give waming of trouble before

any other symptoms become apparent.

2 The engine must be fully warmed-up to

normal operating temperature, the battery

must be fully charged, and all the spark plugs

must be removed (Chapter 14), The aid of an

assistant wil also be required,

8 Disable and depressurise the fuel system,

either by disconnecting the fuel pump wiring

connector (refer to Chapter 4A) or by

identifying and removing the fuel pump fuse

from the fusebox. Start the engine, and run it

Until it cuts out,

4 Disable the ignition system by

disconnecting the LT wiring connector from

the ignition HT coil}, referring to Chapter 58,

for further information.

8 Fit a compression tester to the No 1

cylinder spark plug hole - the type of tester

which screws into the plug thread is to be

preferred.

6 Have the assistant hold the throtile wide

pen, and crank the engine on the starter

mater. After one or tWo revolutions, the

Compression pressure shows build up to &

maximum figure, and then stabilise, Recor

the highest reading obtained,

7 Repaat the test on the remaining eylinders,

recording the pressure in each,

8 All cylinders should produce very similar

pressures; a difference of more than 2 bars

between any two cylinders indicates @ fault.

Note thal the compression should build up

Quickly in a healthy engine; low compression

on the first stroke, followed by gracually-

increasing pressure on successive strokes,

indicates wern piston rings. A low

compression reading on the first stroke, which

does not build up curing successive strokes,

indicates leaking valves or a blown head

gasket (a cracked head could also be the

cause}. Deposits on the undersides of the

valve heads can elso cause low compression.

9 Citro&n do not specity exact compression

pressures. As 2 guide, any cylindor pressure

07 below 10 bars can be considered as less

than healthy. Refer to a Citron dealer or other

specialist ifn doubt as to whather a particular

pressure reading is acceptable.

10 If the pressure in any cylinder is low, cerry

out the following test to isolate the cause.

Introduce a teaspoonful of clean cil into that

cylinder through its spark plug hole, and

repeat the test.

11 If tho addition of oil temporarily improves

the compression pressure, this indicates that

bore or piston wear is responsible for the

pressure loss. No improvement suggests that

leaking or burt valves, er a blown head

gasket, may be to blame.

42. Alow reading from two adjacont cylinders

is almost certainly due to the head gasket

having blown between them; the presence of

Coolant in the engine oll will confirm this.

18 If one cylinder is about 20 percent lower

than the others and the engine has a slightly

rough idle, a worn camshaft labe could be the

44 If the compression reading is unusually

high, the combustion chambers are probably

coated with carbon deposits. If this is the

case, the cylinder head should be removed

and decarbonised.

15 On completion of the test, refit the sperk

plugs and reconnect the ignition system.

3. Engine assembly/valve

timing holes - general

information and usage

Note: Do not aitempt to rotate the engine

whilst the crankshalticamshatt are locked in

positon. ifthe engine isto be fet in this stato

for a iong period of time, it 3 a good ide to

place sultable warning notices inside the

Wahicie, and in the engine compartment. This

wil reduce the possibilty of the engine being

accidentally cranked on the starter motor,

which 1s likely to cause damage with te

locking pins in place

1 On all models, timing holes are dried in the

camahatt sprockel(s) and crankshaft pulloy.

The holes are used io align the crankshaft anc

camshaft, to prevent the possibility of the

valves contacting the pistons when ratitting

the cylindor head, or when rafting the timing

belt, When the holes are aligned with their

corresponcing holes in the cylinder head and

cylinder block (as eppropriate), suitable

diameter pins cen be inserted to lock both the

‘camshaft and crankshaft in position. Proceed

as follows:

2 Remove the timing belt upper (outer) cover

with reference to Section 6.

3 Jack up the front of the car and support it

on axle stands. Remove the right-hand front

roadhoo.

4 From underneath the ‘ront of the car,

unscrew the bolts and prise out the clips

securing the plastic cover to the inner wing

valance. Remove the cover to gain access to

the crankshaft pulley bott, The crankshaft can

then be turned using a suitable socket and

extension bar fitted to the pulley bolt, Note

thatthe crankshaft must always be tured in a

clockwise direction (viewed from the right-

hand side of vehicle)

8-valve engine models

5 Rotate the crankshaft pulley until the timing

hole in the camshaft sprocket is aligned with

its corresponding hole in the cylinder head.

Note thal the holes are aligned when the

sprocket hole isin the 8 o'clock postion, when

viewed from the right-hand end ef the engine.

2Ae6 Petrol engine in-car repair procedures.

inserted through

the crankshaft pulley timing hole

6 With the camshalt sprocket timing hole

cortectly positioned, insert an @ mm diameter

‘bolt or el through the timing (@ mm diameter)

hole in the crankshaft pulley, and locate it in

the corresponding hole in the end of the

cylinder block {see illustration). Note that it

may be necessary to rotate the crankshaft

slightly, to get the Roles to align.

7 Once the crankshaft pulley Is locked in

position, ingert an 9.5 mm diameter bolt or

Grill through the camshait sprecket hole and

locate it in the cylinder head (see illustration).

8 The crankshalt and camshatt are now

Jeckad in pasition, preventing rotation.

16-valve engine models

8 Rotate the crantcshatt pulley unl the timing,

tholes fn both cansshals are aligned swith their

eorespanding holes in the cylinder ead, The

holes are aligned when the inlet camshat

sprocket hole is in approximately the 5

4.2 Breather hoses on the right-hand end

of the oylinder head cover

‘4.3 Disconnecting the intake duct

3,7 9.5 mm diameter drill inserted through

the camshaft pulley timing hole

o'clock position and the exhaust camshaft

sprocket hole Is In approximately the 7

‘o'clock position, when viewed from the right-

hand end of the engine

40 With the camshaft sprocket holes

‘correctly positioned, insert a 6 mm ciamater

bolt or drill through the timing hole in the

crankshaft pulley, and locale it in the

corresponding ho'e in the end of the engine

(Gee illustration). Note that the hole size may

vary according to the type of pulley fitted and

auxiliary drivebelt arrangement, If the bolt or

drill is not a saug fi, try a larger size unt a

4000 fit is achiaved in both the pulley and

‘eylinder block.

