Professional Documents

Culture Documents

B2 Tac Eo

B2 Tac Eo

Uploaded by

mehdi HKOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B2 Tac Eo

B2 Tac Eo

Uploaded by

mehdi HKCopyright:

Available Formats

B2 Anchor Catcher

Simultaneous anchoring and catching at all times

Applications Description

Anchoring tubing string The Evolution Model B2 Tubing Anchor

Catches the tubing if it should part Catcher performs two important functions: 1)

anchors the tubing string, and 2) catches the

Features & Benefits tubing if it should part. Unlike most anchor

No Free Fall If Tubing Parts catchers, the Evolution Oil Tools Tubing Anchor

Tool does not “Beat Itself To Death” Catcher is simultaneously set in anchoring and

Positive Catching Regardless of Well catching positions at all times.

Conditions

Slips Held Securely in Place

Running Procedure

Dependable Drag Springs

Simple Operation and Positive Release

Two Drag Springs must be used in each slot to

Emergency Release

ensure sufficient Drag Spring force to actuate

tool. To prevent the slips from becoming

dulled before reaching setting depth it is

advisable to put a right-hand turn into the

tubing every 5 or 10 stands while running in.

At the desired setting depth rotate the tubing

to the left with hand tongs until the Slips

contact the casing. Maintain left-hand torque

while alternately pulling strain and setting

down weight several times to work all play out

of the tool.

During this slip setting operation the strain

pulled should be at least equal to the final

strain that will be applied; when the tubing is

landed, and full tubing set down weight should

be applied. Release the tongs and continue

working the tubing to remove any residual

torque.

This document is uncontrolled when printed. 610-X-TDS_Rev-B (B2 Anchor Catcher)

© 2014 Evolution Oil Tools Inc. All rights reserved. May 2014 Completion Tools

www.eotools.com Toll Free: 1-800-265-TOOL

B2 Anchor Catcher

Specifications

Recommended

Maximum Minimum

Maximum OD Range of Casing ID

Casing Casing ID for Bore Thru Thread-Box

Tool Anchor

Min Max Safe Setting Anchor Up/Pin Item Number

Size

Down

OD Weight

In/mm In/mm In/mm In/mm In/mm

In/mm In/mm

4½ 9.5-13.5 3.750 3.830 4.090 4.250

43A 610-41

(114.3) (14.1-20.1) (95.25) (97.3) (103.9) (108.0) 1.940

2 3/8 EUE

5 11.5-18 4.000 4.280 4.560 4.560 (49.3)

43B 610-42

(127.0) (17.1-26.8) (101.6) (108.7) (115.80) (115.8)

5½ 13-23 4.500 4.670 5.040 5.190 2.375

45A 610-43

(139.7) (19.4-34.2) (114.3) (118.6) (128.0) (131.8) (60.30

20.3 5.550 6.090 6.460 6.600

2 7/8 EUE 610-47

7 (29.8-47.6) (141.0) (154.7) (164.1) (167.6) 2.440

47A

(177.8) 35-38 5.50 5.680 6.000 6.550 (62.0)

610-47

(52.1-56.5) (139.7) (144.3) (152.4) (166.4)

www.eotools.com

You might also like

- Manual ZX45 MILLDocument24 pagesManual ZX45 MILLnestorNo ratings yet

- Bolting Technology Catalogue Echnology CatalogueDocument56 pagesBolting Technology Catalogue Echnology CatalogueHarold AnilloNo ratings yet

- 2005 Trance SERIES Dual-Suspension Bike Technic Manual: Downloaded From Manuals Search EngineDocument9 pages2005 Trance SERIES Dual-Suspension Bike Technic Manual: Downloaded From Manuals Search EngineРоман ЧехомськийNo ratings yet

- B2 Anchor Catcher Technical DatasheetDocument3 pagesB2 Anchor Catcher Technical DatasheetEvolution Oil ToolsNo ratings yet

- Service ToolsDocument29 pagesService ToolsRobert TirtaNo ratings yet

- RVS Protector System: For Loaders and ExcavatorsDocument8 pagesRVS Protector System: For Loaders and ExcavatorsRyan Abubakar Obili PakayaNo ratings yet

- Halbrite No-Turn Tool Technical DatasheetDocument3 pagesHalbrite No-Turn Tool Technical DatasheetEvolution Oil ToolsNo ratings yet

- TONGS: Large-Capacity, Self-Locking Wrenches Used To Grip Drill String Components and Apply Torque. As WithDocument4 pagesTONGS: Large-Capacity, Self-Locking Wrenches Used To Grip Drill String Components and Apply Torque. As WithAhmed AmirNo ratings yet

