Professional Documents

Culture Documents

190224

190224

Uploaded by

nalanliyanage0080 ratings0% found this document useful (0 votes)

3 views20 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views20 pages190224

190224

Uploaded by

nalanliyanage008Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 20

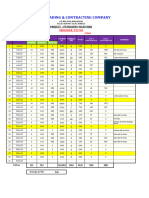

a a pee Doc No: | WG-F411

LOT U Ss EXCAVATOR INSPECTION oe

Date: | Papel 2019

2 REPORT

TRADING & CONTRACTING CO. wer }t

Equipment Details

Date 19/02/24 RegisirationNo. /Equip. Code | 29926 ( €x-25)|

Operator Name Location, Carmp-4!

‘Attachment Jack Hammer | Atiachment Code Gu-22z

‘Note: - Below are the items of this unit to be serviced at receiving inspection.

1: Item being conformed to the specifications or good condition

X: Not conformed or damaged

®: Correction made

N: Not Inspected

Damage Cheek Comments

‘1) Check Radiator/Oil Cooler

Check Radiator Fins

Hosesilampscap

Fan Assembly

Water pump

Change Radiator Water

2) Chesk Take and Exhnust hoses clamps

3) Air Filter Clean and Inspection

4) Crankease Breather - Clean

5) Fuel Pump

@) Fuel Lines lamps

7) Fuel Shut Off System:

8) Check Exhaust Smoke Status

9) Cheek AIC Components for conditioning and

Teas, clean A/C ails and condenser

70) Cheek all belt driven components and belts

for condition, and adjustment

i) Turbo Charger

+ Cracks / Oil Leak

+ Noise

Excessive noise atthe compressor side

Exhaust Leak

TH) Unusual Noise

12) Overall check for leakage / damage

Engine Room

Cheoks

SYS HIST SI RPRPKISIC | ct gt

S

(oy! Os

font. Cabin wppey

non Functional,

< isis

|

Check All | 1) Engine Oit

i

wr

LOTUS

TRADING 8 CONTRACTING CO,

EXCAVATOR INSPECTION

REPORT

Doc No:

we

Date:

TApn

Reve

Fhuid Levels

and Filters Engine Oil level

Oil and Filters Check Last Service report

Combusted engine oil

Engine Oil clarity (water mixed?)

» Chi

2) Water Separator Mixed Water

3) Diesel Filter clarity

Hydraulic Oil

© Check Oil Level

© Tank Hydraulic Filter

+ _ Return Hydraulic Filter

Comments

ain both Sidetrack

5) Swing Gear Oil Level

©) Final Drive Oil Change / Cheek

SISiataiy fsalsisfs

1) Battery Case

Crack

Salis

Battery | 2) Bleetrolyte Level

Mark here

3) The 5.G of battery Electrolyte

in case of |

Dry Cell

<}cis

‘Check All Hoses and Fittings

*

‘Boom and Attachment Pins and Bushings /

Hinges and Pivot Points on Machine

o3

Drive Sprockets

Extomal

aay © Wear

© Damage

© Loose

Idlers and Rollers

‘Overall Undercarriage

SSS [ALS

Lifting Booms

Hydraulic

Peon Chest. | iting Boom

‘Attachment Boom and Stick

<|<\s

Lights

Fire Extinguisher

Others

‘Attachment overall check

sis

Inspector's signature:

Mechanic Name:

A

Breaner Adaptor —*

plate bolt5 1005:

Necessary y

welder

(Shut off Valve leat

K blocki ing Hyd oi) Flow.

COOLING SYSTEM

265-3600 RADIATOR & HYD OIL COOLER GP (contd. )

VIEW OF AREA A

01380038

‘SE8P«674.07 COOLING SYSTEM 93.

