Professional Documents

Culture Documents

wg-180 wg-200 Manual Service

wg-180 wg-200 Manual Service

Uploaded by

rpenavisconti0 ratings0% found this document useful (0 votes)

29 views224 pagesOriginal Title

wg-180 wg-200 manual service

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views224 pageswg-180 wg-200 Manual Service

wg-180 wg-200 Manual Service

Uploaded by

rpenaviscontiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 224

Order No. 5871 162 002 E

ZF - POWERSHIFT TRANSMISSION

WG-180

WG-200

ZF Passau GmbH

Donaustr. 25 - 71

D-94 034 Passau

05.10.95

WORKSHOP MANUAL

FOR ZF-POWERSHIFT

TRANSMISSIONS

WG-180 AND WG-200

In this Workshop Manual, the Disassembly and Reassembly of several Transmission

Versions as well as Assemblies are treated.

‘The technical development of the product and the extension of the possible Versions

may require varying steps, which can be carried out without great difficulty by

trained personnel, consulting the Perspective Illustrations of the corresponding

Spare Parts Lists.

Indications regarding Description, Installation, Instructions, Operating and

Maintenance, see catibeniiog Operating Instructions!

ZF Passau GmbH

Donaustr. 25 - 71

D-94 034 Passau

Abt.: ASTDM / Section : ASTDM

‘Nachdruck auch auszugsweise ohne dic Genehimigung der ZF Passou GribH nicht gestatct!

‘Copyright ZF Passau GmbH!

‘Copying even partially not permitted!

‘Reproduction meme par extrait est interdite!

‘Tectnische Andeningen vorbehalten! With the reserve of technical modifications!

‘Sous reserve de modification techniquest

‘Ausgabe / Edition : 1994/02

PREFACE

‘This documentation has been developped for the skilled Serviceman, trained by the Zahnradfabrik

Passau for the Repair and Maintenance operations on ZF-Units.

‘Treated is a ZF-Serial product according to the design stage of the date of Edition.

However, due to further technical developments of the product, the repair of the unit at your

disposal could require differents steps as well as other adjustment and testing specifications.

Therefore, we recommend to commit your ZF-Product to Masters and to Service-men, whose

‘practical and theoretical training is constantly completed to the actual situation in our Training

School.

The Service Stations, established by the Zahnradfabrik Friedrichshafen all over the world, offer

you:

J. Constantly trained personnel

2. Prescribed installations, e.g. Special Tools

3. Genuine ZF-Spare Parts according to the latest phase of development

Here, all operations are carried out for you with utmost care and realibity.

Repair operations carried out by ZF-Service Stations, are covered additionally within the terms of

the actual contractual conditions, by the ZF-Warranty,

Damages caused by inappropriate or inexpert work, carried out by personnel foreign to ZF, and

after-cxpenditures eventually arising from it, are excluded from this contractual responsibility,

This applies also in case of a renouncement of Genuine ZF-Spare Parts.

Zahoradfabrik Passau GmbH

Service Department

O01

GENERAL WORKING INSTRUCTIONS

During all operations, pay attention to cleanliness and. skilled working.

‘Therefore, Transmissions, removed from the vehicle, must be cleaned prior to open them.

We assume that the Special Tools, specified by ZF, will be used.

‘The Special Tools have a 10-digit Subject-No, and are availabe from ZF-Passau.

After the disassembly, all components must be cleaned, especially comers, cavities and recesses of

housing and covers.

The old sealing compound must be carefally removed.

Check Inbricating holes, grooves and pipes for free passage. They must be free of residues,

foreign material or protective compounds.

The latter refers expecially to mew parts.

Parts which have been inevitably damaged in a disassembly operation, must be generally replaced

by new ones, e.g. : rotary seal rings, O-Rings, U-Section rings, cap boots, protective caps etc...

Components such as roller bearings, thrust washers, synchronizing parts ete. which are subject to

normal wear in automotive operation, must be checked by the skilled Serviceman,

‘He will decide if the parts can be reused.

For the heating of bearings etc., hot plates, rod heaters or heating furnaces must be used.

Never heat parts directly with the flame. An auxiliary solution would be to immerse the bearing in

a vessel filled with oil, which is then heated with the flame.

In this way, damage to the bearings could be avoided.

Ball bearings, covers, flanges and parts like that must be heated to about 90° to 100° C.

Hot-mounted parts must be reset after cooling in order to assure a proper contact,

Before pressing shafts, bearings etc. in position, both parts must be lubricated.

During the reassembly, all specified adjustment values, testing specifications and torque limits

must be respected.

After the repait, ZF-Units are filled up with oil.

‘The procedure and the permitted oil qualities can be taken from the Operator's Manual, resp. from

the Lubrication Instructions and the corresponding List of Lubricants.

‘The Lists of Lubricants are available at all ZF-Service Stations.

Afler the oil filling, the oil level phigs and oil drain phugs must be tightened to th specified torque

limits,

oon

IMPORTANT INSTRUCTIONS

CONCERNING THE LABOUR SAFETY

In principle, Repairers of ZF-Units are themselves responsible for the labour safety.

The observance of all valid Safety Regulations and Legal Rules is a precondition to prevent

damage to individuals and products during the Maintenance and Repair operations,

Refore starting the work, the Repairers have to make themselves familiar with these Regulatisons.

The proper Repair of these ZF-Products requires especially trained personnel.

‘The Repairer himself is obliged to provide for the training.

003

Hinmsis; Uingsnbezogeoe Malle in kg'm; _‘flichanbezogane Malle in vim?

Note: linear density in kg/m; areal density in tn?

Moin; Density Kinonre 6a hpi Density superticielle en vind

Tip=981N

102 pm = = 1 Nas

TPS= 07333 KW

1 KW =1,36 PS

Tia = 91 Ne

oz ata = 1,02 eprom

= Uber = 750 tow

008

1,356 Nm ( 0,138 kpm )

Lkg fem

1 bar ( 1,02 kp/em? )

0,070 bar ( 0,071 kp/cm? )

Tin ( inch)

2,205 Ib ( pounds )

7,233 ibf x ft ( pound force foot)

LIbfx ft ( pound force foot )

5,560 Ib/ in ( pound per inch )

14,233 psi (pound force per squar inch Ibffin2 )

1 psi( Ibfin? )

0,264 Gallon ( Imp. )

1Galllon ( Imp. )

0,220 Gallon ( US )

1 Gallon ( US )

1 Mile ( Landmeile )

432° F ( Fahrenheit )

273,15 Kelvin

os

TORQUE LIMITS FOR SCREWS (IN Nm) ACCORDING TO ZFSTANDARDS |

as for phosphates outs. Tighten by hand!

‘Torque limits, of not exspecially, cam be taken from the following list:

Metric 1S0-Standard Thread DIN 13, Page 13,

hao

Maa

Mae 670, 960 1120

Ma? 7000 1400 1650

2250

1850

2350 3300 3900

Moe 3000 4300 3100

Metric ISO-Fine Tread DIN 13, Page 13

83 109, 129

Mex 2435 36, 8

Mox1 36, 3 a

10x 1 EB 76, ©

IM 10x. a R 4

IM 12x 123, 7 135 150

a 122 145

Misx 15 1s 200 25

M16x 15 205 300 360

Mie 15 310 Ho 520

IM 18x 2 290 20 490

IM 20x 1.5 430 620 720

IM 22% 1.5 380 820 360

IMaax 15 760 1090 1270

Maan? 730 1040 1220

IM27x 1.5 10 1580 1850

[Marx 2 1070 1500 1800

IM30x 15 1540 2190 2560)

[Ma0x2 1490 2120) 2430.

[M33 x15 2050 2920) 3420)

[M33x2 72000 72800, 3300

IM36x 1,5 72680 3820 ‘470

IM 36x3, 72500, 3500 3100,

[o39% 15 3430 4590 3720

39x 3 3200 3600) 3300)

0.06

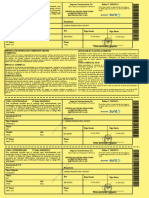

INSCRIPTIONS ON A ZF-MODEL IDENTIFICATION PLATE FOR ZF-HYDROMEDIA-

REVERSING-TRANSMISSIONS:

1 = Gearbox type

2 = Gearbox.No,

ZF-Parts List-No,

‘Total ratio of the Gearbox

Value for the control pressure

‘ZF-Parts List-No. of the Torque Converter

‘Type of the ZF-Torque Converter

vomse

eeena

(6) Zahnradfabrik Passau @

(ras

teense]

NOTES REGARDING THE SPARE PARTS ORDERS:

When ordering genuine 2F-Spare Parts, please indicate:

Gearbox type

Serial-No. | See Model Identification Plate!

ZF-Parts List-No.

Mark and type of vehicle

Denomination of the spare part

Spare parts-No.

Way of transport

see eens

When all of the above required indications ere considered, errors in the delivery of spare part orders

can be avoided!