- RAPTOR Cone CrusherDocument4 pagesRAPTOR Cone CrusherLuis Miguel La TorreNo ratings yet

- KUDU XF Anchor: Xtreme Flow Area Torque AnchorDocument2 pagesKUDU XF Anchor: Xtreme Flow Area Torque AnchorVenus DobosNo ratings yet

- Weight Bar Stem Brio Tech Catalog Revised 1.01s 125Document1 pageWeight Bar Stem Brio Tech Catalog Revised 1.01s 125Mohsin PvNo ratings yet

- NEXO Sliding SleeveDocument3 pagesNEXO Sliding SleevetongsabaiNo ratings yet

- Raptor 600 Cone CrushersDocument4 pagesRaptor 600 Cone CrushersIgnacio León IbarraNo ratings yet

- SPD Instructions 060120Document8 pagesSPD Instructions 060120jezfxrNo ratings yet

- Datasheet FS90RDocument4 pagesDatasheet FS90RAhmad Fakih Muhaimin.RNo ratings yet

- DX6-Manual KurtDocument21 pagesDX6-Manual KurtDISEÑO Y PRODUCCIÓNNo ratings yet

- Dr-Eem: em MWD SystemDocument2 pagesDr-Eem: em MWD SystemMilad Ebrahimi DastgerdiNo ratings yet

- Technical Specification SwedVent 9851 2931 VENTILADORESDocument4 pagesTechnical Specification SwedVent 9851 2931 VENTILADORESJovanyNo ratings yet

- 8m OperationDocument3 pages8m Operationapi-469602394No ratings yet

- Tapmatic 50X Safety and Operation ManualDocument12 pagesTapmatic 50X Safety and Operation ManualrvpilotNo ratings yet

- Smooth Bore Packer RetrieversDocument1 pageSmooth Bore Packer RetrieversMohamed TrabelsiNo ratings yet

- Lathe ManualDocument14 pagesLathe ManualRC Villeda100% (2)

- Gpipth 003Document22 pagesGpipth 003Robinson JimenezNo ratings yet

- B3 Anchor Catcher Technical DatasheetDocument3 pagesB3 Anchor Catcher Technical DatasheetEvolution Oil ToolsNo ratings yet

- DST Tools Catalog PDF FreeDocument103 pagesDST Tools Catalog PDF FreeReza AsakerehNo ratings yet

- Senior: SNR22L-SNR28R SNR22LD-SNR28RDDocument52 pagesSenior: SNR22L-SNR28R SNR22LD-SNR28RDPriyanka PatilNo ratings yet

- Modal Shaker FAQ RevaDocument20 pagesModal Shaker FAQ RevaHOD MECHNo ratings yet

- 938280S Iss4Document84 pages938280S Iss4LuisaNo ratings yet

- SQ Catalog-MinDocument4 pagesSQ Catalog-Minjepoymcsrt2296No ratings yet

- Tap SPDOpInstDocument6 pagesTap SPDOpInstjschaudtNo ratings yet

- Otis R /RN Landing Nipples and Lock MandrelsDocument3 pagesOtis R /RN Landing Nipples and Lock MandrelsJohny Cáceres100% (1)

- bl250d Lathe ManualDocument33 pagesbl250d Lathe ManualfquenNo ratings yet

- RB130Document17 pagesRB130pje207No ratings yet

- Elektra Beckum TF 100 MDocument44 pagesElektra Beckum TF 100 MAlexandre ChauderlierNo ratings yet

- Torque Wrench CatalogueDocument6 pagesTorque Wrench Cataloguewar10ckjupiNo ratings yet

- Info Rex Viva BenefitsDocument4 pagesInfo Rex Viva BenefitsCristian Alejandro SalvatierraNo ratings yet

- Descriptio: Model GXO Sliding SleeveDocument4 pagesDescriptio: Model GXO Sliding SleevefelipeNo ratings yet

- Manual Willis RTM-100Document11 pagesManual Willis RTM-100GioNo ratings yet

- AIR SILENT X and AIR MaX - BLADE INSTALL GUIDE REV C 2-26-21Document3 pagesAIR SILENT X and AIR MaX - BLADE INSTALL GUIDE REV C 2-26-21LAILA IDRISSINo ratings yet

- Torque Wrench LeafletDocument4 pagesTorque Wrench LeafletSibaram DasNo ratings yet

- Manual de Usuario Bead RollerDocument15 pagesManual de Usuario Bead RollerEdSoloNo ratings yet

- Planed Recision Planed American ToolingDocument44 pagesPlaned Recision Planed American ToolingmeiyappannNo ratings yet

- High Cycle - TWHC: Torque WrenchDocument4 pagesHigh Cycle - TWHC: Torque WrenchAlaa saidNo ratings yet

