Professional Documents

Culture Documents

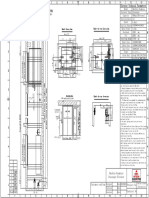

Ife 71A

Ife 71A

Uploaded by

Takumina Services0 ratings0% found this document useful (0 votes)

29 views54 pagesOriginal Title

ife-71A (1)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views54 pagesIfe 71A

Ife 71A

Uploaded by

Takumina ServicesCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 54

Share this

document

f v

m (=

Virtuelt virus: NOK infisert

Nabiznip

The depih at which th Gaphagm i taseried iio he

: Leveling switch | switch is insufficient, resulting in inaccurate switch

BI auesion fault | action Leveling switch damaged, wrong wiring, shor

‘cuit phenomenon

By ator overbea Date switch or wiring problems

Es

ay

Bs

E36

Es

Ey

The magne deflection value of synchronous motor

9 Running abnormal Elevator rated speed, tuning speed, motor

F overspeed ated frequency, moor ated speed setting vals are

uunreasonab

‘Speed monitoring | Wromgconnection of seed monitor Ban o

a Troan ful erspeed dereexed

Cartop board

Bt commniction

tau

BR

3 | Creekeurthe rene |” rong connection or rope broken switch action

ES aa 1 connection or rope broken switch act

TMCP unexpected

Es movement Wiring error or UCMP switch ation

erected

ES Leveling sensor \Woong wiring or wire broke

The upperand

nas | ont emeeT and | ving ero or ICMP doo zone snomaly.04 set x99

‘is not connected sal

ss1__| cna ee | Net nt tec

“The high voluge door lock loop was disconnected, but

the fed

coma feedoack

a ck contactor was detected o be stuck

The high voltage safexy loop is onnsoted, but the

Ls Teited pun pura tes conan

deat

= fault detected sealed star feedback has impart

a teeaS

a RAS HS

[s is Uist ¥ a Ws mm mec vanmoraPso |

: i ToL ee ro Ta]

Nabiznip

Trap door SW Trap doo

Save

D

load any document, ad-free.

‘ibe with a free trial

Nabiznip

pel a

ables the inverter drive dhe moioeo run at emergency speed (function code K3-19) inthe divetion of ight load, unl the

levator detects signal of leveling sens, stp the elevate, open the door and rekcase people, keg the state of opening the

oo, and then stop the operation

16.9 Duplex function comnissioning

Maiboas ni i) Masoud bli

1. DIP SW soning description

Hen

T

t

I

1

fo

3) Noinboard DIP SX

Pul the werminal esistance of CAN on the main board

Specitic Function Seiting range Default

group _| parameter

Ke. Ko.06 | Liftadirese 13s

2 Parvin

Paranet jeter of Lift

6-06 1

XW. Fault diagnosis and fault countermeasure

inormation or protection finetions. When the elevator breaks dow, the ful Wil be

Tsay hs nes 60 Wa

fern he moni Usercan ana he lk cing he nfrtion pomp in thiseeon, drain he ae

Joe rang. oe sotsion

ult code | Fal descripton Salation

el Srey exe The sey circuit wich sof

Won s dor sched te oc ne comes

Door ne fully ‘andthe door is wlosed overtime:

2

close

crane TEeRaee

3 = ae

Virtuelt virus: NOK infisert

Nabiznip [

Fle

a =

eons

Virtuelt virus: NOK infisert

Nabiznip [

Cade Predetermined are tale mark

Save

Le

OPTeR ta m@e(re tir Corl ee teo bucoe

‘ibe with a free trial

ES ie Bee eS el eS le tee

Karrieren hans kan veere ové

Populzre Nyheter

=

Shop IKEA.ph

Populzre Nyheter

[Mainboard V1 bright MCX main contactor

suction, Y2 of JBZ holding brake contactor ftanual est and

[Operator st K7-09 = manual keep release. inverter operation ouput driving \eificaton of

\orque, holding brake force detection. The forake fence

detection process lasted about 158

1, [Check whether the digital ube ofthe main]. No fal, qualifiod ae

{control urd is reporting ES + Reported ESS, not quali wes

qualified

166 Door lock bypass Function

Functional requtements and precautions

1D) When the bypass is effective, the nonnal elevator operation control is invalidated, and the normal elevator operation

includes pover operated elevator auomarie dor opening losing

‘haf self-learning is na allowed when door lock is bypassed

When the bypass is vali, i once to enter he maintenance state

43). Maintenance operation and doe loek bypass, noe a jude dar close in pl

only door clos in place valid hen can

start operation

5) When the bypass is fective snd the maintenance is running, the sound and light alarm out, During the operation,

‘here should be an auibl signal and Mashing lights, as showe in Figuce 3

Set parameters

T

IkS-17 isthe door lock bypas signal input, set w 118, the settings areas flows

>and

door lock bypass funtion involves evo parameters KS 7, K5-09 isthe service signal inpu, set 1040,

Function

ede

Name Predeterained aren socatne] Remark

60118 Door cc bss np omni pe

xs.17 [17 Fant keson ie us

bh. Door lock bypass method

The door lock bypass socket arrangements shown in Figue 1; the door lock bypass is divided int nee states: normal

‘sat, bypass ear door, doorway hall door, as showa in Figure 4

1} The door lock bypass hoard hus two sockets SI and S2, SI is a 4-pestion socket, and S2 isa positon socket

2) Sockets SI and 82 share a 4positon pl

3) Nowmal sane

Tieplug is inserted into S1 socket, as shown in Figure 2 bypass board (normal state)

Datthistime, the INS and X9 ofthe S1 socket are short-circuited and the 24V and X17 ofthe socket a

short-circuited

Asshovn in Figure 2, the maimtenan

gal of the main contol board X9 is normal, and the X17 door lok

bypass signal is normal

3) The door lock circuit shown in Figure Sand Figure 0 snot shorted

4) Bypass car door

The Ti-plug is inserted! into the et 4 postions oFthe S2 socket, as shown in Figuee 4 Bypass Board (By

Do

D_ Atthistime, the INS and XY the S1 socket ate disconnected, and the 24V of the socket is disconnected fom

XU.

nal ofthe main control bard X9 i discomnected, and its switched fom

3) Tha is as shown in Figure 2, she

1

1a WFERES

i [ town [toto | Spates | oom | mv OOPS

Save

brake test function KO-19, bit. bit?