14 With the crankstall tecked In position,

Insert a suitable boll or crit through the tinning

hole in each camshatt sprocket and locate i

In th oylindor hee (see illustration

42 The crankshaft and camshafts are now

locked in position, preventing rotation,

4. Camshaft cover(s) -

yemoval and refitting

WEE

Removal

&-valve engine models

4 Disconnect the battery negative lead

2 Slacken the retaining clips, and disconnect

the breather hoses from the front right-hand

‘end of the cover (see illustration). Where the

‘45a Cylinder head cover retaining nuts.

arrowed)

3.11 Bolts (arrowed) inserted through

timing holes in each camshaft sprocket

original crimpedtstype Citrogn hose clips an

stil fie, cul them off and discard thom ts

Standard worm drive hose efips on retiting

8 Slacker the rstaining cip, anc eisconned

tho air cleaner-to-thrattle Rousing duct fro

the front of the camiahatt cover. Also romow

the intake duct from the left-hand side of thy

head cover (see illustration)

4 Release the two retaining olips, then und.

the two retaining screws located at the fron

and remove the alr cleaner element cova

from the camshaft cover. Remove the ak

leaner element, and store it with the cover.

5 Evenly and progressively unscrew the te

camshalt cover retaining nuts, lift off th

‘camshaft cover, and remove it along with ft

rubber seal (see illustrations). Examine th

seal for signs of damage and deterioration

and if necessary, renow it

4.5p Removing the cylinder head cover

seal

Petrol engine in-car repair procedures 2A*7

‘16-valve engines

16-valve engine models

Note: Modals fram January 1998 onwards are

fitted with plastic camshett covers, rather thant

aluminum alloy as before. The procedtire

given below is not greatly affected by this

Ghange, except that the number of retaining

bots for each cover increases, and the bolts

are located around the edge of each cover. No

lightening sequence for the cover bolls Is

quoted by Citroén, so this stage can be

Ignored for later models.

8 Referring to Chapter 1A if necessary,

disconnect the wiring connector at the lett

hand ene of the ignition coil unit, located in

the centre of the camshall covers. Unde the

Sx retaining hols and lt the coil unit

upwards, eff the spark plugs ane fren ies

loaation between the eamiahadt cavers (ee

ituetration)

7 Remove the Allen bolts from the fuel pipe

48a Disconnect the fuel supply pipe from

the fuel pressure regulator

and remove the fuel pipe carrier

bracket

4d .

4.7a Remove the two Allon bolts...

cover, and

illustrations)

8 Refer to Chapter 4A and depressurise the

fuel system. Taking suitable precautions

‘against fuel spillage, disconnect the fue! pipes

{vom the fuel pressure regulator as necessary.

Detach the fuel supply and return pipes from

the carrier bracket fitted across the camshaft

covers. Unscrew the retaining nuts and

fomove the fuel pipe carrier brackst (see

illustrations).

9 Slacken the retaining clips, and disconnect,

the breather hoses from the front left-hand

side of the front cover (see illustration).

Whore the original crimped type hose: efipss

are stil ited, cut thom off and discard them;

use standard worm-deve hose sips on

remove the cover (see

ceiling

40 Working in a spirat sequence starting from

the outside and working insane

roar slackon, then remove the

-+-and the return pipe, releasing it

from the plastic clip,

4.9 Disconnect the breather hoses from

the front camshaft cover

‘7b ...and lift off the fuel pipe cover

retaining studs and bolts from each camshaft

cover. On the 1.8 litre engine seen in the

‘workshop, one of the front cover bolts {next to

the oil filer cap, nearest the timing belt end}

was shorter than the rest, and did not in fact

pass through the cover into the camshatt

housing! (see illustrations).

11 Lift off each cover in tura and remove it

The cover seal should remain attached as the

cover is removed - do not ry te remove it,

Unless it is obviously damaged

Refitting

8-valve engine models

42 Clean the oylinder heag and camshatt

iflaces, ane remove all trace

cover mating)

ete

48 Locate the Hubber seat in the cover

a that Ile eovrectly located

along ts entice length

4.8¢ Unscrew the retaining nuts .

4.402 Remove the studs .

2Ae8 Petrol engine in-car repair procedures

4.10b . . . and retaining bolts.

14 Apply a smear of suitable sealant to each

camshaft end bearing cap around the area

where the cap contacts the cylinder head

mating surface (see illustration).

16 Carefully rofit the camshaft cover to the

engine, taking great care not to displace the

rubber seal

46 Check that the seal is correctly located,

then refit the cover retaining nuts and,

working in the sequence shown, tighten them

evenly and progressively to tha specified

torque (see illustration)

47 Refit the air cleaner element, and install

the element cover. Securely tighten the caver

retaining screws, and secure itn position with

tne retaining clips

48 Rocomwet the breather hoses,

duct and throttle housing duct to the cover

tightening their retaining clips securely

Raconnast the battery

16-valve engine models

19 Clean the cylinder head and camshett

‘cover mating surfaces, and remove all traces

ofl.

20 Check the condition of the rubber seal

attached to each cover. The seal Is designed

to be re-usable, and so should not

automatically be replaced unless its condition

is suspect. If the seal is broken, it can be

repaired using a bead of suitable sealant.

21 Carefully refit the camshaft covers to the

engine,

22 Refit the cover retaining bolts and studs

and, working in the sequence shown (where

Intake

applicable}, tighten them evenly and

progressively to the specified torque (see

illustration.

23 Fisconnect the breather hases to the front

‘cover, and securely tighten the retaining clps.

24 Ratit the ignition coll unit between the

camshatt covers. Roft the retaining bolts,

tightening them securely, then reconnect the

coil unit wiring connector.

25 Rell the fuel pipe carrier bracket to the

covers, then refit the fuel pipes to their

locations and secure with the fuel pipe cover.

26 Refer to Gnapter 4A, Section 1 and refit

‘the ul rail and fuel injectors.

27 Reconnect the battery nagative terminal

‘On completion, star the engine anc check the

fuel hose unions for signs of leakage.

4.10c -.. and remove the camshaft cover -

rote the short bolt which does not need to

bbe removed (arrowed)

‘nuts in the sequence shown =

‘valve engines

A

Removal

1 Romove the auxiliary drivebelt (Chapter 1A).

2 To prevent the crankshaft turning whilst the

pulley retaining bolt is being slackened, select

4th gear and have an assistant apply the

bbrakas firmly. I the engine has been removed

from the vehicle, lock the fhwheel ring gear

using the arrangement shown (see

‘52 Use a fabricated tool like this one to

lock the flywheel ring gear and prevent

‘erankshaft rotation

4.14 Applying sealant to the camshaft end

bearing caps

vee |

4.22 Camshaft cover fasteners tightening

‘sequence - 16-valve engines

iMustration). Do not attampt to lock the pulley

by inserting a bol/drill through the timing

hole, if the locking pin is in position,

‘temporarily remove it prior to slackening the

pulley bolt, then refit it once the bott has been

slackened.