Optional versions and additional equipment

for the transmissions of the WG range

1 Converter hausing for direct in-

st

2 Torque converter

9 Lock-up elirtch

4 Cover for separate installation

5 Retarder

'@ HN 500 converter transmission

T Input flange (for separate instal-

lation)

@ Contre distance input’ output

shatis

9 Axle disconnect unit

10 Parking brake

11. Speedometer connection

12 Inter-axle ditterential

13 Axle deive, flange-mounted

14 Multi-dise clutch for 4.5

and 6-speed version

18 Emergency steering pump

16 PTO unit, engine driven

17 Transmission contre!

18 Steering column switch SG 4/

sc6

19 Console switch $@ 4/56 6

20 Rotary reversing switch OW 1

21 Automatic control unit EST 2

22 Inching valve

23 Dual pressure control vaive

24 Pressure cut-out

25 Micra-tate

26 Transmission connection for

‘separate filter instaitation

27 Converter charge andi shitt

pump

(Read Tramunishns Division

‘Torque converter transmissions for off-road vehicles and

‘machinery (construction plant, special vehicles, lift trucks) List of Lubricants TE-ML 03

Engine ots

Wo sor 1/88 85 API €D/ CE/ CF/SE/SG

wa 100 (MIL-L-2108 C)-D/-8

WG 120y 121 MIL-L-46132 C/-D/-E

WG 150) 151 + SAE IOW

(WG 180) 181 + SAB 10W20

|W 200) 201 + SAE IOW-40

WG 250 = SAE IS W.40.

wo 6s = SAE 20W.20

N50

Pw ASH (I) ‘For commercial products see overleaf

Pw2sH

Pw Is Automatic Transmission Fluids (ATF) only at ambient

HSC 210

‘emperatures below 10 °C

=

engi

= Engine oils

SAE 20W.20 asc

SAE 15 W-40 oc

SAE 10W, 10.W-30, 10.640 °C

- ATF -10°e

he minimrn oil temperate for starting the vehicle moving ean be achieved

at least 20 minutes” warm-ap in "Nectal” senting

+ preheating

At greasing poiews, use a rmbi-purpose grease with the following propertica:

lithium s04p, trop point above 170°C, NLGH Class 2.

‘The grease mit be ant-conrosive, water-tesitant and walk erable

Note to lubricant suppliers: Pleaic inform ZF immediately of any changes tothe composition or trade names of approved product, and

of differences in. quality between Germany and other countries.

‘This lst ean be obtained through any ZF Telephone (08:51) 498-0

After Sales Service pot. Telex $7849 zp

Telefax (08:51) 45.340

0.09 1208754 1010192

‘oils API CD/CEICRISE/SG, Engine oils API CD/CE/CEISFISG,

MIL-L-2104 C/-D/-E, MIL-L-46182 C/-D/-E MIL-L.2104 C/.D/E, MILAL-46182 C-DIE

soc net can CTNERDOr rs common cusorease

‘Sineao so RRO BASE Seinnce naar otemaberyes

roe ena lc career, Dcrulneri utca KORTRENAASIYY. Bonde

‘tienes soe ems sk areas ova ane

Ne mmosys ancy ‘Srnoecsnce GinimiCouna Coke sTeroaeo Saneee srmon FO mo

fog mrecaps: wcen ‘Soo tes roe

‘soreness fiends oe ream MIR

Neiicramncoorey acrance Forman na Easba cima count,

Mtisnamescwest marcsa fo seutvonses worms

Succ. zane Sirens 2. iim: eukomasria Eicowornsoner a.

‘Spec thane oes Bouma tee

(aoe tecren sev tan karo ausorasenane Som womsan orice

Sratacraar Mearnne Ra

Anetta rine Mswran NowagsioL ou mice coma KeLND RenrasiOULTRALLR

‘anon saat ‘Sub runbansn omenot KGrumacod Waasonome koe tures saeco

‘Soncun sexe ‘Sear hour sa 5008 Soronon sau

‘Sec an ace Sec roma too acomuce ‘ioe incr sce

‘Son kbanai ne ENE ‘Siirzeid wore oa. te Rowan ernaneano AE

Nowab aNcMEND Siw worexmec 10. form. ane

Nominee Aa WADE Neatsroc i W039 FERS On FT SONS ines AL EOAADE TORO,

2 0.10

J. ELECTRO-HYDRAULIC GEARBOX CONTROL

ATTENTION :

In case of malfunctions of the Transmission because of a defective gearbox control, we

fecommend the replacement of the complete gearbox control.

The pressure-control curve of the replacement-gearbox control (see corresponding Spare

Parts List} has been accordingly adapted to the Transmission Version, resp. to the Vehicle

type.

Modifications concerning the pressure-control curve may not be carried out without agree

ment of ZF. Therefore, the repair of gearbox control units should be carried out by ZF-

Service stations only.

The relative shop equipment of our Service stations (gearbox control resp. trans

test benches) as well as constantly trained personnel ensure a professional repair.

The following Disassembly and Reassembly Instructions (Page 1.01 - 1.73) will therefore be

useful only a3 an Information for ZF-Service stations as well as for the Manufacturer of

the vehicle, which are disposing of the required workshop equipment and especially trained

personnel.

ion

101

Note. the ntrol:

Di

Pressuré-control curve gear case

= Pressure in bar

{= Time in seconds

pl = Modulation start

p2 = Modulation

PP = Modklstion start ely in.

‘with 2-ctage pressure control valve

ATTENTION:

curve is different according to the

‘Transmission Version, resp. the vehicle type and will be

1

‘The pressure-control

adjusted by means of corresponding shims and diaphragms (optional)!

Note:

In the following Disassembly and Reassembly Instructions are three different gearbox control Variants

treated.

12 Alumisium sand-casting gearbox control

13° Aluminium die-cast gearbox control with WK-Valve.

With the help of the following Figures, the coordination of the single gearber control variants can be

visually identified because of the different casting contours!

1.1 Cast-iron gearbax control

i

Qa merino freee reser

‘antral pressure)

= Clutch KV

= Cwich KR

= Clutch Kt

‘Clutch K2

se4aean &

‘Clutch K3

= Clutch K4

1.2 Aluminium sand-casting gearbox control

(eg. 4 magnets)

|

Central measuring point for system pressure

(Gantrol pressure)

‘Clutch KV

Clutch KR

‘Clutch KR {in case of Ssmagnet Version)

Clutch Ki

‘Clutch K2

Chuteh KS

Seuagae a

1

Clutch Ka

Clutch Ke (in case of S-magnet Version)

3

13 Aluminium die-cast gearbox control

= Central measuring point for system pressure

\ontrol pressure)

Clutch KR

(Cluteh Kt

Clutch K2

Clutch K3

Clutch Ki

6s

3

ss

6

7

8

oO.

Furthermore, the single gearbox contro! units can include WK-Valve, 2-stage pressure control valve as

latte. Seago (olr fr sesbox cated 12)

Different steps resulting from this, can be carried out without great difficulty by qualified personnel,

Consultag the Perspective Ilustraicas in the corresponding Spare Parts Lint

1.1 CAST-IRON GEARBOX CONTROL

1.1.1 Version 1: Standard Version (without

WK and 2-stage pressure

contro! valve)

1.11.1 DISASSEMBLY

\te_shift-control and_ channel

plate gear case (Figure |... 3).

Loosen socket head screws, install two adjus~

ting screws (Arrows) and remove shift-control

housing.

Now, remove gaskets and intermediate plate.

(3) Adjusting screws (M3) 5870 204 O11

Now, remove gaskets and intermediate plate.

Remove delivery lines.

Loosen socket head screws and separate chan-

nel plate as well as gaskets and intermediate

plate from the gear case.

1.05

Relax spring clip and remove cover.

Pull off cable shoes, loosen the socket head

screws and remove solenoid valves.

Remove components, see Figure on the left!

Loosen two hex. head screws and fix shift-

control housing provisionally, using Special

Tool (5).

Now, loosen the remaining hex. head screws

and separate cover (is spring-loaded) from

the valve body by uniform loosening of the

ruts (5S).

(s)

('S) Adjusting screws (M3) 5870 204 036

with nu

it

(S) Adjusting screws (M6) 5870 204 049

with nut

Remove components, see Figure on the right

Remove stop plates (Arrows) and demount de-

tent blocks.

NOTE +

The use of two spools in order to fix the de-

tent block provisionally axially (Figure 10),

avoids the tilting of the detent blocks, thus

facilitating the disassembly {

1.07

13

Jot.1.2 REASSEMBLY

see also Hlustrated Tables, Page 1.1%

NOTE =

‘Check all components for damage and renew

if necessary !

Check free travel of the moving parts in

‘the housing prior to the installation !

Spools can be exchanged individually !

‘Oil components prior to the reassembly !

Introduce detent blocks (I and 2) into the

bores and fix them by means of stop plates

G and 4),

Install stop plate (5).

NOTE :

Pay attention to the installation position of

the various stop plates, see Figure on the

left I

Is

2= {Lg = 88,6 mm)

ae 8 = 520 mm)

4 = Disk (optional)

3 = Spacer

6 = Spool

7 = Sleeve

8 = Spool

9 = Spring = 81,7 mm)

10 = Spool

11 = Spool

12 = Spring (Ly = 65,4 mm)

13 = Spring (8 = 72,3 mm)

1% = Spool (total length 86,0 mm)

NOTE =

L = Length of the unloaded spring !

ps (control pressure) is determined by the disk

‘(@)! Pay attention to the General Instructions,

Page 1.01 1.031

Install two adjusting screws (5 ) and mount

flat gasket.

Place cover against shoulder, using nuts ( 5 ).

Now, fasten cover by means of screws.