ee Ean

COOLING SYSTEM

265-3600 RADIATOR & HYD OIL COOLER GP

S/N: KGF1-UP; FAL1-UP

PART OF 290-1911, 298-4271, 298-4272 COOLING AR-HIGH ANBIENT TEMP, 290-1892

a _ «i | See

(C- CHANGE FROM PREVIOUS TYPE

D-ORDER BY THE METER

E-ORDER BY THE CENTIMETER

NCMETRIC PART

Y-SEPARATE ILLUSTRATION

92 COOLING SYSTEM 1 of 2 ‘sE6P 4874-07

SmICS-7479

HYDRAULIC SYSTEM

227-0620 GAUGE GP-SIGHT

S/N: KGF4

PART OF 239-1711 TANK & FILTER GP-HYDRAULIC

IP; FAL1-UP

GRAPHIC #1

420 HYDRAULIC SYSTEM.

REF GRAPHIC PART NAME

nore ‘No °"REE PARTNUMBER QTY 1 2s 4 6 5 ireovucrievey

1 cam 236-3258 2 BLOCK on

i 2 1236-32592 BOLT-SPECIAL ——

: 3 4 236-3257 1 ‘PIPE fd

41095-15194 __—SEAL-O-RING

5 1 6F-4855 4 SEAL-O-RING_ Pre

TC PAR

tof

HYDRAULIC SYSTEM

GP-AUXILIARY HYDRAULIC (conta. ) 102475649

Jef

vg Shat off Vole fy

a d el

IEW OF AREAB

(901240796

HYDRAULIC SYSTEM

242-6487 LINES GP-AUXILIARY HYDRAULIC

S/N: KGF1-UP; FAL1-UP

2.92-Ik (9.6-FT) . HIGH PRESSURE

‘AN ATTACHMENT

sicS-5057

io

PART NAME:

REF GRAPHIC

nore HS C'RERS pat numaen ary 1 ss + 2 ¢ eronueriev

1 BI-8510 1 HOSE AS

1 473-7916 4 CLANP-HALF

ancl 255-6445 1 HOSE AS Eee

1 255-0883 _1_ THE 9

——— 2 ee

sea nortan

4 RECTANIGULAS

Hi = 4 FLANGE-HALE

1 @V-0400 4 FLANGE-HALE

+ 7¥-4538 4 a a

sree er-aizt 4 (AAx2iKS. SW THK)

oot 7241398 BOLT (M12X1 .75x30-Um)

1 1241034 BOLT (M12X1.75x40-1)

1 feT-aied_@pOLT (IM2x1..75x45-1) 3

1 “praia 2 BOLT (W12Xt, 75X50- 1M)

1 812422324 WASHER-HARD (13. 5X25. SK9-U THK) —

fo erase 4 BOLT (2X1, 78XS5-WM)

a 1266954 BOLT (1OX1 .5X110-) i

| C-CHANGE FROM PREVIOUS TYPE

{cREFER TO HYDRAULIC INFORMATION SYSTEM

NCMETRIC PART

Y-SEPARATE ILLUSTRATION _

HYDRAULIC SYSTEM

INES GP-HYDRAULIC OIL COOLER-narN PUMP

/N: KGF1-UP; FAL1-UP

pant OF 285-1354, 285-1355 HYDRAULIC AR

102510751

PART NAME SEE

Teg 3 4 6 pnogucr sven PAGE

{SUPPORT AS

LOCKNUT (MitOX1. 15-THD) _

OCKET HEAD (N12X1,75X30- Wil)

~ SEAL -0-RING

‘SEAL-RECTANGULAR

“SEAL -O-RING

‘SEAL-O-RING

CLIP (SLOT)

CLIP (TAB)

(GROMMET

FLANGE -HALF

LIP (TAB)

‘CLIP (SLOT)

GROMMET

‘BOLT (\VOX1.SX104-WiN)

WASHER (11X25%3- Ill THK)

A HARD (11X21X2. 5--Hill THR)

BOLT (Hit 0X1 .SX25-tiit)

BOLT (M12K1.75X30- Ill)

BOLT (U12K1 .75%40-il)

‘BOLT (WTOX1 .5X40-Hil)

7 BOLT (N12X1 -75X60 Ut) a

‘gr -4223 WASHER- HARD (13 -5X25 .BXS-HM THK) _

aT-4956 BOLT (N12X1 75X35 -Ml)

1 ___ 81-6888. ‘BOLT (M12X1 .75XB0-NMl)

AULTC INFORMATION SYSTEM

ISTRATION

LUBRICATION SYSTEM

279-7911 FILTER & NTG GP-ENGINE OIL (contd. ) 402978807

19.24.26 2724.19.32

vewas

LUBRICATION SYSTEM

279-7911 Erie & MTG GP-ENGINE OIL

KGF1-UP; FAL1-UP

PART OF 272-4742 INSTALLATION AR-ENGINE

= 33

SEAL-O-RING

SAUPLING (ENGINE OTL)

