Professional Documents

Culture Documents

Red Book Steel

Uploaded by

Derick Roarty0 ratings0% found this document useful (0 votes)

6 views44 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views44 pagesRed Book Steel

Uploaded by

Derick RoartyCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 44

SOUTHERN AFRICAN

STEEL CONSTRUCTION

HANDBOOK

Fifth Eation 2005,

+ Iuocatios nthe Design of Eerie Trams Srctres, ated by GM

‘Witt

chimneys

+ 4076 Steal chimneys

+5 6399 Part 1 - Code of practice for dead an imposed loads.

1 BS CPS, Chapter V, Part 2- Wind onda, Replaced by BS 999: Past 21985,

which although withdrawn and seplaced by BS 6389 Part 21957 remaine

trent sos llaw an averap petid.

+ Dash of Ml Sel Chines, by DL Henshavs, Droughtsmen’s and Allied

Technician’ Acsciatlon, UK, 1964,

+ Desig and Cavstrcton of Stl Chimney Lins. ASCE, USA, 196,

“Ff nuatonl Ckinney Coon, CICIND (Comité Intemational des

CChinnais Insitute). Conference proceedings, 155.

IND Cade for Ch

ney. CICIND Secretariat, United Kinglom, 1984

+ Chine Rusay Gindrs by BE Gorene, Autraian Institute of Stel

Construction Lid, Syne, 1583.

+ Che Runonys WS of 2147 Coniston XV Design ad Fabricetion (11W’ Dae

XV = 734/90, Doe XV = NGS ~ 5099). Prepazed and ected by JT Bisa,

‘Canada an Bert, Canada, 189

+ Gide oth Design ad Constracon of Mil Builngs. AISE (Assocation of

Iron and Stel Engineers). Technical report No 15, 2008, Pitsburg

Pennsylvanis, 18222

+ DIN 4132 Craneways Stel Structures - Principals for cacultion, design

‘acd conatrucion.

+ Cranes General Design - Par 31: Limit sates and proof of competence of

soo! structures, Ref No pe CEN/TS 13001 - 3-1 2003 (Final draft)

Bropean Commitee for Standardization Rue de Siassart 36 B - 1050

Brocels

2

STEEL, STEEL PRODUCTS -

AND SECTION PROPERTIES

2.1 Structural steel 23

21.1 General 23

2212 Propertes 23

22 Lamellar tearing 27

2.3 Steel at elevated temperatures 28

24 Other properties of structural steel 28

25 Corrosion 241

26 Bifect of hot-dip galvanizing 242

2.7 Identification of steel 242

2172 Kenliation marking 2a

272 Identification by coloue marking 2a

273 Unidentified structural steel 2a

28 Specifications for dimensions of hot-rolled

steel products 243

281 Specification for hotaled sections 2a

2182 Dimensional tolerance for hotrod satons 28

2.83 Standard lengths of hot old sections 216

28: Dimensional tolerances for Hat products 26

a

29 Specifications for hollow sections

2.10 Specifications for open cold-formed sections

2.11 Tolerances on elements used in construction

2.412 Tables of dimensions and properties

218

248

248

219

2.1 Structural steel

24a

‘The contents ofthis seton are based on extracts fom product dala shes

drawn up by the South African steel producer end fom the zelevant

specifications, While all possible eare has been ken in preparing Dis

Information, reference should be made 1 the mast recent pullin for

‘both further detail and to ensure the curtency of information

21.2 Properties

‘The term ‘structural sto’ may be used to define steel une for elements

Whose primary. purpose is to suppor loads or reset forces which act on &

structure, ‘Structural ste” also core fo imean the prot of the sec!