Torque limit, (M3/8-2) 33m

(S ) Adjusting screws (M5) 5870 204 036

‘with nut

(CS) Adjusting screws (M6) 5870 20% 089

‘with nut

Install_ component

1 = Valve body

2 = Spring (L, = 72,5 mm)

3 = Spool G control surfaces)

4% = Spring (Ly = 72,5 mm)

3 = Spool G contro! surfaces)

& = Spring (L, = 72,5 mm)

7 = Spool (total length 72,0 mm)

& = Detent block G pieces)

Preload detent block and install solenoid

valve.

Install remaining solenoid valves accordingly .

NOTE

Employ new O-Rings for solenoid valves !

Pay attention to the radial installation posi-

tion of the solenoid valves, see Figure 21 !

Install cable harness (mount new gaskets),

fasten ground cable and connect solenoid

valves (Figure 20).

NOTE =

Pay attention to the location of the plug.

nose, see Arrow/Figure 21 !

Mount new O-Ring (164,2 x 5,7) and fix co-

ver by means of clamping collar.

Pre-assemble channel plate (Figure 23 and 24)

NOTE :

According to the gearshift Nersions different

The following ly Instruction is trea~

ting the Standard Version (with control dia~

phragm for the backfeed) !

Wet thread of contro! diaphragm with Loctite

(Type-No. 270), install contro! diaphragm (Po-

sition, see Arrow 1), and secure it additionally

by means of center punch.

Now, clean diaphragm from Loctite residues

by means of compressed air.

Install diaphragm for the backfeed (Position,

see Arrow 2) accordingly.

wan ‘thread plug (3) with Loctite (Type-No.

70)

new sealing ring for connecting plug

(0) and screw plug (Position, see Arrow 5),

and install them.

Insert the two check valves (composed of

balls and springs) in the channel plate.

Attach channel and control

ra

Install housing gasket.

NOTE :

Pay attention to the different gaskets, see Fi-

gure 25 and 26 |

(S) Adjusting screws (M3) 5870 204 O11

1a

waz

Install intermediate plate and 2nd gasket.

‘Assemble channel plate and fasten it by

means of socket head screws.

Torque limit (M8/8.8) 23.Nm

NOTE :

Pay attention to a correct position of the

ball seat valves !

Pay attention to the position of the various

screws, see corresponding Spare Parts List !

Install intermediate plate and 2nd gasket.

Place gearbox control assembly

der and fasten ir by svare ad docket band

screws.

Torque limit (M8/8_8) 23Nm

NOTE :

Pay attention to the position of the different

screws (lengths) 1

soe acta eta

(Gee Arrows) as! install them a

ric pwad aalon'r toee pes enact

lustrations in the corresponding Spare Parts

List 1

1.13

course | se aanertyo ted wot vu momen 64

‘ober i yp ttm ee

oxen ANGIE ne EH BSA

1.2 ALUMINIUM SAND-CASTING

GEARBOX CONTROL

1.2.1 Version 1: With Solenoid valves

and attached 2-stage

pressure control valve

1.2.1.1 DISASSEMBLY

Remove delivery line.

(S) Adjusting screws (M8) 5870 204 011

Relax spring clip and remove cover.

Pull off cable shoes and remove cable harness.

‘Loosen socket head screws and remove sole-

noid valves.

Remove components, see Figure on the right !

17

Loosen two socket head screws and fix shift-

Now, loosen the remaining socket head

screws and separate shift-contro! housing (is

from the valve body by uni-

form loosening of the nuts (S ).

(5) Adjusting screws (M5) 5870 208 036

(s) Katine erowe (M6) 5870 208 049

Dismantle pressure control valve.

Remove stop fag (Arrows) and demount

detent blocks (2x).

(NOTE

Check all components for damage and renew

‘if necessary !

‘Check free travel of the moving parts in the

‘housing prior to the installation |

Spools can be exchanged i

Gil companents peloe to the reassembly I

Close the bores by means of balls (8 pieces

# 4,50 mm).

Introduce detent blocks (1 and 2) into the bo-

res and fix them by means of stop plates (3

and 4).

Install detent block (5).

NOTE :

Pay attention to the installation position |

Install components

1 = Spool (total length = 86,00 mm)

2 = Spring L, = 53,40 mm)

= Length of the unloaded spring

19

(optional)

(L, = 38,00 mm)

(18 = 65,40 mm)

p2 is determined by the disk §

(pay attention to Notes, Page 1.01 .. 1.03)!

Pressure control valve :

Install compenents:

1 = Spool

2 = Spring (L,, = 132,40 mm)

3 = Spring 2 = 76,70 mn)

4 = Spool

‘Control pressure valve :

Install components.

Spring (Ly = 78,60 mm)

Spring Ly = 65,40 mm)

Disk(s) (« irical value s = )

Disk(s) tenukial ake + «3.00 mn

Wet thread of diaphragm with Loctite (Type

No. 270) !

A tl Is determined by the diaphragm

(pay attention to Notes, Page 1.01 ... 1.03)!

its

|

‘Compression. spring (L, = 29,90 mm)

Seat

Disk (s = 2,5 mm/empirical value)

‘Spring (L, = 70,90 mm)

= Screw plug (mount new O-Ring)

won Raueun—

Ce

pin (4) 1"

3 is determined by the disk(s) 6a

xy attention to Notes, Page 1.01 a 1.03) I

Close the bore by means of ball (@ 5 mm), see

Arrow |

Install components and fix them by means of

socket head screws and flat washers (Figure

34 and 35).

aN AMeuNS

= plug.

HG

413 is determined by the ring (3)

{pay attention to Notes, Page 1.01 ... 1.03) 1

Torque limit (5/88) 3,5 Nm

(CS) Adjusting screws (M3) 5870 204 036

‘with nut

(S) Adjusting screws (M6) 5870 208 049

with nut

1.21

Pay attention to the installation position of

the components, see Figure 56

Torque limit (M5/8.8) 5,5.Nm

Insert the solenoid valves and fix them by

means of retaining plate and socket head

screws.

Torque limit (M5/8-8) 3,3 Nm

NOTE

Pay attention to the radial installation posi-

tion of the solenoid valves, see Figure 59 !

Pay attention to the location of the plug

nose, see Arrow !

1.22

Connect solenoid valves according to the I-

justration on the right.

Mount new O-Ring (1642 x 5,7 mm), see

ihren and fix cover eae _ Cara ping

collar.

Intall delivery line 1, control pressure sender

2 (according to the Version) as well as screw

plug.

NOTE =

Mount new sealing rings and O-Rings !

Mow new sealing ings and ORIN

of the corresponding Spare Parts List !

Pre-assemble channel plate (Figure 62 .. 6) +

NOTE =

According to the gearshift Version, different

channel plate variants are possible ! Pay atten

tion to the Perspective Illustration of the cor-

Parts List

The Reassembly Instruction is trea-

following

ting the Version with for the back-

feed (without control aiaphery e a T

Wet thread of diaphragm with Loctite (Type

No. 270), install diaphragm (Position, see Ar-

rew 1) and secure it additionally by means of

center punch.

Now, clean diaphragm from Loctite residues

by means of

Wotall thread plug (Pasition, see Arrow 2) ne-

cordingly.

1.23

1.28

eee Plea CD ian acres peg

NOTE =

Mount new O-Rings !

Attach channel _plate_and control

igure 65... 68) = eae eee

NOTE :

Pay attention to the installation position of

‘the components, see corresponding Spare

Parts List !

Install two adjusting screws.

Assemble housing gasket, intermediate plate

and gasket.

(CS) Adjusting screws (M8) 5870 20% 011

‘Assemble channel plate and fasten it by

means of socket head screws.

Torque Limit 20 Nm

NOTE +

Pay attention to the installation position of

the different socket head screws, see cor

responding Spare Parts List !

Assemble Ist gasket, intermediate plate and

and gasket.

NOTE =

Pay attention to the various gaskets, see cor-

responding Spare Parts List !

contact is obtained and fasten it by means of

hex. head screws (mount flat washers).

Torque limit 20 Nm

Install delivery lines according to the Ilustra~

tion in the Spare Parts List !

NOTE =

Mount new sealing rings !

vOHIM2axa,| JNOd sauTOIe61 {90 Std qos 94 suo; yUaSMTT} $97

UBES@p 849 40J Buypula yOu ove suo!qeagsn| TT

\PHIBUTAIeA UST Gunayussny ap Ing pUrS UBoURPE TARY 10

~ 1.26 -

vopmapea,1 mod sauporetyoa seb wuor ou suoqesram £27

ubysap xn 20} Gugeuya row ase ope

Lonnie Woe GUNMAN #IB 4D) PE abmpHeR 8)

> Lar -

1.2.2 Version Il: With 5 Solenoid valves

and attached WK-Valve

‘1.2.2.1 DISASSEMBLY

Relax spring clip and remove cover.

Pull off cable shoes.

‘Loosen socket head screws and remove sole~

noid valves.

1.29

WK-Valve =

Removie components.

Loosen two socket head screws and fix shift-

control housing provisionally, using a Special

Tool (5 ).

Now, loosen the remaining socket head

screws and separate shift-control housing (is

spring-loaded) from the valve body by uni-

form loosening of the nuts (5 ).

('S) Adjusting screws (M5) 5870 209 036

with nut

(CS) Adjusting screws (M6) 5870 203 049

‘with nut

Remove components.

Remove stop plates (see Arrows) and de-

mount the remaining components.

1.2.2.2 REASSEMBLY

‘see also Mlusirated Tables, Page 1.35

iz

OTE =

Check all components fer damage and renew

if necessary !

