0% found this document useful (0 votes)

117 views6 pages4-Fuel System

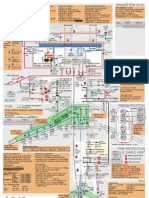

The document discusses checking and maintaining a vehicle's fuel system. It covers inspecting fuel pressure and the fuel pump, replacing the fuel pump if needed, and checking the fuel emission control system including the carbon canister and canister control valve.

Uploaded by

Pomoć Muslimanima (u potrebi)Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

117 views6 pages4-Fuel System

The document discusses checking and maintaining a vehicle's fuel system. It covers inspecting fuel pressure and the fuel pump, replacing the fuel pump if needed, and checking the fuel emission control system including the carbon canister and canister control valve.

Uploaded by

Pomoć Muslimanima (u potrebi)Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd