Professional Documents

Culture Documents

Mitsubishi Forklift TRANSMISION MITSUBISHI

Mitsubishi Forklift TRANSMISION MITSUBISHI

Uploaded by

Richard Godoy0 ratings0% found this document useful (0 votes)

10 views26 pagesOriginal Title

mitsubishi forklift TRANSMISION MITSUBISHI

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views26 pagesMitsubishi Forklift TRANSMISION MITSUBISHI

Mitsubishi Forklift TRANSMISION MITSUBISHI

Uploaded by

Richard GodoyCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 26

POWERSHIFT TRANSMISSION

DESCRIPTION

Hydraulic circuit

Control...

REMOVAL AND INSTALLATION

DISASSEMBLY AND REASSEMBLY ......

Transmission assembly

Disassembly

Reassembly

Pump assembly

Input'shaft assembly

Transmission assembly

Control valve

Disassembly

Reassembly wecees

INSPECTION AND ADJUSTMENT

Testing hydraulic pressure

Adjusting clutch (inching) pedal

Testing clutch valve...

Testing stall speed we

10-m (33-ft) starting acceleration test

TA

72

73

13

14

14

14

7-10

7-10

Tell

714

TAT

TAT

7-18

7-19

7-19

7-21

1-23

7-23

7-24

POWERSHIFT TRANSMISSION

DESCRIPTION

¢

(35)

Figures shown in (__) indicate

‘the number of gear teeth.

31)

a)

) (a)

i

2octa

‘The transmission, integrally coupled to

the torque converter, provides a choice

of from one forward ratio and one

reverse ratio, It has built-in multi-dise

clutches, which are hydraulically actuated

to control the flow of drive from the

converter. The control lever - shift lever

= is for operating a hydraulic control

valve. Thus this transmission is of a

"powershift” type.

The transmission housing and torque

converter housing ean be separated from

each other.

The pump, turbine and stator can be

removed as one assembled unit from the

stator shaft and from the input shaft.

The torque converter is of one-piece

construction fabricated by welding and is

meant to be replaced as one assembled

unit.

The transmission parts, except for torque

‘converter, clutch valve, the output flange and

universal joints, are common to all models.

FG(D)IO thru 18 | FG(D)20 they 35A

‘Model 6687 66H8

‘Type _| _Three-lement, single-stage, two-phase

Range Powerflow

FFORWARD) a-e de

(REVERSE) b

“Transmission reduction ratio

F B10

(oRwARD) | “ap * “a

R 70

(REVERSE) a Th 8

POWERSHIFT TRANSMISSION

Hydraulic Cireuit

98v02

tds 001 + 51 :Poeds out,

sunssaid wo ogo | 0

amssoid yoni | 4

amnssad wey | @

4

1 :Aypedeo pomioy

duind 110

42009 110

0 9407

sunssoud yay Joyanuios enbsoy

7-2

POWERSHIFT TRANSMISSION

Control

@ 3

2o6eus

1 FORWARD-REVERSE lever 4 Clutch (inching) pedal

2 Control valve 5 Bracket (inching)

3. Push rod 6 Clutch valve plunger

REMOVAL AND INSTALLATION

Removal this, place the torque converter in

(1) Remove the engine and transmission as

an assembly from the truck.

(nore)

For removal and installation of the

engine and transmission, refer to

POWER TRAIN. Drain oil from the

transmission housing.

(2) Unserew the bolts securing the

flexible plate through the access hole

in the torque converter housing.

(3) Separate the torque converter and

transmission from the engine.

Installation

(1) Couple the torque converter and

transmission to the engine. To do

the’ transmission housing so that the

distance between the end face of the

housing end the mating face of

flexible plate is 50 to 52 mm [1.97

to 2,05 in] The clearance between

the flywheel and flexible plate should

be 1 to 5 mm[0.04 to 0.20 in.] when

the torque converter is coupled to

the engine. If the clearance is zero,

it is an indication that the torque

converter is improperly coupled to

the engine; recouple the converter to

the engine properly.