Check free travel of the moving parts in the

housing prior to the installation !

Spools can be exchanged individually !

Oil components prior to the reassembly !

Close the bores by means of balls (10 pieces

9 4,50 mm) !

Introduce detent block 1 and fix it by means

of the stop plate 4.

Install subsequently spool 2 and spring 3 (Lo =

51,3 mm), and fix them by means of the stop

te 5.

Install spool 6, spring 7 (Le = 33, mm) and

detent block 8, and fix them by means of the

Pay attention to the installation position of

the different stop plates, see Figure on the

1 = Spring AL, = 53,40 mm)

|

Spool

Disk(s) (optional)

(L, = 38,00 mm)

65,80 mm)

ree

z

TE. =

p2 is determined by the disk 4

(pay attention to Notes, Page 1.01 ... 1.03) !

131

a7

Fe

1s

2- tional)

3s IL, = 76,70 mm)

& = Spring (C3 = 132,40 mm)

3 = Spool

NOTE :

1 is determined by the disk 2

attention to Notes, Page 1.01 ... 1.03) 1

Control valve :

Install components.

1 = Spring (L, = 65,40 mm)

2 = Spring (13 = 78,60 mm)

3 = Disk(s) optional)

i = Disk(s) (optional)

6 = Sleeve

NOTE =

ps is determined by the disks 3 and 4

(pay attention to Notes, Page 1.01 ... 1.03) !

Pre-assemble and attach shift-control_hou-

sing igure 89... 92):

1 = Ball ene)

2 > Diaphn tional)

3s oem 7.00 mm)

NOTE +

Secure diaphragm by means of Loctite (Type

No. 270)

Now, clean diaphragm from Loctite residues

means of com air!

12 (Modulation time-WK) is determined by

the diaphragm 2

(pay attention to Notes, Page 1.01 ... 1.03)!

(3) Adjusting screws (M5) 5870 208 036

with nut

(5) Adjusting screws (M6) 5870 204 069

with nut

Pull shift-control housing by means of threa-

ded bushings (5 ) against shoulder.

Now, fasten housing by means od socket head

screws.

Torque limit (M5/8.8) 3,3 Nm

(S) Adjusting screws (M3) 5870 200 036

with nut

(S) Adjusting screws (M6) 5870 203 049

with nut

Install components :

Shift-control housing,

O-Ring

Solenoid valve

Socket head screws (with spring washer)

Spring (L, = 53,40 mm)

Disk(s) (optional)

Spool

Screw plug (with O-Ring)

:

lt

P init: ie

NA WRN

enw wee

j

p2 is determined by the disk 6

{pay attention to Notes, Page 1.01 ... 1.03) £

Install components =

1 = Shift-control housing

2 = Spring (L, = 51,30 mm)

3

4 = Spool

5 = Spring (Lo = 37,10 mm)

6 = Spool fixing Ceetaining pas plate and

socket head screw)

7 = Spring ‘= 53,40 mm)

& = Spool

9 = Retaining plate ai socket head screw

10 = Solenoid valves (5x)

NOTE +

Pay attention to the installation position of

the valves, see Figure 95

Install cable harness.

NOTE =

Mount new gaskets !

Pay attention to the location of the plug nose

see Arrow !

1.33

Connect solenoid valves according to the Il-

lustration on the left.

Mount new O-Ring (1642 x 3,7) and fix co-

ver by means of clamping collar.

Install screw plugs as well as control pres~

sure sender (according to the Ver:

NOTE :

‘The Reassembly of the channel plate as well

as the attachment of the gearbox control

treated on Page 1.23 ww» 1.25 !

Pay attention to the Perspective Illustration

of the corresponding Spare Parts List !

(8) Adjusting screws (M8) 5870 204 O11

woyynoaxa, | anod saujoqe6y qo sed ywor au su0y

uBps2p 24) 40) Saypune, you ase

1.3. ALUMINIUM DIE-CAST GEARBOX

CONTROL ——~—

1.3.1 Version I: With WK-Valve

1.3.1.1 DISASSEMBLY

(5) Adjusting screws 9870 205 O11

Relax spring clip and remove cover.

Pull off the cable shoes, loosen socket head

screws and remove cable harness.

Loosen socket head screws and demount sole-

noid valves.

1.39

Remove components, see Figure on the left!

Remove and dismantle WK-Valve +

Loosen socket head screws and disassemble

solenoid valve.

Separate WK-Shift-control housing from the

valve body and dismantle it, see Figure on

‘the left 1

Loosen two socket head screws and fix the

shift-control housing provisionally, using a

‘Special Too! (5 ).

Now, loosen the remaining socket head

screws and separate cover (is spring:

from the valve body by uniform loosening of

the nuts (S ).

(3) Adjusting screws (M6) 5870 204 089

with nut

Remove components, see Figure on the

Remove stop plate and demount spring as well

‘as spool.

NOTE:

Installation position of the stop plate, see Ar-

row |

Remove diaphragm and check valves.

10

11 1.42

1.3.1.2 REASSEMBLY

see also Illustrated Tab! 1.49

NOTE

‘Checit all components for damage end renew

if necessary !

Check free travel of the moving parts in

©il components prior to the reassembly !

new O-Rings for all screw plugs (8

and install them.

Install check valves and diaphragm (optional ).

3

TE

mt new O-Rings |

fen O-Ring 6 x 1,5 mm (Arrow) with

Greses on thatend face of the aphvag diaphragm ~

makes the easier f

reassembly

Ue oi ll sole grease forthe reasen-

241 is determined by the diaphragm

(pay attention to Notes, Page 1.01 ... 1.03)!

‘Torque Limit :

Screw plug MIOx1 20.Nm

Screw plug MI8x1,5 35 Nm

Diaphragm 20 Nm

Control pressure valve =

Install components.

1 = Spring WL, = 96,20 min)

2 = Disk(s) (optional)

3 = Spool

NOTE:

ps is determined by the disk

Gur Sines Rawe Page: 101 we 1.03) 1

Pressure control valve =

ents.

‘Control spool

‘Spring, (L, = 124,10 mm)

Spring (3 = 77,10 mm)

Disk(s) (optional)

Displacement spool

Install compons

ween

Install disk 4, with the countersinking facing

the compressison spring !

1 is determined by the disk 5

(pay attention to Notes, Pages 1.01. 1.03) |

Reversing valve :

Install components.

1 = Reversing spool

2 = Speing (1, = 56:30 min)

Control KY:

Install components.

1 = Spool (total length = 55,50 mm)

2 = Spring (1, = 51,30 mm)

183

4

Install two adjusting screws (5) and assem=

ble flat gasket (Arrow).

Now, pull cover against shoulder, using nuts

CS} and fix it provisionally by means of

ae head screws ( pieces, see Figure

(CS) Adjusting screws (Mé) 5870 204 089

with nut

|

Shift-control housing

O-Ring

Screw plug

Disks (optional)

Spring (1, = 53,40 mm)

Deiat block (spring guide)

SN Awe ene

= Connecting piece

NOTE:

Install detent block 7 with the countersin-

!

king

p2 is determined by the disk 5

{pay attention t0 Notes, Page 1.01... 1.03 f

Torque limit (M6/8.3) 9,5 Nm

(3) Adjusting screws (M6) 5470 20% 049

with nut

Mount new O-Rings (Arrows) and fasten so~

Jenoid valve by means of socket head

screws (mount flat washers).

Torque limit (NM5/8.8) 5,5 Nm

Introduce control spool (K4/KR) and compres

sion spring (Lo = 31,30 mm), and fix them by

means of stop plate.

NOTE :

Position of the stop plate, see Arrow 1

= Spring (L, = 51,39 mm)

Control spool K4/KR

Spring, (L, = 51,30 mm)

Control spool K1/K2/K3

ene

woue

(Lo = 37,10 mm)

i

Connect solenoid valves according to the

Figure on the left.

Mount new O-Ring (Arrow) and fix cover by

means of clamping collar.

Pre-assemble and attach channel

126 ou» 129)

Mount connecting pipe (1) and screw plug. (2.

Install two adjusting screws and assemble

housing gasket.

NOTE =

Pay attention to the different gaskets, see

Figure 127 and 128

(CS) Adjusting screws (M3) 5870 204 O11

Install intermediate plate and 2nd gasket.

Assemble channel plate and fasten by means

of socket head screws (mount flat washers).

Torque limit 20 Nm

NOTE =

Use only socket head screws, M8 x 35, DIN

6912 (with low head) !

Position of screws, see Arrows !

Attach control 130... 132)

Assemble Ist gasket.

NOTE :

Pay attention to the different gaskets, see Fi-

gure 130 and 131 1

Assemble intermediate plate and 2nd gasket.

a7

138

1.48,

Mount flat washers 1

Position of the socket head screw M8 x 60

mm, see Arrow !

eee dete ies oot Penge 2ee

ation inthe ‘corresponding ‘Spare. Parte

‘way yMIeKa, | Nod saajoye| [Go Sed yUOs au suo} TesISN][] 587

ebpsep yr 40s Gurpuiy You ost

Wanipurqaan Weoj Bunaunssny |1p 40) PUTS

itt al serentite st visa Soren

isan may soy Aeypnng You mae

sprmurgan seequ Bau ap at) buts woth

al as | .