il such as sections, plats and bes, fom which structural members such

fs beams, gine, columns srs, tes, hanger and gts ae fal

Both SANS 10162: Part and SANS 2001 - C52 require hase! for srutural

applistions must comply withthe requwinents of SANS 141, bot permit

see complying with ober specication lo be used, proved thet any sack

steel meets the requirements of Classe 5.14 of SANS 10162 Part, According

‘© SANS2001-C51, the chemical compotion and mechanical properties of

all ste incorporated ito structures mast be tated on ail est cere,

and acorng to Clause 44.11 of SANS 1922-2 the steclwork contrac must

‘obtain thee cetficates fr all te and forward them tothe employer

‘An anomaly inthe South Aftcan ste! construction industry i the existence

‘of commercial quality ste (CO), sometiies also referred toa‘ tet”

“The chemical composition of CQ fe controled, but no mechanical tet are

performed on it. The self-imposed specifications to which CO is produced

vary somewhat from mil to ml, Buti can be astute that the caton

content will not exceed 0.3%, and the exon equivalent CE not O51, where

CE=C¥Mn/6+(Ce+ Mo + Wy/5+ (Ni ¥ cays

with Ma, Cr, Mo, V; Ni and Cu being, sespecvely, the percentage of

‘bon, manganese, chromium, molybdenum, vanadium, nickel and copper

{nthe ste. A value of CE les than 51% implies that thesis weld

Lite can be said about the yield stese or tensile strength of commer

guns, Acorn to Cee 522 of SANS 1062 Ps he i ese ‘mamez

{ten stengh of ldeted structural ts bal be ken ao more MECHAMICAL PROPERTIES FoR PLATES To SANS 1451

‘than 200 and 365 MPa, respectively. ‘We sre ima) ‘Mitmur sosglioe | Okan Ves pr wl

‘The mechani proper of sels nde accordance with SANS 161 ae me Speen [omvaa

leted n Tables 21 and 22. The ales lot he inact esters nT wT

forthe aos grade of sel. tn ths ates 4 tthe gel osr aero be ed es peed ie oe

es oft et pcien ee

a

Tate 2t am |amsial 20 | ve em fz [eof | a p=] = —

[MECHANUCAL PROPERTIES FOR FLAT BARS AND SECTIONS TO SANS 1431 rome iee| sel celery zi 2 |S

RT a — a TE xo fsa] a0] ae] m [ae [20] «| @ Pe | — [=

a ae pee fes| =| =z lelel=lel2l- |:

wan (2 Te ee pea een x0 | 30 | ao | lan [a | @ | a | @ |

ss ensues cml am | x ||, an a

=| sme Janta} 20 | 9s] 0 | | ana |u| a| a |

ea ae [a [oP foo] mea] wo | 36 20 || as | 2 | || a |

‘oom [eal aa [ao fom | =] me |e p=] || — ee

one |eau| ae | x0 fa | am | a | a | 2 | 2 | o| @ Hao: |sare| | ao| as /an|—| 2 |v |i] a |

seo |enea| ax | sm |s0 | am | wo | a | x | || pecs) ex | «| oe {ae | — | m | | | |

se leee ee rere yaya yl ye Noe: ste yt yaa

[mato | eeneeo} aso | a | oes | ee | es Be At room temperature all structural steels that are free from natch effects are

down |r) 450 | 490 | ais | — | — | ov | we) — P| tough ~ more so than other common construction materials. Even at low

sax [samo] ea] amas || - ||» | a] | w seeprtresnovee members renter ougine han eg

Jeno ero] ol |as|e| =| olla |o| » under morma service codons. However, when notch it are preset

Note Grae S00 nt DW ses mayne nya

‘A very important characteristic of structural steel i its duct; thus the

‘minimum elongation requirement in Tables 21 and 22. In many aspecs of

design itis assumed that some degree of yielding leading to sess

‘estribution, will occur at certain locations in the sucture. Without the

lacity to permit sich yeng, cracks will occur. Plastic design wil be

Jmpasible without dct.