(2) Tighten the bolts securing the flexible

plate to the flywheel through the

access hole in the converter housing.

Tighten the bolts in a criss-cross

pattern.

73

POWERSHIFT TRANSMISSION

DISASSEMBLY AND REASSEMBLY

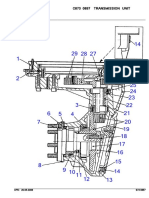

‘Transmission Assembly

Disassembly

Mount bracket

Start by:

1, remove two mount brackets from the

transmission housing.

2. remove the brackets (inching) and springs

TA

Sequence

1 Troque converter assembly, flexible plate

2 Sender unit, drain plug, gasket

3 Oil level gauge, pipe

4 Air breather

5 Oil pipe, eye joint, gasket

6 Output flange

7 Filter case, magnet strainer

8 Control valve

9 Stator shaft, relief valve, spring, washer,

snap ting, O-ring, steel ball

10 Pump body, internal gear, drive gear,

oil seal, O-ring

11 Transmission housing, gasket, O-ring,

steel ball, plug

12 Ball bearing, idler gear

13 Input shaft assembly

(consisting of 14 thru 20)

1) Remove the pump as an assembly

including 9 thru 10.

2) Remove the input shaft as an

assembly including 14 thru 20, and

fisassemble it in the order shown.

Suggestions

1. Removing torque converter assembly

Remove the torque converter assembly

complete with the flexible plate. Prepare

@ container to catch the oil that flows

out of the converter.

POWERSHIFT TRANSMISSION

14 Seal ring, ball bearing, thrust washer

15 FORWARD gear, needle roller bearing,

thrust washer

16 Seal ting, ball bearing, thrust washer

17 REVERSE gear, needle roller bearing,

thrust washer

18 Snap ring, spring retainer, clutch spring

19 Snap ring, pressure plate,’ plates,

friction plates, belleville ‘spring

20 Cluteh piston, ‘seal ring, input shaft

21 Idler shaft, ball bearing, snap ring

22 Output gear, ball bearing

23 Baffle plate

24 Torque converter housing, O-ring,

steel ball

75

POWERSHIFT TRANSMISSION

2. Removing pump assembly

Unserew the pump mounting bolts, and

Setew two bolts (special tool) into the M8

X 1.25 holes in the pump body to remove

the pump assembly. Be sure to tighten

the bolts equally, or the threads. will

suffer damage. Use M8 x 1.25 bolts

having an effective thread length of 55

mm [2.2 in).

‘Special tool needed

Bolt (91268-05100

3. Removing transmission housing bolts

After removing the pump assembly,

unserew two transmission housing bolts

(F1805-10025) from the torque converter

housing side.

4. Removing transmission housing

Lay the transmission and cluteh assembly

with transmission housing down. Unscrew

the transmission housing bolts. Fasten a

hoist to the transmission housing with

slings and eyebolts. Lift the housing, and

take up slack in the slings. Under’ this

condition, tap the transmission and clutch

housing flanges somewhere near the dowel

pins and a plastic hammer to separate the

transmission housing from the cluteh

housing.

5. Removing input shaft ball bearing

Using a special tool, remove the ball

bearing from the input shaft.

Special tool needed

Puller 91268-15810

Plate (91268-13820

Bolt F1035-10020

76

Bolt hole

mare

6. Disassembling input shaft

Using a special tool or an arbor press,

compress the clutch spring, and remove

the snap ring.

Special tool needed

Piston tool | _ 65409-50010

(wore)

1) Do not attempt to remove steel

balls and sealing caps from the

transmission housing and torque

converter housing.

2) Do not remove the oil seals from

the pump body and transmission

housing unless they are defective.

Inspection after disassembly

1. Input shaft

(1) Check the splines for wear or damage.

(2) Check the width of each seal ring

groove for wear; also check the

groove for damage.

(B) Check to be sure that oil grooves and

passages are open and clean, free from

sign of clogging.