\ 4 te aa

1 \ -— an LE -“

tl | 1

in I

¢ om — [ | eo

ltl

@oo

4

e

1st

1.3.2 Version Il: With 2-stage pressure

control valve

1.3.2.1 DISASSEMBLY

Relax spring clip and remove cover.

Remove components, see Figure on the right.

Loosen two socket head screws and fix shift.

contrel_housing provisionally, using a Special

Toot (5 ).

Now, loosen the remaining socket head screws

and separate shift-control housing (is spring-

loaded) from the valve body by uniform loose-

ning of the nuts (5 )-

(5) Adjusting screws (M6) 5870 208 089

with nut

1.53

Remove stop plate and demount spool as

well as spring.

Dismantle pressure control valve, see Figure

on the left.

Dao

Remove diphragm and check valves.

NOTE :

‘Check all components for damage and renew

if necessary !

‘Check free travel of the moving parts in the

housing prior to the installation !

‘Spools can be exchanged individually 1

‘Oil components prior to the reassembly !

Employ new O-Rings for all screw plugs and

install them.

Install check valves and diaphragm (optional).

NOTE =

Bt! is determined by the diaphragm

(pay attention to Notes, Page 1.01 ... 1.03 ) !

Torque limit =

Screw plugs MIOxt 20 Nm

Screw plugs MISx1,5 35 Nm

Diaphragm 20 Nm

Close the bores by means of balls (10 pieces,

# 4,50 mm).

Control. pressure valve =

Install components.

1 = Spring (L, = 96,20 mm)

2 = Disk(s) Koptional)

3 = Spool

NOTE =

is determined by the disk 2

y attention to Notes, Page 1.01 ... 1.03) !

135

133

147

199

1 = Control spool

2 = Spring L, = 124,10 mm)

3 = Spring (Lg = 77,10 mm)

4 = Displacement spool

Install components =

1 = Reversing spool

2 = Disk(s) foptional)

3 = Spring (1, = 36,30 mm)

NOTE :

is determined by the disk 2

attention to Notes, Page 1.01 ... 1.03) !

Ni

trol spool (total Jen; 55,30 mm)

‘ 1,30 mm)

neo

Sens

3

attention to the installation position of

spool, sce Figure !

Fe

Pre-assemble and attach 2- essure

Close the bores by means of balls (4 pieces,

# 9,350 mm).

Install. comy :

Shift-control housing

1

2 = Spool

3 = Spring (L, = 70,30 mmm)

4 Screw

5 = Cylindrical roller (6 x 32 mm)

§ = Ringe) (optional)

8 = Screw plug

9 = Spring {Lg = 34590 mm)

10 = Spool

11 = Screw plug

NOTE =

Install two adjusting screws ('S ) and assemble

flat gasket.

Pull pre-assembled pressure central valve, by

means of nuts ( S ) against shoulder and fas-

ten it subsequently by means of socket head

screws (mount flat washers).

Torque limit (M6/8.8) 9,5 Nm

(5) Adjusting screw (M6) 3870 204 049

with nut

Introduce spool (2) and spring (1), preload and

fix them by means of stop plate (3).

= Speing {Lg = 51,30 mm)

Control spool (total length = 39,50 mm)

ste

= Spring (Lg = 31.30 mm)

Control spool (total length = 39,50 men)

(Ly = 31,30

men Gg )

Spool ‘edt pal

‘Spring oem mn

cs

See thal ctews, (ipteced

Speing (1, = 51,30 mm)

Pilot spool (total length = 52,50 mm)

a3

150

won

ifs

158

155

136

1.58

157

Torque limit (M5/3.8) 3,5. Nm

NOTE:

Pay attention to the installation position of

the disk (mount between valve body and

retaining plate), see Arrow !

Pay attention to the radial installation posi-

tion of the solenoid valves, see Figure 156 !

Install cable harness.

NOTE

Mount new gaskets |

Pay attention to the location of the plug

nose, see Arrow |

Connect the solenoid valves according to

the Illustration on the left.

Mount new O-Ring, see Arrow, and fix the

cover by means of clamping collar.

NOTE

‘The Reassembly of the channel plate as well

as the attachment of the gearbox control

are treated on Page 1.46 ww. 188 |

Pay attention to the Perspective Ilustra-

tions of the corresponding Spare Parts List !

1.3.3 Version I: With WK-Valve and

2estage pressure

‘control valve.

1.33.1, DISASSEMBLY

Relax spring clip and remove cover.

Pull off the cable shoes and remove cable

harness,

Loosen socket head screws and remove sole-

noid valves.

‘Remove components, see Figure on the left.

‘Loosen socket head screws and remove sole-

noid valve (2-stage pressure control valve).

Loosen two socket head screws and fix shift.

central housing provisionally, using a Special

Tool (S

fran the valve body by ‘ené=

SEeméioononing of the tuts (5

('S) Adjusting screws (M6) 5870 208 049

with nut

Remove components of the WK-Yalve as

well a of the 2-stage pressure contro! val-

ve.

1.68

Remove components, see Figure on the right!

Remove stop plate (Arrow) and spool as well

as spring.

Remove diaphragm and check valves.

169

1.65

179

mt

1.3.3.2 REASSEMBLY

see also Mlustrat

ted Table, Page

NOTE,

Check all components for damage and renew

if necessary !

‘Check free travel of the moving parts in

‘the housing prior to the installation #

‘Spools can be exchanged individually !

Oil components prior to the reassembly [

Ref. Figure 170: 1

un

Install components according to the Iustra~

tion on the left.

NOTE :

Employ new O-Rings for all screw plugs.

Figure 171 shows the positions of the O-

Rings on the diaphragm 2.

(Fasten O-Ring 6 x 1,3 mm/Arrow 2 with

grease) !

Ati is determined by the diaphragm 2

(pay attention to Notes, Page 1.01 w. 1.03) !

Torque limit =

Screw plug M10x1 20 Nm

Screw plug MI8xI,3 35 Nm

Diaphragm 20 Nm

Close the bores by means. of balls (10 pieces

6 4,50 mm).

Control pressure valve =

Install components £

= Spring (L, = 96,20 mm)

2 = Disk(s) {eptional)

3 = Spool

NOTE :

= determined by the disk 2

y attention to Notes, Page 1.01 .. 1.03) !

Reversing valve :

components =

i

i

(= 56,30 mem)

otal eg «35,30

a, = 51,30

1.67

tan i

fl a Hg

un Hil

qe Eel i

gil He as

12

5 . i 3 3

2 ES i pf le

. Le Ht ij . t J fu

gia Ge ba whl,

pe dasiidl: i sett uit

187

1.70

Install Sirah nares (Sed asocee:

Me fat gasket (Arrow)

shift-control Tai, against shoulder,

ting nuts (3)

Now, fasten shift-control housing by means

of socket head screws (mount flat washers).

Torque limit (M6/8.8) 9,5 Nm

(S$) Adjusting screws (M6) 5870 204 049

with nut

Fasten the two solenoid valves by means of

socket head screws.

Torque limit (M5/8.8) 5,5. Nm

Assemble control spool (K#/KR) and com

pression spring (lo = 51,30 mm) and fix

‘them by means of stop plate.

NOTE =

Position of stop plate, see Arrow !

|

Spring @, = 51,30 mm)

Control spool (K/KR)

= Spring (L, = 51,30 mm)

Control spool (K1/K2/K3)

Spring (L,, = 37,10 mm)

Retaining plate

Socket head screws

Spring (Ly = 51,30 mm)

Pilot spool (total length = 52,50 mm)

MeNaue WN oH

s

Insert solenoid valves and fix them by means

‘of disks, retaining plates and socket head

screws.

Torque limit (M5/8.8) 5,5 Nm

NOTE :

Pay attention to the installation position of

the disks (mount between valve body and re-

taining plate), see Arrow |

Pay attention to the installation posi

the solenoid valves, see also Figure 191 |

Install cable harness.

Torque limit (M6/3-8) 9,3 Nm

NOTE :

Mount new gaskets |

Pay attention to the ication of the plug nose

see Arrow

Connect solenoid valves according to the Il

lustration on the right.

Mount new O-Ring (Arrow) and fix cover by

means of clamping collar.

NOTE :

‘The reassembly of the channel plate as well

‘as the attachment of the gearbox control, are

‘treated on Page 1.46 ... 1.08 1

Pay attention to the Perspective Ilustration

‘af the corresponding Spare Parts List |

wa

192

sind fOr die Ausfhrung nicht. verbindlich

fons are not binding for the design

rations ne sont pas obl igstotres pour 1*execut ion

\dungen

vo} 329, | nod sa1)0yHBF|GO sed yUOS wu su

wb}s0p win 40) CuTPUIG YOU BIE

ut purqaea qua yu Bunsyngsny @1P 4py pays vobunpL gay 210

13

2 TORQUE CONVERTER

: converter connecting

clutch (WK)

21 DISASSEMBLY

Separate the complete converter from the

transmission by means of lifting device.

(S) Assembly car compl with tilting device $870 350 000

(S) Basie support 5870 350 014.

(8) Support 5870 350 036

(S) Set of eye bolts 5870 204 002

Loosen screwed connection.

2.01

Press free wheel inner ring out of the stator

and remove released components.

Squeeze out snap ring.

Press free wheel auter ring out of the sta-

tor.

Separate turbine wheel from converter im=

peller cover.

2.02

Loosen hex. head screws, remove backing

plate and plate pack.