Brake SW test point X19.X20 8 se as normally’ closed input, 0

+ The elevator is in no-load state and runs tothe level ofa cern floor, and elevators in inspection mode;

Short connection contol cabinet terminal BKC 9 COM connection, then call the il

Re

the short connection ofthe previous sep, rsa the fuk, connect dhe connection oF control cabinet terminal RK

9 COM, then al heli

ii

Inthe above two ste, ifthe elevator fils E10 an eannot run the tests judd tbe

ffl the ts, remove the shor connection al ese the aul

Test ewotfthe elevator does not have te function of "opening the door ahead oie, opening the dor again and leveling

al preparatory operation”, no need 10 dost 10

2-13 seting UCMP detection function is vali

the main coneu! boa input

1. The elevtoris in no-Load state and runs tthe door zone ofthe mille floor CN

points X1 bright, X2 bright) And close the door in places Place the emergency eles switeh athe contol eabinet i

postion (Thats, the mai contol board input point X9 off) To ease that no One ears or

the emergeney el

leaves the cage, set the main congo panel parameter K3-09-~ 0.15

he main contol board parameter K7-D8 =I (open UCMP test function) can only be set after confirming the door

‘when the main contol boars door seal ous point is valid (i.e. V1 indicator ight

+ Flip the contol cabinet UCMP test wit UKI, and the door look oop disconnects afr the Mis

old dawn the slow up button ofthe control cabinet, the clevatrstarts UCMP test operation, and the elevator uns at

maintenance speed

££. When the ca leaves the door zone (at is, the main control beard input point X1 ison and X2 is off), UCMP

protection action, elevator sop, elevator report CMP fut (E4), the elevators pected 10 un

sistance between the oor door

+ Open the floor door ofthe car (pay attention o personal salty), measure the

tnd floor the ear, no mone than 350mm, an judge tha he testis quae

Afr the es, sith hack wo the eon cabinet UCMP es switch UKE Inthe maintenance tate, aul'=02 oF the mai

los down button of the contol eabines 0

control pane! parameter K-01 reset the UCMP fault nd

recurn tote location arte door zone of he Ma oor (Name the main conto board inp pits XI bright, X2

bright), Set main contol board parameters [3-09 ~0 3m,

ss are qualified, itis necessary 1 confim that theres no problem with the elevator, and then put the

Aer the above

‘emergency electri swith ofthe conta canes nthe automsitie postion 1 restore the elevatoe 19 ademal se

165 Brake force test synchronous motor)

w Operating steps VOW functional correlation state | Purpose

The elevator is closed in normal condition

mon | ERS

1

Py x

Populzre Nyheter

RL hd

Funetion diseription

Both door will ope

«all by HOP e¢ CO

KB-00 se1102,

B-Olund KB-02 set by bitto open

+ UCMP funotion have

cmt WERSSE

__,arcehdal chronjcles

Karrieren hans kan veere ové

Populzre Nyheter

Floor mark

code

2" floor 1

I" floor 2

I floor 3

2° floor 4

ected show because the

ofthe shat wo be de

Default

0

°

boar or magnetic stip

Deft

Tunction

homing base sation

fnetion

Deft

fnetion Default

Salyhi 1F

Detait

fnetion Default

Foor dap

Seby hie 1F0sF

Diglay atmaber

FERESE

‘ibe with a free trial

Save

load any document, ad-free.

me ©~Populere Nyheter

Pele Bis d

3. Shostcieuit HOP addeess:

2

Save

LB

load any document, ad-free.

‘ibe with a free trial

10:10 Gu @w

QQ °%scribd.com +

Karrieren hans kan vere ove

x

Populzere Nyheter

| 7 : FEREEE

wae [Re To [wan | 1 ot

LB

load any document, ad-free.

Popu

laare Nyheter

SN | Funeti | Setting Meaning Explanation

oncode | range

1 [E800 | 3 [0s car top board digit | Select the weighing test input method

pat

1+ mainboard analog

put

2+ mainboard cig

pat

3: car top board analog

put

RET | yO 1005 Only valid when Tor 3 are elected fom

8.0, When s 1, etry out he light lad

self-learning of analog quantity: when is

2. erry our the fl load ing of

analog quansiy

a eT Trae [The torque compensation mathod

compensation selected accoing othe fed sition

TF Tava mode) occa

( Pretorque _aviomatic

7 Ken NoToad, -100%%-100%% [Applicable when K-02 slects an

Full oad: 10076-10076 | quanti orgue compensation

5 | xo Displays the eurent load ofthe elevator

© [R05 | ws ‘Only valid when for 3 are

y_| Hall toa! ks.00

|) ROS | ys | FullToad: 907%-100% — | Only valid when | or3 are selected from

7 to2_[ Overtoads 102-110% | ks-60

OF Floor 8 ight and fll | Only valid when | or 3 are selected fom

lod point Senings 400, Show the igh fod and il oad

. values ofeach oor fom 1 8 after

learning

Kee ‘Only valid when | oF 3 are selected fom

Floor 9-16 i 18.00, Show the lihe load and full oad

° load point Sening valves of each for rom 910 16 ater

learning

cm Only valid when 1 or 3 ae

bo Floor 17-26 light and fall | 43-00, Show the

loa point Se values ofeach oor fom 170 24 after

learning

x

Populzre Nyheter

vs. previous recipe ASC Code: G0066P101223M

6 Star Hine

nul time

Star time Normal set 19 1.0

Enultime

the level of te elevator are as follows

SN | Funeti | Setting range | Meaning

Explanation

1 [xeor [-100-100mm |

100-100mm_| a

x03 | -100--100m | U

oor

x04 | -100—100mm | Down level ofeach floor

by adjusting K-08 and 4-0

XW Weighing Device Operation Description

The system parameters related vo weight d

ping areas follows

mon | TERRE

Save

Db

load any document, ad-free.

3) Normal leveling sensor feedback, wells and switches in place

4) The clovatr atthe bottom, ion switeh action:

5) Noi dhe ful alarm state

34 the parameter K-08 flor learing set (93. then tum the contol switch AK 1 NOR position. The lift automatically

moves up slowly and leas the Moor he

1) The floor indication changes concurrently with the floor ehanging lit moves to the tp Moor and touches the

‘op floor and stops, the “sele-leaming’ mode is amomatically switch “OFF” and se-leaming

iscompleted

‘heck the stats oF evel sensor and forced spas ch

vitch, After adjusting the distanee oF ores

or or the signal positon of th

ing of floor height again o ake the elevator run in the best stat,

44 Set the speed asymehronous monitor point

In oder further avoid the abnormal spas oF the elevate, itis necessary wo set the abnormal speed monitoring

SN] ode | Setting Explanation

1 [xsi [1300

f han the monitoring value, the

te set value of K3-10 shoul

value 3-11, monitoring value is obained afi

shat learning

11 | 1800 | Seung value

ation monitoring poi, the set vl

5. 1F the project has UCMP function, k2-3 i

[at shis tise, v0 mia consol board input points

{CMP function ater the completion of shat learning

«tobe added and the function code

SN. Name ofinput | Position New function

xz ext

parameters hat aes the comfort of high speed

me Pieter —t

ADVERTISING

x

we ~=Populeere Nyheter

2ad without ads.

a 2 a oo

G 0 Ll oo

co so Lb

a 35 Pr

EL 5 PD 0

2 1S PB

BS 0s Pa ol

Et 0 uw

E « w

E6 05 uo ow

E us

and Cl then changing A186 co the defiult value

king properly? The It slow down switch whieh}

ADVERTISING

Dole SW

Dov ial Lint SW

bugsing | Paramete busin

Debuging | Param Setting value ee

al n .

aS te ie

Ma i =

AG BR 2

a7 a or

x i a

a : 12 oe

2 n Hy 8

z

ad without ads.

