Professional Documents

Culture Documents

Ficha Tecnica Espirometalicos y Tabla de Torque-1-12-8

Uploaded by

Luis AlbertoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ficha Tecnica Espirometalicos y Tabla de Torque-1-12-8

Uploaded by

Luis AlbertoCopyright:

Available Formats

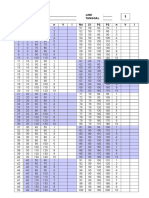

RECOMMENDED TORQUE

Torque Table for CG Spiral Wound Gaskets

class 150 class 300 class 400 class 600

TABLE nPs (in.)

22 Min torque Max torque Min torque Max torque Min torque Max torque Min torque Max torque

0.5 30 40 30 40 30 40 30 40

0.75 30 40 60 70 60 70 60 70

1 30 40 60 70 60 70 60 70

1.25 30 40 60 70 60 70 60 70

1.5 30 60 100 120 100 120 100 120

2 60 90 60 70 60 70 60 70

2.5 60 110 100 120 100 120 100 120

3 90 120 100 120 100 120 100 120

3.5 60 90 100 120 160 190 170 210

4 70 120 100 140 160 200 190 240

5 100 160 110 160 210 260 280 360

6 130 200 110 160 190 240 260 330

8 180 200 180 260 310 400 400 510

10 170 320 250 290 340 440 500 590

12 240 320 360 420 510 640 500 610

14 300 490 360 420 500 890 680 800

16 310 490 500 590 680 800 800 940

18 500 710 500 680 680 810 1100 1290

20 430 710 500 740 800 940 1100 1290

24 620 1000 800 1030 1500 1750 2000 2340

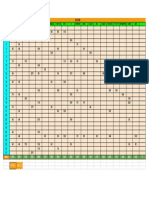

class 900 class 1500 class 2500

nPs (in.)

Min torque Max torque Min torque Max torque Min torque Max torque

0.5 70 120 70 120 50 100

0.75 70 120 70 120 70 100

1 110 190 110 190 110 160

1.25 110 190 135 190 210 250

1.5 170 290 200 290 310 360

2 110 190 130 190 220 250

2.5 170 290 190 290 300 360

3 140 230 265 360 460 500

4 255 420 415 520

5 360 600 585 800

6 300 500 530 680

Not Applicable Use CGI

8 485 800 845 1100

10 505 800 1565 2000

12 570 850

14 630 940

16 910 1290

Not Applicable Use CGI

18 1570 2340

20 1745 2570

24 Not Applicable Use CGI

Notes:

Torque Values are in ft.-lbs., and assume Alloy Steel Bolts (A193 B7 w/ 2H Nuts) with oil/graphite lubrication.

(Nut factors used on these charts are within .15 to .19)

Flexitallic does not generally recommend a bolt stress above 60,000 PSI.

Torque values limit minimum and maximum gasket seating stresses based upon pressure class and certain operating conditions.(i.e: maximum pressure ratings for

given pressure class,not hydrotest pressure), Extreme operating conditions such as high temperature may reduce bolt yield strength. Caution should be used in

these applications. The above torque values are for general use only. For critical or extreme applications (high temperature/pressure) consult with Flexitallic engi-

neering.

Flexitallic does not accept responsibility for the misuse of this information.

YOUR GLOBAL GASKET PROVIDER 33

You might also like

- Electrical DesignDocument6 pagesElectrical DesignxtianNo ratings yet

- King Air 350 Limitations, Specs, and Study Guide N Compressor N PropellerDocument4 pagesKing Air 350 Limitations, Specs, and Study Guide N Compressor N PropellerMikeNo ratings yet

- Axera D07Document79 pagesAxera D07Percy Chero100% (2)

- Phase Clearance - IEC 61936-Part 1Document5 pagesPhase Clearance - IEC 61936-Part 1Sethu Raman75% (4)

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Torque FlexitallicDocument2 pagesTorque FlexitallicLuis Arturo Ramirez Esteban100% (1)