Jove tersperatures, many sels show a decided drop in toughness ad ay be

prone rile recur, Although notch effects ca be minimized is har

possible to avoid them altogether, and in structures that are sujet to low

temperatures and high tensile stresses (loin the form af ida tes), the

‘se of structural see with adoguate notch toughness a wise precaution.

"ewoul be thus wise to specify a WC or WDD steel as chown in Table 21 or

22 for ow temperature spplication, together with notch-tough weld ental,

and to reduce notches toa minim. Stes relloving at ried temperatures

‘0 gtridofresual tensile steesses can be considered,

creo

‘Thickness also hasan influence on notch toughnas Deause more severe

axial sen fects can occur in thick matecal. Thus, ll eter factors being

‘equal thinner matca i les prone rit facta

“Tobe 23 contains rit information on South Afican snl international els

that can be used for structural purposes. South Afric ses mills produce

‘ble 29

‘GENERAL GUDE TO STRUCTURAL STEELS

Ga

Season | twtatingct | Mambots sess | catyayon

tector us

Bua ET a ae

ss 51 2am a0 sia

su nm a sk

ee a 8 i

92s ares zs ge

(acanrcier | a0 30m ac

sis 1 som Ey so ica

750 Tae a a

sm ros 35 st

le-cear/emai | axon 0 conte

as 4 0" 0 uaa

eras sss = pe

ss.080 @ = aw

[sxcararroaaT | = Goa

‘eon ae

aN ORTRIA DR ee

iy a et oe

[elses eaten

aon ao 0 ‘uh ares

asset ten | THD Te al ee

‘fot so im su stos

ear se ection | Baio mene

forse | rasen-o0 sono oun aos

primarily according to SANE 141 fr the foal market, but can produce 10

any ofthe other standards listed ona big enough order. Stel can aso be

Certified ae meeting the requirements of several standards simultaneously.

CChaepy or other tests can be performed If required. BLOG (1983)

provides @ testing method by which the through-hickness properties of

‘too can be messed

2.2 Lamellar tearing

“The information on strength and cuctity presented in the previous section

generally pertains to loadings apie in the plane longitudinal or transverse

Airectin) of asta plate or element ofa section. It should be noted that

‘longation and area reduction values may wel besigniicarly lower in the

}—earoughsthicknees direction than in a planar direction, The Inherent

lrectionality is f small coneaqience in many applications, bat does become

important in the design and fabrication of structures containing tice

|) members with highly eestained welded ois.

Attention should be given tothe posible occurrence of lamellar ering in

highly restrained joints in welded stroctnes, especially those ung thick

~ plates or heneysuetural shapes. The estan ndced by some oi! designs

tn resting weld deposit shrinkage cn impose tensiestrsine sulin high

to cause sepecation or tearing in the ste om planes parallel tothe roiled

surface of the strctual member being joined. The incidence of this

Phenomenon canbe reduced or eliminated through pester anderstancing by

Aesigness, deters and fabricators of (1) the inherent directionality of the

proper oftractra tse, 2) th high rersntdevalopod in certain ype

| of connections, and (3) the need fo adopt appropriate weld details snd

welding procedures for throughthickness connections, Furthermore, scl

can be sponifiad to be produc’ by special practic and/or prcoete 12

‘enhance through thickness ety an thus asst in reducing the iketthood

‘of lamellar fenrng. Note the test procedae refered to in 212. However,

tnles preceuions ae taken in both design and fabrication, lamella tering

may sill cur in thick plates and heavy shapes at resttined through

thickness connections. Some guidelines for minimizing potential problems

‘Tjpins are given in Table 628. Lamellar teoring can be deteced with

tultasonic testing ofthe fabcented steelwork.