Save

Subscribe with a free trial

Populzre Nyheter

ea NNT HSU EE

icons #1001 Cee CeCe ‘ASC Code: G0056P101225M,

Ti disance of2™ slow | Thediaace of" slow

et downswitch down switch

Dams

Ds

(CTRL inte

Limit and final iit site installation requ

Up inal iit Sw

150-180nm

Upbimi sw

sy 30-50nm

Tot v aa

Upper limit, upper limit switch installation requizements

cumridiay

Nabiznip

Virtuell frykt: Al tar over

ve | ons eam

71 Starting torque compensation debug

tule forthe old

en using the encod

od

J” «Switch Installation Specifications

S.Linsallation requirements of slow down switches

The proposed installation:

ight compensation

tamochuan encoder, when K-02 is sat 4;

‘weight compensation

der ERN387, when k8-02 is 00 1F

-16, and the zero-peed stat delay in 3-16 is> 0.4

we the zoro-speed str tine in 3-16, uni the elevator keeps torque compenstion Whe

is opened

fe boot and the guide eu, 1Fyou do nos un the er a

crmuriciay

Rie HE

iFE

ADVER

TISING

Chicken

Cerrar

‘vs. previous recipe

Virtuell frykt: Al tar over

Nabiznip

‘emit excitation sounds

©) Gently move the elevator in inspection state, observe Whether the clevator is runing inthe opposite direction

tnd whether the main board has reported faults. Lhe direction is eppasite, st the unning direction in 1-07 of

be reversed an thon conduct self-learning again. If dere are no other problems, thon observe whether th

curt size is noemal

165 Asynchronous metor rotation self-learning operation steps

8) Ensure that the UVW power line ofthe motor is connccted 0 the UVW terminal port ofthe invert

bb) Set the main board K1-01, k1-02, k1-03, K1-04, KILOS, k1-09 according to the purametces of the moe

hameplate and encoder, IF there is no pole number ar log number (log number is 160 times oF dhe number of

poles} on the nameplate ofthe host machine, it canbe calculated as P= (120*0)N, where N isthe speed of th

rotor is the frequency ofthe host machine. P is the numberof poles ofthe host machine, and thee filled ito

1-06

©) Make sute that the encoder ofthe main engine is connected 1 PG and release the holding brake for shoe ting

bby manual or eletre means 19 monitor she value oF the main board parameter KA-06, When the

088 up

the value shouldbe positive; when the car goes down, th Value should be negative 1° not, invert he value o

the encoder disetion of K-07, and thon

lease the lock brake briefly by manor electric ms

the value ofthe main board parameter 4-02. When #

sup, the value should be positive; when the ea]

goes down, the value should be positive or negative. Hn, invert the value oF the pulse digetion oF 1-0,

8) Elevator traction machine and load (wire) flly release, open the brake according to the principle diagram of th

bake circuit K1-06 valu, K-08 motor selP-eamingfmeter is set 10 L, MCI comtictor absorption, mot

sur turning, if ther is no flue, MC contactor is eleased, thon the motor shows tang is tues, i the

same way and then the K-08 selEHeaning parameter is set 0 the motor into 3, selearaing, to complete

second step afer the succes, then KI-08 motor sel-Leuming parameters se 10 10, to complete the third step

self lemming, thea K1-08 motor selPearning pa Tea]

chal whether the Value of 1-06 is different fiom the previous Vale. HF thexe is no ehange, please contian|

smeters st 11,Complete the fourth step of se learn

whether the caning is sucess

1) Gently move the elevator in inspection state, observe whether the elevator is uning inthe opposite ctestion

and whether the main board has reported faults. Lhe direction is opposite, st the uaning direction in k1-7 1

be reversed, an then conduct selPleatning again. If dere are no other problems, then observe whether th

Il, The «

tor starts

nd stops debusging

Have aes sun after seting parameters asthe following table , according to moter power and motor characteristics

may cause different star effects, the defbult parameters en be adapted wo most machines, so set parameters as the

following tablesnd havea test ru, observe when the motor starts Whether is wil rollback and the sound is normal oF not

you meet some abnonnal situation then reset those parameters and chock ithe sound is eliminate

[: a Definition |

rani FERREe

Function | Sewing

when doe

10:08

Read without ads. Subscribe with a free trial

eee eens me ee

©) Gently move the elevater in inspection sae, obseeve whether the elevator is sunning inthe opposie direction]

und whether the min bourd has reported faults. [the direction is onponit, set the running direction in I-07 af

be reversed, and then conduct selF-letning again. IF there are no other problems, then observe whether th

curreat size is normal

63 Syn

mous motor rotation self-learning operation steps

4) Ensure tha the LWW power line ofthe motor is connected othe LIVW terminal pot of the inverter

|b) Sor he min hoard K-01, I-02, kI-08, k1-04, 1-05, K-09

sing 10 the parameters ofthe motor namepla

and encoder, If her is 0 pole number or log number (log number is Wo times ofthe number of poe) on the

be caleulated as P= (120*1)N, where Nis the speed ofthe motor, Fis thd

frequency of the host machine, Pis the numberof poles ofthe host machine, and then filled into kl-08

©) Make sure thatthe encoder ofthe min engine is connected 10 PG, an

se the hong brake fora shor tim

up

the value shouldbe positive; when the car goes dovsn, the value should be negative, IF not, invert he value o

by manual or cletric means 40 monitor the value ofthe main board parameter KA-06, WI

the encoder dirsction of 1-07. and then release the lock brake briefly by manual or eletrie means to monte

‘he Value ofthe main board parameter 402. When the

sues up, the value should be positive; when dhe ey

10 fn, invert the

of tho pulse direction oF t-00,

ves dow, the vl should be positive

18) levator action machine an oad (vir) fly «

‘pen the brake according to the principle diagram ofthe

brake circuit, K1-06 value, K-08 moter sel-leaming parameters set 10 L, MCI contactor absorption, sot

