Professional Documents

Culture Documents

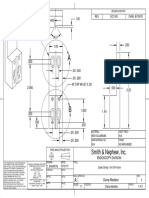

Angle Block

Uploaded by

anderson santosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Angle Block

Uploaded by

anderson santosCopyright:

Available Formats

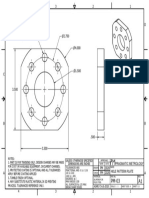

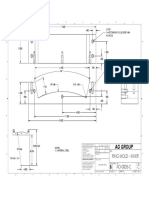

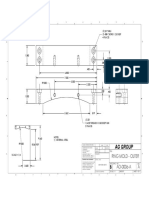

4 3 2 1

A

.315

.610 .840

D D

1.000

3.210

.400 3.450

3.750

4.000

C 3/8-16 UNC - 2B C

C

THRU ALL

1.300

2X R.250

.500 .500 .405 .397 THRU ALL

.260 .350

.625 .375

.72 x .38 .30

40

2X Full Radius

2.340

1.750

B 1.100 1.005 1.33 B

.500 +.0005

.375 - .0000

B .500

1.490 .970 THRU ALL

.397 THRU ALL

2.500

NOTES: APPROVALS

UNLESS OTHERWISE SPECIFIED

1. PART IS FOR TRAINING ONLY. DESIGN CHANGES MAY BE MADE DIMENSIONS ARE INCHES NAME DATE PRAGMATIC METROLOGY

FOR COST OR AVAILABLE EQUIPMENT. DOCUMENT CHANGES. TOLERANCES ARE: DRAWN PM 2019 NAME:

2. PROTECTIVE COATING IS OPTIONAL AND ALL TOLERANCES FRACTIONAL AND .X: 1/16

A APPLY BEFORE COATING APPLIED .XX: .010 CHECK PM 2019 ANGLE BLOCK A

.XXX: .005 MATERIAL: DWG No. REV

3. TUMBLE FINISH OPTIONAL. DEGREES: 1 ALUMINUM OR

4. MAY SUBSTITUTE PLASTIC MATERIAL IN 3D PRINTING MAX RADIUS .030

ALL SURFACES Ra 125 MAX

MILD STEEL PM-02 A1

PROCESS. TOLERANCES REFERENCE ONLY. BREAK SHARP EDGES ASME Y14.5-2018 SCALE: 1 / 2 SHEET SIZE: A SHEET 1/1

4 3 2 1

You might also like

- HES Casing Accessories CatDocument23 pagesHES Casing Accessories CatJoan Corso100% (1)

- Anchor Bolt Design - Apdx D - ACI318-05Document4 pagesAnchor Bolt Design - Apdx D - ACI318-05Manoj JaiswalNo ratings yet

- An805 8Document3 pagesAn805 8jcNo ratings yet

- Plasma Coated Piston RingsDocument4 pagesPlasma Coated Piston RingsThomas JoseNo ratings yet

- For Axial Compressive Load & Biaxial Bending Moments, Including Slenderness Effect, As Per Is:456-2000Document43 pagesFor Axial Compressive Load & Biaxial Bending Moments, Including Slenderness Effect, As Per Is:456-2000Satish Khadse100% (1)

- 9040 Washing and SterilizationDocument1 page9040 Washing and SterilizationCalidad LassNo ratings yet

- RCC12 Bending and Axial ForceDocument4 pagesRCC12 Bending and Axial ForceCioabla Bogdan100% (1)

- Design of Rectangular Column Section by Limit-State MethodDocument44 pagesDesign of Rectangular Column Section by Limit-State Methodsridhar100% (1)

- Application of Spiral Heat Exchangers in Heavy Oil Service External PDFDocument27 pagesApplication of Spiral Heat Exchangers in Heavy Oil Service External PDFProcess EngineerNo ratings yet

