Professional Documents

Culture Documents

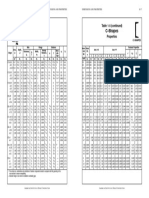

Table 1 8 WT Shapes

Uploaded by

Justine PredillaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table 1 8 WT Shapes

Uploaded by

Justine PredillaCopyright:

Available Formats

1–50 DIMENSIONS AND PROPERTIES DIMENSIONS AND PROPERTIES 1–51

Table 1-8 Table 1-8 (continued)

WT-Shapes WT-Shapes

Dimensions Properties

WT22-WT20

Stem Flange Distance Compact Torsional

Area, Depth, Nom- Section Axis X-X Axis Y-Y Properties

Work-

Thickness, Width, Thickness, inal Criteria

Shape Area able

2 Wt.

Gage

ksi

in.2 in. in. in. in.2 in. in. in. in. in. lb/ft 2 in.4 in.3 in. in. in.3 in. in.4 in.3 in. in.3 in.4 in.6

c 1/2

WT22×167.5 49.2 22.0 22 1.03 1 22.6 15.9 16 1.77 13/4 2.56 25/8 51/2 167.5 4.50 21.4 2170 131 6.63 5.53 234 1.54 600 75.2 3.49 118 0.824 37.2 438

×145c 42.6 21.8 213/4 0.865 7/8 7/16 18.9 15.8 157/8 1.58 19/16 2.36 27/16 145 5.02 25.2 1830 111 6.54 5.26 196 1.35 521 65.9 3.49 102 0.630 25.4 275

×131c 38.5 21.7 215/8 0.785 13/16 7/16 17.0 15.8 153/4 1.42 17/16 2.20 21/4 131 5.57 27.6 1640 99.4 6.53 5.19 176 1.22 462 58.6 3.47 90.9 0.525 18.6 200

×115c,v 33.9 21.5 211/2 0.710 11/16 3/8 15.2 15.8 153/4 1.22 11/4 2.01 21/16 115 6.45 30.3 1440 88.6 6.53 5.17 157 1.07 398 50.5 3.43 78.3 0.436 12.4 139

h

WT20×296.5 87.2 21.5 211/2 1.79 113/16 15/16 38.5 16.7 163/4 3.23 31/4 4.41 41/2 71/2 296.5 2.58 12.0 3310 209 6.16 5.66 379 2.61 1260 151 3.80 240 1.00 221 2340

×251.5h 74.0 21.0 21 1.54 19/16 13/16 32.3 16.4 163/8 2.76 23/4 3.94 4 251.5 2.98 13.6 2730 174 6.07 5.38 314 2.25 1020 124 3.72 197 1.00 138 1400

×215.5h 63.3 20.6 205/8 1.34 15/16 11/16 27.6 16.2 161/4 2.36 23/8 3.54 35/8 215.5 3.44 15.4 2290 148 6.01 5.18 266 1.95 843 104 3.65 164 1.00 88.2 881

×198.5h 58.3 20.5 201/2 1.22 11/4 5/8 25.0 16.1 161/8 2.20 23/16 3.38 31/2 198.5 3.66 16.8 2070 134 5.96 5.03 240 1.81 771 95.7 3.63 150 1.00 70.6 677

×186h 54.7 20.3 203/8 1.16 13/16 5/8 23.6 16.1 161/8 2.05 21/16 3.23 35/16 186 3.93 17.5 1930 126 5.95 4.98 225 1.70 709 88.3 3.60 138 1.00 57.7 558

×181c,h 53.2 20.3 201/4 1.12 11/8 9/16 22.7 16.0 16 2.01 2 3.19 31/4 181 3.99 18.1 1870 122 5.92 4.91 217 1.66 691 86.3 3.60 135 0.991 54.2 511

×162c 47.7 20.1 201/8 1.00 1 1/2 20.1 15.9 157/8 1.81 113/16 2.99 31/16 162 4.40 20.1 1650 108 5.88 4.77 192 1.50 609 76.6 3.57 119 0.890 39.6 362

×148.5c 43.6 19.9 197/8 0.930 15/16 1/2 18.5 15.8 157/8 1.65 15/8 2.83 215/16 148.5 4.80 21.4 1500 98.9 5.87 4.71 176 1.38 546 69.0 3.54 107 0.824 30.5 279

×138.5c 40.7 19.8 197/8 0.830 13/16 7/16 16.5 15.8 157/8 1.58 19/16 2.76 27/8 138.5 5.03 23.9 1360 88.6 5.78 4.50 157 1.29 522 65.9 3.58 102 0.697 25.7 218

×124.5c 36.7 19.7 193/4 0.750 3/4 3/8 14.8 15.8 153/4 1.42 17/16 2.60 211/16 124.5 5.55 26.3 1210 79.4 5.75 4.41 140 1.16 463 58.8 3.55 90.8 0.579 19.0 158

×107.5c,v 31.8 19.5 191/2 0.650 5/8 5/16 12.7 15.8 153/4 1.22 11/4 2.40 21/2 107.5 6.45 30.0 1030 68.0 5.71 4.28 120 1.01 398 50.5 3.54 77.8 0.445 12.4 101

×99.5c,v 29.2 19.3 193/8 0.650 5/8 5/16 12.6 15.8 153/4 1.07 11/16 2.25 25/16 99.5 7.39 29.7 988 66.5 5.81 4.47 117 0.929 347 44.1 3.45 68.2 0.454 9.12 83.5

WT20×196h 57.8 20.8 203/4 1.42 17/16 3/4 29.4 12.4 123/8 2.52 21/2 3.70 313/16 71/2 196 2.45 14.6 2270 153 6.27 5.94 275 2.33 401 64.9 2.64 106 1.00 85.4 796

×165.5h 48.8 20.4 203/8 1.22 11/4 5/8 24.9 12.2 121/8 2.13 21/8 3.31 33/8 165.5 2.86 16.7 1880 128 6.21 5.74 231 2.00 322 52.9 2.57 85.7 1.00 52.5 484

×163.5h 47.9 20.4 203/8 1.18 13/16 5/8 24.1 12.1 121/8 2.13 21/8 3.31 33/8 163.5 2.85 17.3 1840 125 6.19 5.66 224 1.98 320 52.7 2.58 85.0 1.00 51.4 449

×147c 43.1 20.2 201/4 1.06 11/16 9/16 21.4 12.0 12 1.93 115/16 3.11 33/16 147 3.11 19.1 1630 111 6.14 5.51 199 1.80 281 46.7 2.55 75.0 0.940 38.2 322

×139c 41.0 20.1 201/8 1.03 1 1/2 20.6 12.0 12 1.81 113/16 2.99 31/16 139 3.31 19.5 1550 106 6.14 5.51 191 1.71 261 43.5 2.52 69.9 0.920 32.4 282

×132c 38.7 20.0 20 0.960 15/16 1/2 19.2 11.9 117/8 1.73 13/4 2.91 3 132 3.45 20.8 1450 99.2 6.11 5.41 178 1.63 246 41.3 2.52 66.0 0.854 27.9 233

×117.5c 34.6 19.8 197/8 0.830 13/16 7/16 16.5 11.9 117/8 1.58 19/16 2.76 27/8 117.5 3.77 23.9 1260 85.7 6.04 5.17 153 1.45 222 37.3 2.54 59.0 0.697 20.6 156

×105.5c 31.1 19.7 195/8 0.750 3/4 3/8 14.8 11.8 113/4 1.42 17/16 2.60 211/16 105.5 4.17 26.3 1120 76.7 6.01 5.08 137 1.31 195 33.0 2.51 52.1 0.579 15.2 113

×91.5c,v 26.7 19.5 191/2 0.650 5/8 5/16 12.7 11.8 113/4 1.20 13/16 2.38 21/2 91.5 4.92 30.0 955 65.7 5.98 4.97 117 1.13 165 28.0 2.49 44.0 0.445 9.65 71.2

×83.5c,v 24.5 19.3 191/4 0.650 5/8 5/16 12.5 11.8 113/4 1.03 1 2.21 25/16 83.5 5.76 29.7 899 63.7 6.05 5.19 115 1.10 141 23.9 2.40 37.8 0.454 6.99 62.9

×74.5c,v 21.9 19.1 191/8 0.630 5/8 5/16 12.0 11.8 113/4 0.830 13/16 2.01 21/8 74.5 7.11 30.3 815 59.7 6.10 5.45 108 1.72 114 19.4 2.29 30.9 0.436 4.66 51.9

c

Shape is slender for compression with = 50 ksi.

h

Flange thickness greater than 2 in. Special requirements may apply per AISC Section A3.1c.

v

Shear strength controlled by buckling effects ( < 1.0) with = 50 ksi.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION AMERICAN INSTITUTE OF STEEL CONSTRUCTION

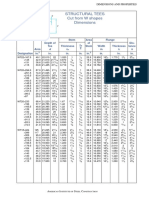

1–52 DIMENSIONS AND PROPERTIES DIMENSIONS AND PROPERTIES 1–53

Table 1-8 (continued) Table 1-8 (continued)

WT-Shapes WT-Shapes

Dimensions Properties

WT18-WT16.5

Stem Flange Distance Compact Torsional

Area, Depth, Nom- Section Axis X-X Axis Y-Y Properties

Work-

Thickness, Width, Thickness, inal Criteria

Shape Area able

2 Wt.

Gage

ksi

in.2 in. in. in. in.2 in. in. in. in. in. lb/ft 2 in.4 in.3 in. in. in.3 in. in.4 in.3 in. in.3 in.4 in.6

h

WT18×326 96.2 20.5 201/2 1.97 2 1 40.4 17.6 175/8 3.54 39/16 4.49 413/16 71/2 326 2.48 10.4 3160 208 5.74 5.35 383 2.73 1610 184 4.10 290 1.00 295 3070

×264.5h 77.8 19.9 197/8 1.61 15/8 13/16 32.0 17.2 171/4 2.91 215/16 3.86 43/16 264.5 2.96 12.4 2440 164 5.60 4.96 298 2.26 1240 145 4.00 227 1.00 163 1600

×243.5h 71.7 19.7 195/8 1.50 11/2 3/4 29.5 17.1 171/8 2.68 211/16 3.63 4 243.5 3.19 13.1 2220 150 5.57 4.84 272 2.10 1120 131 3.96 206 1.00 128 1250

×220.5h 64.9 19.4 193/8 1.36 13/8 11/16 26.4 17.0 17 2.44 27/16 3.39 33/4 220.5 3.48 14.3 1980 134 5.52 4.69 242 1.91 997 117 3.92 184 1.00 96.6 914

×197.5h 58.1 19.2 191/4 1.22 11/4 5/8 23.4 16.8 167/8 2.20 23/16 3.15 37/16 197.5 3.83 15.7 1740 119 5.47 4.53 213 1.73 877 104 3.88 162 1.00 70.7 652

×180.5h 53.0 19.0 19 1.12 11/8 9/16 21.3 16.7 163/4 2.01 2 2.96 35/16 180.5 4.16 17.0 1570 107 5.43 4.42 192 1.59 786 94.0 3.85 146 1.00 54.1 491

×165c 48.4 18.8 187/8 1.02 1 1/2 19.2 16.6 165/8 1.85 17/8 2.80 31/8 165 4.49 18.4 1410 97.0 5.39 4.30 173 1.46 711 85.5 3.83 132 0.976 42.0 372

×151c 44.5 18.7 185/8 0.945 15/16 1/2 17.6 16.7 165/8 1.68 111/16 2.63 3 151 4.96 19.8 1280 88.8 5.37 4.22 158 1.33 648 77.8 3.82 120 0.905 32.1 285

×141c 41.5 18.6 181/2 0.885 7/8 7/16 16.4 16.6 165/8 1.57 19/16 2.52 27/8 141 5.29 21.0 1190 82.6 5.36 4.16 146 1.25 599 72.2 3.80 112 0.844 26.3 231

×131c 38.5 18.4 183/8 0.840 13/16 7/16 15.5 16.6 161/2 1.44 17/16 2.39 23/4 131 5.75 21.9 1110 77.5 5.36 4.14 137 1.16 545 65.8 3.76 102 0.799 20.8 185

×123.5c 36.3 18.3 183/8 0.800 13/16 7/16 14.7 16.5 161/2 1.35 13/8 2.30 25/8 123.5 6.11 22.9 1040 73.3 5.36 4.12 129 1.10 507 61.4 3.74 94.8 0.748 17.3 155

×115.5c 34.1 18.2 181/4 0.760 3/4 3/8 13.9 16.5 161/2 1.26 11/4 2.21 29/16 115.5 6.54 23.9 978 69.1 5.36 4.10 122 1.03 470 57.0 3.71 88.0 0.697 14.3 129

WT18×128c 37.6 18.7 183/4 0.960 15/16 1/2 18.0 12.2 121/4 1.73 13/4 2.48 25/8 51/2 128 3.53 19.5 1210 87.4 5.66 4.92 156 1.54 264 43.2 2.65 68.5 0.920 26.4 205