- Signum-Technical-Guide LO SAMPLING GUIDEDocument30 pagesSignum-Technical-Guide LO SAMPLING GUIDEshirishkv100% (1)

- Torque Chart Spiral Wound GasketsDocument2 pagesTorque Chart Spiral Wound GasketsMocanu MarianNo ratings yet

- Flexitallic Tabla de TorqueDocument2 pagesFlexitallic Tabla de TorqueWalter100% (1)

- Torque Spiral Wound GSKT TableDocument2 pagesTorque Spiral Wound GSKT TableCarlos Roberto Tamariz100% (1)

- Flexitallic CGI Torque Chart Spiral Wound GasketsDocument1 pageFlexitallic CGI Torque Chart Spiral Wound GasketstinzarmoeNo ratings yet

- Bolts Torque ChartDocument13 pagesBolts Torque ChartkhaireddinNo ratings yet

- Change Torque Chart 11-30-2017Document1 pageChange Torque Chart 11-30-2017Titino AlejandroNo ratings yet

- RM 2131 2Document38 pagesRM 2131 2Jeicol CarranzaNo ratings yet

- Electrical/Mechanical Downtilt (Continued)Document3 pagesElectrical/Mechanical Downtilt (Continued)ZteTems OptNo ratings yet

- Actividad Ant0 10sep22Document2 pagesActividad Ant0 10sep22Andrés Alejandro Martínez GuerreroNo ratings yet

- RM 2131 1Document38 pagesRM 2131 1Jeicol CarranzaNo ratings yet

- Table of Heat ConservationDocument1 pageTable of Heat ConservationnincitoNo ratings yet

- Centipoise (CPS) or Millipascal (Mpas) Poise (P) Centistokes (CKS) Stokes (S) Saybolt Universal (Ssu)Document4 pagesCentipoise (CPS) or Millipascal (Mpas) Poise (P) Centistokes (CKS) Stokes (S) Saybolt Universal (Ssu)Felipe Lepe MattaNo ratings yet

- Excel Formula CollectorDocument1 pageExcel Formula CollectorCindyNo ratings yet

- Modelo Excel Util Costos 18-8Document10 pagesModelo Excel Util Costos 18-8matiasNo ratings yet

- Assignment 1Document7 pagesAssignment 1nmt5qfp5v9No ratings yet

- Maximum Torque Settings For Composite FlangesDocument1 pageMaximum Torque Settings For Composite FlangesJulius ContrerasNo ratings yet

- Gambar Kerja Acp PolresDocument5 pagesGambar Kerja Acp PolresHeru SusetyoNo ratings yet

- S F E S F E S F E: Kil Ab Ngineering Kil Ab Ngineering Kil Ab NgineeringDocument3 pagesS F E S F E S F E: Kil Ab Ngineering Kil Ab Ngineering Kil Ab NgineeringDurga PrasadNo ratings yet

- Fast Modulator: SFG Detector1Document1 pageFast Modulator: SFG Detector1wuuuuudNo ratings yet

- Experiment 1 - Run 1 Magnetization CurveDocument4 pagesExperiment 1 - Run 1 Magnetization CurveJay EmNo ratings yet

- Luminaire PropertyDocument20 pagesLuminaire PropertybishoyNo ratings yet

- Bearing Tolerance DataDocument2 pagesBearing Tolerance DatacarlosorizabaNo ratings yet

- Homework 1Document11 pagesHomework 1Dridi FyrasNo ratings yet

- Form 2D Spasi 10 480mDocument6 pagesForm 2D Spasi 10 480mAsep U SaepullahNo ratings yet

- Cerdeñola, Jane Paula C. 1798 BEPMC 311: TB-TC ApproachDocument4 pagesCerdeñola, Jane Paula C. 1798 BEPMC 311: TB-TC ApproachGamers HubNo ratings yet

- Broiler Feed ChartDocument2 pagesBroiler Feed ChartAaron JenksNo ratings yet

- Broiler Feed Chart EXDocument2 pagesBroiler Feed Chart EXAaron JenksNo ratings yet

