0% found this document useful (0 votes)

317 views20 pagesRammer Performance 2020

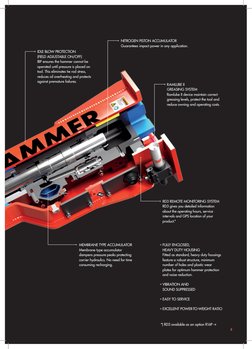

The document discusses Rammer performance line hammers, which are designed for a wide range of breaking demands. Key features include excellent power-to-weight ratio, proven Rammer quality, optimized performance, easy servicing, and compliance with ISO standards.

Uploaded by

OswaldoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

317 views20 pagesRammer Performance 2020

The document discusses Rammer performance line hammers, which are designed for a wide range of breaking demands. Key features include excellent power-to-weight ratio, proven Rammer quality, optimized performance, easy servicing, and compliance with ISO standards.

Uploaded by

OswaldoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Unbeatable Performance

- 40 Years of Innovation

- Optimized Performance

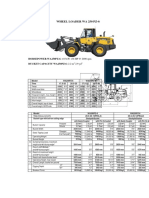

- Small Hammers

- Medium Hammers

- Large Hammers

- Greasing and Data Options

- First Class Service and Support