×116c 34.0 18.6 181/2 0.870 7/8 7/16 16.1 12.1 121/8 1.57 19/16 2.32 27/16 116 3.86 21.4 1080 78.5 5.63 4.82 140 1.40 234 38.6 2.62 60.9 0.824 19.7 151

×105c 30.9 18.3 183/8 0.830 13/16 7/16 15.2 12.2 121/8 1.36 13/8 2.11 25/16 105 4.48 22.0 985 73.1 5.65 4.87 131 1.27 206 33.8 2.58 53.4 0.794 13.9 119

×97 c 28.5 18.2 181/4 0.765 3/4 3/8 14.0 12.1 121/8 1.26 11/4 2.01 23/16 97 4.81 23.8 901 67.0 5.62 4.80 120 1.18 187 30.9 2.56 48.8 0.702 11.1 92.7

×91c 26.8 18.2 181/8 0.725 3/4 3/8 13.2 12.1 121/8 1.18 13/16 1.93 21/8 91 5.12 25.1 845 63.1 5.62 4.77 113 1.11 174 28.8 2.55 45.3 0.635 9.20 77.6

×85 c 25.0 18.1 181/8 0.680 11/16 3/8 12.3 12.0 12 1.10 11/8 1.85 2 85 5.47 26.6 786 58.9 5.61 4.73 105 1.04 160 26.6 2.53 41.8 0.566 7.51 63.2

×80 c 23.5 18.0 18 0.650 5/8 5/16 11.7 12.0 12 1.02 1 1.77 115/16 80 5.88 27.7 740 55.8 5.61 4.74 100 0.980 147 24.6 2.50 38.6 0.522 6.17 53.6

×75 c 22.1 17.9 177/8 0.625 5/8 5/16 11.2 12.0 12 0.940 15/16 1.69 17/8 75 6.37 28.6 698 53.1 5.62 4.78 95.5 0.923 135 22.5 2.47 35.4 0.489 5.04 46.0

×67.5c,v 19.9 17.8 173/4 0.600 5/8 5/16 10.7 12.0 12 0.790 13/16 1.54 111/16 67.5 7.56 29.7 637 49.7 5.66 4.96 90.1 1.23 113 18.9 2.38 29.8 0.454 3.48 37.3

h

WT16.5×193.5 57.0 18.0 18 1.26 11/4 5/8 22.6 16.2 161/4 2.28 21/4 3.07 33/16 5 1/2 193.5 3.55 14.3 1460 107 5.07 4.27 193 1.76 810 100 3.77 156 1.00 73.9 615

×177h 52.1 17.8 173/4 1.16 13/16 5/8 20.6 16.1 161/8 2.09 21/16 2.88 215/16 177 3.85 15.3 1320 96.8 5.03 4.15 174 1.62 729 90.6 3.74 141 1.00 57.1 468

×159 46.8 17.6 175/8 1.04 11/16 9/16 18.3 16.0 16 1.89 17/8 2.68 23/4 159 4.23 16.9 1160 85.8 4.99 4.02 154 1.46 645 80.7 3.71 125 1.00 42.1 335

×145.5c 42.8 17.4 173/8 0.960 15/16 1/2 16.7 15.9 157/8 1.73 13/4 2.52 25/8 145.5 4.60 18.1 1060 78.3 4.96 3.93 140 1.35 581 73.1 3.68 113 0.991 32.5 256

×131.5c 38.7 17.3 171/4 0.870 7/8 7/16 15.0 15.8 153/4 1.57 19/16 2.36 27/16 131.5 5.03 19.9 943 70.2 4.93 3.83 125 1.23 517 65.5 3.65 101 0.900 24.3 188

×120.5c 35.6 17.1 171/8 0.830 13/16 7/16 14.2 15.9 157/8 1.40 13/8 2.19 21/4 120.5 5.66 20.6 872 65.8 4.96 3.84 116 1.12 466 58.8 3.62 90.8 0.864 18.0 146

×110.5c 32.6 17.0 17 0.775 3/4 3/8 13.1 15.8 153/4 1.28 11/4 2.06 21/8 110.5 6.20 21.9 799 60.8 4.95 3.81 107 1.03 420 53.2 3.59 82.1 0.799 13.9 113

×100.5c 29.7 16.8 167/8 0.715 11/16 3/8 12.0 15.7 153/4 1.15 11/8 1.94 2 100.5 6.85 23.5 725 55.5 4.95 3.77 97.8 0.940 375 47.6 3.56 73.3 0.718 10.4 84.9

c

Shape is slender for compression with = 50 ksi.

h

Flange thickness greater than 2 in. Special requirements may apply per AISC Section A3.1c.

v

Shear strength controlled by buckling effects ( < 1.0) with = 50 ksi.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION AMERICAN INSTITUTE OF STEEL CONSTRUCTION

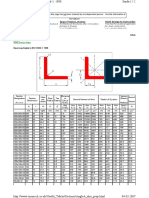

1–54 DIMENSIONS AND PROPERTIES DIMENSIONS AND PROPERTIES 1–55

Table 1-8 (continued) Table 1-8 (continued)

WT-Shapes WT-Shapes

Dimensions Properties

WT16.5-WT13.5

Stem Flange Distance Compact Torsional

Area, Depth, Nom- Section Axis X-X Axis Y-Y Properties

Work-

Thickness, Width, Thickness, inal Criteria

Shape Area able

2 Wt.

Gage

ksi

in.2 in. in. in. in.2 in. in. in. in. in. lb/ft 2 in.4 in.3 in. in. in.3 in. in.4 in.3 in. in.3 in.4 in.6

c

WT16.5×84.5 24.7 16.9 167/8 0.670 11/16 3/8 11.3 11.5 111/2 1.22 11/4 1.92 21/8 51/2 84.5 4.71 25.2 649 51.1 5.12 4.21 90.8 1.08 155 27.0 2.50 42.1 0.630 8.81 55.4

×76 c 22.5 16.7 163/4 0.635 5/8 5/16 10.6 11.6 115/8 1.06 11/16 1.76 115/16 76 5.48 26.3 592 47.4 5.14 4.26 84.5 0.967 136 23.6 2.47 36.9 0.579 6.16 43.0

×70.5c 20.7 16.7 165/8 0.605 5/8 5/16 10.1 11.5 111/2 0.960 15/16 1.66 113/16 70.5 6.01 27.6 552 44.7 5.15 4.29 79.8 0.901 123 21.3 2.43 33.4 0.525 4.84 35.4

×65 c 19.1 16.5 161/2 0.580 9/16 5/16 9.60 11.5 111/2 0.855 7/8 1.56 13/4 65 6.73 28.4 513 42.1 5.18 4.36 75.6 0.832 109 18.9 2.38 29.7 0.496 3.67 29.3

×59 c,v 17.4 16.4 163/8 0.550 9/16 5/16 9.04 11.5 111/2 0.740 3/4 1.44 15/8 59 7.76 29.8 469 39.2 5.20 4.47 70.8 0.862 93.5 16.3 2.32 25.6 0.451 2.64 23.4

WT15×195.5h 57.6 16.6 165/8 1.36 13/8 11/16 22.6 15.6 155/8 2.44 27/16 3.23 33/8 51/2 195.5 3.19 12.2 1220 96.9 4.61 4.00 177 1.85 774 99.2 3.67 155 1.00 86.3 636

×178.5h 52.5 16.4 163/8 1.24 11/4 5/8 20.3 15.5 151/2 2.24 21/4 3.03 31/8 178.5 3.45 13.2 1090 87.2 4.56 3.87 159 1.70 693 89.6 3.64 140 1.00 66.6 478

×163h 48.0 16.2 161/4 1.14 11/8 9/16 18.5 15.4 153/8 2.05 21/16 2.84 215/16 163 3.75 14.2 981 78.8 4.52 3.76 143 1.56 622 81.0 3.60 126 1.00 51.2 361

×146 43.0 16.0 16 1.02 1 1/2 16.3 15.3 151/4 1.85 17/8 2.64 23/4 146 4.12 15.7 861 69.6 4.48 3.62 125 1.41 549 71.9 3.58 111 1.00 37.5 257

×130.5 38.5 15.8 153/4 0.930 15/16 1/2 14.7 15.2 151/8 1.65 15/8 2.44 29/16 130.5 4.59 17.0 765 62.4 4.46 3.54 112 1.27 480 63.3 3.53 97.9 1.00 26.9 184

×117.5c 34.7 15.7 155/8 0.830 13/16 7/16 13.0 15.1 15 1.50 11/2 2.29 23/8 117.5 5.02 18.9 674 55.1 4.41 3.41 98.2 1.15 427 56.8 3.51 87.5 0.951 20.1 133

×105.5c 31.1 15.5 151/2 0.775 3/4 3/8 12.0 15.1 151/8 1.32 15/16 2.10 21/4 105.5 5.74 20.0 610 50.5 4.43 3.39 89.5 1.03 378 50.1 3.49 77.2 0.895 14.1 96.4

×95.5c 28.0 15.3 153/8 0.710 11/16 3/8 10.9 15.0 15 1.19 13/16 1.97 21/16 95.5 6.35 21.5 549 45.7 4.42 3.34 80.8 0.935 336 44.7 3.46 68.9 0.819 10.5 71.2

×86.5c 25.4 15.2 151/4 0.655 5/8 5/16 10.0 15.0 15 1.07 11/16 1.85 2 86.5 7.01 23.2 497 41.7 4.42 3.31 73.5 0.851 299 39.9 3.42 61.4 0.733 7.78 53.0

c

WT15×74 21.8 15.3 153/8 0.650 5/8 5/16 10.0 10.5 101/2 1.18 13/16 1.83 21/16 51/2 74 4.44 23.5 466 40.6 4.63 3.84 72.2 1.04 114 21.7 2.28 33.9 0.718 7.24 37.6

×66 c 19.5 15.2 151/8 0.615 5/8 5/16 9.32 10.5 101/2 1.00 1 1.65 17/8 66 5.27 24.7 421 37.4 4.66 3.90 66.8 0.921 98.0 18.6 2.25 29.2 0.657 4.85 28.5

×62 c 18.2 15.1 151/8 0.585 9/16 5/16 8.82 10.5 101/2 0.930 15/16 1.58 113/16 62 5.65 25.8 396 35.3 4.66 3.90 63.1 0.867 90.4 17.2 2.23 27.0 0.601 3.98 23.9

×58 c 17.1 15.0 15 0.565 9/16 5/16 8.48 10.5 101/2 0.850 7/8 1.50 13/4 58 6.17 26.5 373 33.7 4.67 3.94 60.4 0.815 82.1 15.6 2.19 24.6 0.570 3.21 20.5

×54c 15.9 14.9 147/8 0.545 9/16 5/16 8.13 10.5 101/2 0.760 3/4 1.41 111/16 54 6.89 27.3 349 32.0 4.69 4.01 57.7 0.757 73.0 13.9 2.15 21.9 0.537 2.49 17.3

×49.5c 14.5 14.8 147/8 0.520 1/2 1/4 7.71 10.5 101/2 0.670 11/16 1.32 19/16 49.5 7.80 28.5 322 30.0 4.71 4.09 54.4 0.912 63.9 12.2 2.10 19.3 0.493 1.88 14.3

×45 c,v 13.2 14.8 143/4 0.470 1/2 1/4 6.94 10.4 103/8 0.610 5/8 1.26 11/2 45 8.52 31.5 290 27.1 4.69 4.04 49.0 0.835 57.3 11.0 2.09 17.3 0.403 1.41 10.5

WT13.5×269.5h 79.3 16.3 161/4 1.97 2 1 32.0 15.3 151/4 3.54 39/16 4.33 47/16 51/2g 269.5 2.15 8.30 1530 128 4.39 4.34 242 2.60 1060 138 3.65 218 1.00 247 1740

×184h 54.2 15.2 151/4 1.38 13/8 11/16 21.0 14.7 145/8 2.48 21/2 3.27 33/8 51/2 184 2.96 11.0 939 81.7 4.16 3.71 151 1.85 655 89.3 3.48 140 1.00 84.5 532

×168h 49.5 15.0 15 1.26 11/4 5/8 18.9 14.6 141/2 2.28 21/4 3.07 33/16 168 3.19 11.9 839 73.4 4.12 3.58 135 1.70 587 80.8 3.45 126 1.00 65.4 401

×153.5h 45.2 14.8 143/4 1.16 13/16 5/8 17.2 14.4 141/2 2.09 21/16 2.88 3 153.5 3.46 12.8 753 66.4 4.08 3.47 121 1.56 527 72.9 3.41 113 1.00 50.5 304

×140.5 41.5 14.6 145/8 1.06 11/16 9/16 15.5 14.4 143/8 1.93 115/16 2.72 213/16 140.5 3.72 13.8 677 59.9 4.04 3.35 109 1.44 477 66.4 3.39 103 1.00 39.6 232