3 Unscrew the retaining bolt and washer,

then slide the pulley off the end of the

crankshatt (see illustrations). If the pulley

locating roll pin or Woodruff key (ae

applicable} ie a loose ft, remove it and store it

with the pulley for safe-keeping. f the pulley is

tight ft, t can be drawn off the crankshaft

using a suitable puller.

5.38 Removing the crankshaft pulley

retaining bolt

Petrol engine in-car repair procedures 2A¢9

5b Removing the crankshaft pulley from

‘the end of the crankshaft

Refitting

4 Ensure the Woodruff key is correctly

Jocated in its crankshaft groove, or that the

ral pin is in postion {as applicable). Rofit tha

pulay to the end of the crankshaft, aligning its

locating groove or hole with the Woodruff key

pin,

5 Thoroughly clean the threads of the pulley

Fetairing bolt, then apply a coat of locking

compound to the bolt threads. Citro&n

recommend Loctite {available from your

Citrotn dealer); in the absence of this, any

good-quality locking compound may oe

sed,

6 Refit the crankshaft pulley retaining bolt

and washer. Tighten the bolt to the spscttisd

torque, preventing the crankshatt trom turning

ising the method employod on removal,

7 Refit and tension the aunilary drivebelt as

decribed in

6.10 Removing the auxiliary drivebelt

tensioner assembly

‘6.10b Unscrew the retaining bolts

68a Upper timing belt cover retaining

bolts (arrowed)

6 Timing belt covers -

removal and refitting

WE

1.6 and 1.8 litre 8-valve models

Upper cover

4 Release the rataining lps, and free the fuel

hoses from the top ofthe cover.

2 Undo the two cover retaining bots (situated

at the base of the cover, and remove the

Cover from the engine compartment

Gentre cover

3 Slacken and remove the two cover retaining

bolts focated dirgetly bonoatt the mounting

backal), Move the cover upwards to tree i

fromm tho wo locating pis situated at the bse

of the cover, and remove it from the engine

‘compartment.

Lower cover

4 Flemove the erarikshatt pulley (Section 5).

5 Flemove the centre cova: (paragraph 3).

6 Undo the two cover retaining bolts, and

remove the cover from the enging. Note that

fon some mode's it may be necessary to

Unbolt the auxiliary. drivebelt tensioner

assembly and remove It from the engine in

tard to allow the cover to be removed

2.0 litre 8-valve models

Upper cover

7 Release the retaining clip, anc free the fuel

hoses from tha top of the timing belt cover.

6.10e . .. and remeve the lower timing,

6.8b Removing the upper timing belt cover

8 Slacken and remove the two eover retaining

bolts, then lft the upper cover upwards and

out of the engine compartment (see

illustrations)

Lower cover

8 Remove the crarkshatt pulley (Section 5)

40 Slacken and remove the three retaining

bolts, then remove the lower timing belt cover

from the engine. Note that on some models it

may be necessary to unboit the auxiliary

drivabelt tensioner assembly and ramove it

from the engine in order to allow the cover to

be removed (see illustrations)

Refitting

14 Refitting is a revarsal of the rolovant

removal provadure, ensuring that each cover

section is comreelly oeated, snd that Me Cover

retaining nuts and/or bolts are securely

tightened! to the specified torqua, where

ven,

1.8 and 2.0 litre 16-valve models

Upper (outer) cover

42. Unclip the wiring harness from its iovation

in the shaped top of the engine right-nand

‘mounting, and from the inlet manifold bracket

{600 illustrations). Where applicable, reloase

‘he air conditioring hose which runs between

the timing belt cover and the engine

mounting. Move the hose end wiring hemes,

to one side (do NOT attempt to disconnect

the air conditioning hose}

18 Prise out the clips and remove the trim

‘cover trom the top of the engine right-hand

mounting (s¢e illustrations).

6.12a Unclip the wiring hamess from the

‘engina mounting . ..

2Ae10 Petrol engine in-car repair procedures

6.12b .... and from the inlet manifold

bracket

44 On models up to 1999, lift the tab

provided in the contre of the timing belt cover

upwards to release the centre locating pegs

{see illustration).

15 Unscrew and remove the thros upper

relaining screws, and withdraw the timing belt

‘cover (see illustrations). Recover the rubber

pads from the centre locating pegs, where

applicable.

Lower cover

16 Remove the crankshaft pulley (Section 5)

17 Slacken and remove the retaining bolts,

then remove the lower timing belt cover trom

the engine. Note that on some models it may

bbe racessary to unbolt the auxiliary deivebelt

tensioner assembly and remove if (rom the

engine im oreter fe allow the cover te Be

removes.

Upper {inner) cover

48 Remove the timing belt ag aeacribed in

Section 7

19 Remove both camshait sprockets as

described in Section 8,

20 Remove the six bolts securing the cover

to the side of the cyinder head,

the cover from the engine.

Refitting

21 Rofitting Is a reversal of removal. When

refitting the upper (outer) cover with the

locating tab, ensure that the rubber pads are

In place on the centre locating peas, where

applicable. Locate the cover in place over the

‘centre and lower pegs, then press the centre

of the cover inwards to engage the locating

pegs, and secure by lowering the plastic tab.

6.14 Lift up the locking tab in the centre of

the cover

6.19a Using a suitable tool, rolease the

retaining olips ..-

Refit and locate all other components

securely

7 Timing belt - &

general information, x

Temoval and refitting x

Note: Citroen specify the use of a special

electronic too! (SEEM 4122-7) to conectly sot

tho timing belt tension, access t0 this

equipment cannot be abtained, an approximate

setting can be achieved using the method

described below. If the mathod daseribed is

used, the tension must be checked using the

Special electronic tool af the earliest possible

eaeertunity: Devnet dre

distances, oF wse high engine speadis. unt te

Bait tenon fe Arow to BS CORTECR, AMET TO a

Citroen aealer tor acne.