2. Check the gears and splines for wear

or defects.

3. Cluteh drums

(1) Cheek the plate sliding surface for

wear or damage.

(2) Check the clutch piston sliding

surface for wear or damage.

POWERSHIFT TRANSMISSION

zone

Seal ring grooves,

017

rT

POWERSHIFT TRANSMISSION

4, Friction plates and plates

(1) Cheek for sign of seizure, uneven

contact, warpage or excessive wear.

(2) Cheek the splines for wear or damage.

Unit: mm fin]

2300.10

Thickarsof | {0.0806 + 0.0039),

La B 2.0 (0.08)

365401

Thickness of [A] (0.1437 40.008)

a B 3.210.131

5. Cluteh pistons

(2) Shake each piston, making sure that

the balls move freely in it. When

piston {s overhauled and ‘cleaned,

serew in the plug until its head gets

flush with piston end face, and lock

it there by punching.

Do not disassemble the piston unless

it is defective.

(2) Cheek the seal rings and their grooves

for wear or damage.

6. Transmission housing

Check the seal ring contact surfaces for

wear or damage.

7. Magnet stainer

Cheek for clogging or breakage.

8. Idler shaft

Check the splines for wear or damage.

9. Output flange

Check the splines for wear or damage.

Also, check the oil seal contact surface

for defects.

200119]

10. Oil pump

(1) Cheek top clearance A between the

drive gear and pump body with a

feeler gauge.

(2) Check side clearance B between the

internal gear and drive gear and the

pump body with a straight edge and

a feeler gauge.

(3) Cheek the backlash between the drive

gear and internal gear with a feeler

gauge.

(4 Put the drive gear on the torque

converter pump impeller, and check

clearanee C between the gear and

pump boss.

aie mm fin

Toy 0.30 to 0.33

A derance || (00118 0 0.0130)

AT 0.080 w 0085

2 Ss (oe 2 oan

anes 0.150 (0.00591)

Gane cea

a To

© fesend”? |A| —ogo4 0 0.016)

eed

aL bab wore

Gear backlash {0.0039 to 0.0071]

Ell 0.30 [0.0118]

POWERSHIFT TRANSMISSION

204891

7-9

POWERSHIFT TRANSMISSION

Reassembly

Pump assembly

zo1es2

Sequence

1 Stator shaft, relief valve, spring,

washer, snap ring

2 Pump body, oil seal

Suggestions

1, Installing oil seal

Using installer (special tool), install

oil seal to the pump body.

Special tool needed

Installer

91268-05300

the

3 Internal gear, drive gear, O-ring,

bolt, washer

2. Installing pump

When installing the pump, coat the pump

body interior, internal gear and drive

gear with automatic transmission fluid.

3. Inspection after reassembly

Turn the drive gear by hand to make sure

the pump gears rotate smoothly.

Input shaft assembly

POWERSHIFT TRANSMISSION

Sequence

Input shaft, elutch piston, seal ring

2 Cluteh spring, spring retainer,

snap ring

3 Belleville spring, plates, friction

plates, pressure ‘plate, snap ring

4 Thrust washer, needle roller bearing,

FORWARD gear

5 Thrust washer, ball bearing

6 Thrust washer, needle roller bearing,

REVERSE gear

7 Thrust washer, ball bearing, seal ring

8 Seal ring

Reassembly of the cluteh spring and

plates on the REVERSE gear side is

the same as that on the FORWARD

gear side.

mH

POWERSHIFT TRANSMISSION

‘Suggestions

1, Installing piston assembly

When installing the piston assembly to the

input shaft, coat the seal ring with

automatic transmission fluid.

2. Reassembling input shaft

To install the snap ring, compress the

clutch spring with piston tool (special

tool) or an arbor press.

‘Special tool needed

Piston tool [65409-50010

3. Installing plate

(1) Make sure that the combination and

number of plates are correct.

(2) Install the belleville spring with its

inside (concave side) facing the

piston,

(3) Coat the plates and friction plates

with automatie transmission fluid

when installing them.