‘sur turning, if ther is no flue, MC contactor is eleased, thon the motor shows tang i tues, i the

same wy and then the K-08 self Ieaming parameter s set the motor inta 3, seLeaming, to compete she

second step afer the succes, then K-08 movor sel-lesming parameters se 10 10, 1 complete the thd! sep

self lemming, thea K1-08 motor selElearning parameters set 11 Compete the fourth sep of se-learing. The

check whether the Value of k1-Oo isi

erent foi the peevious value. IF there is no change, please contin]

whether the ning is success

©) Gently move the elevator in inspection sae, observe whether the elevator is running inthe opposite direction}

and whether the main board has reported faults. 1 ction in kl

nection is opposite, set the ruaning di

be reversed, and then conduct selPlearning again, If tere are no other problems, then observe whether th

66.4 Asynchronous motor stop ype self-learning operation steps

) Ensure thatthe UVW power ine ofthe mot

bb) Set the main board KI-01, 1-2, k1-03, K1-04, KI-05, k1-09 according

is connected yo the LVW ternal port oF the inverer

nameplate and encode, I there is no pole number or log number (log number is sso times of dhe number

poles) on the nameplate of the host machine, i ea be caleulated as P—(120%H)N, where Nis the spea of thd

motor Fis the frequency of the host machine, P is he number oF poles oF the host machine, and then filled ico

1-04

©) Make sure that the encadr ofthe main engine is connected x0 PG and release the holding rae fr short tg

bby manual or cletric mcans 40 monitor tke value of the main board parameter KA-06, When the ca

the value should be positive; when the car goes down, the value should be negative, IF not, invert he value o

the encode direction of 1-07. and then release the lock brake briefly by manual or electric means to monitor

the value ofthe main board parancter K-02. When #

sup, the value should he postive; when the ea

oes down, the value should be positive ur negative. Yao, invert the value of the pulse dicetion of 1-00,

cunea TERESe

SPST SS apare = Ties

les

TTT

sleHey]

Read without ads Subscribe with a free trial

12 _[ Ove lo NO input $4_[ Over load NC ipa

13_[ Up Releveling sensor NO input 35_[ Up Releveling sensor NC input

14_[_Down Releveling sensor NO inputs | 46 | Down Releveling sensor NC inputs

15 | Door motor overheat NO input 727 | Door motor overheat NC ing

10_[ Cartep INS NO input 2_[ Car top INS NC inp

17_[ Cartop slow up NO input [29 | Cartop slow up NC inpat

15 | Cartep slow down NO inp 50 | Cartop slow down NC input

|v). Traction machine(Motor) selJearniny method and procedure

This step have been finished before eaving the factory, When commissioning, the selF-leaming can be done agai

(64 Tuning inssucton

) Magnetic pole position identitication must he cared out before the fist operation of the synchronous motor

tnerise it cannot be used normally and is extromely dangerous;

bb) Forsafay, the elevator mst motor self-learning under the maintenance stat, can choose

stop the engin’

seléstudy or rotary engine's study, fiom the operating convenience and safety, we suggest 1 stop gd

selflearning, rotate engine's self earning, the motor can’ hang rope and brake © open.

©) During the learning proces, dere will beat large excitation sound ofthe synchronous mevor, andthe process wl

last for few minutes, Ihere is anything wrong withthe leaming proves, it should be stopp media.

During the whole process, if dheve is any seported fal, please start the sel earning again,

0) When replacing the encoder ofthe synchronous moror, the the motor must be carried out again

‘When replacing the wiring of the host or the PG card and the drive of the inverter, ts also ecommendd t

re-Jearn the sol earning ofthe motor i there is no empirical operation from the perspective oF safer

©), During te whole sel Tearing proces, all personnel are prohibited from entering the roo ofthe car, the ca,

well ad other be

iors that lad 9 da

(62 Synchronous motor stp type self leaming operation steps

) Ensure thar the UW powcr lin ofthe motor is enanocted 10 the UVW terminal port of the iver

1b) Set the main board k1-01, kI-02,kI-03,k1-04, 1-05, 1-09 according to te parameters ofthe motor namepla

and encoder, If ther is no pole number or log number (log number isso tines of the aumsber of pole) onthe

aoplate ofthe host machine, ican be calculated as P (120°F)N, where Nis the speed ofthe motor, fis thd

1 ofthe host machine, Pis he numberof poles the host machine, an then Filled into k1-04

©), Make sure thatthe encoder ofthe main engine is connected 0 PG, and eelease the holding brake fora short ting

boy manal or eletrc means to monitor the value ofthe main board parameter KA-06, When the car goes up,

the Value should be positive: when the car goes dovsn, the Value should be negative, 1 not, invert he valu o

ths encoder disetion of K-07, and thon release the loc: rake briefly by manual or eletrie means t0 monte

the value ofthe man board parameter 402, When the car goes up, the value should be postive; when the cay

goes down, the value should be positive or negative. Lao, invert the Value of the pulse direction of 1-00.

4) Record the Value of the K1-06, sot KI-08 ho 1 fault, MCL contacto

learning pavaunotrs to 13,38 thre

will sick, rive motor, excitation sound, afer fRW minutes, 3f there is no ule wer the success OF MCE

contactor will wloase, motherboard shows tuning is success, hen again soe KI-06 values ean and previous

value if there isa difference, i there is no change, pease confirm whether tuning is sucessful, i K-08 in th

eur cun WERR Se

parameter can choose, You Will aged to set thre 1 and 4

complete motor steaming

ADVERTISING

BETTER

Chicken McDo

vs previous recipe

Tap To Order

sleHey]

Read without ads. Stren Rar)