General information

1 The timing belt drives the camshati(s) and

coolant pump from a toothed sprecket on the

front of the crankshaft. If the alt breaks or

slips in service, the pistons are likely to hit the

vaive heads, resulting in extensive (and

expensive) damage.

2 The timing belt should be renewed al the

‘Specified intervals (see Chapter 1), or earlier

If itis contaminated with oll, or fit is at all

Noisy in operation (a ‘scraping’ noise due to

uneven wear)

3 Ifthe timing belt is being removed, itis a

wise precaution to check the condition of the

coolant pump at the same time (check for

‘signs of coolant leakage). This may avoid the

reticle over Fa

6.15a Remove the Allen screws

arrowed) .-

6.13b .

the top of the engine mounting

need to remove the timing belt again ata later

stage, should the coolant pump fal

Removat

4 Disconnect the battery negative terminal

5 Jack up the front of the vehicle and support

it on axle stands (see “Jacking and vehicle

support"), Remove the right-hand front wheel

6 To improve access, refer to Section 18 and

remove the engins right-hand mounting. This

is not essential, but it does make several of

the timing belt components much easier to

remove with the engine in the cer.

7 Where applicable, prise out the clips and

unbelt the inner splash guara.

8 Remove the auxliary dhiveboll as described

ln Chapter 14, Where applicadie, unbolt and

wmove tle aunifiary deivebett tensioner

9 Remove the timing belt user (UNE) COVE

with reference to Section 6,

10 Align the engine assembly/ealve timing

holes as described in Section 3, and lock the

camshaft sprockei(s} in position. Do not

attempt to rotate the engine whilst the pins

are in position.

11 Remove the crankshaft

escribed in Section 5.

12 On 18 and 1.8 lie 8-valve models,

remove the centre and lower timing belt

covers as described in Section 6. On all other

models, unbolt and remove the timing belt

lower cover (refer to Section 6 if necessary).

19. Aft the crankshaft pullay, and tighton the

bolt moderately, holding the engine against

rotation as fer removal. Fit the locking too!

through the crankshatt pulley, to prevent

rotation,

pulley as

and lift away the upper cover

Petrol engine in-car repair procedures 2A¢11

we

14 Loosen the timing belt tensioner pulley

ralaining bolt (eee illustration). Pivot the

pullay In a clockwise direction, using a

suitable square-section key fitted to the hole

in the pulley hub, then securely retighton the

fatzining bol

15 If the timing bell is to be re-used, use

vfite paint or chalk to mark the direction of

rotation on the belt (f markings do not alrandy

‘xs then slip the belt off the sprocket

Wustration). Note that the crankshelt must,

ol berated wisi es belt is rernoverd

46 Check the timing belt caretully tar say

sins of uneven wear, splitting, or oil

conlarination. Pay particular attention to the

rots of the tacth. Renaw it if there is the

sightest doubt about its condition. If the

ongine Is undorgoing an overhaul, and has

covered more than 36 000 ries (G0 000 km}

wit the existing belt fitted, renew the belt as a

inattar of course, regardiass of its apparent

cordition. The cost of a new belt is nothing

compared with the cost of rapairs, should the

belt break in service. If signs of oil

contamination are found, race the source of

the oil leak and rectify it. Wash down the

engine timing belt area and all related

componants, 16 remove all traces of ol

Refitting

B-valve engine models

17 Belore refitting, thoroughly clean the

tining belt sprockets. Check that the

tensioner pulley rotates freely, without any

sign of roughness. If necessary, renew the

tensioner pulley as described in Section 8

48 Enaure that the camshaft sprocket and

crankshaft pulley locking pins. are stil in

poston.

49 Manoauyre the timing belt into position,

ensuring that any arrows on the belt are

pointing in the diraction of rotation (clockwise

when viewed from the right-hand end of the

engine,

20 Do not twist the timing belt sherply while

‘ofiing it. Fit the bolt over the crankshaft and

714 Release the belt tensioner retaining bolt

camshaft sprockets {it preferred, the

crankshaft pulley can ba removed for this

stage, but ensure that the crankshaft is not

moved from its reference position). Ensure

‘that the belt "front run" is taut - e., any slack

should be on the tensioner pulley side af the

bell, Fil the belt over the water pump sprocket

and tensioner pulley (See illustration). Ensure

that the belt teeth are sated cently in the

eprockets

21 If removed, refit the crankshatt pulley at

this stage and tightan the bolt moderately.

thon refit the locking pin. Note: The: timing

belt i tensioned with the timing covers

removed, than the crankshaft pulloy is

removed again to fit the belt lower cover,

before boing tially refitted.

22 Loosen the tensioner pulley retaining bok.

Using the square-section key, pivot the pulley

anti-clockwise to remove all free play from the

timing bet

23 If the special belt tension measuring

fequigment is available, it should be fitted to

the “front run” ofthe timing belt, Tre tensioner

roller should be adjusted so that the intial bait

tension is 16 «2 units on 2.0 lire models, and

302 units on 1.6 an 1.6 litre models.

24. Remove the locking pins, then rotate the

‘ranishalt through two complete rotations in

a clockwise direction {viewed from the right-

hhand end of the enaine). Realign the camshaft

and crankshaft engine assembly/vaive timing

holes (see Section 3). Do not at any time

rotate the crankshaft anti-clockwise. Both

camshaft and crankshaft timing holes sheule

be aligned so that the locking pins can be

‘easily inserted, This indicates that the valve

timing Is correct. I alls wal, ramave the pins.

25 If the timing holes are not comrectiy

positioned, repeat the fitting procedure so far.

26 ‘ifthe fension is being set without using

the special measuring tool, proceed as

follows. Check thal, under moderate pressure

from the taumb and forafinger, the belt can

[ust be twisted through 90° at the mid-point of

the “front run” of the belt. Note that this

mothod is only an initial setting, and the belt

7.45 Lift the timing belt off the sprockets

tension must be checked at the earliest

available opportunity using the spacial

‘measuring tool, Failure to do so could lead to

‘the belt breaking (through over-tightening) or

“jumping a tooth" (through slackness),

resulting in serious engina damage. IF

necessary, readjust the tensioner pulley

position as required. Tighten its retaining bolt

to the specified torque on completion

27 Ui the special measuring tool is being

used, rotate the crankshaft fwe mare tures

without tuming backwards and refit the

‘camshaft Jocking pin, then check that the final

belt tension on the taut “front run” of the belt

ip 44 x 2 units. If not, repoat the complete

iting procedure,

28 With the bel tension correctly sat remove

the camshaft locking pin, then remove the

crankshatt pulley and refit the timing cover(s).