Ee

23 Steel at elevated temperatures

Figure 21 shows some of the effects associated with sructral steel at

clevated temperatures, Figure22 shows how the yield ates of steel drops as

5 temperature ris, while Figure 23 demonstrates the redaction in the

‘odulis of elasticity at elevated temperatures, These Sigurs are not

‘necessarily accurate fr any particular soa but they do demonstrate that by

the time the temperature reaches 50°C both the yl sess and the tines

(ood indeed the tensile steng:) wil have been markedly reduced. The

strength an stability ofastractae will thasbe seriously imped a elevated

temperatures. This demonstrates why fire protection or intelligent

engineering i required to proventsaious damage or cllapee ofa structure

exposed tofire,

4 genera aol structural tel which hasbeen exposed fo ire wil not be

ermanenty damaged in so far as ts mechanical properties are concerned if

the temperature has not exceeded approximately 900 °C. At higher

temperatures the steal may autor ible damage,

‘Asa genera ul, team be stated ha stelwork that as na been distorted

‘or suffered significant surface dogradaton during a fe wil not have an

mpaited strength. Should any doubt exist about the adequacy of tel

‘exposed to ire, tests can be performed. The fasteners should be given

special atetion,

24 Other properties of structural steel

‘Thefllowingis a ummary of eran properties the ange sels used in

structural aplicatons

Deity

7850 kg/m

Moulus of elstilty (Youngs moduli) E = 200% 10 MPa

Polson ratio

‘Shear modulus C= £/2 (14a)

Couficen of expansion

Srctc heat, approximately

‘Thermal conductivity, proximately

#2030

Ca 77x10 Ma

ay xioy7c

$807/kg°C

s0W/m'C

Figure 21 Temperature cart ost with 020% carbon content

aa

as

Sou yhov

8

om

a

Steel

0 a ao

Tempe)

‘yan yi arnt 20°C

Sys lective ye sree stead tpn

Figura 22 Relationship betneen temperature and ete yield tress

By x10" MPa

suo

2 a0

‘Temp CO)

ig = mois feast of sol at elevated teperture

Fgwe 23 Ratoni between temperate and modules of astciy

2.5 Corrosion,

‘Structural tel subject corrosion In th prance of moisture al oxygen

Ina arose environment eset canbe protected by painting galvanizing

‘or metal spraying

Alternatively an atmospheric corvosion rstantTowalloy te suchas COR-

TEN can be used, COR-TEN is sultable for use inthe uncoated condion

Exposure to normal atmospheric conditions cause a tightly adherent oxide

patna to frm on the surface which considerably reduces the rte of further

‘oxidation. The reduced maintenance resltng from the use of ti sel may

‘oles higher nil cost, butts aesthetic iexpact may bos greatast ase

‘The conosion of a metal may be aecolorated throught conict with another

‘metal in mols conditions this known as bimetalic galvanic or electrolytic

‘corrosion, The to metals and the liquid present between the corse 2

‘coll ausing the fle of sll ler curen whic lends othe corosion af

‘he ese noble meta. Is ths advisable to insulate ste! fom oter materials

te prevent accelerated corrsion in the contact res,

“The following able of potenti of metals provids an inl guide 1 the

posse effects of beac contac. A meal with «higher potenti will

provide protect to more noble one by sacrificial ston.

Ngati

va vs)