(4) The frietion plates and the plates

should be replaced at the same time.

7-12

200116!

|

Plate (6)

Friction plate (5)

Belleville

spring (1)

Pressure plate

@

ald

BONY

ZA

4. Installing FORWARD gear and

REVERSE gear

Make sure that the oil groove side of

thrust washer faces the gear when

installed,

5. Installing bearing

To install the ball bearing to the input

shaft, use installer (special tool).

Special tool needed

Installer 91268-04100

6. Testing clutch piston

After reassembling the input shaft, apply

pressure ait to the clutch piston through

oil hole on the FORWARD gear side to

make sure that the piston works properly.

POWERSHIFT TRANSMISSION

mooi

203400

FORWARD side

REVERSE side

FORWARD

REVERSE

204837]

POWERSHIFT TRANSMISSION

Transmission assembly

Sequence

Torque converter housing, baffle plate

Output gear, ball bearing

Idler shaft, ball bearing, snap ring

Input shaft assembly

Idler gear, ball bearing

Gasket, O-ring

Transmission housing, oil seal

Pump assembly, O-ring

Gasket, control valve, O-ring

Oil pipe, eyebolt, gasket

Air breather, oil level gauge, pipe

Output flange

Magnet strainer, filter case

Drain plug, gasket, sender unit

Torque converter assembly

Suggestions

To reassemble, follow the reverse of

disassembly sequence.

2. Lay the torque converter housing with

its engine side down,

3. Apply grease to the lips of the oil

seals of the pump assembly and

transmission housing.

4, Coat the input shaft seal ring with

automatic transmission fluid.

5. Fasten a hoist to the transmission

housing with slings and _eyebolts.

Lower the housing onto the torque

converter housing by aligning the input

shaft with the transmission.

6. Installing pump assembly

(2) Ley the transmission housing in a

normal position.

(2) Drive the input shaft (which has not

been inserted into the transmission

yet) into position with a copper rod

from the torque converter side.

(3) Tighten two torque converter housing

mounting bolts,

(4) Put the O-ring on the pump assembly.

Apply grease to the O-ring, and

install the pump assembly to the

torque converter assembly. Be sure to

install the O-ring in the oil inlet

port.

POWERSHIFT TRANSMISSION

208820|

POWERSHIFT TRANSMISSION

7. Installing torque converter

(1) Install the torque converter in position

by mating the splines of stator shaft

and input and by positioning the

groove of pump drive gear correctly.

(2) Make sure that the distance between

the end face of torque converter

housing and the mating face of

flexible plate is 50 to 52 mm [1.97

to 2.05 in}.

(3) Fasten the flexible plate to the

torque converter housing with a wire

to prevent the torque converter from

slipping out of position until the

torque converter is coupled to the

engine.

8, Filling torque converter with ATF

Fill the torque converter after the

transmission has been mounted on the

truck and the engine is ready to be

started.

Run the engine at idle speed for a while.

Stop the engine and, after having waited

1 minute, check the oil level in the

transmission with the oil level gauge in

less than 15 minutes.

7-16

$0%052

| 1.97 0 2.05)

Control Valve

Disassembly

POWERSHIFT TRANSMISSION

Sequence

Solenoid valve

Plug, O-ring, strainer

Cover, O-ring

Accumulator piston, spring

Main regulator valve, spring seat, O-ring,

‘main regulator spring, plug

wawne

Inspection after disassembly

() Check oil ways and passages for

clogging.

(2) Cheek each spool for sign of wear,

damage or seizure.

(3) Cheek oil seals for damaged lips.

(@ Cheek the orifice in the main

regulator valve for cleanliness; also

check the valve spring for weakness

or damage.