29 Rofit the crankshaft pulley out this time

Apply locking fluid to the threads of the bolt

before inserting it. Tighten the belt to the

specified torque and refer to Section 5 if

necessary.

16-valve engine models

380 Before refitting, thoroughly clean the

timing belt sprockets. Check that the

tensioner and idler pulleys rotate freely,

without any sign of roughness. if necessary,

renew the pulleys as cescrited in Section 8,

7.20 Fit the timing belt over the water

pump sprocket

2Ae12 Petrol engine in-car repair procedures

31 Ensure that the camshaft spracket locking

pins are stil in position. Temporarily refit the

crankshaft pulley (f removed), and insert the

locking pin through the pulley timing hole to

censure that the crankshatt is still correctly

positioned.

32 Without removing the locking pins, on

‘models up to 1998, slacken the six camshatt

sprocket retaining bolts (three on each

sprockel). On models after 1998, only the

single bolt securing each camshatt sprocket

need be slackaned. Check thal both

sprockets are free to turn within the limits of

their elongated bolt holes, or that the

protruding lug on single-boll sprockets can

move within its limits (see illustrations}.

38 Tighten tho camshaft sprocket retaining

bolts finger-tight, then slacken them ali by one

sixth of a tum.

84 Again without removing the locking pins,

tum each camshaft sprocket clockwise to the

fends of their retaining bolt slots, or until the

protruding lug reaches the end ofits travel.

35. Remove the crankshaft pulley. Manoeuvre:

‘the timing bolt into position on the crankshaft

sprocket, ensuring thet any arrows on the belt

are pointing in the direction of rotation

(clockwise when viewed from the right-hand

‘ond af tha engine)

36 Refit the timing belt lower cover and the

crankshaft pulley (Sections 6 and 8),

87 With the timing belt engaged with the

‘crankshaft sprocket, keep it tight on its right-

hand run and engage it with the front idler

pulley then up and into engagement with the

inlet carnshaft sprocket.

38 Keeping the belt fight and rotating the

inlot camshaft sprocket anti-clockwise a3

necessary, feed the belt over the exhaust

camshaft sprocket, taking care not to let the

belt jump a tooth on the crankshatt sprocket

a its being fited,

39 While still keeping the bolt tight, fesc it

over the rear tensioner pulley and finally

around the caolant pump.

40 If the special belt tension measuring

7.82a Slacken the camshaft sprocket retaining bolts (arrowed)

7.82b Camshaft sprocket details - models up to 1988 (A) have

throe retaining bolts (1) in elongated slots, while models after

1998 have a single bolt and a protruding lug (2)

equipment is available, proceed as described

in paragraphs 41 to 81, and then to paragraph

58 onwards. Ifthe tension is being set without

the use of the special measuring equipment,

proceed to paragraph 52.

41 If the special belt tension measuring

equipment is available, it should be fitted 10

the *front run” of the timing belt. The tensioner

Pulley should be adjusted, by turning it anti-

‘clockwise to give a bolt pro-tensioning setting

‘of 45 units. Hold the tensioner pulley in this,

position and tighten the retaining bolt to the

specified torque.

42 Check thal the sprockets have not been

tuned so far that the retaining bolts are at tho

fand of their slots, or that the protruding lug on

single-bolt sprockets is at the end ofits travel

If either condition is evident, repeat the

refiting operation. I all is satisiactory, lighten

the sprocket retaining bolts to the spectfied

torque,

43, Ramovo the locking pins, then rotate the

crankshait through two complete rotations

a clockwise direction (viewed from the right-

hand end of the engine). Realign the

crankshall engine assembiy/valve timing hole

and refit the locking pin to the crankshaft

pulley.

44 Slacken the camshaft sprocket retaining

bolts, retighten them finger-ticht, thon siackon

thom all by one sixth of a turn,

45 Relit the camshaft sprocket locking pins,

thon slacken the tensioner pulley retaining

bolt once more. Refit the belt tension

measuring equipment to the front run of the

belt, and turn tha tensioner pulley to give a

final sotting of 26 units (models with three

bolls per camshaft sprocket) or 32 units

(single-bolt sprocket. models) on the

tensioning gauge. Hold the tensioner pulley in

this position and tighten the retaining bolt to

the specified torque.

46 Retighten all sprocket retaining bolts to

the specified torque,

47 The belt tension must now be checked as

follows. Remove the locking pins, then rotate

the crankshaft once again through tvs

complete rotations in a clockwise direction

Foalgn the crankshaft engine aesembly/vahe

timing hole, and refit the locking pin to te

crankshaft pulloy.

48 Slacken the cemshatt sprocket retaining

bolts, tighten ther finger-tght, then slacker

them all by one sixth of a turn

49 fil tho camshail sprocket locking pirs

turning the sprockets slightly if required

Tighten tho camshaft sprocket retaining bot

to the specified torque.

50 Flemove the camshaft and cranksha

locking tools. Turn the cranksnatt approx

imately one quarter of a tum in the norma

direction of rotation, unl the locking too! hal

in the erankshatt pulley is aligned with te

timing belt ower cover font retaining bolt. Its

imporent thet this position is achieved ONLY

ay turing the belt forwards ~ ifthe belt

fumed back at alto achieve alignment, the

bot tension check will not be vai

51 Inthis position, rfitne tension moasuring

equipment to the front run of the belt, and

‘check that the reading is between 32 and 4

units. If not, the entire bel tensioning

procedure must be repeated trom the start

52 I the tension Is being set without the usa

fof the special measuring equipmant, the

tensioner pulley should be acusted, by

turning it anti-clockwise, until all tree play s

removed from the belt. Hold the tensioner

pulley inthis position and tighten the retaining

bolt to the specified torque.

53 Cary out. the check described in

paragraph 42. If alls sat stactory, tighten a

proce! retaining bots to the specified torgu

4 Remove the locking pins, then rotate the

crankshaft through two campiste rotations ine

ockwise direction (iewec from the right-hand

fend of the engine). Realign the crankshat

engine assemblytalve ting hole, and refit

locking pinto the erarksht pul.