exes 17

Zee to

unin cs

Suet tet re

fe) 5

tm asa

Sts ts “13-03

ass os

oer oe

oat a

2.6 Effect of hot-dip galvanizing

Stan bet avai or conson proton. Begin i hat

sis a ier aco sae ses ing ene

ingen ingle shouls spl aire pd gulp cnt

and also to reduce costs, ve comme °

Sto cae rr ho pave yn cd piling, the

seat highstengih el and severly cl tral whee ces

ike rar sce ono eee te lt ning

Foro ah pking recone, Te mcr ove panel

SSponie to ald which may Incease the propel Yor hydrogen

entitlement an im fly inset ee

The sel inert in mele sin at temper of bout °C. The

rela chem racton forte serie of on/ae alloys tat

‘etl bod the conan pete cating fo he sel Where

‘eiig i near alr oi aang he ae congo eel

tra mst te emoved be welding pice, Damaged cong suns

‘lng om wen roar cnr an be untyped yng

eeevoa spre ep cere

‘The elevated temperature of molten zine may reel in aceerted sein

‘gpg ina susceptibeste! particulary where severe cold working ha taken

place, eg. cokheaded bolls. Where thi could be devimentl the use of 3

‘Snegrinedstel made by killing with alsminium is rcommerded, In the

‘ewe of a susceptible steel, appropiete heat treatment prior to hot ip

‘galvanizing wil avo hi form of emnnitement,

‘To obtain an aesthetically plasing surface guaity ater galvanizing itis

‘commenced thatthe silicon content ofthe sel should be either les than

(05%, or between 08% and 0.78%,

2.7 Identification of steel

2.7 Identification marking

‘SAS 1491 requires that the manafeturer identifies ll ingots billets lbs,

plats sections ars, ec, with cast numbers or identification masks in sucha

‘ay a enable ll nshed siel tobe trace to te east frm which it wos

‘made ofr hollow sections made by the continuous proces, the cast rom

Which they overe mad, Esch pce or parcel of sel mut alse be legibly

‘marked with the manufacturer name or edema.

2.7.2 Identification by colour marking,

Color cong of structural te! sna required by SANS 1481 and such scl

rcs from producer wll aly be colour coded if this requirement i

ald onthe order. “There may be a change for colour coding.

Colour coding will be in accordance with SANS 10202: Code of Practice for

{he Colour Coding of Steel Products. Te system consists ofa band of theoe

‘lous, the principal colour indenting the functional group to which the

product belongs (for scural steel the colour is red). This colour i

flanked on one side by a ier second colour and on the other by ¢ tied

colour. There colours indicate the stel grade strngih category and

Charpy or other requirement.

273 Unidentified structural steel

Unidentified structural steel most not be wed, unless approved by the

Engines, ovhich approval eSould not be given without performing cetain

tests on the ste. Etcesvely hard ar bite sta can and have n he past,

lead to serious acidens. Ifthe use of unidentified ste! is authorize for hot

rolled steelwork, the minimum yield sess f and the minimum tensile

strength used for design stall be taken as not more than 200 MPa ana

365 MPa respectively, as stated in Clause 5.22 of SANS 1016: Pact 1. The

terms ‘snidentied ste” and ‘commercial quality” do not have Se seme

meaning. (Alsosee21)

2.8 Specifications for dimensions of hot-rolled steel

products

2.81 Specifications for hot-rolled sections

Hobolled sections are producsd to the following standards in Sosth

‘Asie, but It is advisable to consult the product data she's ofthe specific

Supplier in any ease where the dimensions of » secon ate critical, of #2

contact the supplier

eo

Steel

Universal beams and columns

“Taper Mange sections

DIN taper flange channels

2S taper fange channels

‘A parallel Range cannes

Angles

854: Part :19%5,

EV 10024

DIN 1025: 1965

Internal specification SPE 250

DIN 1025: 1963

BS 4: Part 1999

EN 10078

EN 10055

2.8.2 Dimensional tolerances for hot-rlled sections

Incentive a

sonal tolerance fr hotoled sectons are summaslzed in

‘Table 24. More accurate and comprehensive information can be abained

from tol producer and the elevant specfictins

Taie24

!NOIATIVE OMENSOUAL TOLERANCES FoR HO-ROLED SECTIONS

‘en cs a

= =

‘aril fangs) me

ese aia esse

ppl meio soso

= mocbses fan sao

Web et cent = (0 — 2 “Ne a cane

sentencing | het, ao0e20

‘ble 24 (onions)

INDICATIVE DIMESIONAL TOLERANCES FOR HOT-ROLLED SECTIONS

a

eh

erst

1 arts

neat

ero

asain

orb)

ap +30

siseeis

erreeyy

Chaz rad

ers

neo sero

1. 12 aone4d

oa)

‘le 24 (onions)

IWICATIVE DIMENSIONAL TOLERANCES FOR HOT-ROLLED SECTIONS

co ‘em tn

oe ow +075

ssebe 15 Ob +10

sensi Sow+ts

at pe)

1 asw+as

ste Sow+ia

an Aswns

ante 4

tose bese 19 seaman

wege s aem+0s

sede Sam+i3

#5100 fsm43

283 Standard lengths of hot-olled sections

In gener, structural stot sections are avaiable in lengths of ep #9 24 m.