×129 38.1 14.5 141/2 0.980 1 1/2 14.2 14.3 141/4 1.77 13/4 2.56 211/16 129 4.03 14.8 613 54.7 4.02 3.27 98.9 1.33 430 60.2 3.36 93.3 1.00 30.7 178

×117.5 34.7 14.3 143/8 0.910 15/16 1/2 13.0 14.2 141/4 1.61 15/8 2.40 21/2 117.5 4.41 15.7 556 50.0 4.00 3.20 89.9 1.22 384 54.2 3.33 83.8 1.00 23.4 135

×108.5 32.0 14.2 141/4 0.830 13/16 7/16 11.8 14.1 141/8 1.50 11/2 2.29 23/8 108.5 4.71 17.1 502 45.2 3.96 3.10 81.1 1.13 352 49.9 3.32 77.0 1.00 18.8 105

×97 c 28.6 14.1 14 0.750 3/4 3/8 10.5 14.0 14 1.34 15/16 2.13 21/4 97 5.24 18.8 444 40.3 3.94 3.02 71.8 1.02 309 44.1 3.29 67.8 0.956 13.5 74.3

×89 c 26.3 13.9 137/8 0.725 3/4 3/8 10.1 14.1 141/8 1.19 13/16 1.98 21/16 89 5.92 19.2 414 38.2 3.97 3.04 67.7 0.932 278 39.4 3.25 60.8 0.935 10.0 57.7

×80.5c 23.8 13.8 133/4 0.660 11/16 3/8 9.10 14.0 14 1.08 11/16 1.87 2 80.5 6.49 20.9 372 34.4 3.95 2.98 60.8 0.849 248 35.4 3.23 54.5 0.849 7.53 42.7

×73 c 21.6 13.7 133/4 0.605 5/8 5/16 8.28 14.0 14 0.975 1 1.76 17/8 73 7.16 22.6 336 31.2 3.95 2.94 55.0 0.772 222 31.7 3.20 48.8 0.763 5.62 31.7

c

Shape is slender for compression with = 50 ksi.

g

The actual size, combination and orientation of fastener components should be compared with the geometry of the

cross section to ensure compatibility.

h

Flange thickness greater than 2 in. Special requirements may apply per AISC Section A3.1c.

v

Shear strength controlled by buckling effects ( < 1.0) with = 50 ksi.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1–56 DIMENSIONS AND PROPERTIES DIMENSIONS AND PROPERTIES 1–57

Table 1-8 (continued) Table 1-8 (continued)

WT-Shapes WT-Shapes

Dimensions Properties

WT13.5-WT12

Stem Flange Distance Compact Torsional

Area, Depth, Nom- Section Axis X-X Axis Y-Y Properties

Work-

Thickness, Width, Thickness, inal Criteria

Shape Area able

2 Wt.

Gage

ksi

in.2 in. in. in. in.2 in. in. in. in. in. lb/ft 2 in.4 in.3 in. in. in.3 in. in.4 in.3 in. in.3 in.4 in.6

c

WT13.5×64.5 18.9 13.8 137/8 0.610 5/8 5/16 8.43 10.0 10 1.10 11/8 1.70 2 51/2 64.5 4.55 22.6 323 31.0 4.13 3.39 55.1 0.945 92.2 18.4 2.21 28.8 0.763 5.55 24.0

×57 c 16.8 13.6 135/8 0.570 9/16 5/16 7.78 10.1 101/8 0.930 15/16 1.53 113/16 57 5.41 23.9 289 28.3 4.15 3.42 50.4 0.832 79.3 15.8 2.18 24.6 0.697 3.65 17.5

×51c 15.0 13.5 131/2 0.515 1/2 1/4 6.98 10.0 10 0.830 13/16 1.43 13/4 51 6.03 26.2 258 25.3 4.14 3.37 45.0 0.750 69.6 13.9 2.15 21.7 0.583 2.63 12.6

×47 c 13.8 13.5 131/2 0.490 1/2 1/4 6.60 10.0 10 0.745 3/4 1.34 15/8 47 6.70 27.6 239 23.8 4.16 3.41 42.4 0.692 62.0 12.4 2.12 19.4 0.525 2.01 10.2

×42 c 12.4 13.4 133/8 0.460 7/16 1/4 6.14 10.0 10 0.640 5/8 1.24 19/16 42 7.78 29.1 216 21.9 4.18 3.48 39.2 0.621 52.8 10.6 2.07 16.6 0.473 1.40 7.79

WT12×185h 54.5 14.0 14 1.52 11/2 3/4 21.3 13.7 135/8 2.72 23/4 3.22 35/8 51/2 185 2.51 9.20 779 74.7 3.78 3.57 140 1.99 581 85.1 3.27 133 1.00 100 553

×167.5h 49.1 13.8 133/4 1.38 13/8 11/16 19.0 13.5 131/2 2.48 21/2 2.98 33/8 167.5 2.73 10.0 686 66.3 3.73 3.42 123 1.82 513 75.9 3.23 119 1.00 75.6 405

×153h 44.9 13.6 135/8 1.26 11/4 5/8 17.1 13.4 133/8 2.28 21/4 2.78 33/16 153 2.94 10.8 611 59.4 3.69 3.29 110 1.67 460 68.6 3.20 107 1.00 58.4 305

×139.5h 41.0 13.4 133/8 1.16 13/16 5/8 15.5 13.3 131/4 2.09 21/16 2.59 3 139.5 3.18 11.6 546 53.6 3.65 3.18 98.8 1.54 412 61.9 3.17 96.3 1.00 45.1 230

×125 36.8 13.2 131/8 1.04 11/16 9/16 13.7 13.2 131/8 1.89 17/8 2.39 213/16 125 3.49 12.7 478 47.2 3.61 3.05 86.5 1.39 362 54.9 3.14 85.2 1.00 33.2 165

×114.5 33.6 13.0 13 0.960 15/16 1/2 12.5 13.1 131/8 1.73 13/4 2.23 25/8 114.5 3.79 13.5 431 42.9 3.58 2.96 78.1 1.28 326 49.7 3.11 77.0 1.00 25.5 125

×103.5 30.3 12.9 127/8 0.870 7/8 7/16 11.2 13.0 13 1.57 19/16 2.07 21/2 103.5 4.14 14.8 382 38.3 3.55 2.87 69.3 1.17 289 44.4 3.08 68.6 1.00 19.1 91.3

×96 28.2 12.7 123/4 0.810 13/16 7/16 10.3 13.0 13 1.46 17/16 1.96 23/8 96 4.43 15.7 350 35.2 3.53 2.80 63.5 1.09 265 40.9 3.07 63.1 1.00 15.3 72.5

×88 25.8 12.6 125/8 0.750 3/4 3/8 9.47 12.9 127/8 1.34 15/16 1.84 21/4 88 4.81 16.8 319 32.2 3.51 2.74 57.8 1.00 240 37.2 3.04 57.3 1.00 11.9 55.8

×81 23.9 12.5 121/2 0.705 11/16 3/8 8.81 13.0 13 1.22 11/4 1.72 21/8 81 5.31 17.7 293 29.9 3.50 2.70 53.3 0.921 221 34.2 3.05 52.6 1.00 9.22 43.8

×73 c 21.5 12.4 123/8 0.650 5/8 5/16 8.04 12.9 127/8 1.09 11/16 1.59 2 73 5.92 19.1 264 27.2 3.50 2.66 48.2 0.833 195 30.3 3.01 46.6 0.940 6.70 31.9

×65.5c 19.3 12.2 121/4 0.605 5/8 5/16 7.41 12.9 127/8 0.960 15/16 1.46 17/8 65.5 6.70 20.2 238 24.8 3.52 2.65 43.9 0.750 170 26.5 2.97 40.7 0.885 4.74 23.1

×58.5c 17.2 12.1 121/8 0.550 9/16 5/16 6.67 12.8 123/4 0.850 7/8 1.35 13/4 58.5 7.53 22.0 212 22.3 3.51 2.62 39.2 0.672 149 23.2 2.94 35.7 0.794 3.35 16.4

×52 c 15.3 12.0 12 0.500 1/2 1/4 6.02 12.8 123/4 0.750 3/4 1.25 15/8 52 8.50 24.0 189 20.0 3.51 2.59 35.1 0.600 130 20.3 2.91 31.2 0.692 2.35 11.6

WT12×51.5c 15.1 12.3 121/4 0.550 9/16 5/16 6.75 9.00 9 0.980 1 1.48 17/8 51/2 51.5 4.59 22.4 204 22.0 3.67 3.01 39.2 0.841 59.7 13.3 1.99 20.7 0.773 3.53 12.3

×47 c 13.8 12.2 121/8 0.515 1/2 1/4 6.26 9.07 91/8 0.875 7/8 1.38 13/4 47 5.18 23.7 186 20.3 3.67 2.99 36.1 0.764 54.5 12.0 1.98 18.7 0.707 2.62 9.57

×42 c 12.4 12.1 12 0.470 1/2 1/4 5.66 9.02 9 0.770 3/4 1.27 111/16 42 5.86 25.7 166 18.3 3.67 2.97 32.5 0.685 47.2 10.5 1.95 16.3 0.606 1.84 6.90

×38 c 11.2 12.0 12 0.440 7/16 1/4 5.26 8.99 9 0.680 11/16 1.18 19/16 51/2g 38 6.61 27.3 151 16.9 3.68 3.00 30.1 0.622 41.3 9.18 1.92 14.3 0.537 1.34 5.30

×34 c 10.0 11.9 117/8 0.415 7/16 1/4 4.92 8.97 9 0.585 9/16 1.09 11/2 51/2g 34 7.66 28.7 137 15.6 3.70 3.06 27.9 0.560 35.2 7.85 1.87 12.3 0.486 0.932 4.08

WT12×31c 9.11 11.9 117/8 0.430 7/16 1/4 5.10 7.04 7 0.590 9/16 1.09 11/2 31/2 31 5.97 27.7 131 15.6 3.79 3.46 28.4 1.28 17.2 4.90 1.38 7.85 0.522 0.850 3.92

×27.5c,v 8.10 11.8 113/4 0.395 3/8 3/16 4.66 7.01 7 0.505 1/2 1.01 17/16 31/2 27.5 6.94 29.9 117 14.1 3.80 3.50 25.6 1.53 14.5 4.15 1.34 6.65 0.448 0.588 2.93

c

Shape is slender for compression with = 50 ksi.

g

The actual size, combination and orientation of fastener components should be compared with the geometry of the

cross section to ensure compatibility.

h

Flange thickness greater than 2 in. Special requirements may apply per AISC Section A3.1c.

v

Shear strength controlled by buckling effects ( < 1.0) with = 50 ksi.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1–58 DIMENSIONS AND PROPERTIES DIMENSIONS AND PROPERTIES 1–59

Table 1-8 (continued) Table 1-8 (continued)

WT-Shapes WT-Shapes

Dimensions Properties

WT10.5-WT9

Stem Flange Distance Compact Torsional

Area, Depth, Nom- Section Axis X-X Axis Y-Y Properties

Work-

Thickness, Width, Thickness, inal Criteria

Shape Area able

2 Wt.

Gage

ksi

in.2 in. in. in. in.2 in. in. in. in. in. lb/ft 2 in.4 in.3 in. in. in.3 in. in.4 in.3 in. in.3 in.4 in.6

WT10.5×100.5 29.6 11.5 111/2 0.910 15/16 1/2 10.5 12.6 125/8 1.63 15/8 2.13 21/2 51/2 100.5 3.86 12.6 285 31.9 3.10 2.57 58.6 1.18 271 43.1 3.02 66.5 1.00 20.4 85.4

×91 26.8 11.4 113/8 0.830 13/16 7/16 9.43 12.5 121/2 1.48 11/2 1.98 23/8 91 4.22 13.7 253 28.5 3.07 2.48 52.1 1.07 241 38.6 3.00 59.5 1.00 15.3 63.0

×83 24.4 11.2 111/4 0.750 3/4 3/8 8.43 12.4 123/8 1.36 13/8 1.86 21/4 83 4.57 14.9 226 25.5 3.04 2.39 46.3 0.983 217 35.0 2.99 53.9 1.00 11.8 47.3

×73.5 21.6 11.0 11 0.720 3/4 3/8 7.94 12.5 121/2 1.15 11/8 1.65 2 73.5 5.44 15.3 204 23.7 3.08 2.39 42.4 0.864 188 30.0 2.95 46.3 1.00 7.69 32.5

×66 19.4 10.9 107/8 0.650 5/8 5/16 7.09 12.4 121/2 1.04 11/16 1.54 115/16 66 6.01 16.8 181 21.1 3.06 2.33 37.6 0.780 166 26.7 2.93 41.1 1.00 5.62 23.4

