Professional Documents

Culture Documents

Plano de Avion Exper 79710 Downloadable 5698003

Uploaded by

charly36Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plano de Avion Exper 79710 Downloadable 5698003

Uploaded by

charly36Copyright:

Available Formats

Accede a apuntes, guías, libros y más de tu carrera

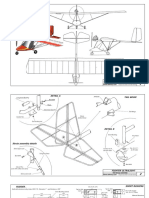

PLANO DE AVIÓN EXPERIMENTAL

24 pag.

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

OSVALDO DURAN

A

A

N

A

R

U

D

O

LD

A

V

S

O

FIGHTER ULTRALIGHT -

Three view

Plans delivery.com Designed and drawn by Osvaldo Durana 1

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

DETAIL A

AN Bolts

Long Inner Bushing TAIL BOOM

Bolt AN4

Hinge

Short Inner Bushing

Tail fittings

Struts

Control Tee

(dotted lines)

Self locking nut

DETAIL B

Inner Bushing

Pop Rivet

Struts assembly details

B

O

S

Dia. 25,4 (1)

V

A

Strut Upper Link Contour to fit

L

D

O

D

U

R

(to fit tube)

A

N

elevator tube

A

25,4

(1)

Tail group Strut

Bolt AN4

Dia.6,35

(.25)

Bolt AN4

Clevis Pins

(use with safety lock pins)

FIGHTER ULTRALIGHT -

Tail Group assembly

Strut Lower Link

Plans delivery.com Designed and drawn by Osvaldo Durana 2

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

SHORT BUSHING

RUDDER . Dia. 6,35 (.25)

Built with aluminum alloy tubes 6061-T6 - Diameter 1 - wall thickness .065 Tap for AN4

Tap for AN4

Bolt Dia. To fit snuggly

Bolt 15 (.59)

Inner Bushing (short)

into 25,4 (1) tubes

Dia. To fit

406 203

snuggly 12

(8) Material Aluminum

12

(16)

(.47)

into 25,4 (.47)

30 (1.18)

22 (.86)

(1) tubes 22(.86)

B 60 (2.36)

B 36 (1.42)

LONG BUSHING

Radius 127 (5) Rad.127 5 =(.197)

(5) 21,5 = (.846) TAIL GROUP

558 (22)

5

21,5

5 FITTING

Material

FIN

Dia.25,4 Dia.25,4 304 Stainless Steel

Rad. 11

(1) (1)

Bend line

35 56 1,5 (.063) thickness

(0.43)

(1.38) (2.20) 3 Required.

Dia. 6,35

Dia. 19 (3/4) x (.25)

1,65 (.065)

Hardwood bushing

1255 (49-7/16)

Dia.19 (3/4) x 92 (3.62)

1,65 (.065)

114,5 (4.5)

70

1360 (53-1/2)

(2.76)

Rad. 9

CONTROL TEE

(.35) 2024-T3 Aluminum

Rad. 127 (5)

Dia 6,35 5 (.190)Thickness

(.25) 1 Required

Rad.12,7 33 (1.30)

Long Inner (.50)

Bushing

225 (8-7/8)

Dia 6,35

127 (5) (.25) 30 (1.81)

B B

127

(5)

482 Rad. 9 (.35)

(19)

450

(17-3/4)

FIGHTER ULTRALIGHT -

Tail Group /Rudder

Plans delivery.com Designed and drawn by Osvaldo Durana 3

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

ELEVATOR .

Built with aluminum alloy tubes Quality 6061-T6 - Diameter 25,4 (1)

130 127

1185 (46-5/8) Wall thickness .065

(5.11) (5)

600 (23-3/8)

425 (16-3/4)

Lower link attachment point

Dia. 19 (3/4) x 1,65 (.065)

(see plan #2) Rad. 152 (6)

203 (8)

Dia. 25,4 (1) x 1,65 (.065)

B B B

B

2500 (98.425)

B B

B B

101 (4) Lower link attachment point

R (see plan #2)

301 (11-7/8)

R 152 (6)

27º

625 (24-5/8)

UPPER LINK .

R 225 (8-7/8)

Stainless Steel

1,5 (.063) Thickness

1 Required

Dia. 6,35 (.25)

25,4 930 (36-5/8)

Dia.5 (3/16)

(1)

Drill to fit Clevis pin Dia. 5 (3/16)

Dia. 5 17 (.67) Dia 15 (5/8)

50,8 (2)

(3/16)

TAIL GROUP STRUTS .