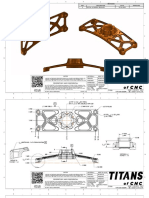

- Modular CNC 3-Axis RouterDocument4 pagesModular CNC 3-Axis RouterModularCNC75% (4)

- Project Report On GearsDocument40 pagesProject Report On Gearsjai70% (27)

- Project Title: Proposed One-Storey Residential Building Governing Codes and SpecificationDocument8 pagesProject Title: Proposed One-Storey Residential Building Governing Codes and SpecificationPamela Joanne Falo AndradeNo ratings yet

- Envicool Cabinet Air Conditioner Service ManualDocument22 pagesEnvicool Cabinet Air Conditioner Service ManualCONSORCIO TECA 2019100% (2)

- Fresa 1Document1 pageFresa 1anderson santosNo ratings yet

- JR1360 Det1Document1 pageJR1360 Det1TONY HERNANDEZ.No ratings yet

- Ag Group: B Ring Mold - Inner AG-0005-BDocument1 pageAg Group: B Ring Mold - Inner AG-0005-BAnonymous IQD4PqB876No ratings yet

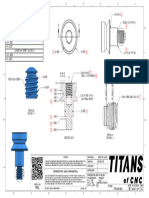

- Custom Ball Valve TITAN-810: Proprietary and ConfidentialDocument1 pageCustom Ball Valve TITAN-810: Proprietary and ConfidentialGundhi AsmoroNo ratings yet

- Titan-505m Ra PDFDocument6 pagesTitan-505m Ra PDFUbaldo Garcia ZaragozaNo ratings yet

- 20008-001-1703 01-12-005-13-A Palanca para Sin FinDocument1 page20008-001-1703 01-12-005-13-A Palanca para Sin FinKarlosdcd WikiNo ratings yet

- Index Feed Final - Jake FalbeDocument1 pageIndex Feed Final - Jake Falbeapi-537722646No ratings yet

- Ag Group: .44 C'BORE X .25 DEEP 5 Places .257 THRUDocument1 pageAg Group: .44 C'BORE X .25 DEEP 5 Places .257 THRUAnonymous IQD4PqB876No ratings yet

- Titan 72m PDFDocument1 pageTitan 72m PDFKmilo tellezNo ratings yet

- Torno 1Document1 pageTorno 1anderson santosNo ratings yet

- Vanrobaeys Catalog 2016Document1 pageVanrobaeys Catalog 2016MarcoMoraisNo ratings yet

- Ag Group: .44 C'BORE X .25 DEEP 5 Places .257 THRUDocument1 pageAg Group: .44 C'BORE X .25 DEEP 5 Places .257 THRUAnonymous ONsqg3No ratings yet

- Ag Group: C Ring Mold - Inner AG-0005-CDocument1 pageAg Group: C Ring Mold - Inner AG-0005-CAnonymous IQD4PqB876No ratings yet

- Tc.v1.am - Lahr V1 R1Document1 pageTc.v1.am - Lahr V1 R1almedin_hecimov8494No ratings yet

- Ag Group: .438 C'BORE X .25 DEEP 4 Places .257 THRUDocument1 pageAg Group: .438 C'BORE X .25 DEEP 4 Places .257 THRUAnonymous IQD4PqB876No ratings yet

- New Symbols: New Symbols in The 2009 Revision of The GD&T StandardDocument5 pagesNew Symbols: New Symbols in The 2009 Revision of The GD&T StandardJose Manuel OSNo ratings yet

- Ag Group: .44 C'BORE X .25 DEEP 5 Places .257 THRUDocument1 pageAg Group: .44 C'BORE X .25 DEEP 5 Places .257 THRUAnonymous ONsqg3No ratings yet

- Plano Utililaje CalibreDocument3 pagesPlano Utililaje CalibreMario EnriquezNo ratings yet