Remove cup spring and demount all criving

pins (Arrow)

Separate piston from converter impeller cover

by means of compressed air.

(3) Rubber cap 3870 309 009

2.2 REASSEMBLY

Squeeze snap ring into the annular groove

(Arrow) of the converter impeller cover.

NOTE +

Install O-Ring (Arrow) and grease it.

Thread up profiled bush ( § ) and press the

drive dog in until the snap ring engages in

the annular groove.

NOTE :

The snap ring is by means of the

profiled bush ( 5 ), thus allowing the reas~

sembly of the drive dog !

(S) Profiled bush 5870 345 073

Install the two rectangular rings, see Arrows!

il piston bearing surfaces as well as rect-

angular rings and insert piston in the con-

verter impeller cover until contact is obtai~

ned.

NOTE =

Expand the inner rectangular ring (140 x 149

x 2 mm) slightly, to ensure a correct con

tact in the piston recess |

Install all driving pins (12 pieces) into the

bores.

2.08

Insert cup spring, with the concave side

showing upwards (see draft, fig 17).

Determine Dimension I from the straightedge

to the outer plate.

Dimension I e.g. 44,0 mm

(CS) Straightedge 5870 200 022

(S$) Digital depth gauge 5870 200 072

Determine Dimension Il from the straightedge

‘to the contact surface of the backing plate.

Dimension I e.g. 43,5 mm

Dimension I 44,0 mm,

Dimension I = 43,5 mm

Difference = Clearance mm

NOTE

Carry out any corrections by means of cor—

responding (5 = 9,2 mm, 9,8 mm and

10,5 mm) |

Torque limit (M8%25/10.9) 34.Nm

(5) Adjusting screw (M%) 5870 204 O11

Fasten turbine wheel hub by means of hex.

head screws (mount flat

Torque limit (M8x18/8.8) 23. Nm

Secure hex. head screws with Loctite (Type-

No. 270) !

Heat the ball bearing and mount it against

shoulder until contact is obtained.

Squeeze in rectangles ring (Aerow 1 end en

Fee Gring (Arrow 2) in the recest of the

turbine wheel hub and grease it.

Thread up pre-assembled turbine wheel until

the inner plates have been received.

Heat stator and insert free wheel outer ring

until contact is obtained.

Fix free wheel outer ring by means of snap

ring.

3

‘The Illustration on the left shows the com

Ponents of the stator.

Shim (constant, s = 1,0 mm)

Ball bearing

Thrust washer (5 = 1,5 mm)

Free wheel inner ring

oes

a

£

"

0 = Shim (optional, e.g. 5 = 0,2 mm)

NOTE :

‘The stator end play is determined by means

‘of shim 10, see Example "B" |

Insert bearing rollers, springs and spring

caps (8, 7, and 6) according to the Illustra-

tion on the left with grease into the bores

of the free wheel hub.

Place ball bearing (2) on the long hub side

(29 mm) against shoulder, install thrust was-

her (3) 3 = 1,5 mm and press free wheel in-

ner ring against shoulder.

Press spring

(CS) into the free

lindrical roller pairs (5) can be installed.

The second roller pair has to be installed

‘opposite to the first roller pair - makes the

installation of the remaining roller pairs ea~

sier !

(S) Guide plate 5870 345 020

Mount thrust washer 3) 5 = 1,5 mm and press

bearing against shoulder.

Install shim (1) s = 1,0 mm and shaft washer

(60x85x9,75).

Opposite side =

Install shim (1) 5 = 1,0 mm, shim (10) (optio~

nal e.g. 5 = 0,5 mm) and shaft washer (60x85x

4,7 5)e

NOTE :

The end play of the stator is determined by

eae of shim (10) (e.g. s = 0,5 mm/empirical

t

However, a later check (Figure 39 — Example

"B*) is absolutely essential |

Mount housing washer (62xB5x0,5 mm) and

bearing (60x85x3 mr).

2.09

210

Install axial roller beatiog ant hoveing “ete

her (62x85x9,79 mm)

Mount new flat gasket and fasten flange by

means of hex. head screws (mount flat was

hers) on the impeller wheel.

Torque limit (M38x18/8.8) 23.Nm

NOTE:

Pay attention to the radial installation posi-

Sous ex head screws with Lectite (Type-

Gane Bane

"3

Mount flat gasket (Arrow).

Determine Dimension 1 from the flange-

mounted surface (gasket) to the plane sur-

face/impeller wheel flange.

Dimension 1 e.g. 88,05 mm

CS) Straightedge 5870 200 022

(5) Gouge Moss 3870 200 066

Digital depth gauge 5870 200 072

Meanire Dimension TI from the flange-moun-

ted surface (converter impeller cover) to the

housing washer.

Dimension I exge 87,95 mm

Example "B" =

Dimension 1

Dimension 0

Difference = End

NOTE

In case of deviations from the permitted end

play (max. 0,2 mm) correct by means of cor-

ting shim 1

The shim is illustrated on Figure 34 !

Screw two adjusting. screws into the converter

impeller cover and mount flat gasket.

Place impeller wheel against shoulder and fas-

ten it by means of hex. head screws.

Torque limit (M8x32/8.8) 23.Nm

NOTE =

Install flat washers

Pay attention to the radial position, see mar-

kings !

(S) Adjusting screw (M8) 5870 208 011

Squeeze the rectangular ring into the annular

groove (Arrow) and engage it.

NOTE :

Install converter, see Page 3.77 |

ait

3. GEARBOX

3.1 DISASSEMBLY

3.1.1 CONVERTER CHARGE PUMP and

Loosen hollow screw and remove delivery line.

Loosen screwed connection (Figure 2) and se-

parate engine connecting case from gear case

by means of pry bars (Figure 3).

Loosen hollow screw and remove delivery line.

3.01

bearing cap.

5870 000 062

Remove locking device.

Loosen socket head screws and remove hou-

sing.

Loosen hex. head screws and lift complete

power take-off housing out of the bore.

(S) Set of eye bolts 5870 204 002

3.07

3.08

Fasten power take-off in a vise.

the two snap rings, align them

centrically and drive the drive dog

wisionally about 5 .. 10 mm ahead

(direction of Arrow).

NOTE :

For this step, an assistant is absolutely

necessary !

(8) Ciretip pliers 5870 900 026

i

ts ting (Figure 29), tap the

drive dog loose and drive it out of the spur

gear, po housing bore (Figure 30).

NOTE =

Pay attention to the released components 1

5870 300 006

5870 300 003

i

i

i

i

|

I

3.1.3 LATERAL POWER TAKE-OFF

Squeeze out circlip (housing interior).

3

4 REMOVE EMERGENCY STEERING

PUP —s—sS

‘Loosen hex. nuts and separate emergency

steering pump from gear case.

3.1.3 REMOVE MULTI-DISK CLUTCHES

NOTE:

In case of Versions with Spur gear fia KL,

the two set screws ( ve to be remo

ved prior to the disassembly of the axle, see

Figure on the right !

&

Loosen hex. nuts and pull axle by means of

Special device out of the clutch, resp. gear

case.

(3) Puller 5370 000 069

Lift clutch out of the gear case and deposit it.

NOTE :

Use lifting device !

Remove clutch KR/K2 accordingly.

In the case of clutch K4/K3, push the lower

spacing washer to the rear, Only then, the

clutch can be removed.

(S) Lifting device 5870 350 O41

3.1.6 REMOVE COUNTERSHAFT ASSEMBLY

Remove closing cover.

Ban

3.12

Loosen socket head screw.

Pull axle by means of Special device out of

the housing bore, resp. spur gear bearing.

(S) Puller 5870 000 083

Remove spur gear and disk.

3.1.7 DISMANTLE MULTI-DISK CLUTCH

Remove spur gear K1 and demount compo-

nents.

‘Squeeze out snap ring.

Remove plate pack.

Preload compression spring, squeeze out cir~

clip and remove components.

4S) Assembly jig 5870 345 028

3.13,

3.14

‘Remove piston by means of clamping pliers.

(5) Clamping pliers 5876 900 007

Pull needle bush out of the bore, using in-

‘ternal puller.

NOTE,

The disassembly of the clutch KV, KR/K2

and K4/K3 has to be carried out accordingly.

(S) Internal puller 5870 300 O18

(3) Back-up tool 5870 300 003

3.1.8 FINAL DRIVE - VERSION WITH

DRUM BRAKE

Remove lock plate and loosen hex. head

screws.

Pry output flange off the shaft.

CS) Pry bar 5870 345 065

Tilt gear case 130°.

Loosen hex. head screws.

Separate brake drum from output flange.

(S) Crow bar 3870 343 O71

315

Remove lock plate and loosen hex. head

screws.

Pull output flange from the shaft.

(S) Two-leg puller (5870 970 004

Unhook return springs and remove brake

shoes.

(5) Brake spring pliers 5870 900 006

Pry shaft seal out of the housing bore.

(S) Crow bar 5870 345 O71

3.16

‘Squeeze out circlip and remove shim.

(S) Circlip pliers 5870 900 021

Loosen the two closing covers by central tap-

ping and remove them.

Remove upper oil retainer.

317

Drive output shaft by means of striker out

‘of the output gear and remove it.

ATTENTION

In case of the Yersion with a mechanical

speedometer, the speedometer-drive shaft

(complete) has to be removed prior to: the

disassembly of the output shaft

(3) Puller 5870 023 O17

(3) Puller 5870 023 026

(5) Striker 5870 650 001

Remove output gear and plate.

Squeeze out circlip and remove brake cam.

(S) Set of external 5870 900 015

snap ring pliers

Drive the pin out of the housing bore and

remove it.

3.18

g

ye 8

2

3

case 180°,

aft seal out of the housing bore.

Squeeze out circlip and remove spacing was-

5870 900 O21

(S) Circlip pliers

3.19

3.2 REASSEMBLY

3.2.) Final drive - Version with Drum brake

Install O-Ring (Arrow), insert pin until con-

tact is obtained and fasten by means of hou-

sing washer, flat washer and hex. head screw.

NOTE :

Secure hex. head screw with Loctite (Type-No-

270)!

Illustration on the right shows the components

of the brake cam.

cam has got contact on the housing without

play and pressure.

NOTE :

scone hee head screw with Loctite (Type-No.

Grease O-Ring (Arrow/Figure 92) !

3.21

For the fol steps pay attention to the

1

H

hee ee

3

4 7

a

‘Squeeze in circlip 1.

Tir gear cave 180"

(CS) Clamping pliers 3870 900 021

Heat bearing inner race 5 and assemble it un-

til contact is obtained.

Position spur gear 6, see Draft !

Position oil retainer 7, sec Draft !

3.23

Fasten both plates by means of hex. head

screws (install flat washers).

Torque limit (M38/3.8) 23. Nm

NOTE,

‘Secure hex. head screws with Lectite (Type-

No. 270).

Squeeze in circlip 8.

(S) Clamping pliers 5870 900 O21

Press the speedometer-drive worm against

shoulder.

NOTE +

In case of a Version without mechanical

@ spacer has to be installed

speedometer,

instead of the speedometer-drive worm !

Thread up output shaft 9 until contact is

obtained.

Check _end ‘of the output shaft_beari

=0,3 =. 0,5 mm 104... Example "A":

Measure Dimension I from the end face/out-

put shaft to the contact face (ball bearing).

Dimension I e.g. 79,60 mm

('S) Digital depth gauge 5870 200 072

Determine Dimension Il from the end face/out-

put shaft to the upper plane surface of the

at

Dimension It e.g. 79,10 mm

Example "A" =

Dimension 1 79,60 mm

Dimension IL = 73,10 mm

Difference = End play = 0,50 mm

NOTE =

In case of deviations from the required end

play, correct by means of a

shim (2), see Figure 95 |

Press ball bearing against shoulder.

3.25

Heat housing bore and thread up output

shaft until contact is obtained.

Fix ball bearing free of play by means of

shim and circlip.

(CS) Clamping pliers 5870 900 021

Install shaft seal with the sealing lip facing

the oil chamber.

NOTE :

The exact installation ‘ition is obtained

by application of the prescribed driver !

If the outer diameter of the shaft seal is

rubberized, wet the sealing surface with spi-

rit!

If not, use sealing compound (Curil T) 1

Grease sealing lip !

(S) Driver 5870 048 067

‘The Figure on the left shows a Version with

two shaft seals (Version with fording ability)

Ee ee Fe oll chamber § inner

shaft seal chamber. Sealing

lip of outer shaft seal is showing outwards.

The installation depth is given by applica-

tion of the prescribed driver !

NOTE

Fill space between upper and lower sealing

lip with grease |

(CS) Driver (5870 O88 067

Install the two closing covers.

NOTE

Sia eae oe Sth tarts (Type-No.

270) t

5) Driver 35870 057 G15

(5) Handle 5870 260 02

n3

Heat output flange and assemble it until con-

tact is obtained.

Fasten output flange by means of disk and

hex. head screws.

NOTE :

Wet the contact surface of disk and screw

heads with sealing compound |

Torque limit (M10/8.3) 46 Nm

Fix hex. head screws by means of lock plate

iver

5870 057 009

5870 260 o02

8

Assemble brake drum and fasten it by

means of hex. head screws (mount flat was

Torque limit (M10/10.9) 68 Nm

(5) Adjusting screws (MIO) 5870 209 007

Figure 119 shows a Version with 2 shaft seals

(Version with fording ability).

Installation ion: Sealing lip of inner

‘shaft seal is facing the oil chamber !

o

Torque limit (M10/8.8) 46 Nm

Fix hex. head screws by means of lock plate.

(5) Driver 5870 057 009

(3) Handle 5870 260 002

Press drive gear flat against the end face/

speedometer-drive shaft.

Introduce speedometer-drive shaft and fix it

by means of straight pin.

(S) Driver 5870 088 072

Torque limit (M8/8.3) 23. Nm

Wet sealing surfaces with Loctite (Type-No.

3.2.3 CLUTCH KA/K3

3.2.3.1 Pre-assemble plate carrier K4/K3

NOTE :

The following steps (Figure 132 .. 138) have

to be carried out on both sides of the plate

carrier |

Press needle bush carefully against shoulder,

using drift (5 ).

NOTE :

‘The needle bush is marked on one end face.

‘At the pressing in, the marking must be show-

ing upwards (to the drift) 1

(8) Drift 5870 506 055

‘Check operation of the bleeder valves.

NOTE :

Ball may not stick, if necessary, clean it by

means of compressed air or renew it !

Insert the profiled sealing rings (Arrows) in

‘the recesses of the piston with the sealing lip

facing the pressure chamber.

NOTE +

— = Pressure side !

Ol profiled sealing rings and insert piston un-

til contact is obtained.

NOTE +

Use installer (S$)!

(S) Installer 5870 651 023

3.33

132

133

134

13s

Assemble lower spring guide (1), ox

Sea, haat eee oes guide G)

Mount guide ring (#) and cirelip (9) (Figure

137), peeload compression spring and fix the

components by means of circlip (Figure 138) -

Assembly jig 5870 345 028

PLATE INSTALLATION

1 Determine Plate installation-No. (Page 3.35)

IL Table for plate installation (Page 3.36 ... 3.360)

I Example with Draft (Page 3.364)

Refit Dateanine Fate iniilotcnt No, reid tho ed ofthe corresponding Syare Parts Lit,

The following List shows the abstract from a Spare Parts

A = Transmission Parts List

B= Group 151, Clutch KV/K1

C = Assembly Note - Plate installation

D = Plate installation-No.

‘The Transmission Parts List (see Model aestncation Plate) must be identical with the

corresponding Parts List of the Spare Parts List!

‘The Plate installations-No. ean be found on the ict Table margin of the following Pages

(3.368 ... 3.366)!

3.35

IL Table for Plate installation

Clutch KV and KR

Jrrceie ft een | ee fee

[Our plate 3 2501 309330,

2 nner plats a S64 308 3

= 3 is ¥644 308 330%)

> (Compensating pais 8

i wns 2s 4644 308 330

16

22.24

pie eS TE

i 1 5 Z0

al mner plate, 4 25

3 | 8% [Compensating plate T 20 $648 108 329

4 3] (laser ple) os = 4644-308 330

2 Na. of friction arfaews 2

= Plate clearzoce 36.28

Gates a im is

4 a, anes plate Z 23 1s

mex plato __

i. it [Compensating plate 7 1S TS Teta 308 1)

3 if (Outer plate) «20 20 4644 308 014°")

i No.of frietion rurfaces 1s

Plate clearance 22a

F [Omens 5 20 Te 0501 300330

2g ay [Tamer plate 7 23 75 $544 308 350

2 [loner plc

i: 8 2 [Compensating plate T 1 Ky Fea sie i)

*| oes oa | ed ee

i By i i

Plats clearance as

Gane plate 7 A) 20 TOL 308350

é toner plate 8 30, Fa $4308 365

= & [too piate

ay i [Compensating plate ze 30 Tea 308 329

a (laanex pave) 1 ons 2s 4644 308-330

3 i = 30 oe 3.0 4644 308 365

2 Ne. of Rien rare ig

Plate clearance 7.28

= [Outer plate oy 20 20 05013183

i |ij ie —*

a g i [toner plate,

Gs EE | compensating ine ie Boss

19/55 [imran eles aioe

3 |2 30

= 2 Na of friction murfaces

Plate clesrance

3.368

‘Gutch K1 and K2

ser 7 a Tse sm

= oie z 3a S08

5 ise pt z a5 e307)

j=———— es

2 or 25. MAL 308 330

of ficton acer

Fie doermnes

= t pn HTH

5 ene z Fm THEI

ies t i asa

i a 7 30 TOE

53 ) 25 4644 308 330

a ichon nabs

Pie doarnes

z z ny is

oo i = 20

Fa [Ener pate z 0 ©

3 e Dierpiae $ as 35

| a T 3a 30

3 was | ozs seitsen 0

: et thckon surthee 1

acs ia

7 = Fn i

coe = ar 3

iJ or z a3 5 Coarse ss

a 7 2 ie C301 314385

il wis | ws Siosiea

E> eetiewrnaten i

Pie cesnes Ta

[0501 309 329

Plate invelinion No

0

Pine talon,

1

Plate inital No

32

3360

* is D501 399338

* 13 6 a6 308 330

z 20. = $645 308332

T 33 as 6a 308 331"

iz Ts “ea2 308 330

1 20 20 4942 908332

25 35 45423083.