155. Slacken the camshaft sprocket retaining

bots, rstighton them finger-tight, then slacken

them ail by one sixth of a turn,

Petrol engine in-car repair procedures 2A*13

56 Refit the camshatt sprocket locking pins,

than slacken the tensioner pulley retaining

bolt once more. Turn the tensioner pulley to

tension the belt until, under moderate

pressure from the thumb and forefinger, the

bel can just be twisted through 43° at the

mid-point between the inlet camshaft

sprocket and the idler pulley. Note that this

method is only a provisional setting, and the

batt tension must be checked at the earliest

‘opportunity using the special belt tonsioning

oqulament. Failure to do this could lead to the

bet breaking (through over-tightening) or

Sipping (Hhrough siackness), resulting in

serious engine damage. With the tension set,

hold the tensioner pulley inthis position, and

Lighten the retaining bolt to the specified

torque.

57 Retighten all sprocket retaining bolts to

the specified torque.

58 Once the belt tension has been correctly

fal, refit the engine right-hand mounting

components as described in Section 18.

59 Felt the timing belt upper, contre and

lower covers (as applicable) as described in

Section 6.

60 Refit the auriliary drivebelt tensioner then

‘oft and tension the crivebelt with reference

toChapter 1A.

41 Felt the inner splash guard and front

fgft-nand whee, then lower the vehicle to the

‘round.

62 Reconnect the battery negative terminal

8: Timing bel tensioner ana

"sprockets - removal,

inspection and refitting &

x

Note: This Section describes the removal and

feftting of the components concemed as

invita! operations = if more than one is 10

be removed at the same time, start by

remaving the timing belt as described in

Section 7; remove the actual component as

Sescribed below, ignoring the preliminary

ismanting steps.

Removal

1 Disconnect the battery negative terminal.

2.Align the engine assembly/valve timing

holes as described in Section 3, locking the

camshaft sprockat(s) and the crankshaft

pully in position, and proceed as described

under the relevant sub-heading. Do not

attempt to rotate the engine whilst the pins

‘vin position. Once the sprockets have been

removed, their shafts should not be turned.

‘Camshaft sprocket -

Salve engine models

3 Remove the timing belt upper cover as

escrived in Section 6.

4 Loosen the timing belt tensioner pulley

retaining bolt. Rotate the pulley in a clockwise

tieection, using a suitable square-saction key

fited to’ the Aole in the pulley hub, then

ralighton the retaining bot.

5 Remove the locking pin from the camshatt

sprocket. Disengage the timing belt from the

sprocket and position it clear, taking care not

‘to bend or twist the belt sharply.

6 Slacken the camshaft sprocket retaining

bolt and remove It, along with its washer. To

prevent the camshatt rotating as the bolt is

slackened, a sprocket holding tool will be

required. In the absence of the special Citron

tool, an acceptable substitute can be

fabricated at home (gee Tool Tip). Do aor

attampt to use the sprocket locking pin to

prevent the sprockat from rotating whilst the

bolt is slackened,

7 With tho retaining bolt removed, slide the

sprocket off the end of the camshaft. If the

locating peg is a loose fit in the rear of the

sprocket, romovo it for safe-keeping. Examine

‘the camshaft oil seal for signs of oil leakage

and, If necessary, renew it as described in

Section 9,

Camshaft sprockets -

16-valve engine models,

8 Remove the timing belt upper (outer) anc

lower covers as described in Section 6.

9 For Improved access, support the engine

fon a jack, and remove the right-hand engine

mounting components as doseribed. in

Section 18.

40 Loosen the timing belt tensioner pulley

retaining bolt and pivot the pulley in 2

clockwise direction, using a suitable square-

section key fitted to the hole in the pulley hub,

then retighten the retaining bot.

11 Check that the camshaft sprocket locking

pins are stil in position, then cisengage the

liming belt from the camshaft sprockets anc

position it clear, taking care not to bend or

twist the belt sharply.

42 If the early-type sprockets are to be

removed without thelr hubs, undo the three

retaining bolts anc remove the relevant

sprocket, Suitably merk the sprockets “init”

and/or “exhaust” as they are removed

{although in fact the sprockets are identica).

18 If both the sprockets and the hubs are to

be removed, remove the sprocket locking

pins, then slacken the sprocket hub centre

retaining bolt. To prevent the sprockets

rotating as the bolt is slackened, a sprocket

holding tool will be required. in the absence of

the special Citroén tool, an acceptable

substitute can be fabricated at home (see

Tool Tip). Do not attempt to use the sprocket

locking pin to provont the sprocket from

rotating whilst the bolt is stackened

44 Unc the retaining bolt(s} and remove the

relevant sprocket. Remove the previously-

slackened hub retaining bolt, and withdraw

the hub from the end of the camshalt. Note

that the hubs are marked fer Identification

with a single digit on their front face. On 1.8

litra models, the inlet hub is marked “1" anc

the exhaust hub is marked "2". On 2.0 litre

models, the inlet hub is marked “3” and the

exhaust hub is marked “4”, Make your own

markings if none are visible,

camshaft sprocket whilst the sprocket

retaining bol is tightened

Crankshaft sprocket -

8-valve engine models

415. Remove the upper, centre and/or lower

timing belt coverts) (as applicable) as

scribed in Section 6.

16 Loosen the timing bolt tonsioner pulley

retaining bok. Rotate the pulley in a clockwise

Girection, using @ suitable square-section key

fitted to the hole In the pulley hub, then

ratighten the retaining bot.

17 Disengage the timing belt from the

Crankshaft sprocket, and slide the sprockot

aff the end of the crankshaft. Remove the

‘Woodruff key from the erankshaft, and store it

with the sprocket for safe-keeping. Where

necassary, also slide the spacer (where fitted)

aff the end of the erankshat.

48 Examine the crankshaft oll seal for signs

of oil leakage and, if necessary, renew it as

described in Section 18.

Crankshatt sprocket -

16-valve engine models

19 Remove the timing belt upper (outer) and

lower covers as described in Section 6,

20 For Improved access, support the engine

fon a jack, and remove the right-hand engine

mounting components as described

Section 18.

21 Loosen the timing belt tensioner pulley

retaining bolt, and pivot the pulley in a

clockwise direction, using a suitable square-

section kay fitted to the hole in the pulley nub,

then retighten the retaining bolt.