- Broiler Feed ChartDocument2 pagesBroiler Feed ChartAaron JenksNo ratings yet

- Research Methods and TechniquesDocument27 pagesResearch Methods and TechniquesadeelNo ratings yet

- MOSFET and To Determine Its Threshold Voltage and TransconductanceDocument7 pagesMOSFET and To Determine Its Threshold Voltage and TransconductanceHarshith TsNo ratings yet

- Phase Clearance - IEC 61936-Part 1 - Insulator (Electricity) - Electrical EquipmentDocument6 pagesPhase Clearance - IEC 61936-Part 1 - Insulator (Electricity) - Electrical EquipmentAnand KumarNo ratings yet

- Layers: 50lb Bags 40lb BagsDocument2 pagesLayers: 50lb Bags 40lb BagsAaron JenksNo ratings yet

- Hood Filter Static Pressure: StaticpressurechartforheavydutychghoodfiltersDocument1 pageHood Filter Static Pressure: StaticpressurechartforheavydutychghoodfilterssamirNo ratings yet

- SolvingDocument15 pagesSolvingManoo ValievNo ratings yet

- Experiment 1Document6 pagesExperiment 1danix183No ratings yet

- 加载及卸载表ASTM-800t rev02Document2 pages加载及卸载表ASTM-800t rev02Hafiz NurahimNo ratings yet

- Untitled Spreadsheet-2Document2 pagesUntitled Spreadsheet-2api-398388514No ratings yet

- Viscosity Converting ChartDocument3 pagesViscosity Converting ChartMaria Victoria Morales GalindezNo ratings yet

- GBT 9439 2010 Gray Cast Iron CastingsDocument19 pagesGBT 9439 2010 Gray Cast Iron CastingsAwad SalibNo ratings yet

- Log DataDocument25 pagesLog DataAurangzeb JadoonNo ratings yet

- Color BlocksDocument25 pagesColor BlocksAmr HaithemNo ratings yet

- Activity Optimization TechniquesDocument2 pagesActivity Optimization TechniquesAliezaNo ratings yet

- Luminaire PropertyDocument7 pagesLuminaire PropertyLucas NunesNo ratings yet

- Below 30k Incentive Analysis AprilDocument20 pagesBelow 30k Incentive Analysis Aprilanand mishraNo ratings yet

- Hollow SectionDocument1 pageHollow Sectiondhiny.andrianiNo ratings yet

- ACC LengthsDocument1 pageACC LengthsShoayful IslamNo ratings yet

- US1823002 - Test Curve - GH20F2X - Pump BDocument5 pagesUS1823002 - Test Curve - GH20F2X - Pump BJosé RíosNo ratings yet

- P9999mko 2Document26 pagesP9999mko 2otman geotechChausséeNo ratings yet

- Visc Equiv ChartDocument1 pageVisc Equiv ChartTravis SkinnerNo ratings yet

- V5.1 - RatioMatic - RM0200 - SparePartsList 110-3 PDFDocument2 pagesV5.1 - RatioMatic - RM0200 - SparePartsList 110-3 PDFcarlosloucaoNo ratings yet

- Hydro Paper SolutionDocument7 pagesHydro Paper Solutionzain IshaqNo ratings yet

- Program Code For CNC LatheDocument2 pagesProgram Code For CNC LatheMuhammad HassanNo ratings yet

- Catalog 5Document7 pagesCatalog 5Ashirvad RathNo ratings yet

- MTG Ref StarMetDocument30 pagesMTG Ref StarMetAhmed AtefNo ratings yet

- MTG Ref StarMetDocument30 pagesMTG Ref StarMetAhmed AtefNo ratings yet

- Lundry 12.2022Document1 pageLundry 12.2022Áh LyHaiNo ratings yet

- Hipps: High Integrity Pressure Protection SystemsDocument9 pagesHipps: High Integrity Pressure Protection SystemsAndrew XuguomingNo ratings yet

- College of Engineering - UOZ Department of Petroleum Engineering Reservoir Fluid Properties Stage: Three Student NamesDocument20 pagesCollege of Engineering - UOZ Department of Petroleum Engineering Reservoir Fluid Properties Stage: Three Student NamesShaaban HassanNo ratings yet