Clutch valve plunger, valve spring, clutch

valve, return spring, slug, stopper pin, O-ring

Oil seal

Plug, bearing roller, O-ring

Accumulator spring seat, pin, O-ring

Drain plug, gasket

Orifice screw

200220)

POWERSHIFT TRANSMISSION

Reassembly

‘Sequence

Accumulator spring seat, O-ring, pin

Plug, O-ring, bearing roller

Oil seal

‘Clutch valve plunger, O-ring, stopper pin

Clutch valve, valve spring, slug, return

spring

‘Main regulator valve, slug, main regulator

spring, O-ring, spring seat

Start by:

thoroughly clean the oil ways and

passages in the valve by washing.

7 Accumulator piston, spring

8 Orifice screw

9 O-ring, cover

10 Drain plug, gasket

11 Strainer, O-ring, plug

12. Solenoid valve

__J

POWERSHIFT TRANSMISSION

INSPECTION AND ADJUSTMENT

Testing Hydraulic Pressure

1. Run the engine at idle speed for a

while. Stop the engine and, after

having waited 1 minute, check’ the oil

level in the transmission with the oil

level gauge in less than 15 minutes.

2, Warm up until the transmission oil

temperature rises (the torque

converter oil temperature gauge needle

moves into the white zone).

3. Cheek the no-load minimum and

maximum speeds of the engine. If the

speeds are not correct, make an

adjustment by referring to SERVICE

MANUAL for the engine.

Uni ym

Foidwhw 8] FOa0 ti 35a

Ebiovtes i | @bs0 ase)

Seid | 6s0 ‘so

a 650) (650)

Rete 600 2600

maximum) 500) 6300)

4. After checking the engine speeds, stop

the engine. Raise the front wheels. To

do this, jack the front axle housing,

or place wood blocks under the outer

mast and tilt the mast forward.

The front wheels

the cluteh pressure

rotate when

tested.

5. Connect a pressure gauge to a tap for

the pressure to be tested. The

pressure taps are located es shown,

© Torque converter

4 Main pressure © Torgue come

rel

—_—

NX

© Lube oil

b Clutch pressure

d Torque converter

outlet pressure

saat

7-19

POWERSHIFT TRANSMISSION

6. Use the following tools when testing

the oil pressure:

Tool name Pressure tap

Remais

Toate wT. [ae

Consestor —[wiat3 |

stzekono | tread ac

“Connecor [ROT 1

64309-17733 | thread ~ i) °

Connestor | oie x 3 3

si26ea2%00 | ted | ~ | ~

™ 6 kgffem?

Gauge

S8oSirns [O89 | - | 0 | 0

« 20 kgf/cm?

Gauge

SioSirris [Gabe | of - | -

Tie

64309-17722, o1° °

Connecior

Sew [Frm [ol o fo

Remarks: The asterisked tools are included in the

‘gauge kit (64309-17701),

7. Start the engine. Move the

FORWARD-REVERSE LEVER to the

neutral position, and test the main

Pressure, torque converter inlet

Pressure, torque converter _ outlet

Pressure end lube oil pressure.

8, Move the FORWARD-REVERSE LEVER

to the FORWARD and REVERSE

position, and test the clutch pressure.

Unit: kPa Ckgtfem?) (psi)

883 10 1079

2 Main pressure A} @w19

(128 t0 156)

883 10 1079,

b Clutch pressure A] @w10)

[128 to 156]

196 10 490

@w5)

(28 0 71)

147 10 294

5103)

(Gi 43)

98 10 147

© Lube oll pressure al dois)

[14 0 21)

Torque converter

inlet pressure S

Torque converter In

outlet pressure

Engine speed: 1500 = 100 rpm

7-20

Adjusting Clutch (Inching) Pedal

POWERSHIFT TRANSMISSION

206474

The clutch (inching) pedal is interlocked

with the brake pedal so that, when this

Pedal is depressed, hydraulic pressure

acting on the transmission is reduced to

zero before the brake is applied to bring

the transmission into neutral condition.

If this linkage is out of adjustment, the

transmission clutch will not disengage or

grab, resulting in poor braking, abnormal

temperature rise or clutch disk seizure.