22 Check thal the camshaft sprocket locking

pins are still position, then disengage the

iming belt from the crankshaft sprocket, and

slide the sprocket off the end of the

crankshaft, Remove the Woodruff key from

the crankshatt, and store it with the sprocket

for safa-keeping,

23 Examine the crankshaft oil seal for signs

of oll leakage and, if necessary, renew it as

described in Section 16.

Tensioner pulley -

&-valve engine models

24 omove the upper and where necessary

the centre timing belt covers as desenibed in

Section 6,

214 Petrol engine in-car repair procedures

25 Slacken and remove the timing belt

tensioner pulley retaining bell, and slide the

pulley off its mounting stud. Examine the

mounting stud for signs of damage and if

nocassary, renew it.

Tensioner and idler pulleys -

16-valve engine models

26 Remove the timing belt upper (outer) anc

lower cavers as described in Section 6.

27 For improved access, support the engine

fon a jack, and remove the right-hand engine

mounting components as described in

Section 18,

28 Loosen the timing belt tensioner pulley

retaining bok, and pivot the pulley in «

clockwise direction, using a suitable square-

section key fitted to the hole in the pulley hub,

then retighten the retaining bo.

29° Chock that the camshaft sprocket locking

pine are stil in position, then disengage the

timing belt from the camshaft sprockets and

position it clesr, taking care net to bend or

tusist the belt sharply.

30 Undo the tensioner and idler pulley

retaining bolts, and remove the pulleys from

the engine,

Inspection

34 Clean tho camshatt/crankshatt sprockets

thoroughly, ancl renew any thal show wigs of

wear, damage or arch.

33 Clean the tonsionoridier pulleys, but do

hot use any strong solvent, ast ay ae A

pully boarings, Check that the pulleys rotate

realy, with no zigh of stiffness or free play

Renew them if there is any doubt about thei

canaition, or it there ere any obvious signs of

‘weer or damage.

Refitting

‘Camshatt sprocket -

8-valve engine models

‘33 Refit the locating peg (where removed) to

the rear of the sprocket, Locate the sprocket

‘on the ond of the camshaft, ensuring that the

locating peg is correetly engaged with the

‘cut-out in the camshaft enc.

34 Refit the sprocket retaining bolt and

washer, and tighten it to the specified torque.

Retain the sprocket with the tool used on

removal

35. Realign the hole in the camshaft sprocket

with the correspending hole in the cylinder

head, and refit tne locking pin. Check that the

coranikshatt pulley locking pin is stil In position,

36 Flefit the timing belt to the camshaft

sprocket, Ensure that the "front run” of the

ball is taut - Le., that any slack is on the

tensioner pulley side of the belt. Do not twist

the belt sharply while refitting it, and ensure

that the belt teeth are seated centrally in the

sprockets.

37 With the timing belt correctly engaged on

the sprockets, tension the belt as described in

Section 7,

38 Once the belt's correctly tensioned, refit

‘tien erin helt Comets ae Section B

Camshaft sprockets -

16-valve engine models

29 If both the sprockets and the hubs have

been removed, engage the sprocket hub with

the camshaft. Ensure that the correct hub is,

fitted to the relevant camshaft by observing

the hub identification markings described in

paragraph 14)

40 Refit the sprocket retaining bolt and

‘washer, and tighten it to the specified torque.

On models with the early-type three-bolt

sprockets, temporariy refit the sprockets, 10

allow the hub to be held stationary with the

tool as the bolt is tightened.

41 Turn the hub so that the locking pin can

bbe engaged.

42 If the three-bolt sprockets have been

removed, leaving the hubs in place, position

the sprocket on ils hub, and refit the three

bolts finger-light only at this stage. Ensure

that the correct sprocket is fitted to the

relevant camshaft according to the

identification made on removal (soo

paragraph 12).

43 Relocate and tension the timing bell as

described in Section 7. If removed, raft the

engine right-hand mounting as described in

Section 18,

Crankshaft sprocket -

8-valve engine models

48 Slide me spacer (where fitted late

postion, taking graat eare nat to darnage The

‘slankshaft od, and refit the Woodult Key to ta

Slot in the crankshaft on

45 Slide on the crankshatt sprockat, aligning

its slot with the Woodruff key.

4G Ensure that the camshaft eprocket locking

pin js still in position. Temporarily refit the

trankshaft pulley, and insert the locking pin

through the pulley timing hola, to onsure that

‘the crankshaft i stil correctly positioned.

47 Remove the crankshaft pulley. Engage the

timing belt with the crankshaft sprocket.

Ensure that the belt "front run” is taut - .e.,

that any slack is on the tensioner pulley side

Cf the belt, Fit the belt over the water pump

sprocket and tensioner pulley. Do not twist

the bell sharply while refitting it, and ensure

that the bell teeth are seated centrally in the

sprockets,

43 Tension the timing belt as described in

Section 7,

49 emove the crankshatt pulley, then refit

the timing belt cover(s) as doscribed in

Section 6,

180 loft the crankshaft pulley as described in

Section 5, and reconnect the battery negative

termina

Crankshaft sprocket -

16-valve engine models

51 Refit the Woodruff key to its slot in the

Crankshaft end,

52 Slide on the crankshaft sprocket, aligning

Its slot with the Woodruff key.

59 Relocate and tension the timing belt as

described in Section 7. If removed, refit the

engine right-hand mounting as described In

Section 18.

Tensioner pulley -

8-valve engine models

54 Reiit the tensioner pulley to its mounting

Stud, and tthe retaining bolt

‘55 Encuro that the “front run" of the bel |s

taut Le, that any slack is on the pulley sce

‘of the bell. Check that the belt is centraly

located on al its sprockets. Rotate the pues

anti-locktvise to remove al fre play from tho

timing belt, and securely tighten the pulley

relaining nut

‘86. Tonsion the belt as described in Section 7.

57 Once the belt is correctly tensioned, ret

the timing bell covers as described In

Section 6

Tensioner and idler pulleys -

16-valve engine models

158. Rofit tho tensioner and idler pulleys and

secure withthe retaining bolts.

59 Alslocate and tension the timing belt as

described in Section 7. If removed, refit tha

engine right-nené mounting as deseribed in

Section 18.

© Camehatt oll soat(a) - x

renewal s

g

Note: If the camshaft oil soal is to be renewed

with the timing belt stil in place, check frst

that the belt is frae from oll contamination.