- Ag GroupDocument1 pageAg GroupTonyTzuNo ratings yet

- Ag Group: .438 C'BORE X .25 DEEP 4 Places .257 THRU 7.600 .400Document1 pageAg Group: .438 C'BORE X .25 DEEP 4 Places .257 THRU 7.600 .400Anonymous IQD4PqB876No ratings yet

- C Stile, Latch WG-1010: Double E Creations LLCDocument1 pageC Stile, Latch WG-1010: Double E Creations LLCGPNo ratings yet

- Lab 2Document2 pagesLab 2macsen.malacaiNo ratings yet

- Quiz 5 DrawingDocument1 pageQuiz 5 DrawingIan Van SciverNo ratings yet

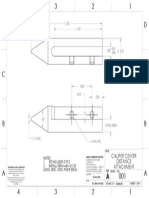

- Caliper Center Distance AttachmentDocument1 pageCaliper Center Distance Attachmentwilde.irwinNo ratings yet

- 750 24 Uns 2aDocument1 page750 24 Uns 2amacsen.malacaiNo ratings yet

- Clamp MediatorDocument2 pagesClamp Mediatorapi-349134962No ratings yet

- PolarDocument1 pagePolarCAO FAO CNC عربيNo ratings yet

- Vivienda Unifamiliar: Produced by An Autodesk Educational ProductDocument1 pageVivienda Unifamiliar: Produced by An Autodesk Educational ProductEysten Oblitas TarrilloNo ratings yet

- Y Bearing BlockDocument1 pageY Bearing BlockEdgar SouzaNo ratings yet

- TF 000105Document1 pageTF 000105api-299556237No ratings yet

- Titan-84l 2022 BubbledDocument1 pageTitan-84l 2022 BubbledOyunbat GansukhNo ratings yet

- Air BoxDocument1 pageAir BoxThái TrangNo ratings yet

- Large New 4 CCP-rev. DDocument2 pagesLarge New 4 CCP-rev. DElma TabakNo ratings yet

- Structure DesignDocument1 pageStructure DesignTuyishime EnockNo ratings yet

- CM RTNG WallDocument1 pageCM RTNG WallSoumya Ranjan MeherNo ratings yet

- 5l Gantry Side LeftDocument1 page5l Gantry Side LeftEveraldo Amorim Dias ArantesNo ratings yet

- 625 24 Unef 2aDocument1 page625 24 Unef 2amacsen.malacaiNo ratings yet

- Acrilic 1Mm: Note Unspecified Edge: Champer 0.3Document2 pagesAcrilic 1Mm: Note Unspecified Edge: Champer 0.3AgungNo ratings yet

- A B D C C A B D C C 2' 2' 1 2 3 4 3': Front Elevation Cross - Section Right - Side ElevationDocument1 pageA B D C C A B D C C 2' 2' 1 2 3 4 3': Front Elevation Cross - Section Right - Side Elevationjohnalfred051801No ratings yet

- Et 1 Tavan Gips-CartonDocument1 pageEt 1 Tavan Gips-CartonStan EdaurdNo ratings yet

- Retaining WallDocument1 pageRetaining WallChandan MoharanaNo ratings yet

- Gear Assembly Rev 01Document1 pageGear Assembly Rev 01steedNo ratings yet

- Floor PlanDocument1 pageFloor PlanKanyika MwangaNo ratings yet

- Est. Weight: N/A: Great Lakes Case & Cabinet Co., IncDocument1 pageEst. Weight: N/A: Great Lakes Case & Cabinet Co., IncGS Meena0% (1)

- PlanetarycarrierDocument1 pagePlanetarycarrierapi-439334789No ratings yet

- Corn Hopper Funnel DrawingDocument1 pageCorn Hopper Funnel DrawingJane Mary LopezNo ratings yet

- NIMARAM 2x15 MMS GADocument1 pageNIMARAM 2x15 MMS GABibhuti R DubeyNo ratings yet