- Altronic Agv5 Operating Manual Gas Fuel Valve Form Agv5 Om 8-03Document12 pagesAltronic Agv5 Operating Manual Gas Fuel Valve Form Agv5 Om 8-03SMcNo ratings yet

- EX-7 Overhauling of Boiler BurnerDocument2 pagesEX-7 Overhauling of Boiler BurnerAayush Agrawal100% (1)

- 654 Guess Paper Physics 10th ClassDocument9 pages654 Guess Paper Physics 10th ClassMuhammad MujtabaNo ratings yet

- Honda Cm185 Workshop ManualDocument206 pagesHonda Cm185 Workshop ManualGerman HurtadoNo ratings yet

- To Download List of A Books Available in Library I - 59d42dbc1723dd1de323c9b4 PDFDocument188 pagesTo Download List of A Books Available in Library I - 59d42dbc1723dd1de323c9b4 PDFRISHIKESH KUMARNo ratings yet

- TSSA-DLB-2020-Feb-09-2021-Biogas ProjectDocument9 pagesTSSA-DLB-2020-Feb-09-2021-Biogas ProjectNazrul IslamNo ratings yet

- Listino Velox 2011 Inglese (30-03-2011)Document39 pagesListino Velox 2011 Inglese (30-03-2011)panos320No ratings yet

- TMA2 12 09 2021 UploadDocument3 pagesTMA2 12 09 2021 UploadG.G. PRABHATH CHINTHAKANo ratings yet

- 1D Monoatomic Chain 3-5Document33 pages1D Monoatomic Chain 3-5M IrfanNo ratings yet

- flowIT FTBGDW-16Document1 pageflowIT FTBGDW-16technicalsupportNo ratings yet

- Wafflemat Design WhitepaperDocument13 pagesWafflemat Design WhitepaperantiacidoNo ratings yet

- JNTUK-DAP-Course Structure and Syllabus-B.tech (Mechanical Engineering) - II YEAR.R10 StudentsDocument25 pagesJNTUK-DAP-Course Structure and Syllabus-B.tech (Mechanical Engineering) - II YEAR.R10 StudentsAnusha MylavarapuNo ratings yet

- Viscometer Test PDFDocument2 pagesViscometer Test PDFAshishJamadarNo ratings yet

- Abdul Ameen CVDocument4 pagesAbdul Ameen CVanon_151755103No ratings yet

- 172-8660 Fluid Level SwitchDocument1 page172-8660 Fluid Level SwitchDannyNo ratings yet

- 01 Excelon FiltersDocument16 pages01 Excelon Filtersalex_alfonso9407No ratings yet

- Tube HydraulicsDocument8 pagesTube HydraulicsrijalharunNo ratings yet

- BOSCH - Master Brake Cylinder & EPDM SealsDocument3 pagesBOSCH - Master Brake Cylinder & EPDM Sealsgautamnaveen1986No ratings yet

- MY Pajero Sport VGT Service Plan & PriceDocument1 pageMY Pajero Sport VGT Service Plan & PriceNugroho FamNo ratings yet

- Developer Instruction Guide (Video Development) : Sensitivity: LNT Construction Internal UseDocument18 pagesDeveloper Instruction Guide (Video Development) : Sensitivity: LNT Construction Internal UseGokul SelvarajNo ratings yet

- FD 1200 W, 1600 W SN 750040 OnwardsDocument20 pagesFD 1200 W, 1600 W SN 750040 OnwardsDangolNo ratings yet

- Mfaf BK: ScopeDocument23 pagesMfaf BK: ScopesbalajimNo ratings yet

- MEZCLADORA CONTINUA Ingles PDFDocument2 pagesMEZCLADORA CONTINUA Ingles PDFDouglas TondelloNo ratings yet

- Gearbox Failure of Large Gas Turbine Generator Case StudyDocument2 pagesGearbox Failure of Large Gas Turbine Generator Case StudyJesusNo ratings yet