38-1306, 1308 102978807:

REF _ GRAPHIC PART NAME SEE

re No "REF" part NuMBER Le 34 5 6 eroouertevey PAGE

1 1 6V-5266 3 __SEAL-O-AING

Zi 4 70-1493 1 VALVE AS-BYPASS

3 1 7W-9028_1__ BASE AS-OIL FILTER

4 2P-2587 1 STUD-HOLLOW

4 1 8C-34a5 1 GAP-DUST

5 1 9L-9188 1 SPRING- VALVE

6 4 121-0307 1 ‘BASE

7 1 305-471 : PLATE

+ 1 1R-0739 1 _ FILTER AS-ENGINE OTL (STANDARD EFFICIENCY)

1 1 452-2938 1 __SEAL-0-RING

12 4 27-2091 1 CONNECTOR

13 4 189-9977 1 SEAL-0-RING

14 1 183-4906 1 SEAL-O-RING

15 1 033-5853 SEAL-O-RING

16 1 033-6038 2 SEAL-O-RING

17 4 5P-8196 1 PLUG

18 1 5P-9617 1 _ ADAPTER

19 1 60-1661 4 CLIP

20 1 6v-8713 1 CONNECTOR

1

0

FER TO HYDRAULIC INFORMATION SYSTEM

TAIG PART

1

aT-a121

aT-4136

173-8073,

7K-1181

i

3

3

4

3

5

2

4

1

1

WASHER- HARD (11X21X2..5-AU THK)

BOLT (M1OX1 5X25 Mit)

BOLT (M10X1.5X20-ut)

BOLT (M10X1.5X40-Mll)

BOLT (MBX .25X40-Ml)

WASHER-HARD (B.8X16X2-l THK)

BOLT (NBX1.25K30-Nill)

PLUG

‘SPACER (11X25X20-Uil THK)

'STRAP-CABLE

AIR_INLET AND EXHAUST SYSTEM

124-1711 AIR CLEANER GP

S/N: KGF1-1471; FAL1-1266

PART OF 109-9313 AIR CLEANER & MOUNTING GP

IcS-1051, 1054 02412207

REF GRAPHIC PART NAME SE

ore TRER'” PARTNUMBER _aTY ns 3 4"e # emopvcruee) PAGE

5 1 3L-3293 1 FITTING

2 1 412-0717 1 VALVE-VACUA

a 1 131-6821

4 1 131-8622 1

5 4 131-0826 4 TRU

6 1 131-6932 4—_LATCH

Ea 1 184-3083 1 COVER AS

1 131-6624 1 SEAL (266.7-Ui 10 X 6.9-hM THK)

=O ata

1 166-0702 i SEAL (280.17 1D X 6-16 THK)

3 1 255-2966 1 —_‘TNOTOATOR AS-AIA FILTER CHANGE

(AtRRESTArCTION)

y | mney

Iker outer /I v

liv f ee

PHIG #1 (901229003

LOTUS

TRADING & CONTRACTING CO,

EXCAVATOR INSPECTION

REPORT

Doctor | WG-Fa1a

Date: | 1” Aprilz039

Revi |

‘Equipment Details

Date

17/02/24

Repistration No. / Equip. Code

17515 (EX -1y)

Operator Name

Kul 2 Bahadur | Location

72303

Attachment

Clam Shell

Attachment Code

‘Note: - Below are the items of this unit to be serviced at receiving inspection,

\: Item being conformed to the specifications or good condition

@

‘Not conformed or damaged

Correction made

N: Not Inspected

Damage

Engine Room

‘Checks:

1) Check Radiator/Oi Cooler

Check Radiator Fins

Hoses/clamps/cap

Fan Assembly

Water pump

© Change Radiator Water

2) Check Intake and Exhaust hoses/ clamps

3) Air Filter Clean and Inspection

‘4 Crankcase Breather - Clean

5) Fuel Pump

© Fuel Lines/Clamps

7) Fuel Shut Off System

8) Check Exhaust Smoke Status

9) Check A/C Components for conditioning and

leaks, clean A/C coils and condenser

10) Check all belt driven components and belts

for condition, and adjustment

11) Turbo Charger

‘© Cracks / Oil Leak

© Noise

‘¢ Excessive noise at the compressor side

¢ Exhaust Leak

11) Unusual Noise

12) Overall check for leakage / damage

Cheek All

Fluid Levels

and Filters

1) Engine Oi1

‘© Oiland Filters Check Last Service report

nse.