×61 17.9 10.8 107/8 0.600 5/8 5/16 6.50 12.4 123/8 0.960 15/16 1.46 113/16 61 6.45 18.0 166 19.3 3.04 2.28 34.3 0.724 152 24.6 2.91 37.8 1.00 4.47 18.4

×55.5c 16.3 10.8 103/4 0.550 9/16 5/16 5.92 12.3 123/8 0.875 7/8 1.38 13/4 55.5 7.05 19.6 150 17.5 3.03 2.23 31.0 0.662 137 22.2 2.90 34.1 0.915 3.40 13.8

×50.5c 14.9 10.7 105/8 0.500 1/2 1/4 5.34 12.3 121/4 0.800 13/16 1.30 111/16 50.5 7.68 21.4 135 15.8 3.01 2.18 27.9 0.605 124 20.2 2.89 30.8 0.824 2.60 10.4

WT10.5×46.5c 13.7 10.8 103/4 0.580 9/16 5/16 6.27 8.42 83/8 0.930 15/16 1.43 15/8 51/2 46.5 4.53 18.6 144 17.9 3.25 2.74 31.8 0.812 46.4 11.0 1.84 17.3 0.966 3.01 9.33

×41.5c 12.2 10.7 103/4 0.515 1/2 1/4 5.52 8.36 83/8 0.835 13/16 1.34 11/2 41.5 5.00 20.8 127 15.7 3.22 2.66 28.0 0.728 40.7 9.74 1.83 15.2 0.854 2.16 6.50

×36.5c 10.7 10.6 105/8 0.455 7/16 1/4 4.83 8.30 81/4 0.740 3/4 1.24 17/16 36.5 5.60 23.3 110 13.8 3.21 2.60 24.4 0.647 35.3 8.51 1.81 13.3 0.728 1.51 4.42

×34 c 10.0 10.6 105/8 0.430 7/16 1/4 4.54 8.27 81/4 0.685 11/16 1.19 13/8 34 6.04 24.7 103 12.9 3.20 2.59 22.9 0.606 32.4 7.83 1.80 12.2 0.657 1.22 3.62

×31c 9.13 10.5 101/2 0.400 3/8 3/16 4.20 8.24 81/4 0.615 5/8 1.12 15/16 31 6.70 26.3 93.8 11.9 3.21 2.58 21.1 0.554 28.7 6.97 1.77 10.9 0.579 0.913 2.78

×27.5c 8.10 10.4 103/8 0.375 3/8 3/16 3.90 8.22 81/4 0.522 1/2 1.02 13/16 27.5 7.87 27.7 84.4 10.9 3.23 2.64 19.4 0.493 24.2 5.89 1.73 9.18 0.522 0.617 2.08

×24 c,f,v 7.07 10.3 101/4 0.350 3/8 3/16 3.61 8.14 81/8 0.430 7/16 0.930 11/8 24 9.47 29.4 74.9 9.90 3.26 2.74 17.8 0.459 19.4 4.76 1.66 7.44 0.463 0.400 1.52

WT10.5×28.5c 8.37 10.5 101/2 0.405 3/8 3/16 4.26 6.56 61/2 0.650 5/8 1.15 15/16 31/2 28.5 5.04 25.9 90.4 11.8 3.29 2.85 21.2 0.638 15.3 4.67 1.35 7.40 0.597 0.884 2.50

×25 c 7.36 10.4 103/8 0.380 3/8 3/16 3.96 6.53 61/2 0.535 9/16 1.04 11/4 31/2g 25 6.10 27.4 80.3 10.7 3.30 2.93 19.4 0.771 12.5 3.82 1.30 6.08 0.533 0.570 1.89

×22 c,v 6.49 10.3 103/8 0.350 3/8 3/16 3.62 6.50 61/2 0.450 7/16 0.950 11/8 31/2g 22 7.22 29.4 71.1 9.68 3.31 2.98 17.6 1.06 10.3 3.18 1.26 5.07 0.463 0.383 1.40

WT9×155.5h 45.8 11.2 111/8 1.52 11/2 3/4 17.0 12.0 12 2.74 23/4 3.24 37/16 51/2 155.5 2.19 7.37 383 46.6 2.89 2.93 90.6 1.91 398 66.2 2.95 104 1.00 87.2 339

×141.5h 41.7 10.9 107/8 1.40 13/8 11/16 15.3 11.9 117/8 2.50 21/2 3.00 33/16 141.5 2.38 7.79 337 41.5 2.85 2.80 80.2 1.75 352 59.2 2.91 92.5 1.00 66.5 251

×129h 38.0 10.7 103/4 1.28 11/4 5/8 13.7 11.8 113/4 2.30 25/16 2.70 3 129 2.56 8.36 298 37.0 2.80 2.68 71.0 1.61 314 53.4 2.88 83.1 1.00 51.1 189

×117h 34.3 10.5 101/2 1.16 13/16 5/8 12.2 11.7 115/8 2.11 21/8 2.51 23/4 117 2.76 9.05 261 32.7 2.75 2.55 62.4 1.48 279 47.9 2.85 74.4 1.00 39.1 140

×105.5 31.2 10.3 103/8 1.06 11/16 9/16 11.0 11.6 111/2 1.91 115/16 2.31 29/16 105.5 3.02 9.72 229 29.1 2.72 2.44 55.0 1.34 246 42.7 2.82 66.1 1.00 29.1 102

×96 28.1 10.2 101/8 0.960 15/16 1/2 9.77 11.5 111/2 1.75 13/4 2.15 27/16 96 3.27 10.6 202 25.8 2.68 2.34 48.5 1.23 220 38.4 2.79 59.4 1.00 22.3 75.7

×87.5 25.7 10.0 10 0.890 7/8 7/16 8.92 11.4 113/8 1.59 19/16 1.99 27/16 87.5 3.58 11.2 181 23.4 2.66 2.26 43.6 1.13 196 34.4 2.76 53.1 1.00 16.8 56.5

×79 23.2 9.86 97/8 0.810 13/16 7/16 7.99 11.3 111/4 1.44 17/16 1.84 23/8 79 3.92 12.2 160 20.8 2.63 2.17 38.5 1.02 174 30.7 2.74 47.4 1.00 12.5 41.2

×71.5 21.0 9.75 93/4 0.730 3/4 3/8 7.11 11.2 111/4 1.32 15/16 1.72 23/16 71.5 4.25 13.4 142 18.5 2.60 2.09 34.0 0.937 156 27.7 2.72 42.7 1.00 9.58 30.7

×65 19.2 9.63 95/8 0.670 11/16 3/8 6.45 11.2 111/8 1.20 13/16 1.60 21/16 65 4.65 14.4 127 16.7 2.58 2.02 30.5 0.856 139 24.9 2.70 38.3 1.00 7.23 22.8

×59.5 17.6 9.49 91/2 0.655 5/8 5/16 6.21 11.3 111/4 1.06 11/16 1.46 115/16 59.5 5.31 14.5 119 15.9 2.60 2.03 28.7 0.778 126 22.5 2.69 34.5 1.00 5.30 17.4

×53 15.6 9.37 93/8 0.590 9/16 5/16 5.53 11.2 111/4 0.940 15/16 1.34 113/16 53 5.96 15.9 104 14.1 2.59 1.97 25.2 0.695 110 19.7 2.66 30.2 1.00 3.73 12.1

×48.5 14.2 9.30 91/4 0.535 9/16 5/16 4.97 11.1 111/8 0.870 7/8 1.27 13/4 48.5 6.41 17.4 93.8 12.7 2.56 1.91 22.6 0.640 100 18.0 2.65 27.6 1.00 2.92 9.29

×43 c 12.7 9.20 91/4 0.480 1/2 1/4 4.41 11.1 111/8 0.770 3/4 1.17 15/8 43 7.20 19.2 82.4 11.2 2.55 1.86 19.9 0.570 87.6 15.8 2.63 24.2 0.935 2.04 6.42

×38 c 11.1 9.11 91/8 0.425 7/16 1/4 3.87 11.0 11 0.680 11/16 1.08 19/16 38 8.11 21.4 71.8 9.83 2.54 1.80 17.3 0.505 76.2 13.8 2.61 21.1 0.824 1.41 4.37

c

Shape is slender for compression with = 50 ksi.

f

Shape exceeds compact limit for flexure with = 50 ksi.

g

The actual size, combination and orientation of fastener components should be compared with the geometry of the

cross section to ensure compatibility.

h

Flange thickness greater than 2 in. Special requirements may apply per AISC Section A3.1c.

v

Shear strength controlled by buckling effects ( < 1.0) with = 50 ksi.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1–60 DIMENSIONS AND PROPERTIES DIMENSIONS AND PROPERTIES 1–61

Table 1-8 (continued) Table 1-8 (continued)

WT-Shapes WT-Shapes

Dimensions Properties

WT9-WT8

Stem Flange Distance Compact Torsional

Area, Depth, Nom- Section Axis X-X Axis Y-Y Properties

Work-

Thickness, Width, Thickness, inal Criteria

Shape Area able

2 Wt.

Gage

ksi

in.2 in. in. in. in.2 in. in. in. in. in. lb/ft 2 in.4 in.3 in. in. in.3 in. in.4 in.3 in. in.3 in.4 in.6

c

WT9×35.5 10.4 9.24 91/4 0.495 1/2 1/4 4.57 7.64 75/8 0.810 13/16 1.21 11/2 31/2g 35.5 4.71 18.7 78.2 11.2 2.74 2.26 20.0 0.683 30.1 7.89 1.70 12.3 0.961 1.74 3.96

×32.5c 9.55 9.18 91/8 0.450 7/16 1/4 4.13 7.59 75/8 0.750 3/4 1.15 17/16 32.5 5.06 20.4 70.7 10.1 2.72 2.20 18.0 0.629 27.4 7.22 1.69 11.2 0.875 1.36 3.01

×30 c 8.82 9.12 91/8 0.415 7/16 1/4 3.78 7.56 71/2 0.695 11/16 1.10 13/8 30 5.44 22.0 64.7 9.29 2.71 2.16 16.5 0.583 25.0 6.63 1.68 10.3 0.794 1.08 2.35

×27.5c 8.10 9.06 9 0.390 3/8 3/16 3.53 7.53 71/2 0.630 5/8 1.03 15/16 27.5 5.98 23.2 59.5 8.63 2.71 2.16 15.3 0.538 22.5 5.97 1.67 9.26 0.733 0.830 1.84

×25 c 7.34 9.00 9 0.355 3/8 3/16 3.19 7.50 71/2 0.570 9/16 0.972 11/4 25 6.57 25.4 53.5 7.79 2.70 2.12 13.8 0.489 20.0 5.35 1.65 8.28 0.620 0.619 1.36

WT9×23c 6.77 9.03 9 0.360 3/8 3/16 3.25 6.06 6 0.605 5/8 1.01 11/4 31/2g 23 5.01 25.1 52.1 7.77 2.77 2.33 13.9 0.558 11.3 3.71 1.29 5.84 0.635 0.609 1.20

×20 c 5.88 8.95 9 0.315 5/16 3/16 2.82 6.02 6 0.525 1/2 0.927 13/16 20 5.73 28.4 44.8 6.73 2.76 2.29 12.0 0.489 9.55 3.17 1.27 4.97 0.496 0.404 0.788

×17.5c,v 5.15 8.85 87/8 0.300 5/16 3/16 2.66 6.00 6 0.425 7/16 0.827 11/8 17.5 7.06 29.5 40.1 6.21 2.79 2.39 11.2 0.450 7.67 2.56 1.22 4.02 0.460 0.252 0.598

WT8×50 14.7 8.49 81/2 0.585 9/16 5/16 4.96 10.4 103/8 0.985 1 1.39 17/8 51/2 50 5.29 14.5 76.8 11.4 2.28 1.76 20.7 0.706 93.1 17.9 2.51 27.4 1.00 3.85 10.4

×44.5 13.1 8.38 83/8 0.525 1/2 1/4 4.40 10.4 103/8 0.875 7/8 1.28 13/4 44.5 5.92 16.0 67.2 10.1 2.27 1.70 18.1 0.631 81.3 15.7 2.49 24.0 1.00 2.72 7.19

×38.5c 11.3 8.26 81/4 0.455 7/16 1/4 3.76 10.3 101/4 0.760 3/4 1.16 15/8 38.5 6.77 18.2 56.9 8.59 2.24 1.63 15.3 0.549 69.2 13.4 2.47 20.5 0.986 1.78 4.61

×33.5c 9.81 8.17 81/8 0.395 3/8 3/16 3.23 10.2 101/4 0.665 11/16 1.07 19/16 33.5 7.70 20.7 48.6 7.36 2.22 1.56 13.0 0.481 59.5 11.6 2.46 17.7 0.859 1.19 3.01

c

WT8×28.5 8.39 8.22 81/4 0.430 7/16 1/4 3.53 7.12 71/8 0.715 11/16 1.12 13/8 31/2g 28.5 4.98 19.1 48.7 7.77 2.41 1.94 13.8 0.589 21.6 6.06 1.60 9.42 0.940 1.10 1.99