- DIgSILENT Time-Overcurrent Plot1Document1 pageDIgSILENT Time-Overcurrent Plot1Javier PillcoNo ratings yet

- Me 359 HW 03 P 10 DRW 2Document2 pagesMe 359 HW 03 P 10 DRW 2api-576392651No ratings yet

- FLECHADocument1 pageFLECHAnerproci2023No ratings yet

- Section A-A Scale 1 / 2 E: Team 5 5/21/2020 MECH 2410Document1 pageSection A-A Scale 1 / 2 E: Team 5 5/21/2020 MECH 2410Ana-Maria BogatuNo ratings yet

- Galvanized Tank 3300mm X 7mDocument10 pagesGalvanized Tank 3300mm X 7mabdelrahmansamir.engNo ratings yet

- BlueprintDocument4 pagesBlueprintapi-385778405No ratings yet

- An800 6Document3 pagesAn800 6jcNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Mobrey CLT PDFDocument18 pagesMobrey CLT PDFAnonymous Oydnu9No ratings yet

- PPTDocument12 pagesPPTajaydev2224No ratings yet

- Documents - MX - Fisher Desuperheaters Bulletin April 2008 PDFDocument12 pagesDocuments - MX - Fisher Desuperheaters Bulletin April 2008 PDFsaji_t1984No ratings yet

- Roper 3611-22 GHB PumpsDocument1 pageRoper 3611-22 GHB PumpsDark CenobiteNo ratings yet

- Rf00025-Quantitative Fractography and Modelling of FatiguDocument14 pagesRf00025-Quantitative Fractography and Modelling of Fatiguzixin chenNo ratings yet

- Xseries Wrap Around Bottle HeaterDocument2 pagesXseries Wrap Around Bottle HeaterNoneNo ratings yet

- Sheet Rolling Machine - SynopsisDocument8 pagesSheet Rolling Machine - SynopsisTanviNo ratings yet

- BKL Metal Bellows CouplingsDocument1 pageBKL Metal Bellows CouplingsJesus OponNo ratings yet

- Flow Chart Neozep F Exp TabletDocument4 pagesFlow Chart Neozep F Exp TabletRio FebriansyahNo ratings yet

- STEICO LVL Bonded LVL Sections EN IDocument2 pagesSTEICO LVL Bonded LVL Sections EN IClaudiu BaditaNo ratings yet

- VCAA Chem 2011 U4 Solutions MaoDocument3 pagesVCAA Chem 2011 U4 Solutions MaoJames HancockNo ratings yet

- Transmission Towers DetailingDocument38 pagesTransmission Towers DetailingFeleki AttilaNo ratings yet

- Cleanroom CablesDocument12 pagesCleanroom CablesluisRuben medinaNo ratings yet

- Pulp and PaperDocument226 pagesPulp and PaperAktharNo ratings yet

- IBR FormsDocument204 pagesIBR FormsRajivharolikarNo ratings yet

- Engineering Standards SAEC Waste Disposal LandfillsDocument17 pagesEngineering Standards SAEC Waste Disposal LandfillsAhmad RazaNo ratings yet

- HRF 669ffa SP (04 09 27)Document5 pagesHRF 669ffa SP (04 09 27)yayayalNo ratings yet

- World Class Manufacturing PracticesDocument5 pagesWorld Class Manufacturing PracticesSumit_Raj_Patn_8373No ratings yet

- 8 - CE 511 - Welded ConnectionsDocument32 pages8 - CE 511 - Welded ConnectionsVictor Czar AustriaNo ratings yet

- Item Description UOM Quantity Unit Rate in Amount inDocument35 pagesItem Description UOM Quantity Unit Rate in Amount inIshwar AltNo ratings yet

- Influence of Fabric Softeners On Performance Stability of The Textile MaterialsDocument4 pagesInfluence of Fabric Softeners On Performance Stability of The Textile MaterialsDidem PaydaşNo ratings yet