- 1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFDocument2 pages1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFboyka yuriNo ratings yet

- 1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFDocument2 pages1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFrabmusukeNo ratings yet

- 1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFDocument2 pages1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFBeni MulyanaNo ratings yet

- FL4025 QD Para-FlexDocument4 pagesFL4025 QD Para-FlexIsaac MonteroNo ratings yet

- Service Manual: CPD-110GS/110ESTDocument39 pagesService Manual: CPD-110GS/110ESTManuel HernandezNo ratings yet

- Fl4025 Cople DodgeDocument4 pagesFl4025 Cople DodgeGelasio VegaNo ratings yet

- A33 Manual Acople WoochangDocument16 pagesA33 Manual Acople WoochangEduardoNo ratings yet

- CH4400 Controls Rev.2 IS 4400Document8 pagesCH4400 Controls Rev.2 IS 4400jpagustinNo ratings yet

- Fastener Tensile Strength 170,000/180,000 PSI (1,171 NMM 190,000/200,000 PSI (1,309 NMM 220,000 PSI (1,515 NMMDocument1 pageFastener Tensile Strength 170,000/180,000 PSI (1,171 NMM 190,000/200,000 PSI (1,309 NMM 220,000 PSI (1,515 NMMGabriel ChiavettoNo ratings yet

- Breaker Vulcan V40GS Operation ManualDocument57 pagesBreaker Vulcan V40GS Operation Manualardiansyah arfahNo ratings yet

- RTTS Packer: Technical Data SheetDocument5 pagesRTTS Packer: Technical Data SheetHamid Reza Babaei100% (1)

- 1206 Bando V Belt Tension Gauge InstructionsDocument2 pages1206 Bando V Belt Tension Gauge InstructionsJasperken2xNo ratings yet

- 1206 Bando V Belt Tension Gauge Instructions 2017-10-09Document2 pages1206 Bando V Belt Tension Gauge Instructions 2017-10-09dzkamiraNo ratings yet

- Catalog International Series Control Transformers Solahd en Us 7438536Document3 pagesCatalog International Series Control Transformers Solahd en Us 7438536zhang012mike0727No ratings yet

- K Tron K2 ML D5 S60 失重秤数据Document2 pagesK Tron K2 ML D5 S60 失重秤数据ARK MurpheyNo ratings yet

- Sakai sw800 - 2016.11Document2 pagesSakai sw800 - 2016.11phannaNo ratings yet

- Lot 2Document7 pagesLot 2mehdi HKNo ratings yet

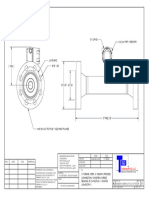

- TM0200X4 1500RTJ 27.9 - E112 PDFDocument1 pageTM0200X4 1500RTJ 27.9 - E112 PDFmehdi HKNo ratings yet

- Viking Braidline Nylon: ContactDocument1 pageViking Braidline Nylon: Contactmehdi HKNo ratings yet

- 20 3 12 Eu Pin X 3 12 Vam TopDocument1 page20 3 12 Eu Pin X 3 12 Vam Topmehdi HKNo ratings yet

- Daniel Acquisition AnnouncementDocument1 pageDaniel Acquisition Announcementmehdi HKNo ratings yet

- Technical Data Sheet (TDS) :: Landing Nipple GF ProfileDocument1 pageTechnical Data Sheet (TDS) :: Landing Nipple GF Profilemehdi HKNo ratings yet

- Single Point Mooring: Product Options SPM Types and Ocimf ConformityDocument4 pagesSingle Point Mooring: Product Options SPM Types and Ocimf Conformitymehdi HKNo ratings yet

- BS5467 AWA PVC CablesDocument4 pagesBS5467 AWA PVC Cablesmehdi HKNo ratings yet

- Operation Manual: Q250 Pneumatic Spinning WrenchDocument12 pagesOperation Manual: Q250 Pneumatic Spinning Wrenchmehdi HKNo ratings yet

- Product Data Sheet: PDS A11 - EDocument2 pagesProduct Data Sheet: PDS A11 - Emehdi HKNo ratings yet

- TD DFD5595Document9 pagesTD DFD5595mehdi HKNo ratings yet

- Abra Beta Catalogue 2023 - ENDocument140 pagesAbra Beta Catalogue 2023 - ENmehdi HKNo ratings yet

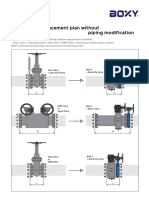

- SelectionguidDocument2 pagesSelectionguidmehdi HKNo ratings yet

- HEINDA E-CatalogueDocument18 pagesHEINDA E-Cataloguemehdi HKNo ratings yet