(onew the belt as a matter of course if signs

of olf contamination are found: see Section 7.

Cover the pelt, to protect it from

contamination by olf, while work isin progress.

if the timing belt is removed, ensure that ai

traces of oll are removed from the area before

the bolt is refitted.

1 Romove the camshaft sprocket(s) as

described in Section 8. On 16-vaive engine

models, remove the sprockels and sprocket

hubs.

2 Punch or drill two small holes opposite

‘each athor in the oll seal. Screw a self-iapping

screw into each, and pull on the screws with

pliers to extract the seal

3 Clean the seal housing, and polish off any

burrs or raised edges, which may have

‘caused the seal to fail inthe first place.

4 Lubricate the lios of the new seal with olean

engine oil, and drive It inte position unti it

seats on ils locating shoulder. Use a sultable

tubular drift, such es a seckst, which bears

‘only on the hard outer edge of the seal. Take

‘care nat to damage the seal lips during ftin.

Note that the seal lips should face inwards.

5 Refit the camshaft sprockets) as described

in Section 8,

Petrol engine in-car repair procedures 2A*15

10 Camshatt(s) and followers -

removal, inspection and

refitting

He

Removal

1 Disconnect the battery negative terminal,

then remove the camshaft cover as described

in Section 4, Proceed as described under the

relevant sub-heading

S-valve engine models

2Remove the camshaft

descrioed in Section 8.

3 Remove the ignition HT coll as described in

Chapter 5B.

4 With the coll removed, slacken the upper

boll securing the thermostat housing to the

lefthand end of the cylinder head. Remove

‘he boit, along with its sealing washer. This is

nocessery since the bolt screws into the left=

and (No 1) camshatt bearing cap,

8 Garefuly ease the oll supply pipe out from

the top of the camshaft bearing caps, and

remove it. Note the O-ring seals flited to each

ofthe pipe unions (see illustration). Also note

‘he position of the adapters at each end of the

supply tue.

8 The camshaft bearing caps should be

rumbered 1 ta 8, number 1 belng at the

transmission end of the engine. Int, make

‘enteation marks on the caps, using white

paint or a sultble marker pen. Also mark

each cap in some way to indicate its correct

‘ited oxtentation. this will avoid the possibitity

of instating the caps the wrong way aroun!

onrefting,

7 Evenly and progressively slacken the

camshaft bearing cap retaining nuts by one

‘um at a time, This will relieve the valve spring

pressure on the bearing caps gradually and

evonly. Onc the pressure has been relieved,

the nuts can be fully unscrewed and removed

(see illustration).

8 Note the correct fitted orientation of the

bearing caps, then remove them from the

cyinder head (see illustration).

8 Lift the camshaft away from the cylinéer

head, and slide the oll seal off the camshaft

end (see illustration).

40 Obtain eight smal, clean

containers, and number them 1

aheratively, divide a larger container into eight

compartments, Using a rubber sucker,

witrdraw each follower in turn, and place it in

Itsrespective container. Do nat interchange the

cam followers, or the rate of wear willbe much=

increased. Hf necessary, also remove the shim

from the top of the valve stem, and store it with

iis respective follower. Note that the shim may

stick to the inside of the follower as it is

withdrawn. If this happens, take care not to

alo to drop out aa the follower is removed.

16-valve engine models

41 Remove bath camshaft covers as

eactibed in Section 4,

sprocket as

10.5 Removing the oil supply pipe from the

‘camshaft bearing caps

42 Refer to Section 8 and remove both

camshaft sprockets together with their hubs,

and also remove the liming belt tensioner

puley.

19 Remove the timing belt upper (inner)

‘cover as described in Section 6.

14 Progressively siackon, a litle at a time,

the twelve bolts securing each camshaft

bboaring housing to the cylinder head. Release

the bearing housings from their doviels and

cylinder head locations. When each housing is,

free, remove the bolts and washers

‘completaly, and lft off the bearing housings.

418 As both camshafts are identical, suftably

mark them “inlet” and “exhaust”, or front”

and “rear” hefora remo

46 Tilt the camshafts by prossing them down

at their transmission end to releaso the

ccantralising bearing a the timing belt end.

‘Carefully it the camehatts up and out of their

loeations, and slide the oil geal off each

‘amshait end.

17 Obtain sixteen email, clean plastic

containers, and number them inlet 1 to 8 anc

exhaust 1 to 8; alternatively, divide a larger

container into sixteen compartments, and

‘number each compartment accordingly. Using

fa rubber sucker, withdraw each hydraulic

tappet in turn, and place it in its respective

container. Do not interchange the tappets, or

the rate of wear will be much increased.

Inspection

48 Examine the camshaft bearing surfaces

and cam lobes for signs of wear ridges and

scoring, Renew the camshaft if any of these

ceonditions are apparent. Examine the condition

and remove the camshaft bearing

caps...

“10.7 Working as described in the text,

unscrew the retaining nuts .

cof the bearing surfaces, both on the camshaft

Journals anc in the eylindar head/bearing caps.

If the head bearing surfaces are wom

‘excessively, the cylinder head will need to be

renewed, If suitable measuring equipment is

‘available, camshaft bearing journal woar can

be checked by direct measurement (where the

necessary specifications have been quoted by

Citroen), noting that No 1 journal is at the

‘Wansmission end of the head,

49 Examine the cam fellower/hydraulic

tappet bearing surfaces which contact the

‘camshaft lobes for wear ridges and scoring.

Fenow any fellowor/tappet on which these

‘conditions are apparent. If follower/tappet

benring surface fs badly scored, also examin

the corresponding lobe on the camshatt for

‘waar, a it is Hkely that both will be worn.

onow worn components as necessary,

Refitting

B.valve engine models

20 Where removed, refit each shim to the lop

of ils original vaive stem. Do not interchange

the shims, a9 this will upsot the valve

Clearances (see Section 11).

21 Liberally oll the cylinder head cam

follower bores anc the followers, Carefully

refit the followers to the cylinder head,

ensuring that each follower is refitted to its

‘original bare. Some care will be required to

‘enter the folowers squarely into their bores.

22 Liberally oll the camshaft bearings and

lobes, then refit the camshaft to the cylinder

hoad. Temporarily refit the sprocket to the end

of the shaft, anc position it so that the

sprocket tiring hole is aligned with the

« then lft the camshaft away from

the cylinder head

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)