Dia. 5 (3/16)

Aluminum tube Dia. 15 (5/8) x 1.65 (.065)

1,5 (.060)

2 Required

Dia. 5

Length*

(3/16)

30 (1.18)

FIGHTER ULTRALIGHT -

* Once the tail group is built and assembled, align it and Tail Group /Elevator

Stainless Steel 1,5 (.063)

LOWER LINK . 2 Required

take the exact measurement of the struts

Plans delivery.com Designed and drawn by Osvaldo Durana 4

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

WING

Wing Spar

Wing Spar Bracket

Wing Tip Aileron

. Wing rib

Boom

Compression Struts

See Details A, B, C, D, E and F on Page 6

Wing rib Detail

Turnbuckles

,

Rib/Spar attachment

Compression Strut

Turnbuckles

Rear Spar

Reinforcement Bushings

Tensor Cable

Link

Wing Root

O

S

V

Front Spar

A

L

D

O

D

U

R

A

FIGHTER ULTRALIGHT

N

A

Wing Spar

-

Bolts

Wing /Assembly

Wing strut fittings

Plans delivery.com Designed and drawn by Osvaldo Durana 5

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

DETAIL B DETAIL C

Aileron Ribs Aluminum tube Dia. 9,5

DETAIL A

(3/8) 0,90 (.035) Wall Thk

Trailing edge tube

Aileron Spar Aluminum tube Dia. aluminum Dia 15,8 (5/8)

38(1-1/2) 1,47 (.058) Wall Thk 1,47 (.058) Wall Thk

Aluminum Sheet tip

Aileron Spar

Wood screw

Steel pop rivet

Aileron Rib Hardwood insert

Aleron Root

DETAIL F

Aileron Tip Assembly Wing Tip

DETAIL D

Wing Spar

Reinforcement Bushing

Aileron Spar

Plastic bushing

25,4 (1)

DETAIL E

5 Steel pop rivets

Wing Spar Hinge

Hardwood Bushing

50,8

(2)

Tensor cable

30

Aileron Control Arm

(1.18)

Hardwood inner reinforcement

101(4) long.

4 Reqd.

Link

Bolt

FIGHTER ULTRALIGHT -

Wing /Details

Plans delivery.com Designed and drawn by Osvaldo Durana 6

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

Wing .

Spars: 2024-T3 Diameter 50,8 (2) -1,65 (.065) wall thickness - Compression Struts 2024-T3 Aluminum tube Dia 25,4 (1) - 1,65 (.065)Wall Thk

Top view

200(7.87)

4520 (177.95) Wing root

2970 (117)

1320 (52)

Front Spar 550(21.65) 101 (4)

Compression strut

le

Compression strut

Wing Tip b

Wing ribs (9 per wing)

a

c

r

o

s

n

e

T

1170 (46.06)

Hinge

Wing tip bolted

to rear Spar

200 (7.87) Hinge Hinge

Hinge 260(10.23)

Aileron

Trailing edge

Dia 15,8(5/8) 640 (25.19)

20º

4450 (175.20)

Wing Brackets .

Mat: Stainless Steel - 2,5 (.100) Thick - 4 Required

6061-T6 Aluminum Tube Dia

25,4(1)

R 16 Dia 8

(.63) (.312)

Wing Tip . R160

Dia 8

Bending line

200(7.87) 54 (2.12)

(6.30)

2 Required (.312)

Dia11

150(5.90)

(7/16)

54(2.12)

150(5.90)

1175(46.26)

FIGHTER ULTRALIGHT -

Wing /Construction Details

Plans delivery.com Designed and drawn by Osvaldo Durana 7

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

AILERON CONTROL ARM

Bend around Dia 8 (.312) WING STRUT FITTING

80 (3.15)

to get a U shape 72

74

R 18 R.16

(2,83)

(2.91) R. 17

(.70) (.63)

(.67) R. 17

R. 9 (.35) Dia. 6,36 (.25) 2024-T3 Alum.

(.67)

50

Thickness: 5 (.190)

(1.97)

Dia. 6,35 (.25) 8 Required

35

Dia. 8 (.312)

(1.38)

Dia. 8 (.312)