A11_[° door tight eurain 1 | KAPA | Cirton Kos 3 Ne

112 | doorlighteurain2 | Kapp | Cirton K5.05 3 NC

As spare Carton Ks.05 mm

mM Upreleveing ves__| Carter 506 wo NO

M5_[ Downreleveling | vex | Cirton K5.06 oo No

Alo Overload Kor | earn K-00 oo

Aly Full load xzr_| Corton K-00 oo

20 spare Cartop Ks.00 ow

Conrespondin

output | nsustion of put | Coot | Subordinate | CPIM | parameter |

point point output point | position ne 5

noo | Frondooropensignal| nem | Carp Ks.07 oo

Front door elose Carp ow

som ks.07

Bol signal

Front dor Sow Carp co oo

wos Ks.07

B02 losing signal

B03 spare a7 ow

Bo4 | Back door opensignal | WM | C2 KS ow

BOS | Back door close signal] GM | Cp KOT ow

Back door Slow CaroP KOT ow

mont

B00 losing signal

bit fan FSi, sz | Cre KS07 ow

Bi Carton KS.07 o

Bis sue Carton Ks07 ow

Bit spare Carton KS-08 o

BIS Upamive gong Carton =e a

Bio | Downanive yong Carton KS.08 ow

B17 | _soundsigh alam pe | cep R508 oo

‘Car 100 input terminal function definition code table

Cote] Input point description | Code [Input point description

00 | tins

1] Door 1 ight cunain NO inpue 35_| Boor 1 ight cunain NC input

(02_| Door? light cunain NO input 34_[ Door? light curtain NC input

(05 | Door lly open NO inp: 38 | Door t filly opea NC inp

(4 | Door? fly open NO input 36[ Door? fly pea NC input

(05 | Door 1 fully lose NO input 37_[ Door 1 fly close NC input

(06 oor? fly elose NO input 38 | Door? fly close NC input

(07 | Door 1 safer ede NO iat 29[ Door 1 safety edge NC inputs

(8 | Dour sary edge NO inputs 40 | Door safe edge NC input

(09 Light load NO input -41_|Righe load NC input

10 Half oad NO input 42_[ nal ood NC inpus

1 Full oad NO inp 43 [Fullioad NC inp

coma WERBRE

aif pain Bene | cma tly ORE

we [we | wen om i a [ever Da

sleHey]

Read without ads. Subscribe with a free trial

bee LT dell 2 ee ae —

i 10 the Field neva

Instruction of input

point

§3 SCRIBD

Trusted by over 1 million

members

sleHey]

Read without ads. Subscribe with a free trial

SCRIBD

ead without ads.

lions of documents at your

sleHey]

Read without ads.

Subscribe with a free trial

6 | Ring cup Redback NO] 38] Running outpat Feedback

= | P| xcnpe

G7 Brake ouput aback} 39] Brake ouput Teedback NC

ng input

8 [inspection signal NO igus | 40 | inspection signa NC ipa

09 ispecron pwardsigal NO] a1 | Tspecton upward signal NC

ng inp

{0 [Inspect Gownwvardsigal | 42 | Ispecon dowawardNC

Nop inp

Fire prveeion signal NO Fite proecion NC ap

np

pin aad NO Tp [ip ni aa NC

3 [Down mit signal NO pat [#8] Down Timi sina Nn

4 [Over NO inp 4 Overlawa NC npn

Full oad NO ious 47] ull fos NC input

5 w down | NO ap ‘Up slow down L NC ap

7 ow down NO np ‘Daven slow down NC

[ip slo dn? NO aa Tp low down NC na

3] Bownslow down? NO ipa evn slow down NC np

20 [ Upslow down NO input Tp slow dovnd NC np

Down low down NO ina Down low down’ NC ip

‘Dor slop fedbask NO ‘Door al ouput dash NC

np | ino

Fireman SWNO put 3 [ FrenanSWNC par

‘ocr operatrt ight eu ‘Door operator Hight cra

np Ne inn

35] Doar operator Hew o oper igi arn

No inp NC ip

36 Bake otpur bask 1NO ke opr lhack VN

ng inp

over ae soy 3 Power hus enero

opratioNO inp puraio NC ipa

BE | Flevatorlock sgnaTNO apa | G0 | Elva lock inal NC pan

Salty signal NO inp Saf sgnal NC input

30] Syncronous motor trea Syishronos motors

fled NO in fiudbad NC input

31 Pdoorlockcicut eedbak | —@3—] Door lock cia feedback NC

XO inp inp

| Door periorsafay gear Door opto say Bea

No

Toor opeararatayeeara | 5H | Door aero maa nar

Xo. | lic

Moir ovata NO 39 _| Moioc owe NC

68 | Earthquake signal NO; 100 _| Earthquake signal NC; |

69 — | Rear door fen NO; TOI | Rear door rien NC

70 | Lighead NOs 102 Lied NC

71_| Fo NO; 103 Half NC

72 [Fire base or stchoverNOs | 104 | Firebase Toor awinhaver NC

ets

sa ERBSE

7 it Ol

ne [at Penh m 1 Teer]

SCRIBD

ead without ads.

10:06

Read without ads. Subscribe with a free trial

‘Coca-Cola is a trademark of The Coca-Cola Company.

© 2023 The Coca-Cola Company. ASC Code: G0066P101223M

xu | UPlistsiowdowa [| Shater | yoy w | xc

swith wp

‘Down frst slow down Shaft car

x5 Xk K5.02 w |xe

swiet | wp

Second sow dows Shatt car

xi6 xSK2 m | we

swt Mp

xI7 we

XI [ser orm | K5.02 [No

x19 | Loft brake switeh BI “— » | xc

x20 | Right beakeswitch | pk2 | MEP TK s.o m |e

Star seal feedback IX m | xo

OF | wR user NO.

Fie mun KxY | Fike NO

Lock signal YE | tock hax No

Ts w

x25 ection 03 | Mainboart | K-08

Car door signal bigh o

xz0 | voliage dewection 24 | Mainboard | 5.03

point

x7 22 | Mainboard

point

Back door signal igh

x28 | volage deection 224 | Mainboar

point

x Spare

Mainboard input terminal function definition code table

Code | Inputpoint description | Code | Input paint deseription

0 | Unused

a leveling sensor normally [33 Up leveling sensor normaly

7 _| Down eveling sensornonnally | 34 nFeveling sensor normal

pen input snp

| Door ze NO Tap 35__| Door zone NC apt

03 _ | Satay ere feedback NO 30 Satay ircut Feedback NC

input np

05 | Doorlockciair RedhackNO | 37 | Door Tock circuit feedback

pu NC input

aS

aw Re Be

z CRT NY WET

mare | . F

SCRIBD

ead without ads.

10:05 @

Read without ads. Ted eer nur

KN ‘Safety gear switels [Car boron small oom) / er top

(rooms)

YE VI. VIB | __ Buller Swich pit

SK XK4 | Upand down lin shat

suiteh

VK Govemor switch Governor

KYD Traction ropeani-ofT Rope hea ‘Only for2:1 vope rato

ssviteh

AKT ‘Sop snitch come Control cabinet

x Control cabinet

PCK ‘Motor (only for elevator with room)

cat door locks an all the landing €or locks, in the normal state, Mainboard high vo

monitoring poi

‘door X28) light un, And one by ane manual ation, make the mainboand high pre

ack door X28) of

5.6 The default function definition of mainboard input points is as follows, Confim whether the input point definitiog

‘caresponds 1 the following able aceoeing to che field needs

Conespondia

Input | Instruction ofinput | Code ot | subordinate | OP" | rameter se

point Point input point | position a ‘

x loving woe cn carp | KS01 w [xo

a

x2 | ucmPdoor zone KSo1 ov [No

vgs ose dor ony eon w Ino

ace detection

Cont

xt al | xson 0 No

XS_| canguake MR S01 ow _[No

Devstion of MCI and Conta

xo Met Ks! oo |ne

xx | Pestonotimte Tay mt Pea w Ino

xe ARD signal MR S01 w [No

Inspection / nama Control :

xo Ksol 0 |ne

signal inet

Conta

x10 Slow up Ms KSo1 0 [No

xu Siow dow Mx Kool w [no

xi2_| Uptiminswien | sxaqiisy [shun K-01 a Is

x13 Downimicswieh | 3i3 Sha K5.02 w [Nc

rane TFERESE

SCRIBD

ead without ads

lions of documents at your

x

Cheek the external circuit

‘

Pre-torque function

Running comfort adjustment

¥

t

Basie parameters setting, Sh

ul SW signal check .

‘Other function test

Slow speed run

|

t

+

‘Motor Tuning

7

Toor self-learning

[|__

\V, Peripheral line inspection

Tum on the main power

Commissioning flow chat

mrcasure the Voltage among R, S,T, it must satisfy as below

RS

ST

Ra

AC3ROV27%

Check the Phase sequence relay in working

power supply is failure or wroi

‘Check ifthe lift is in Inspection Mode:

34 Che

all safety switches, safety cireuit in the normal state, Mainboard high voltage test point X25 I

the alarm indicator is ON, please check the3 phase AC

up. The

safety citouit switches are

Code [__ Name Respective positions Note

ay E.stop switeh next to Beside the motor Only For machine

the motor oomless elevator

ADI Floor E.stop switch | Shaft inspection and lighting deview

AD. Pitstop switch | Pit inspection and lighting device

KXZ “Governor rope off Pit

swith

7K COP E.stop switeh cor

at Cartop stop switeh | Car top maintenance lighting deviee

SDK Car top lock switch Car top Only for machine

roomless elevator

Continued table

Cole Name Respective positions Noie

KT ‘Trap door Switch Car top Only for machine

roomless elevator

THLTL (71M) 1

RS

a

Check the extemal eiveuit | Pre-torque funetion Running comfort adjustment

Basie parameters setting Shaft SW signal cheek (Other Function test,

t

Parameters recording

4

os)

Motor Tunin, —_—_

Floor self-learning

| | [

\V, Peripheral line inspection

5.1 Tum on the c among R, S, Tita

satisfy as below

AGwOVITs |

ncsovare |

Re ACRE |

check the Phase sequence relay in working nowmal or not the alam indicator ON, please check the} phase

power supply is lee oro

Check ifthe lit sin Inspection Mode

5.4 Check ll safe switches, safety iret in the normal sate, Mainboard! high voltage est point X25 Highs up. Th

Cote ra ee Noi

ay TEsop sich next to Beside the motor Only for machine

AD1___[ P'Floorti.sop switch | Shaft inpeion and fuhing devi

AD Pitstop switch | Pit inspection and lighting devise

OZ Govemor rope off Pit

7 COP Estep sit cor

aI CartopE sop switch | Cartop maintenance ighing device

SDK | Cartop lock switch Car top Only for machine

Contnsed ble

Cole RES ren enoES Noe

KT Trap door Switch Car top Only for machine

ac

cranial WERESE

SCRIBD

‘ead without ads.

inverter replication

select: 0-1, Osinvalid: I-valid: ]

setting: 0-3, invalid: Lead; |

Deopy; 3-verifys

‘Mainboard replication

select: 0-1, Osinvalid: I-valid: [ 0

setting: 0-3, O-invalid: Lead: |

2-copy: I-verify:

Read: write the inverter parameters to the operator

verify: compare operator and converter parameters

\write the operator parameters to the inverter

(ODELA

Fault analysis

F: 00

s. vt

T:_monthiday/hour/minute

Tnverter monitoring

BV-busbar voltage (U2-08).

OV, output voltage((2-07).

Ts output current(1i2-08):

S:output speed (U2-04).

Mainboard monitori

Sigiven speed SPESPI

communication quanlity, 0-9,

S-highest, O-interupt

W: Weight data percentage

CTR + car top board

communication quanity

Mainboard monitori

Change trom 0 to | when input

and outpat ace valid

input; XO-X24

output: YO-Y7

Car top board monitoring

Change from 0 to 1 when input

and ouput are valid

Input: AQ~A7, AIQ~AIT, A20

output: BO-B7. B1O-BI7

COP board monitoring

Change from 0 to | when input

and output are valid

input: X0-X24

outputs YO-Y7

First two failures

The first 50 failures

IV. Commissioning flow chat

cries WERBBH

TD) ANE

Bee comossiy

Pi Tost [ek ven [a0

KCO1 missing phase] enabled: O-invalid always | T

detects 2-detect when running:

= Onl ata certain speed

voltage: 0.0%~50.0%

Ke02 Ouipat missing

phase detection

0; no detect 1; Deteet one phase | 0

‘output missing phase 2+ Detect

the missing phase of the output

above two phases

Koos motor overload 0.05.0 min 10

protection

Keo Main circuit 150V=210V

uundervolta 2 ooV~420V

Ke0s ‘Overspeed detection 0% 120% 115%

0.02.0 00

Kone Speed variation 7-50 10%

0.0~10.0 8 0.58

KCO7 PG Breakline detection | 0; nodeteets 1 detect 1

0,010.08 20

Ove

clertion detection | 0: Detect when the power is on | O

1; Detect only when entering run | 1

0.0%-200%

Koos | Run tine proweotion (0299 S

KD KD-00 Baud rate setting 0: 20K-1 o

KD-01__| Monitoring address 0-256 1

KF Password ‘0000 como

‘mainboard parameters initializes O-Nalh

update Factory parameter

initializes 0000 initialization

fault: 0 23330- Data initialization withthe

exception of shaf parameters and

‘weighing parameters

Faull: O-invalid; 1-eset UCMP

fault, 2-esctall full, 3-Clear

fault record

KF KFS [Taverterparameterupdate | initializes O-Nully

initializes 0000 1110- User parameter values are

maid initialized

2220- Factory parameter

initialization, 5550-0PE04

Ie reset

fault : O-invalid; 1-Clear the

contents ofthe inverter U2/U3

K-00 | Tanguage setting chinese’enelish english

Mainboard: english

inverter: chinese

cri TFERSae

SCRIBD

‘ead without ads.