To adjust the cluteh pedal, proceed as

follows:

1. Adjusting the brake

(1) Adjust the released height A of the brake

pedal to 220 + 3 mm [8.7 +0.1 in.].

(2) Set the master cylinder pushrod length

E to 106.6 mm [4.20 in}.

Unit: mm fin.

FG(D)I0 thra 354,

106.6 {420}

E _Pushrod length

(3) Adjust and confirm the brake drum

to-lining clearance. Do not adjust the

Clearance by. setting the pushrod

fength.

Unit: mm {in}

FEO | FED tw 5A

Berto | asi 10 02007

lining | coozw009 | oor wos)

Stoke

forbitke| 35 1061 531089

applica 11.4024] (2.1035)

&

7-21

POWERSHIFT TRANSMISSION

2. Adjusting the inching pedal

Start by:

warm up the transmission oil, raise the

front wheels, and block the rear wheels

(1) Connect a pressure gauge to the clutch

pressure tap.

@) Adjust the released height A of the inching

pedal to 220 mm (8.7 in.) by means of the

stopper bolt. Set the clearance B between

the inching pedal and brake pedal

connecting parts to 9 to 9.5 mm [0.354 to

0.374 in,] for the 1-ton models or 0.1 to

0.5 mm [0.004 to 0.020 in.] for the 2- to

3-ton models.

@) Start the engine, and release the brake

pedal. Depress the clutch (inching) pedal

until the brake starts to be applied (the

pedal encounters resistance). Under this

condition, make an adjustment by means

of the push rod so that the clutch valve

plunger stroke (D) is 16.5 mm [0.65 in.]

at 0 kgf/cm? hydraulic pressure.

(4) Release the clutch (inching) pedal, and

‘make sure that clutch valve plunger stroke

(Os 9 t0 9.5 mm [0.354 to 0.374 in.] for

the 1-ton models or 6 to 9.5 mm [0.236

to 0.374 in] for the 2- to 3-ton models at

883 to 1079 kPa (9 to 11 kgf/cm?) [128 to

156 psi] read on the pressure gauge. Make

an adjustment by means of the inching

cable. If the plunger stroke is out of

specification, readjust the brake and brake

pedal, and repeat the adjustment.

+ If the plunger stroke is more than 9.6 mm

(0.378 in.], the drum-to-lining clearance

is too small.

If the plunger stroke is less than 8.9 mm

{0.350 in.] for the 1-ton models or 5.9 mm

{0.232 in] for the 2- to 3-ton models, the

drum-to-lining clearance is too large.

7-22

2048194

wa 8k

| 838 oo,

Cinch ave phnger sete in} agate

Unit: mn in]

Relesed Regi peal BOTT

Clearance between] Fon 31095

Sieh (acting) pan | models | (0384000374

end brake pedal 2-3 0105

comecing pars | fod" (abet 0.020)

Ton 31095

uch vave 1035406374)

ger Soke ro

(0236 6374)

Stover aceon aoe at 165 (0.65)

Testing Cluteh Valve

1. Connect a pressure gauge to the

cluteh pressure tap.

2, Start the engine,

FORWARD-REVERSE

FORWARD position.

and move the

lever to the

Depress the clutch (inching) pedal.

Gradually pull out the clutch valve

plunger from its fully pushed position,

fand plot the hydraulic pressure curve

relative to the clutch valve plunger

stroke. Make sure that the plotted

pressure curve coincides with the

curve shown.

Testing Stall Speed

1. Check to make sure that the

transmission oil level is correct. See

the topic, 1. Testing hydraulie

pressure.)

2. Warm up until the transmission oil

temperature reaches 40°C to 60°C

(104°F to 140°F] (the torque converter

oil temperature gauge needle moves

into the green zone).

3. Block the front and rear wheels, and

apply the parking brake.

4. Cheek the no-load maximum speed of

the engine.

5. Run the engine at

le speed.