×25 c 7.37 8.13 81/8 0.380 3/8 3/16 3.09 7.07 71/8 0.630 5/8 1.03 15/16 25 5.61 21.4 42.3 6.78 2.40 1.89 12.0 0.521 18.6 5.26 1.59 8.15 0.824 0.760 1.34

×22.5c 6.63 8.07 81/8 0.345 3/8 3/16 2.78 7.04 7 0.565 9/16 0.967 11/4 22.5 6.23 23.4 37.8 6.10 2.39 1.86 10.8 0.471 16.4 4.67 1.57 7.22 0.723 0.555 0.974

×20 c 5.89 8.01 8 0.305 5/16 3/16 2.44 7.00 7 0.505 1/2 0.907 13/16 31/2 20 6.93 26.3 33.1 5.35 2.37 1.81 9.43 0.421 14.4 4.12 1.56 6.36 0.579 0.396 0.673

×18 c 5.29 7.93 77/8 0.295 5/16 3/16 2.34 6.99 7 0.430 7/16 0.832 11/8 31/2 18 8.12 26.9 30.6 5.05 2.41 1.88 8.93 0.378 12.2 3.50 1.52 5.42 0.553 0.272 0.516

WT8×15.5c 4.56 7.94 8 0.275 1/4 1/8 2.18 5.53 51/2 0.440 7/16 0.842 11/8 31/2 15.5 6.28 28.9 27.5 4.64 2.45 2.02 8.27 0.413 6.20 2.24 1.17 3.51 0.479 0.230 0.366

×13 c,v 3.84 7.85 77/8 0.250 1/4 1/8 1.96 5.50 51/2 0.345 3/8 0.747 11/16 31/2 13 7.97 31.4 23.5 4.09 2.47 2.09 7.36 0.372 4.79 1.74 1.12 2.73 0.406 0.130 0.243

c

Shape is slender for compression with = 50 ksi.

g

The actual size, combination and orientation of fastener components should be compared with the geometry of the

cross section to ensure compatibility.

v

Shear strength controlled by buckling effects ( < 1.0) with = 50 ksi.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1–62 DIMENSIONS AND PROPERTIES DIMENSIONS AND PROPERTIES 1–63

Table 1-8 (continued) Table 1-8 (continued)

WT-Shapes WT-Shapes

Dimensions Properties

WT7

Stem Flange Distance Compact Torsional

Area, Depth, Nom- Section Axis X-X Axis Y-Y Properties

Work-

Thickness, Width, Thickness, inal Criteria

Shape Area able

2 Wt.

Gage

ksi

in.2 in. in. in. in.2 in. in. in. in. in. lb/ft 2 in.4 in.3 in. in. in.3 in. in.4 in.3 in. in.3 in.4 in.6

h

WT7×365 107 11.2 111/4 3.07 31/16 19/16 34.4 17.9 177/8 4.91 415/16 5.51 63/16 71/2g 365 1.82 3.65 739 95.4 2.62 3.47 211 3.00 2360 264 4.69 408 1.00 714 5250

×332.5h 97.8 10.8 107/8 2.83 213/16 17/16 30.6 17.7 175/8 4.52 41/2 5.12 513/16 71/2g 332.5 1.95 3.82 622 82.1 2.52 3.25 182 2.77 2080 236 4.62 365 1.00 555 3920

×302.5h 89.0 10.5 101/2 2.60 25/8 15/16 27.1 17.4 173/8 4.16 43/16 4.76 57/16 71/2 302.5 2.09 4.04 524 70.6 2.43 3.05 157 2.55 1840 211 4.55 326 1.00 430 2930

×275h 80.9 10.1 101/8 2.38 23/8 13/16 24.1 17.2 171/4 3.82 313/16 4.42 51/8 275 2.25 4.24 442 60.9 2.34 2.85 136 2.35 1630 189 4.49 292 1.00 331 2180

×250h 73.5 9.80 93/4 2.19 23/16 11/8 21.5 17.0 17 3.50 31/2 4.10 413/16 250 2.43 4.47 375 52.7 2.26 2.67 117 2.16 1440 169 4.43 261 1.00 254 1620

×227.5h 66.9 9.51 91/2 2.02 2 1 19.2 16.8 167/8 3.21 33/16 3.81 41/2 227.5 2.62 4.71 321 45.9 2.19 2.51 102 1.99 1280 152 4.38 234 1.00 196 1210

×213h 62.7 9.34 93/8 1.88 17/8 15/16 17.5 16.7 163/4 3.04 31/16 3.63 45/16 213 2.75 4.97 287 41.4 2.14 2.40 91.7 1.88 1180 141 4.34 217 1.00 164 991

×199h 58.4 9.15 91/8 1.77 13/4 7/8 16.2 16.6 165/8 2.85 27/8 3.44 41/8 199 2.92 5.17 257 37.6 2.10 2.30 82.9 1.76 1090 131 4.31 201 1.00 135 801

×185h 54.4 8.96 9 1.66 111/16 13/16 14.8 16.5 161/2 2.66 211/16 3.26 315/16 185 3.10 5.40 229 33.9 2.05 2.19 74.4 1.65 994 121 4.27 185 1.00 110 640

×171h 50.3 8.77 83/4 1.54 19/16 13/16 13.5 16.4 163/8 2.47 21/2 3.07 33/4 171 3.31 5.69 203 30.4 2.01 2.09 66.2 1.54 903 110 4.24 169 1.00 88.3 502

×155.5h 45.7 8.56 81/2 1.41 17/16 3/4 12.1 16.2 161/4 2.26 21/4 2.86 39/16 155.5 3.59 6.07 176 26.7 1.96 1.97 57.7 1.41 807 99.4 4.20 152 1.00 67.5 375

×141.5h 41.6 8.37 83/8 1.29 15/16 11/16 10.8 16.1 161/8 2.07 21/16 2.67 33/8 141.5 3.89 6.49 153 23.5 1.92 1.86 50.4 1.29 722 89.7 4.17 137 1.00 51.8 281

×128.5 37.8 8.19 81/4 1.18 13/16 5/8 9.62 16.0 16 1.89 17/8 2.49 33/16 128.5 4.23 6.94 133 20.7 1.88 1.75 43.9 1.18 645 80.7 4.13 123 1.00 39.3 209

×116.5 34.2 8.02 8 1.07 11/16 9/16 8.58 15.9 157/8 1.72 13/4 2.32 3 116.5 4.62 7.50 116 18.2 1.84 1.65 38.2 1.08 576 72.5 4.10 110 1.00 29.6 154

×105.5 31.0 7.86 77/8 0.980 1 1/2 7.70 15.8 153/4 1.56 19/16 2.16 27/8 105.5 5.06 8.02 102 16.2 1.81 1.57 33.4 0.980 513 65.0 4.07 98.9 1.00 22.2 113

×96.5 28.4 7.74 73/4 0.890 7/8 7/16 6.89 15.7 153/4 1.44 17/16 2.04 23/4 96.5 5.45 8.70 89.8 14.4 1.78 1.49 29.4 0.903 466 59.3 4.05 90.1 1.00 17.3 87.2

×88 25.9 7.61 75/8 0.830 13/16 7/16 6.32 15.7 155/8 1.31 15/16 1.91 25/8 88 5.97 9.17 80.5 13.0 1.76 1.43 26.3 0.827 419 53.5 4.02 81.3 1.00 13.2 65.2

×79.5 23.4 7.49 71/2 0.745 3/4 3/8 5.58 15.6 155/8 1.19 13/16 1.79 21/2 79.5 6.54 10.1 70.2 11.4 1.73 1.35 22.8 0.751 374 48.1 4.00 73.0 1.00 9.84 47.9

×72.5 21.3 7.39 73/8 0.680 11/16 3/8 5.03 15.5 151/2 1.09 11/16 1.69 23/8 72.5 7.11 10.9 62.5 10.2 1.71 1.29 20.2 0.688 338 43.7 3.98 66.2 1.00 7.56 36.3

WT7×66 19.4 7.33 73/8 0.645 5/8 5/16 4.73 14.7 143/4 1.03 1 1.63 25/16 51/2 66 7.15 11.4 57.8 9.57 1.73 1.29 18.6 0.658 274 37.2 3.76 56.5 1.00 6.13 26.6

×60 17.7 7.24 71/4 0.590 9/16 5/16 4.27 14.7 145/8 0.940 15/16 1.54 21/4 60 7.80 12.3 51.7 8.61 1.71 1.24 16.5 0.602 247 33.7 3.74 51.2 1.00 4.67 20.0

×54.5 16.0 7.16 71/8 0.525 1/2 1/4 3.76 14.6 145/8 0.860 7/8 1.46 23/16 54.5 8.49 13.6 45.3 7.56 1.68 1.17 14.4 0.548 223 30.6 3.73 46.3 1.00 3.55 15.0

×49.5f 14.6 7.08 71/8 0.485 1/2 1/4 3.43 14.6 145/8 0.780 3/4 1.38 21/16 49.5 9.34 14.6 40.9 6.88 1.67 1.14 12.9 0.500 201 27.6 3.71 41.8 1.00 2.68 11.1

×45 f 13.2 7.01 7 0.440 7/16 1/4 3.08 14.5 141/2 0.710 11/16 1.31 2 45 10.2 15.9 36.5 6.16 1.66 1.09 11.5 0.456 181 25.0 3.70 37.8 1.00 2.03 8.31

WT7×41 12.0 7.16 71/8 0.510 1/2 1/4 3.65 10.1 101/8 0.855 7/8 1.45 111/16 51/2 41 5.92 14.0 41.2 7.14 1.85 1.39 13.2 0.593 74.1 14.6 2.48 22.4 1.00 2.53 5.63

×37 10.9 7.09 71/8 0.450 7/16 1/4 3.19 10.1 101/8 0.785 13/16 1.38 15/8 37 6.41 15.8 36.0 6.25 1.82 1.32 11.5 0.541 66.9 13.3 2.48 20.2 1.00 1.93 4.19

×34 10.0 7.02 7 0.415 7/16 1/4 2.91 10.0 10 0.720 3/4 1.31 19/16 34 6.97 16.9 32.6 5.69 1.81 1.29 10.4 0.498 60.7 12.1 2.46 18.4 1.00 1.50 3.21

×30.5c 8.96 6.95 7 0.375 3/8 3/16 2.60 10.0 10 0.645 5/8 1.24 11/2 30.5 7.75 18.5 28.9 5.07 1.80 1.25 9.15 0.448 53.7 10.7 2.45 16.4 0.971 1.09 2.29

c 3/8 3/16 11/16

WT7×26.5 7.80 6.96 7 0.370 2.58 8.06 8 0.660 1.25 11/2 51/2 26.5 6.11 18.8 27.6 4.94 1.88 1.38 8.87 0.484 28.8 7.15 1.92 11.0 0.956 0.967 1.46

×24 c 7.07 6.90 67/8 0.340 5/16 3/16 2.34 8.03 8 0.595 5/8 1.19 17/16 24 6.75 20.3 24.9 4.49 1.88 1.35 8.00 0.440 25.7 6.40 1.91 9.80 0.880 0.723 1.07

×21.5c 6.31 6.83 67/8 0.305 5/16 3/16 2.08 8.00 8 0.530 1/2 1.12 13/8 21.5 7.54 22.4 21.9 3.98 1.86 1.31 7.05 0.395 22.6 5.65 1.89 8.64 0.773 0.522 0.751

c

Shape is slender for compression with = 50 ksi.

f

Shape exceeds compact limit for flexure with = 50 ksi.

g

The actual size, combination and orientation of fastener components should be compared with the geometry of the

cross section to ensure compatibility.

h

Flange thickness greater than 2 in. Special requirements may apply per AISC Section A3.1c.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1–64 DIMENSIONS AND PROPERTIES DIMENSIONS AND PROPERTIES 1–65

Table 1-8 (continued) Table 1-8 (continued)

WT-Shapes WT-Shapes

Dimensions Properties

WT7-WT6

Stem Flange Distance Compact Torsional

Area, Depth, Nom- Section Axis X-X Axis Y-Y Properties

Work-

Thickness, Width, Thickness, inal Criteria

Shape Area able

2 Wt.

Gage

ksi

in.2 in. in. in. in.2 in. in. in. in. in. lb/ft 2 in.4 in.3 in. in. in.3 in. in.4 in.3 in. in.3 in.4 in.6

c

WT7×19 5.58 7.05 7 0.310 5/16 3/16 2.19 6.77 63/4

0.515 1/2 0.915 11/4 31/2g 19 6.57 22.7 23.3 4.22 2.04 1.54 7.45 0.412 13.3 3.94 1.55 6.07 0.758 0.398 0.554