‘Standard lengis of 9m, 1m and 13 maze generally svslableex sock.

284 Dimensional tolerances for flat products

‘Stabs, pats and sheos are usually supped to EN 10029. The tolerances in

“Tables 26, 27 and 28 below roflct those of EN 10029, When 2 pie is

produced to other international standards mich as ASTM, DIN or 5 the

Tolerances are according tothe relevant specication, Closer tolerances on

lt thickness canbe specif (conic! suppl)

Table 28

TOLERANCES ON THICKNESS

Thar

sonnet | “ove Soin has anni se a)

sommes | mist

sles Pein wb

‘gm_| ies | tom | 35m |

wares | ie te ta te =

sees | 1s oe aa a

ast | 17 10 10 “1

sete | ta M1 2 12

lactco | 22 2 2 13

fasten | 28 2 13 4 ‘

fose

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Tapping Sizes and Clearance HolesDocument1 pageTapping Sizes and Clearance HolesDerick RoartyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Red Book FloorsDocument16 pagesRed Book FloorsDerick RoartyNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Jaw CrusherDocument4 pagesJaw CrusherDerick RoartyNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Red Book ConnectionsDocument54 pagesRed Book ConnectionsDerick RoartyNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Red Book DateDocument23 pagesRed Book DateDerick RoartyNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Dual-Band Ceiling Mount AntennaDocument2 pagesDual-Band Ceiling Mount AntennaDerick RoartyNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- GR 4 Wiskunde November 2015Document10 pagesGR 4 Wiskunde November 2015Derick RoartyNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Work Breakdown Structure 101Document3 pagesWork Breakdown Structure 101Derick RoartyNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

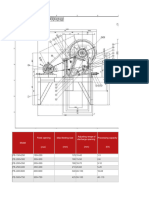

- A Full Range of Proven Feeders and The People To Support YouDocument8 pagesA Full Range of Proven Feeders and The People To Support YouDerick RoartyNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Quick Installation Instructions - Es PDFDocument5 pagesQuick Installation Instructions - Es PDFDerick RoartyNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Diseko MEDocument112 pagesDiseko MEDerick RoartyNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Approach To Project Talent Management FrameworkDocument5 pagesApproach To Project Talent Management FrameworkDerick RoartyNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 05 131019143024 Phpapp02Document1 page05 131019143024 Phpapp02Derick RoartyNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Managing Smaller and Medium Sized ProjectsDocument240 pagesManaging Smaller and Medium Sized ProjectsDerick RoartyNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- C762375 PDFDocument20 pagesC762375 PDFDerick RoartyNo ratings yet

- BK AutoCAD 2008 Ch24 Dynamic BlocksDocument44 pagesBK AutoCAD 2008 Ch24 Dynamic BlocksDerick RoartyNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Light Steel Frame Homes Light Steel Framing SystemsDocument4 pagesLight Steel Frame Homes Light Steel Framing SystemsDerick RoartyNo ratings yet

- MCO 305 Operating InstructionDocument43 pagesMCO 305 Operating InstructionDerick RoartyNo ratings yet

- Commissioning Guidelines ION-IX Rev.1Document8 pagesCommissioning Guidelines ION-IX Rev.1Derick RoartyNo ratings yet

- Assembly Instructions ION-IX Rev.0Document10 pagesAssembly Instructions ION-IX Rev.0Derick RoartyNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)