10:02 @

Read without ads Ct erer e ue ctk al

vs. previous recipe ASC Code: G0066P101223M

KA? | Expand) board Monitoring valusr BIO“B22

coulput state

KA-Is [HOP communication state | Monitoring values 1P-04P, | O3

1 display by bit

xe KE-00 | Door machine 12 T

squaity

EEO Door operitord Setby bits 1F-O8F

service floor

KBO2 | Door operator ‘Setby bit 1P=0HF

service Mage

KO | Door preotion 599 iz

ome 2

K-04 | Times of falure om

‘opening and closing

KEnOS | Operating base (0: clossnormallyy Te waiting a

station door sate the base floor with door opening

+ waiting at every floor with

‘door opening

Kiste | Door holding ime T=1000s 3

K-07 ‘base floor door open hold | 110005 0

KB-O8 | Closing delay tame To=10005 130)

KB.09 | Special door hold 10-1000 30

KB-10 | Forcod closing ume S188 120)

KB | Open mode (00; Front and back contol o

simultaneously

1; Extemal call independence

inernal call independence

(02: Extemal call independent,

‘ntrnal call atthe same tan

(03; Extemal call independent,

ingornal call manual

xe KE-I2 | Door contol biiD: Non - door zone ean open

selection

during maintenance,

‘8n00c00000000000 5

itl: Open door in postion to

hold open outputs

birds Manual consol through door

‘opens only one door

bird: Continue 1 lose he door

after the doors fully losed

bites spare

bis-bitis: sp

[ke Keo [inverse overkoas “Tempemue 50-150 3

Action Selection: 0- Slowing

down sion: I- Free nunning

stop:

cre.r1 (7 WERBBR

ea

smesgency stop: 3-keep

10:01 @

Read without ads. Subscribe with a free tri

Floor al ae

afo0o

onion.

Ko 9-00, Tdle return to base station | 0-240min (5 3

a ec :

fan 0-248 4

wie sp dae a w

Toe Aaa gaw oupae delay OOD 7

han Wn vr dy

st he dese

ged cn he areal

2, When the set value is < 10m:

he lea yan os

Za ee | Ramat TS 7

Eastman So tT

a ibn OOD

ead an

a

ca ease emer arp oar Wo.00

sarod Cortend. 20000

caPtoed

| eras FEASTTIDOO

ore ROM 100

TRIE] Spent command Monitoring values Dipay %

voce

Kate Raita Moning wahe7Dies

Spl spec inboard hel

tolomne oapel

ea tar ‘oni

fa —Soaptomet Montreal

a ening value

Rat Oupurvalage Neniongvaie

a

Tae [pare Moning ane 7-108

Eats [outat power Moning value 9.99

ea-14 | sommutiatonjanniag? [CANIO“9CANEDSS sigh

cansos —_canens [gna

ais | commanieten mine? [SPL hah

Te [ Bap barat aie | Monorg ate ADO-N

Ys

t ic emai ERS Hie

: ' Ta

L 7 I r 1

; mb = I

SCRIBD

ead without ads.

10:01 @

Read without ads. Subscribe with a free tri

E705 | Door enabled (0-1, 05 permit; 1: forbad [0

R706 | Overload enabled (0-1, 0; permit, ty forbid 7

Nowe: only’ nin once, after one

amomavic recovery is allowed;

K-07 | Limit enabled (Ont, 05 permit; 1: forbid [0

Nove: only run once, after one

amomaric ecavery i allow

R708 [Testfunetion selection | 0: invalid v

L: UCMP funetion test

2 Skidding test function test

Sot est

17 Rrow | Taqusesrofhale Tos [modes ofVauionatcmanal | avtomate

times, 1440 min time +1440

KE] Reo] Weighing amas slenion | O- cartop oar digalinpans [3

1s mainboard analog inp

2+ mainboard digtal inp

3 cartop board analog input

RED] Weighing wat — teaming PO=100% 7

KEOT | Petorque section Ta: Tongue compensations TF

IP: Through mode (Pretorque

function "

EROS | Pretorque —sompensaton | No oud, 10071007 “30%

value Fullloade -100%-100% | 450%

Keo! | Curent ade ie laoes

Te sein inte car | Light lod 1o-20%0

Halfloals 20%-70% rs

Only valid when 1 and 3 are | half loud

selected from k8-0 50%

Ree [Toad sating inthe war2— [Ful oad 907-1007 Full Toad

Ove oad: 102-110 os

Only salid when | and 3 are | Over load

seloid fro kS-0 12.

REBT Foor Ta00'000-2Fupo7bo0 —PwodioeD

3000000 44:000'000 | Sampling

7F:0001000 —sF:n00,000 | learning

sequisition

No. loai/full

ie, self

oad

K&N | Floor load 15 Soon TOF Dae | on0 THT

Ke21 L1F:000000 —12F:000/000 | Sampling

value, self

1000000 16F:090/000 | learning

acquisition

No. load/full

load

manne) TERR

| z

§3 SCRIBD

Trusted by over 1 million

members

10:01 @

Read without ads. Otter ee Rk al

ee bre itd) bes Rim ST ogo}

SCRIBD

‘ead without ads.

llions of documents at your

10:01 @

Read without ads. Subscribe with a free tri

ae ‘pe. Chicken MeDo-

with DOUBLE RICE & Drink

oslo > ‘90 coe: 60066101225

Te Fag Bo Anon Se Gow Be] SER

Bi Ana set of adhesive

bio Night secuity Moo

bi downs ek seni

Sti comelpek

bi Uea shan Ae

ba Ueto foe up shw

bra Ui shr or dwn slow

os

BiH. High sped slow down

Tit mode (gs toe)

Bia: deen fe dor

Biss Lowe lea opens if dor

nor in lc

Mar soneonerah Gow

on

el etm ear a eee — Pee

No renondng HOP] scion coe

sate

seins | 2 ever

tim sai

he aster

eap

— Sens

cnn Re Be

= | Ca Cio wae

cop en

ao Ta]

10:00 @

Read without ads. Tren ee R ck al

erred) De OTTO 8

SCRIBD

ead without ads.