×17 c 5.00 6.99 7 0.285 5/16 3/16 1.99 6.75 63/4 0.455 7/16 0.855 13/16 31/2 17 7.41 24.5 20.9 3.83 2.04 1.53 6.74 0.371 11.6 3.45 1.53 5.32 0.667 0.284 0.400

×15 c 4.42 6.92 67/8 0.270 1/4 1/8 1.87 6.73 63/4 0.385 3/8 0.785 11/8 31/2 15 8.74 25.6 19.0 3.55 2.07 1.58 6.25 0.329 9.79 2.91 1.49 4.49 0.611 0.190 0.287

c

WT7×13 3.85 6.96 7 0.255 1/4 1/8 1.77 5.03 5 0.420 7/16 0.820 11/8 2 3/4 g 13 5.98 27.3 17.3 3.31 2.12 1.72 5.89 0.383 4.45 1.77 1.08 2.76 0.537 0.179 0.207

×11c,v 3.25 6.87 67/8 0.230 1/4 1/8 1.58 5.00 5 0.335 5/16 0.735 11/16 2 3/4 g 11 7.46 29.9 14.8 2.91 2.14 1.76 5.20 0.325 3.50 1.40 1.04 2.19 0.448 0.104 0.134

WT6×168 h 49.5 8.41 83/8 1.78 13/4 7/8 14.9 13.4 133/8 2.96 215/16 3.55 37/8 51/2 168 2.26 4.72 190 31.2 1.96 2.31 68.4 1.84 593 88.6 3.47 137 1.00 120 481

×152.5h 44.7 8.16 81/8 1.63 15/8 13/16 13.3 13.2 131/4 2.71 211/16 3.30 35/8 152.5 2.45 5.01 162 27.0 1.90 2.16 59.1 1.69 525 79.3 3.42 122 1.00 92.0 356

×139.5h 41.0 7.93 77/8 1.53 11/2 3/4 12.1 13.1 131/8 2.47 21/2 3.07 33/8 139.5 2.66 5.18 141 24.1 1.86 2.05 51.9 1.56 469 71.3 3.38 110 1.00 70.9 267

×126h 37.1 7.71 73/4 1.40 13/8 11/16 10.7 13.0 13 2.25 21/4 2.85 31/8 126 2.89 5.51 121 20.9 1.81 1.92 44.8 1.42 414 63.6 3.34 97.9 1.00 53.5 195

×115h 33.8 7.53 71/2 1.29 15/16 11/16 9.67 12.9 127/8 2.07 21/16 2.67 215/16 115 3.11 5.84 106 18.5 1.77 1.82 39.4 1.31 371 57.5 3.31 88.4 1.00 41.6 148

×105 30.9 7.36 73/8 1.18 13/16 5/8 8.68 12.8 123/4 1.90 17/8 2.50 213/16 105 3.37 6.24 92.1 16.4 1.73 1.72 34.5 1.21 332 51.9 3.28 79.7 1.00 32.1 112

×95 28.0 7.19 71/4 1.06 11/16 9/16 7.62 12.7 125/8 1.74 13/4 2.33 25/8 95 3.65 6.78 79.0 14.2 1.68 1.62 29.8 1.10 295 46.5 3.25 71.2 1.00 24.3 82.1

×85 25.0 7.02 7 0.960 15/16 1/2 6.73 12.6 125/8 1.56 19/16 2.16 27/16 85 4.03 7.31 67.8 12.3 1.65 1.52 25.6 0.994 259 41.2 3.22 62.9 1.00 17.7 58.3

×76 22.4 6.86 67/8 0.870 7/8 7/16 5.96 12.5 121/2 1.40 13/8 2.00 25/16 76 4.46 7.89 58.5 10.8 1.62 1.43 22.0 0.896 227 36.4 3.19 55.6 1.00 12.8 41.3

×68 20.0 6.71 63/4 0.790 13/16 7/16 5.30 12.4 123/8 1.25 11/4 1.85 21/8 68 4.96 8.49 50.6 9.46 1.59 1.35 19.0 0.805 199 32.1 3.16 48.9 1.00 9.21 28.9

×60 17.6 6.56 61/2 0.710 11/16 3/8 4.66 12.3 123/8 1.11 11/8 1.70 2 60 5.57 9.24 43.4 8.22 1.57 1.28 16.2 0.716 172 28.0 3.13 42.7 1.00 6.42 19.7

×53 15.6 6.45 61/2 0.610 5/8 5/16 3.93 12.2 121/4 0.990 1 1.59 17/8 53 6.17 10.6 36.3 6.92 1.53 1.19 13.6 0.637 151 24.7 3.11 37.5 1.00 4.55 13.6

×48 14.1 6.36 63/8 0.550 9/16 5/16 3.50 12.2 121/8 0.900 7/8 1.50 113/16 48 6.76 11.6 32.0 6.12 1.51 1.13 11.9 0.580 135 22.2 3.09 33.7 1.00 3.42 10.1

×43.5 12.8 6.27 61/4 0.515 1/2 1/4 3.23 12.1 121/8 0.810 13/16 1.41 111/16 43.5 7.48 12.2 28.9 5.60 1.50 1.10 10.7 0.527 120 19.9 3.07 30.2 1.00 2.54 7.34

×39.5 11.6 6.19 61/4 0.470 1/2 1/4 2.91 12.1 121/8 0.735 3/4 1.33 15/8 39.5 8.22 13.2 25.8 5.03 1.49 1.06 9.49 0.480 108 17.9 3.05 27.1 1.00 1.91 5.43

×36 10.6 6.13 61/8 0.430 7/16 1/4 2.63 12.0 12 0.670 11/16 1.27 19/16 36 8.99 14.3 23.2 4.54 1.48 1.02 8.48 0.439 97.5 16.2 3.04 24.6 1.00 1.46 4.07

×32.5f 9.54 6.06 6 0.390 3/8 3/16 2.36 12.0 12 0.605 5/8 1.20 11/2 32.5 9.92 15.5 20.6 4.06 1.47 0.985 7.50 0.398 87.2 14.5 3.02 22.0 1.00 1.09 2.97

WT6×29 8.52 6.10 61/8 0.360 3/8 3/16 2.19 10.0 10 0.640 5/8 1.24 11/2 51/2 29 7.82 16.9 19.1 3.76 1.50 1.03 6.97 0.426 53.5 10.7 2.51 16.2 1.00 1.05 2.08

×26.5 7.78 6.03 6 0.345 3/8 3/16 2.08 10.0 10 0.575 9/16 1.18 13/8 51/2 26.5 8.69 17.5 17.7 3.54 1.51 1.02 6.46 0.389 47.9 9.58 2.48 14.5 1.00 0.788 1.53

WT6×25 7.30 6.10 61/8 0.370 3/8 3/16 2.26 8.08 81/8 0.640 5/8 1.14 11/2 51/2 25 6.31 16.5 18.7 3.79 1.60 1.17 6.88 0.452 28.2 6.97 1.96 10.6 1.00 0.855 1.23

×22.5 6.56 6.03 6 0.335 5/16 3/16 2.02 8.05 8 0.575 9/16 1.08 13/8 22.5 7.00 18.0 16.6 3.39 1.59 1.13 6.10 0.408 25.0 6.21 1.95 9.47 1.00 0.627 0.885

×20 c 5.84 5.97 6 0.295 5/16 3/16 1.76 8.01 8 0.515 1/2 1.02 13/8 20 7.77 20.2 14.4 2.95 1.57 1.09 5.28 0.365 22.0 5.50 1.94 8.38 0.885 0.452 0.620

c

WT6×17.5 5.17 6.25 61/4 0.300 5/16 3/16 1.88 6.56 61/2 0.520 1/2 0.820 13/16 31/2 17.5 6.31 20.8 16.0 3.23 1.76 1.30 5.71 0.394 12.2 3.73 1.54 5.73 0.854 0.369 0.437

×15 c 4.40 6.17 61/8 0.260 1/4 1/8 1.60 6.52 61/2 0.440 7/16 0.740 11/8 15 7.41 23.7 13.5 2.75 1.75 1.27 4.83 0.337 10.2 3.12 1.52 4.78 0.707 0.228 0.267

×13 c 3.82 6.11 61/8 0.230 1/4 1/8 1.41 6.49 61/2 0.380 3/8 0.680 11/16 13 8.54 26.6 11.7 2.40 1.75 1.25 4.20 0.295 8.66 2.67 1.51 4.08 0.566 0.150 0.174

c

Shape is slender for compression with = 50 ksi.

f

Shape exceeds compact limit for flexure with = 50 ksi.

g

The actual size, combination and orientation of fastener components should be compared with the geometry of the

cross section to ensure compatibility.

h

Flange thickness greater than 2 in. Special requirements may apply per AISC Section A3.1c.

v

Shear strength controlled by buckling effects ( < 1.0) with = 50 ksi.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1–66 DIMENSIONS AND PROPERTIES DIMENSIONS AND PROPERTIES 1–67

Table 1-8 (continued) Table 1-8 (continued)

WT-Shapes WT-Shapes

Dimensions Properties

WT6-WT4

Stem Flange Distance Compact Torsional

Area, Depth, Nom- Section Axis X-X Axis Y-Y Properties

Work-

Thickness, Width, Thickness, inal Criteria

Shape Area able

2 Wt.

Gage

ksi

in.2 in. in. in. in.2 in. in. in. in. in. lb/ft 2 in.4 in.3 in. in. in.3 in. in.4 in.3 in. in.3 in.4 in.6

c

WT6×11 3.24 6.16 61/8 0.260 1/4 1/8 1.60 4.03 4 0.425 7/16 0.725 15/16 21/4g 11 4.74 23.7 11.7 2.59 1.90 1.63 4.63 0.402 2.33 1.15 0.847 1.83 0.707 0.146 0.137

×9.5c 2.79 6.08 61/8 0.235 1/4 1/8 1.43 4.01 4 0.350 3/8 0.650 7/8 9.5 5.72 25.9 10.1 2.28 1.90 1.65 4.11 0.348 1.88 0.939 0.821 1.49 0.597 0.0899 0.0934

×8c 2.36 6.00 6 0.220 1/4 1/8 1.32 3.99 4 0.265 1/4 0.565 13/16 8 7.53 27.3 8.70 2.04 1.92 1.74 3.72 0.639 1.41 0.706 0.773 1.13 0.537 0.0511 0.0678

×7c,v 2.08 5.96 6 0.200 3/16 1/8 1.19 3.97 4 0.225 1/4 0.525 3/4 7 8.82 29.8 7.67 1.83 1.92 1.76 3.32 0.760 1.18 0.593 0.753 0.947 0.451 0.0350 0.0493

WT5×56 16.5 5.68 55/8 0.755 3/4 3/8 4.29 10.4 103/8 1.25 11/4 1.75 115/16 51/2 56 4.17 7.52 28.6 6.40 1.32 1.21 13.4 0.791 118 22.6 2.67 34.6 1.00 7.50 16.9

×50 14.7 5.55 51/2 0.680 11/16 3/8 3.77 10.3 103/8 1.12 11/8 1.62 113/16 50 4.62 8.16 24.5 5.56 1.29 1.13 11.4 0.711 103 20.0 2.65 30.5 1.00 5.41 11.9

×44 13.0 5.42 53/8 0.605 5/8 5/16 3.28 10.3 101/4 0.990 1 1.49 111/16 44 5.18 8.96 20.8 4.77 1.27 1.06 9.65 0.631 89.3 17.4 2.63 26.5 1.00 3.75 8.02

×38.5 11.3 5.30 51/4 0.530 1/2 1/4 2.81 10.2 101/4 0.870 7/8 1.37 19/16 38.5 5.86 10.0 17.4 4.05 1.24 0.990 8.06 0.555 76.8 15.1 2.60 22.9 1.00 2.55 5.31

×34 10.0 5.20 51/4 0.470 1/2 1/4 2.44 10.1 101/8 0.770 3/4 1.27 17/16 34 6.58 11.1 14.9 3.49 1.22 0.932 6.85 0.493 66.7 13.2 2.58 20.0 1.00 1.78 3.62

×30 8.84 5.11 51/8 0.420 7/16 1/4 2.15 10.1 101/8 0.680 11/16 1.18 13/8 30 7.41 12.2 12.9 3.04 1.21 0.884 5.87 0.438 58.1 11.5 2.57 17.5 1.00 1.23 2.46

×27 7.90 5.05 5 0.370 3/8 3/16 1.87 10.0 10 0.615 5/8 1.12 15/16 27 8.15 13.6 11.1 2.64 1.19 0.836 5.05 0.395 51.7 10.3 2.56 15.6 1.00 0.909 1.78

×24.5 7.21 4.99 5 0.340 5/16 3/16 1.70 10.0 10 0.560 9/16 1.06 11/4 24.5 8.93 14.7 10.0 2.39 1.18 0.807 4.52 0.361 46.7 9.34 2.54 14.1 1.00 0.693 1.33