70

R. 44 (1.73)

STRUT INNER LINK

(2.75) 50

Mat: Stainless Steel

(1.97)

Dia. 6,35 108º Thickness: 2 (.080)

(.25) R.16 (.63)

4 Required

87

R. 17

(3.42)

WING STRUT TIP

(.67)

4130 Steel

50

Thickness: 2 (.80)

Material 2024-T3 aluminum Thickness 5 (.190) 2 Required (1.97)

Dia 8

8 Required

(.312)

73

2 (.080)

Dia 5 (.187) (2.87)

R 8 (.31)

8 (.31)

HINGES Chamfer Detail

Dia. 8 (.312)

20

22 (.86)

R. 17

Mat: Stainless Steel 1,5 (.063) Thick

(.80)

13

SPACER

(.51)

(.67)

14 Required

Mat: Steel

14

23

2 (.080) Thick.8 Required

(.90) (.55)

25º

R.15 (.60)

LINK

9

Dia.6,35

(.35)

(.25) 30 (1.18)

30 (1.18)

84 (3.30)

180 (7.08) 5 (.20)

R.11 (.43) Dia.6,35

112 (4.41) 30 (1.18) (.25)

Dia 3(.12) Dia. 8

Bend 90º

20 (.312)

(.80) upward by

Bending lines 15 (.60)

38 (1.50)

Dia. 3 dotted lines

Dia.6,35

(.12)

(.25)

Material :Stainless Steel

53 (2.08)

5 (3/16) 104 (4.09) Thickness 1,5 (.063)

8 Required

232 (9.13) FIGHTER ULTRALIGHT -

Wing /Construction Details

AILERON TIP Mat: Aluminum sheet 2024-T3 - 0,7 (.025) Thick - 2 Required Plans delivery.com Designed and drawn by Osvaldo Durana

8

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

(4.527)

(6.575)

(6.220)

(6.693)

(6.417)

(6.772)

(7.441)

(5.905)

(6.732)

(6.614)

(6.496)

(3.740)

(6.338)

(6.732)

(5.590)

(5.118)

167

158

170

163

172

189

150

171

168

165

161

171

115

142

130

95

(2.835)

72

25,4

(1)

Wing ribs are made from aluminum alloy tubes Dia. 9.52 (3/8) .035 wall thickness

riveted from leading edge spar to trailing edge spar.

Wing Rib Attachment

Mat: 2024-T3 Aluminum Sheet

30

0,7(.025) Thick - 36 required

(1.18)

1170

Drill for pop rivets

(2.76)

(46.063)

25,4

(1)

70

101

FIGHTER ULTRALIGHT -

(4) Detail rear spar

Wing /Airfoil-Wing rib

Plans delivery.com Designed and drawn by Osvaldo Durana 9

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

Front mast DETAIL A DETAIL B

Fuselage Front end

Exploded view Boom ring

AN5 Bolts

Fuselage nose plate

Central Brackets

(upper) Fork

Central boom support

Bushing

Rear boom support

Fuselage nose plate

(lower)

Side member

Rear member 3

Front mast

Reinforcement

B

tube

Side member

2

Fork

Side member

1) Boom support bracket

2) Rear link plate

3) Wing strut link plate

Nose wheel

4) Landing gear mounting bracket

FIGHTER ULTRALIGHT -

Fuselage/Cockpit - Assembly Details

Plans delivery.com Designed and drawn by Osvaldo Durana 10

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

3900 (153.54)

530(20.86) 1170(46.06)

Boom

650(25.60) 1550(61.02)

40(1.57) 153(6.02) Mat: 6063-T3 Aluminum Tube

463(18.23)

Dia 101 (4) 2 (.078) Wall Thk

90(3.54) 240(9.45) 437(17.20)

Rear Boom

Central Plate 135(5.32) Support

Mat: 2024-T3 Aluminum 5(.190) thick - 1 Required

Mat: 6061-T6 Aluminum

R 180 (7.09) 168(6.61) tubes Dia 28 (1-1/8)

R 150(5.90)

1,5 (.058) wall Thickness

Central Boom Support

2 Required (rigth/left)

Mat: 6061-T6 Aluminum

950 (37-7/16)

tubes Dia 28 (1-1/8) Central plate

1,5 (.058) wall Thickness Riveted here

Dia 101(4)

2 Required (rigth/left) 150(5.90)

5

8

(.196)

(.312)

1360 (53.54)

280(11.02)

25,4(1)

Dia 28

Fuselage Rear Member (1-1/8)

Mat: same as side member-1 Reqd.