10:00 @

Read without ads. Subscribe with a free tri

KS08 [Car tp board ouput | BI4-BIT

selection 2 See". Input and output points

for dows

es E509 [CoPboudinpurselosionl | X01: ot N02 02 NOS: | Oo. anvali

xoI-X12 3 ol: ArT

Settings and monitoring, the | XO4: 04 X05: 00 X00: | 02s bypass:

background will be lit when. | 00 fireman

the input ini valid xoT: 07 x08: 09x09: | 04,

o independent

X10; 10 XUls 1X12: | 0S: spare

2 os spare

- OS + spares

KS-10__ | COP board input selection Xi 1X15: | 09, puser off

XI3-X19 sigoal

Settings and monitoring. the | X16: 00 x17, 00x18: | 10 Driver

background will be lit when | 00 bee)

the input point is valid 9: 00 upssar

a a Ie door

sop:

12+ lighton

13s fan offs

wy VP

13+ Driver

crientod

downed

Kail ‘COP ourpat selection 01-08 0: invalid

Sertings and monitoring, the | Qo: 06 01-05. spare

background will be fit shen | Q7; 07 Thenestaftheseeo | Qo. ICeard

he input point is valid fn, over

Ko Ko.00 | Lili loor “Top floor

Lowest flor

Kool | Base sation Parking base

Lock base

Koo? | Fire asesation First bas

Second hase

Koo HOP senive Toor ‘Sorby bits LO

Ken | CoP service for ‘Sexby bits Los

e058 | Grip come ‘on om

Ko.00 [Lit ake Leas

Ko-07 | VIP floor top Hoo

Ko-08 | Seeurity four

Ko.09 | Down collective ime: 00; 00-00; 00

Ke-10 | Down collecnve times 00; 00-00; 00

Kell Sept ime service S-sta time, E-end tine, Waveek

time: 00; 00-23: 59

Set by bit from Monday 10

Ko-12 | Separateiime service | Toor | Ser hy bits IF_64F

crm (7

10:00 @

Read without ads. Subscribe with a free tri

ed rere ind teem Rie Te stot -8

eos | Canoe pasion

Reo] Upward te

K408 | Downlink floor-by-a

406 | Maxima pl

eo7 Foor puke

Kaos ay play

Koy splay

iS 5-04

S01

ut and output points!

R50: ‘Mainboard input slecton

ur and ouput point

S05 | Mainboard input soletion

put and output points

KS: Mainboard ouput

nd ouput points

for deals,

S06 | Cartop board rapa saleerom

board ou

SCRIBD

ead without ads.

9:59 @

Read without ads. Subscribe with a free tri

kos

rs KAO = speed Or 100.0% | O%

Ddata[73] oos

time : 0.0-10.0

74]

000 | 0700

sO 1.50

ends 0.15-10.08

700

a 1.50

nd: 0

o-oo ET)

os 000

(0000 mm,

Kaos | Relealinglincion

309)

Ka10 reduction 1500

comm Wee reduction | Set value: 0-9999 mums i800

srvaluc: 0-9999mms | 0

Kor

Ker

Kee Set values (9909 munis

Mor 0-9999mmis

B15 | Brkedehy ame ‘open: 0-10.00 opens 025

offs 0-10.05 olf: 02.

FERRER

SCRIBD

‘ead without ads.

9:59 @

Read without ad Subscribe with a free tri

. |p. Chicken Medo

Peers Fwith DOUBLE RICE & Drink

fiche mame one ASC Code: COD6EP 101203

Kilo | Facoder wie bak [0~l00S(Las than 058 the [?

desction time 0.08 | detection funtion is invalid)

RIT otetine resiines | Minimum vale; 0.0000

(synchronous machine) | Maximum valuce 65.0000

Kia | Raved slip esyncinonows | 000-2000 HZ

machine)

ooo HZ

ra | beake Teastanse | Minimum vanes 010%

(synchronous machine) | Maximum value: 40.0%

ono

Kile | No-load caeent} Minimum values OA

Gesyneinonous machine) | Maximum vale

Eis] motorinducunes Minima vae0 Domi

Maximum value;600 00mHt

motor stator 0.000-05.0006

jal Anale:0:0-6500.0

Langle:0.0-65000

Tndussd voltage system | Elba

© R200 | Tow weeding Proportional guia 0.00-00.00

nigral ne, 000 10,000

R201 1.0%%- 100.08

R207] Highspeed ring proportional gain'0.00-300.00

inna ime0.000- 10,000

Slop speed ring proportional gain: 0.00-30000 | Get the value

inogral ime: 0.000-10,090 | Of frequency

lees erent Toa ‘proportional gains O-2000rads

inegral ime: 0.0-100.0m8 __| 10.ims

Torque colina elecaie Forwardelecivics 09%-800"% | Forward

Backwardelecic: 0%-300% | 200%

Backward

200%

R206 | Torque upper Timi | Forwardregeneration, 06-3000 | Forwan

regeneration regeneration 200%

Backward

200%

R207 | Zero see gain Gains O-100.00 0.00

responsiveness; -30,00-30.00 | 0.00

Rz0N | Zero seve speed loop proportional gain: 0.000-300.00 | Get the value

inegral dine: 0.000-10.0008 | of frequenc

Ka09 | Sopa seve gain 7100 5

K210 | fimeto peak tomque accelerates 0-050 accelerate

decelerate: 01,008 0.5005

decelerate

0.1005

JVIDONE-IODIN

Boy)

Read without ads. Subscribe with a free tri

KOT Rated power

Rio | Rated volage OS10v

Eros | Rave eumrent Miia

‘Numba

Froque

Rios] Rmp o5000

jon: O-L, O-the

learning: 0-15

KO) | Hheoder pulse number [1 ~ 1S000ppe 30

K-Content and

Dl

available

Read without ads. Subscribe with a free tri

FSC Tm any si, press ESC 1 exie tho Curent function group menu number ar edit tate without

saving the relevant operation value

vw Ta the function group menu, the group number can be incremented by the UP key, and

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Case Study 2 Oily Shoe SoleDocument4 pagesCase Study 2 Oily Shoe SoleTakumina ServicesNo ratings yet

- Ningbo GNL Elevator Spare Parts Co.,Ltd.2.HTMLDocument1 pageNingbo GNL Elevator Spare Parts Co.,Ltd.2.HTMLTakumina ServicesNo ratings yet

- Nona CatalogDocument25 pagesNona CatalogTakumina ServicesNo ratings yet

- 客梯诺 电气原理图(无机房 老国标 默纳克) 中性英文图纸20230407Document29 pages客梯诺 电气原理图(无机房 老国标 默纳克) 中性英文图纸20230407Takumina ServicesNo ratings yet

- FUJIPRE2400304-ZGF01 W24030468-J400-07 (1720×1200,1100×900,M750) (2CO) 钢带 英文 ModelDocument1 pageFUJIPRE2400304-ZGF01 W24030468-J400-07 (1720×1200,1100×900,M750) (2CO) 钢带 英文 ModelTakumina ServicesNo ratings yet

- Tarlac State University MRL 800KG 2350X1700 1400X1350 CO800-ModelDocument1 pageTarlac State University MRL 800KG 2350X1700 1400X1350 CO800-ModelTakumina ServicesNo ratings yet