WT5×22.5 6.63 5.05 5 0.350 3/8 3/16 1.77 8.02 8 0.620 5/8 1.12 15/16 22.5 6.47 14.4 10.2 2.47 1.24 0.907 4.65 0.413 26.7 6.65 2.01 10.1 1.00 0.753 0.981

×19.5 5.73 4.96 5 0.315 5/16 3/16 1.56 7.99 8 0.530 1/2 1.03 13/16 19.5 7.53 15.7 8.84 2.16 1.24 0.876 3.99 0.359 22.5 5.64 1.98 8.57 1.00 0.487 0.616

×16.5 4.85 4.87 47/8 0.290 5/16 3/16 1.41 7.96 8 0.435 7/16 0.935 11/8 16.5 9.15 16.8 7.71 1.93 1.26 0.869 3.48 0.305 18.3 4.60 1.94 7.00 1.00 0.291 0.356

WT5×15 4.42 5.24 51/4 0.300 5/16 3/16 1.57 5.81 53/4 0.510 1/2 0.810 11/8 23/4 g 15 5.70 17.5 9.28 2.24 1.45 1.10 4.01 0.380 8.35 2.87 1.37 4.41 1.00 0.310 0.273

×13 c 3.81 5.17 51/8 0.260 1/4 1/8 1.34 5.77 53/4 0.440 7/16 0.740 11/16 13 6.56 19.9 7.86 1.91 1.44 1.06 3.39 0.330 7.05 2.44 1.36 3.75 0.900 0.201 0.173

×11c 3.24 5.09 51/8 0.240 1/4 1/8 1.22 5.75 53/4 0.360 3/8 0.660 15/16 11 7.99 21.2 6.88 1.72 1.46 1.07 3.02 0.282 5.71 1.99 1.33 3.05 0.834 0.119 0.107

WT5×9.5c 2.81 5.12 51/8 0.250 1/4 1/8 1.28 4.02 4 0.395 3/8 0.695 15/16 21/4g 9.5 5.09 20.5 6.68 1.74 1.54 1.28 3.10 0.349 2.15 1.07 0.874 1.67 0.870 0.116 0.0796

×8.5c 2.50 5.06 5 0.240 1/4 1/8 1.21 4.01 4 0.330 5/16 0.630 7/8 8.5 6.08 21.1 6.06 1.62 1.56 1.32 2.90 0.311 1.78 0.887 0.844 1.40 0.839 0.0776 0.0610

×7.5c 2.21 5.00 5 0.230 1/4 1/8 1.15 4.00 4 0.270 1/4 0.570 13/16 7.5 7.41 21.7 5.45 1.50 1.57 1.37 2.71 0.305 1.45 0.723 0.810 1.15 0.809 0.0518 0.0475

×6c,f 1.77 4.94 47/8 0.190 3/16 1/8 0.938 3.96 4 0.210 3/16 0.510 3/4 6 9.43 26.0 4.35 1.22 1.57 1.36 2.20 0.322 1.09 0.551 0.785 0.869 0.592 0.0272 0.0255

WT4×33.5 9.84 4.50 41/2 0.570 9/16 5/16 2.57 8.28 81/4 0.935 15/16 1.33 15/8 51/2 33.5 4.43 7.89 10.9 3.05 1.05 0.936 6.29 0.594 44.3 10.7 2.12 16.3 1.00 2.51 3.56

×29 8.54 4.38 43/8 0.510 1/2 1/4 2.23 8.22 81/4 0.810 13/16 1.20 11/2 29 5.07 8.59 9.12 2.61 1.03 0.874 5.25 0.520 37.5 9.13 2.10 13.9 1.00 1.66 2.28

×24 7.05 4.25 41/4 0.400 3/8 3/16 1.70 8.11 81/8 0.685 11/16 1.08 13/8 24 5.92 10.6 6.85 1.97 0.986 0.777 3.94 0.435 30.5 7.51 2.08 11.4 1.00 0.977 1.30

×20 5.87 4.13 41/8 0.360 3/8 3/16 1.49 8.07 81/8 0.560 9/16 0.954 11/4 20 7.21 11.5 5.73 1.69 0.988 0.735 3.25 0.364 24.5 6.08 2.04 9.24 1.00 0.558 0.715

×17.5 5.14 4.06 4 0.310 5/16 3/16 1.26 8.02 8 0.495 1/2 0.889 13/16 17.5 8.10 13.1 4.82 1.43 0.968 0.688 2.71 0.321 21.3 5.31 2.03 8.05 1.00 0.384 0.480

×15.5f 4.56 4.00 4 0.285 5/16 3/16 1.14 8.00 8 0.435 7/16 0.829 11/8 15.5 9.19 14.0 4.28 1.28 0.969 0.668 2.39 0.285 18.5 4.64 2.02 7.03 1.00 0.267 0.327

WT4×14 4.12 4.03 4 0.285 5/16 3/16 1.15 6.54 0.46561/2 7/16 0.859 15/16 31/2 14 7.03 14.1 4.23 1.28 1.01 0.734 2.38 0.315 10.8 3.31 1.62 5.04 1.00 0.268 0.230

×12 3.54 3.97 4 0.245 1/4 1/8 0.971 6.50 61/2 0.400 3/8 0.794 7/8 31/2 12 8.12 16.2 3.53 1.08 0.999 0.695 1.98 0.272 9.14 2.81 1.61 4.28 1.00 0.173 0.144

c

Shape is slender for compression with = 50 ksi.

f

Shape exceeds compact limit for flexure with = 50 ksi.

g

The actual size, combination and orientation of fastener components should be compared with the geometry of the

cross section to ensure compatibility.

v

Shear strength controlled by buckling effects ( < 1.0) with = 50 ksi.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1–68 DIMENSIONS AND PROPERTIES DIMENSIONS AND PROPERTIES 1–69

Table 1-8 (continued) Table 1-8 (continued)

WT-Shapes WT-Shapes

Dimensions Properties

WT4-WT2

Stem Flange Distance Compact Torsional

Area, Depth, Nom- Section Axis X-X Axis Y-Y Properties

Work-

Thickness, Width, Thickness, inal Criteria

Shape Area able

2 Wt.

Gage

ksi

in.2 in. in. in. in.2 in. in. in. in. in. lb/ft 2 in.4 in.3 in. in. in.3 in. in.4 in.3 in. in.3 in.4 in.6

WT4×10.5 3.08 4.14 41/8

0.250 1/4 1/8 1.04 5.27 51/4

0.400 3/8 0.700 7/8 23/4 g 10.5 6.59 16.6 3.90 1.18 1.12 0.831 2.11 0.292 4.88 1.85 1.26 2.84 1.00 0.141 0.0916

×9 2.63 4.07 41/8 0.230 1/4 1/8 0.936 5.25 51/4 0.330 5/16 0.630 13/16 23/4 g 9 7.95 17.7 3.41 1.05 1.14 0.834 1.86 0.251 3.98 1.52 1.23 2.33 1.00 0.0855 0.0562

WT4×7.5 2.22 4.06 4 0.245 1/4 1/8 0.993 4.02 4 0.315 5/16 0.615 13/16 21/4g 7.5 6.37 16.6 3.28 1.07 1.22 0.998 1.91 0.276 1.70 0.849 0.876 1.33 1.00 0.0679 0.0382

×6.5 1.92 4.00 4 0.230 1/4 1/8 0.919 4.00 4 0.255 1/4 0.555 3/4 6.5 7.84 17.4 2.89 0.974 1.23 1.03 1.74 0.240 1.36 0.682 0.843 1.07 1.00 0.0433 0.0269

×5c,f 1.48 3.95 4 0.170 3/16 1/8 0.671 3.94 4 0.205 3/16 0.505 11/16 5 9.61 23.2 2.15 0.717 1.20 0.953 1.27 0.188 1.05 0.531 0.840 0.826 0.733 0.0212 0.0114

WT3×12.5 3.67 3.19 31/4

0.320 5/16 3/16 1.02 6.08 61/8 0.455 7/16 0.705 15/16 31/2 12.5 6.68 10.0 2.29 0.886 0.789 0.610 1.68 0.302 8.53 2.81 1.52 4.28 1.00 0.229 0.171

×10 2.94 3.10 31/8 0.260 1/4 1/8 0.806 6.02 6 0.365 3/8 0.615 7/8 10 8.25 11.9 1.76 0.693 0.774 0.560 1.29 0.244 6.64 2.21 1.50 3.36 1.00 0.120 0.0858

×7.5f 2.21 3.00 3 0.230 1/4 1/8 0.689 5.99 6 0.260 1/4 0.510 3/4 7.5 11.5 13.0 1.41 0.577 0.797 0.558 1.03 0.185 4.66 1.56 1.45 2.37 1.00 0.0504 0.0342

WT3×8 2.37 3.14 31/8 0.260 1/4 1/8 0.816 4.03 4 0.405 3/8 0.655 7/8 21/4g 8 4.98 12.1 1.69 0.685 0.844 0.676 1.25 0.294 2.21 1.10 0.966 1.69 1.00 0.111 0.0426

×6 1.78 3.02 3 0.230 1/4 1/8 0.693 4.00 4 0.280 1/4 0.530 3/4 6 7.14 13.1 1.32 0.564 0.862 0.677 1.01 0.222 1.50 0.748 0.918 1.16 1.00 0.0449 0.0178

×4.5f 1.34 2.95 3 0.170 3/16 1/8 0.502 3.94 4 0.215 3/16 0.465 11/16 4.5 9.16 17.4 0.950 0.408 0.842 0.623 0.720 0.170 1.10 0.557 0.905 0.856 1.00 0.0202 0.00736

×4.25f 1.26 2.92 27/8 0.170 3/16 1/8 0.496 3.94 4 0.195 3/16 0.445 11/16 4.25 10.1 17.2 0.905 0.397 0.848 0.637 0.700 0.160 0.995 0.505 0.890 0.778 1.00 0.0166 0.00620

WT2.5×9.5 2.78 2.58 25/8 0.270 1/4 1/8 0.695 5.03 5 0.430 7/16 0.730 13/16 23/4 9.5 5.85 9.56 1.01 0.485 0.604 0.487 0.970 0.276 4.56 1.81 1.28 2.76 1.00 0.157 0.0775

×8 2.35 2.51 21/2 0.240 1/4 1/8 0.601 5.00 5 0.360 3/8 0.660 3/4 23/4 8 6.94 10.5 0.845 0.413 0.599 0.458 0.801 0.235 3.75 1.50 1.26 2.28 1.00 0.0958 0.0453

WT2×6.5 1.91 2.08 21/8 0.280 1/4 1/8 0.582 4.06 4 0.345 3/8 0.595 3/4 21/4 6.5 5.88 7.43 0.526 0.321 0.524 0.440 0.616 0.236 1.93 0.950 1.00 1.46 1.00 0.0750 0.0233

c

Shape is slender for compression with = 50 ksi.

f

Shape exceeds compact limit for flexure with = 50 ksi.

g

The actual size, combination and orientation of fastener components should be compared with the geometry of the

cross section to ensure compatibility.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION AMERICAN INSTITUTE OF STEEL CONSTRUCTION

You might also like

- Wire Rope Sling Capacity Charts PDFDocument18 pagesWire Rope Sling Capacity Charts PDFRiko Bin Zulkifli100% (3)

- Micro Pile DesignDocument3 pagesMicro Pile DesignPreethiNo ratings yet

- Perry's Maternal Child Nursing in CanadaDocument1,620 pagesPerry's Maternal Child Nursing in Canadagilbertwilliams1234No ratings yet

- The Best of Bruce's Postgres Slides: Ruce OmjianDocument26 pagesThe Best of Bruce's Postgres Slides: Ruce OmjianPhotoHawkNo ratings yet

- Vikash Kumar: Career ObjectiveDocument2 pagesVikash Kumar: Career ObjectiveAnikesh SinghNo ratings yet

- The Triathlete's Training Bible: The World's Most Comprehensive Training Guide, 4th Ed. - TrainingDocument5 pagesThe Triathlete's Training Bible: The World's Most Comprehensive Training Guide, 4th Ed. - Trainingrenogodo0% (1)

- ASM Subject Guide - Aluminum PDFDocument5 pagesASM Subject Guide - Aluminum PDFzeeshaniqbalNo ratings yet

- Lump Sum Contract NotesDocument1 pageLump Sum Contract NotesamrkiplNo ratings yet

- Three-Quater Face Schematics PDFDocument20 pagesThree-Quater Face Schematics PDFSchiteanu ClaudiuNo ratings yet

- 02 Technical Data - NZ PDFDocument4 pages02 Technical Data - NZ PDFaNo ratings yet

- Tablas de Propiedades de Perfiles de Acero - AISCDocument106 pagesTablas de Propiedades de Perfiles de Acero - AISCMerary ChaguaNo ratings yet