6. Move the FORWARD-REVERSE lever

to the FORWARD position. Gradually

depress the accelerator pedal all the

way by the right foot. Under this

condition, read the stall speed with an

electric or stroboscopic tachometer.

(nore)

Do not depress the clutch (inching)

pedal. Also, do not allow the engine

to keep on running at the highest

speed attained or the torque

converter may suffer damage. Stall-

speed running of the engine should be

limited to 30 seconds.

POWERSHIFT TRANSMISSION

——_—_—_—_—<_<_< $$

on

(io,

tay

sat

&

Pathan

Gch

3) to

02 | oa

(Cuch valve planger sok, Fin]

2ocsss

7-23

POWERSHIFT TRANSMISSION

7. Similarly read the stall speed for

reverse drive.

FGIO thru 18 |FG20 and 25] FG30 and 354]

(FD10 thru 18) |“ (FD20 thru 35a)

Sallspeed

Sul speed | 1370 v1 | ism

Gegamee:| asa (20095)

(nore)

The stall speed is determined on the

basis of a combination of the engine

and torque converter. It will vary if

the engine or torque converter is

changed.

10-m [33-ft] Starting Acceleration Test

1, Stand ready to start with the engine

idling and the FORWARD-REVERSE

lever in the neutral position.

2. At the signal, shift into forward and,

at the ‘same time, depress the

accelerator pedal all the way.

3. Measure the amount of time that the

truck elapses to travel 10 meters (33

feet) by using a watch.

4. Measure for reverse, too.

“Time required for 10 m (33 ft] | 5 seconds,

travel (n0 load) maximum

7-24

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (347)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Kubota v2403 Serie 03-M-E3b Di-E3b M-E3bgDocument197 pagesKubota v2403 Serie 03-M-E3b Di-E3b M-E3bgRichard Godoy100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ecu - De-En Still EcuDocument39 pagesEcu - De-En Still EcuRichard GodoyNo ratings yet

- NR14 PartsDocument2 pagesNR14 PartsRichard GodoyNo ratings yet

- U88 - Cpqc1-1.8&serie Parts ManualDocument204 pagesU88 - Cpqc1-1.8&serie Parts ManualRichard GodoyNo ratings yet

- U88 - CPCD5-7 - Oud Parts ManualDocument101 pagesU88 - CPCD5-7 - Oud Parts ManualRichard GodoyNo ratings yet

- U88 - CPQC1-1.8 - Oud Parts ManualDocument140 pagesU88 - CPQC1-1.8 - Oud Parts ManualRichard GodoyNo ratings yet

- NR14 PartsDocument2 pagesNR14 PartsRichard GodoyNo ratings yet

- Parts Manual 7NK10166Document58 pagesParts Manual 7NK10166Richard Godoy100% (1)

- Machine Card 7NK10166Document1 pageMachine Card 7NK10166Richard GodoyNo ratings yet

- NR14 PartsDocument2 pagesNR14 PartsRichard GodoyNo ratings yet

- Lista de Falhas em Codigo de Piscadas STILL R06Document4 pagesLista de Falhas em Codigo de Piscadas STILL R06Richard GodoyNo ratings yet

- STILL R70-45 517082C00005 - Es (Partes)Document545 pagesSTILL R70-45 517082C00005 - Es (Partes)Richard GodoyNo ratings yet

- 0100091A-Catálogo de Peças STILL ERX Rev00Document57 pages0100091A-Catálogo de Peças STILL ERX Rev00Richard GodoyNo ratings yet

- Manual de Partes (Chino)Document99 pagesManual de Partes (Chino)Richard Godoy100% (1)

- 2306979c Esq Elet STILL EJE ER 0135 PDFDocument1 page2306979c Esq Elet STILL EJE ER 0135 PDFRichard GodoyNo ratings yet

- Catálogo de Peças Geral C Cod. BaoliDocument213 pagesCatálogo de Peças Geral C Cod. BaoliRichard GodoyNo ratings yet

- ISUZU c240 PartsDocument196 pagesISUZU c240 PartsRichard Godoy100% (4)