16

Ha

z 3 1s 01 3S

i 30 30. ‘O50 313 80")

7 20 14 “et 300

T as a 9642 308 331°)

1s Ts AE 308 330

1 or 20 20 4542308332

oeBS 25 4612300331

ie

Ea

3 3, is COLTTaIO

4 1s 6 0301 314367

z 20 4 Osoi 314383

T 25 zs D501 314 386°)

13 TS 0501 314387

1 20 20 0501 314385

25 or 35 0501 314.386

1.

2.20

Note ref. *) Install inner plate close to the piston.

Note ref. **) Outer plate one-sided coated -

Install plate with the uncoated side facing the piston.

a Outer plate uncoated - install plate facing the piston

‘As second plate, a lining outer plate has to be installed.

‘Attention! In case of plates with different thicknesses,

the thinner plates must be always installed on the backing plate side!

3386

II, EXAMPLE FOR PLATE INSTALLATION

The following Draft shows the plate installation of the Clutch KY and KI |

Ref. Draf

A = Clutch KV

(Plate installation-No. e.g. 12) A B

B = Clutch Kt

won

a

(Plate installation-No. e.g. 22)

Plate carrier

Backing plate

Piston

Outer plates 2

(Outer plates

(one-sided coated)

‘Compensating plate

(Outer plate uncoated)

7 = Inner plates I |

& = Compensating plate Plate thicknesses | Pate thicknesses

(inner plate) decreasing, decreasing,

Attention =

In principle, the arrangement of the outer and inner plates has to be

carried out alternately.

Starting with the piston side, the first plate must be one double-sided

coated outer plate (Standard Version).

Exception

In case of Plate installation-No. 22, 31 and 41, the

first plate must be one one-sided coated outer

plate, and in this case, the plate must be always in-

stalled with the uncoated side facing the piston 1

Exception *B* :

In case of Plate installation-No. 12 and 13, the first

plate must be one double-sided uncoated outer plate

(compensating plate}.

‘As second plate, one coated outer plate has to be

installed.

Now, pile up the inner and outer plates alternately

again |

3.36 d

3.2.3.2 Install plate pack Ke

Install plate pack and replace backing plate.

NOTE :

Plate arrangement,

see

Plate installation, Page 3.35 ... 3.36 d !

Fix plate pack by means of snap ring.

Check plate clearance (Figure 141 to Example

NOTE :

The plate clearance of the different clutches

can be taken from the Table, Page 336 a ...

3.361

In case of Plate installation-No. 40, €.g- = 2,0

oe BGM 1

Measure Dimension I from the end face of

the plate carrier to the backing plate.

Dimension 1 e.g. 5,3 mm

Place backing plate against snap ring until

contact is obtained (upwards), and determine

Dimension Il.

Dimension I e.g. 32 mm

3.37

139

~“¢ )

149

141

142

18

145

Dimension 1 3.3 mm

Dimension IL = 3,2 mm

Difference = Plate clearance 2,1 mm

NOTE :

In case of deviations from the required plate

clearance, correct by means of correspon-

ding compensating plates.

‘The pre-assembly of the remaining clutches

(3, KV/K1 and KR/K2) has to be carried

‘out accordingly.

3.2.3.3 Pre-assemble and install spur gear K4

ATTENTION +

According to the Transmission Version, resp.

‘operating conditions, different spur gear

bearings are possible, see corresponding

Spare Parts List as well as Figures 143 and

vat

‘Spur_gear Ko, Version "A" (Figure 13),

‘Thrust plate = Spur gear

Thrust washer 6 = Bearing inner race

Collar shim 7 = Shim

Roller cage (2x)

‘Spur_gear Ko, Version "BY (Figure 144)

Thrust plate

Thrust washer

‘Spur gear

Needle cage

‘Thrust washer

‘Thrust washer

‘Compensating plate (optional)

Install components 2 ... 6 (Figure 1&3), resp.

2 sw» (Figure 144), replace thrust plate (1)

and introduce spur gear until all inner plates

are received.

NOTE =

Make thrust plate (2) adhere with grease !

3.2.3.4 Install plate pack K3

Install plate pack and check clearance.

NOTE :

Plate arrangement, see plate installation,

Page 3.35 ... 3.36 d!

Exchange cylindrical rollers 5 in sets only !

Install components 2 ... 5, replace thrust plate

1 (Arrow) and introduce spur gear until all in-

ner plates are received.

NOTE :

Make thrust washer 2 and cylindrical rollers 3

adhere with grease.

3.2.3.6 Install clutch K4/K3

Adjust end. of clutch

e188 to

Determine Dimension I from the flange-moun-

ted surface/axle to the plane surfacefhousing

(Arrow).

Dimension I e.g. 231,13 mm

NOTE:

In case of spur gear bearing K4, Version "B*

Gigue (ah, ley forked washer ond. thrust

washer upon the plane surtace of the housing

and measure up to the thrust washer.

3.39

Wa

laTb

3.40

Measure Dimension Il from the butting face

Toearing rollers to the flange-mounted sur~

face.

Dimension I e.g. 21,00 mm

le "C, for the determination of the

i ension

Dimension 1 e.g. 251,15 mm

imension I e.g =_21,00 mm,

Difference = Housing

dimension e.g. 230,15 rum

Place clutch on a suitable surface plate and

determine Dimension Ill from the end face/

cylindrical rollers to the surface plate.

Dimension MI e.g. 227,20 ram

Example "D", for the determination of the

ieulatordineslen

Dimension I e.g. 227,20 mm

End play e.g. + 0,20 mm

gives installation dimension

= Glutch 227,40 mm

Example “E", for the determination of the

shim

Housing dimension e.g. 230,15 mm

Installation dimension - Clutch - 227,40 mm

Difference = Shim e.g. 2,75 mm

Insert clutch K4/KR by means of lifting de-

vice into the housing and position it.

(3) Lifting device 5870 350 O81

Align clutch by means of drift and fix it pro-

visionally..

CS) Drift $870 345 025

For the moment, tilt gear case 90* and

the compl. clutch opposite to the drive side

against shoulder until contact is obtained.

Now, tilt gear case forward in the horizontal

position.

Pull drift downwards until the shim (e.g. =

2,75 me, see Example "E") can be inst

Now, align the complete clutch as well

shim by means of drift again and fix it.

zt

NOTE :

Jin case of spur gear bearing KG, Version "A",

without forked washer and thrust washer (Fi-

gure: 153)!

In case of spur gear bearing Kt, Version "B",

another forked washer as well as one thrust

washer have to be installed in addition to the

shim.

ATTENTION :

Pay attention to the radial installation posi-

tion of the forked washer !

Now, tilt gear case back in the original posi-

3.1

Squeeze in and engage rectangular rings (1).

Install O-Ring (2).

NOTE

Crossman align rectangular rings centrical-

y-

Install stud bolts, see Arrows |

NOTE :

Seowe the stud bolts with Loctite (Type-No.

270) 1

‘Heat housing beres (about 90° C).

(S) Hot-air blower 220 V 5870 221 500

(CS) Hot-air blower 10V 5870 221 501

Thread up axle (compl) until contact is ob-

tained.

3.82

—————— tS! 8.8) 23 Nm

of the clutch 0,1 ... 0,3 mm

SS" if necessary.

base 5870 200 055

—Sstor 3870 200 057

9870 345 O71

es of the clutches K¢ and K3 by

—_ essed air.

———————— are correctly installed, the

ing of the clutches is clear-

3.43

ear beari

1 = Thrust plate 8 = Spur gear

2 = Theust washer 9 = Plate

3 = Theust washer 10 = Hex. head screws

4 = Cylindrical rollers 11 = Thrust washer

(short) 12 = Forked washer

3 = Disk 13 = Shim (optional)

6 = Cylindrical rollers

(ong)

7 = Theust washer

NOTE

‘Secure hex. head screws (M6/8.8 = 9,5 Nin)

with Loctite (Type-No. 270) |

Install components 2 ... 6 (Fig. 171 and 172 a)

resp. 2 ... 10 (Fig. 172 b).

‘Replace thrust plate | (Arrow) and thread up

Spur gear until all inner plates ate received.

NOTE

Make thrust washers and cylindrical rollers

adhere with grease !

3.2.3.3 Plate pack K2

Install plate pack and check clearance.

\NOTI

Plate arrangement, see

Plate installati 3.35... 3.36 d 1

3.2.5. Pre-assemble and install spur gear K2

NOTE

According to the Transmission Version, resp.

‘operating conditions, different spur gear bea-

rings are possible, see corresponding Spare

Parts Listas well as the following Figures

(075 and 176) 1

307

174

15

176

3.48

Spur_gear bearing K2, Version "A" Fig, 173

Pay attention to the installation position of

‘the roller cage (8), the larger inner diarne-

ter of the brass cage is showing outwards

(Arrow) |

The broad butting faces of the angle rings

are always facing the bearing rollers }

Make thrust washer (2) adhere with grease !

‘Spur_gear bearing KZ, Version "B" Fig. 176

NOTE =

Pay attention to the installation position of

the roller cage (9), the larger inner diame~

ter of the brass cage is showing outwards

(Arrow) t

Ih case of an equal inner diameter, the in-

stallation position is optional.

Make thrust washer adhere with grease 1

Install components 2 ... § (Figure 175), resp.

2 a 6 (Figure 176).

Replace thrust plate 1 (Arrow) and thread up

spur gear until all inner plates are received.

NOTE :

Make: thrust washer adhere with grease 1

3.2.5.5 Install clutch KR/K2