- Table 1 1 W ShapesDocument9 pagesTable 1 1 W ShapesJustine PredillaNo ratings yet

- Catalogo WsDocument18 pagesCatalogo WsGABRIEL BRUNO CALLEJAS PARRAGANo ratings yet

- Table 1 5 C ShapesDocument1 pageTable 1 5 C ShapesJustine PredillaNo ratings yet

- Table 1-1Document12 pagesTable 1-1Nadira Islam NilaNo ratings yet

- Tabla 1-1 (W Shapes)Document17 pagesTabla 1-1 (W Shapes)Leonardo ZambranoNo ratings yet

- W-Shapes: Table 1-1Document23 pagesW-Shapes: Table 1-1Ruf FethNo ratings yet

- AISC - Prelims - 14th Ed - Perrfiles 23-138Document116 pagesAISC - Prelims - 14th Ed - Perrfiles 23-138S PNo ratings yet

- W-Shapes: Table 1-1 DimensionsDocument18 pagesW-Shapes: Table 1-1 DimensionsKhalid AlqahtaniNo ratings yet

- AISC - Prelims - 14th EdDocument108 pagesAISC - Prelims - 14th EdFranco SilvaNo ratings yet

- AISC Secciones W Tabla 1 1 PDFDocument18 pagesAISC Secciones W Tabla 1 1 PDFLuis Enrique SalinasNo ratings yet

- Manual AISC14 CompletoDocument107 pagesManual AISC14 CompletoLaura RivasNo ratings yet

- Stell Construction - Perfiles AISC - LRFDDocument112 pagesStell Construction - Perfiles AISC - LRFDelpijuNo ratings yet

- Bolt Torque Specifications: Maintenance MinuteDocument2 pagesBolt Torque Specifications: Maintenance MinuteJamil AlsalemNo ratings yet

- Tablas WTDocument18 pagesTablas WTAlvaro UceloNo ratings yet

- Propiedades de Perfiles Tipo WTDocument22 pagesPropiedades de Perfiles Tipo WTHector Anibal Castillo RaymundoNo ratings yet

- Structural Tees Cut From W Shapes DimensionsDocument23 pagesStructural Tees Cut From W Shapes DimensionsJuan Spencer Silva RuizNo ratings yet

- AISCShapesDocument64 pagesAISCShapeslabsotNo ratings yet

- Table 1 7 A B AnglesDocument4 pagesTable 1 7 A B AnglesJustine PredillaNo ratings yet

- Mechanical-T Bolted Branch Outlet: Victaulic Firelock Style 927Document15 pagesMechanical-T Bolted Branch Outlet: Victaulic Firelock Style 927Kenix TehNo ratings yet

- Spesifikasi Teknis Steel Sheet Pile: U TypeDocument1 pageSpesifikasi Teknis Steel Sheet Pile: U TypebagusNo ratings yet

- Ss Pipe Tube Schedule Pipes WeighDocument2 pagesSs Pipe Tube Schedule Pipes WeighHimTex GlobalNo ratings yet

- Wide Flange Shape: Accordingjis 1993Document12 pagesWide Flange Shape: Accordingjis 1993adityadhNo ratings yet

- Drill Pipe Data API Ex VAMDocument2 pagesDrill Pipe Data API Ex VAMShane_d980No ratings yet

- Table 1-1. Availability of Shapes, Plates, and Bars According To ASTM Structural Steel SpecificationsDocument17 pagesTable 1-1. Availability of Shapes, Plates, and Bars According To ASTM Structural Steel SpecificationsAwi YakumoshiNo ratings yet

- Table 1-1. Availability of Shapes, Plates, and Bars According To ASTM Structural Steel SpecificationsDocument17 pagesTable 1-1. Availability of Shapes, Plates, and Bars According To ASTM Structural Steel SpecificationsAwi YakumoshiNo ratings yet

- ProductsGuide - WideFlangeBeams RED PDFDocument7 pagesProductsGuide - WideFlangeBeams RED PDFPablo Lobato MaciasNo ratings yet

- Supporti in PlasticaDocument8 pagesSupporti in PlasticaAlex MathewNo ratings yet

- Unit Weight of Ms Pipe Schedule 40 - Civil Engineer's DiaryDocument9 pagesUnit Weight of Ms Pipe Schedule 40 - Civil Engineer's DiaryMean Meen100% (2)

- Planilla de Metrados (Acero Corrugado Fy 4200kg/cm2)Document4 pagesPlanilla de Metrados (Acero Corrugado Fy 4200kg/cm2)John PalaciosNo ratings yet

- Heavy Lift Swivel Hoist Rings: HR-1000 UNC ThreadsDocument1 pageHeavy Lift Swivel Hoist Rings: HR-1000 UNC ThreadsAlex RotsNo ratings yet

- H Section: Dimensions and Sectional PropertiesDocument43 pagesH Section: Dimensions and Sectional Properties박현도No ratings yet

- ASTM Fasteners Dimension Tables-15Document1 pageASTM Fasteners Dimension Tables-15tylerstearnsNo ratings yet

- Standard Sectional Dimension of I-Steel and Its Sectional Area, Unit Weight and Sectional CharacteristicDocument2 pagesStandard Sectional Dimension of I-Steel and Its Sectional Area, Unit Weight and Sectional CharacteristicEndar SudarnoNo ratings yet

- Sheet PileDocument1 pageSheet PiledikhwanaNo ratings yet

- Aciers Mottard 1 6 PDFDocument2 pagesAciers Mottard 1 6 PDFAhmed Ben HmidaNo ratings yet

- Ipe 2Document5 pagesIpe 2Aboalmaail AlaminNo ratings yet

- Torque Wrench 200-2000 NMDocument1 pageTorque Wrench 200-2000 NMArdi 4791No ratings yet

- 11 - OrificeDocument7 pages11 - OrificeANDERSON NERESNo ratings yet

- Dikdörtgenprofiller D eDocument1 pageDikdörtgenprofiller D eMKNo ratings yet

- Angulo1 PDFDocument9 pagesAngulo1 PDFGILBRAM JACINTO MENGUAL CUADRADONo ratings yet

- UB UC Steel SectionsDocument10 pagesUB UC Steel SectionsMuhammad HasanNo ratings yet

- Flemish Eye Wire Rope SlingsDocument3 pagesFlemish Eye Wire Rope SlingsSalihNo ratings yet

- American Wide F Beam 6Document1 pageAmerican Wide F Beam 6bhaskarNo ratings yet

- UNI 5587 - 1968thick Hexagon Nuts (Special Purpose) - ISO Metric Coarse and Fine Thread - Finish ADocument9 pagesUNI 5587 - 1968thick Hexagon Nuts (Special Purpose) - ISO Metric Coarse and Fine Thread - Finish ANarimane BentyNo ratings yet

- Gunung Garuda - T-BeamDocument2 pagesGunung Garuda - T-Beamfakkih amiludinNo ratings yet

- BETE WL-metricDocument1 pageBETE WL-metriccpvwqthcghoNo ratings yet

- Spade Spacer API 5000 10000 RTJDocument1 pageSpade Spacer API 5000 10000 RTJFauzan Rusmayadi100% (1)

- AngleA Dim PropDocument2 pagesAngleA Dim PropserkanNo ratings yet

- Boquillas WL - MetricDocument1 pageBoquillas WL - MetricDavid Fernando Tirado ArizaNo ratings yet

- Metric Hex BoltsDocument2 pagesMetric Hex BoltsCelestine OzokechiNo ratings yet

- Tim Stock Book Web 0812Document72 pagesTim Stock Book Web 0812Wajid khanNo ratings yet

- Rolled Steel Channels: Dimensions and PropertiesDocument1 pageRolled Steel Channels: Dimensions and PropertiesSATISH GAIKWADNo ratings yet

- ANSI B16.5 Class 300 Welding Neck FlangesDocument2 pagesANSI B16.5 Class 300 Welding Neck FlangeslehuyNo ratings yet

- Superman PDFDocument2 pagesSuperman PDFlehuyNo ratings yet

- Engg. LawsEthicsContracts 2 HYFLEX SYLLABUS 2nd 2023 2024Document11 pagesEngg. LawsEthicsContracts 2 HYFLEX SYLLABUS 2nd 2023 2024Justine PredillaNo ratings yet

- Assessment - Lab. Work 5 (Midterm Cover)Document2 pagesAssessment - Lab. Work 5 (Midterm Cover)Justine PredillaNo ratings yet

- Grant RDDocument7 pagesGrant RDJustine PredillaNo ratings yet

- Assessment - Lab. Work 4 (Midterm Cover)Document2 pagesAssessment - Lab. Work 4 (Midterm Cover)Justine PredillaNo ratings yet

- Experiment No. 5 DETERMINATION OF METACENTER OF A BODYDocument6 pagesExperiment No. 5 DETERMINATION OF METACENTER OF A BODYJustine PredillaNo ratings yet

- Environmental ScieDocument4 pagesEnvironmental ScieJustine PredillaNo ratings yet

- Chem Assignment No. 4BDocument2 pagesChem Assignment No. 4BJustine PredillaNo ratings yet

- Predilla JA G175 LW8cDocument3 pagesPredilla JA G175 LW8cJustine PredillaNo ratings yet

- Chem Assignment No. 4ADocument1 pageChem Assignment No. 4AJustine PredillaNo ratings yet

- Predilla JA G175 LW7bDocument1 pagePredilla JA G175 LW7bJustine PredillaNo ratings yet

- Predilla JA G175 LW5Document2 pagesPredilla JA G175 LW5Justine PredillaNo ratings yet

- Dif Conrete Tension (Malvar)Document5 pagesDif Conrete Tension (Malvar)mohamed_gmal22No ratings yet

- Bioshock Audio DiariesDocument6 pagesBioshock Audio DiariesGeorge CuriosoNo ratings yet

- Gene KnockDocument5 pagesGene KnockAnne Marian JosephNo ratings yet

- Top Tips For Marriage Habits For A Happy Marriage 2019Document2 pagesTop Tips For Marriage Habits For A Happy Marriage 2019Marcel Henri Pascal Patrice Moudiki KingueNo ratings yet

- Image Harmonization With Diffusion ModelDocument8 pagesImage Harmonization With Diffusion Modelzhangzhengyi443No ratings yet

- FTL20.pdf Ultrasonic SondeDocument20 pagesFTL20.pdf Ultrasonic SondeJaroslav BiresNo ratings yet

- GSE580Document132 pagesGSE580Anonymous g4wR41qNeNo ratings yet

- Ebook PDF Consumer Behaviour Asia Pacific Edition by Wayne D Hoyer PDFDocument41 pagesEbook PDF Consumer Behaviour Asia Pacific Edition by Wayne D Hoyer PDFmarvin.tappen826100% (35)

- Thesis On Corporate Governance and Firm PerformanceDocument10 pagesThesis On Corporate Governance and Firm Performancegja8e2sv100% (2)

- CS317 IR W1aDocument20 pagesCS317 IR W1aHatim Juzer KhambatwalaNo ratings yet

- Algorithm Exam HelpDocument9 pagesAlgorithm Exam HelpProgramming Exam HelpNo ratings yet

- Choose The Best Answer From The Four Options (Marked A, B, C, or D) To Complete The Sentences. Exercise 1Document6 pagesChoose The Best Answer From The Four Options (Marked A, B, C, or D) To Complete The Sentences. Exercise 1Van AnhNo ratings yet

- SLGR 20121Document27 pagesSLGR 20121Marieta AlejoNo ratings yet

- It Didn't Snow On Saturday. It Rained On SaturdayDocument1 pageIt Didn't Snow On Saturday. It Rained On SaturdayAnna Talhammer100% (1)

- F2-14 Budget PreparationDocument18 pagesF2-14 Budget PreparationJaved Imran100% (1)

- Word 2016, Using Mail MergeDocument6 pagesWord 2016, Using Mail MergePelah Wowen DanielNo ratings yet

- As Me Certificate Holder ReportDocument5 pagesAs Me Certificate Holder ReportpandiangvNo ratings yet

- RTI Online Submit Request FormDocument1 pageRTI Online Submit Request FormRinky SharmaNo ratings yet

- API Ne - Con.prvt - CD Ds2 en Excel v2 5455687Document94 pagesAPI Ne - Con.prvt - CD Ds2 en Excel v2 5455687aaaNo ratings yet

- Using Snap Test Kits Poster enDocument1 pageUsing Snap Test Kits Poster enMoisés RodríguezNo ratings yet

- Chapter 4 IR ModelsDocument34 pagesChapter 4 IR ModelsYohannes KefaleNo ratings yet

- DOH Breast Cancer Guidelines FinalDocument123 pagesDOH Breast Cancer Guidelines Finalsupratimbiswas073380No ratings yet

- Our Proper Home Garbage Disposal GuideDocument7 pagesOur Proper Home Garbage Disposal GuideNovelNo ratings yet