rene left Side Inney ture

DocNo: | WG- Fai6

LOTU s EXCAVATOR LOADER TIRE Dare | April zon

INSPECTION REPORT fi

TRADING & CONTRACTING CO,

Revs [i

Trem Identification

‘Registration Number Code |

Operator Name Project, a

INNER INNER

Tire Brand: - atk Tire Brand: -.

Pressure Check: « z Pressure Check: ~

Pressure After Maintaining: Pressure After Maintaining:

— | Tire Status: -

Tire Status: - | (Very good / Good / Bad / Very Bad)

(Very good / Good /Bad / Very Bad) | Rate of Air Refill: X

Rate of Air Refill: | (Weekly / Daily / less than daily)

(Weekly / Daily / less than daily)

Outer

Tire Brand: -..

Pressure Check: -....

Pressure After Maintaining: -

Pressure After Maintaining: ~.

‘Tire Status: -

(Very good / Good / Bad / Very Bad)

Rate of Air Refill:

(Weekly / Daily / less than daily)

Tire Status: :

(Very good / Good / Bad / Very Bad)

INNER,

‘Tire Brand: -,

Pressure Check: -

Pressure Afer Maintaining ~

Tie Stans Change

(Very good / Good /Bad/ Very Bad)

Raie of Air Refi:

(Weekly / Daily / less than daily)

FALKEN

(Very good / Good / Bad / Very Bad)

Rate of Air Refill

(Weekly / Daily / less than daily)

Outer Note: - Outer

Tire Brand: - Size 1000 R.20 Tire Brand: -..... FALKEN

Pressure Check: ~ Pressure Check.

New(t a

Pressure After Maintaining | (New[445Psi Winter 110Psi Summer] pressure After Maintaining -..

Tire Status: = | (Old) [100Psi Winter 90Psi Summer] ‘Tine Status: - Change

(Very good / Good /Bad /Very Bad) | (Very good / Good /Bad/ Very Bad) |

Rate of Air Refill: Rate of Ait Refil: |

(Weekly / Daily / less than daily) 1 (Weekly / Daily / less than daily)

Service Man ‘W/S Engineer

OUTRIGGER JACK (LEFT SIDE)

Goth Jacks need Complete Seal

Change.

BALANCER JACK(LEFT SIDE)

WS Kill suuick nonfunctional

loppet Cover v cy

has oil leak.

ih Tnjectors 8 Injector Revop_

pecesany) Servvice-

4 |

Need proper alg

oom Upper Stick Codes ed Complete, oil Seal

Change.

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- 110823Document3 pages110823nalanliyanage008No ratings yet

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- Gen 02Document1 pageGen 02nalanliyanage008No ratings yet

- Gen 21Document1 pageGen 21nalanliyanage008No ratings yet

- JC-21Document1 pageJC-21nalanliyanage008No ratings yet

- Gen 27Document1 pageGen 27nalanliyanage008No ratings yet

- Gen 40Document1 pageGen 40nalanliyanage008No ratings yet

- Ac 02Document1 pageAc 02nalanliyanage008No ratings yet

- Asphalt CutterDocument1 pageAsphalt Cutternalanliyanage008No ratings yet

- HSE INDUCTION-aDocument1 pageHSE INDUCTION-analanliyanage008No ratings yet

- Gen 26Document1 pageGen 26nalanliyanage008No ratings yet

- WG - F406 External Warning - JASMEET SINGH (30930)Document1 pageWG - F406 External Warning - JASMEET SINGH (30930)nalanliyanage008No ratings yet

- Ac 20Document1 pageAc 20nalanliyanage008No ratings yet

- Oil Barrel Required PaperDocument3 pagesOil Barrel Required Papernalanliyanage008No ratings yet

- 05.trencher TR 2700 Daily Report Petroserv July 2022Document1 page05.trencher TR 2700 Daily Report Petroserv July 2022nalanliyanage008No ratings yet