R 336 (13-1/4)

Fuselage

74(2.91)

Side Member

101 (4) Mat: 2024-T3 Aluminum

tubes Dia 50,8 (2) 1,65

700 (27-9/16) (.065) Wall Thickness

730 (28-3/4)

2 Required (left/right)

1140(44.88)

74(2.91)

75(2.95)

530(20.87) R 336

(13-1/4)

340(13.38)

45(1.8)

270(10.63)

380(15)

25,4(1)

210(8.27)

50.8(2)

10(.39)

Dia 8

155(6.10)

300(11.81) (.312)

110(4.33)

700 (27-9/16)

101 101 101 101 101 101 101 101

FIGHTER ULTRALIGHT -

(4) (4) (4) (4) (4) (4) (4) (4)

35(1.38)

1460(57.49) 25,4(1) Boom / Fuselage components

Plans delivery.com Designed and drawn by Osvaldo Durana 11

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

90 (3.54) Rear Link Plate Fuselage Nose Plate

2(.080) 2(.080) Mat: 2024-T3 Aluminum 5 (.190) Thick 2 Required

26

(1.02) (Upper/Lower see instructions)

90(3.54)

60(2.36) 210 (8.27)

90 (3.54)

R 15

35(1.38)

60(2.36)

40(1.57) (.60)

Dia 8

(.312) Dia 8

(.312)

105(4.13)

74(2.91)

R11

(.43)

Dia 8

(.312)

Boom support bracket Mat: 2024-T3 Aluminum

Mat: Stainless Steel 2 (.080) Thick -2 required 5 (.190) Thick

4 Required

Wing Strut Link R 15

Mat: Stainless Steel -2 (0.80) Thick -4 Required (.60)

230 (9.05)

Dia 8

Landing Gear Bracket !4(.55) (.312)

Dia 8

Mat: Stainless Steel

(.312)

36(1.42) 2 (.080) Thick - 2 Required

71 (2.80)

40(1.57)

88 (3.46)

Bending line

35(1.38)

Dia 8

Bend 7º upward

92 (3.62)

(.312)

66 (2.60)

R13

Dia12,7(1/2)

60(2.36) (.51) 2(.080)

26(1.02)

90(3.54)

20(.79)

Pop rivet to boom

Bend around 4 tube and Boom Ring

80 (3.15) 46 comform like this

Section

(1.81) Mat: 2024-T3 Aluminum -

3 (.125) Thick Dia 8

(.312)

1 Required

57

(2-1/4)

FIGHTER ULTRALIGHT -

340 (13.38) Fuselage brackets

370 (14.57) Plans delivery.com Designed and drawn by Osvaldo Durana 12

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

FORK FRONT AXLE LANDING GEAR

425

Mat: Steel tube Front View

(16-3/4)

62 (2.44) Link from 2 (.83) Thick

320

pedal

(12-5/8)

attachment

point

FRONT FITTING

Mat: Steel

660 (26)

Steel Tube 2,5 (.100) Thick

Dia 22 (7/8) Steel Tube

1,2 (.049) Thick Dia 22 (7/8)1,2 (.049) Thick

353 (13-7/8) Dia 44 62 (2.44)

165 (6-1/2)

(1-3/4)

Steel Tube

Dia 22 (7/8)

90

Dia 12,7 (1/2) 1,2 (.049) Thick

(3.54)

2 (.083) Thick.

Welded Reinforcement

Attach Clevis Pin

Cotter pin

Steel Tube

Dia. 12,7 (1/2)

Weld

REAR LANDING GEAR LEG

DETAIL

6 (.23)

Drill for cotter pin

Axle housing

(each end)

To slide fit axle

Landing Gear Pivot Bracket Tap (see rear axle)

Mat: Steel 2 (.080) Thick 30 (1.18)

4 required

R 15 (.60)

Brake Attachment Fitting

FORK HEAD Dia 22 (7/8)

10 x 10 (.39 x .39)

R 12 (.47)

Mat: Steel 2,5 (.100) Thick Dia 8 (.187)

2 required

Welded steel washer

14 (.55)

Dia 9,5 (3/8) 3 (3/16) Thick

52 (2.05)

R 17 (.67) 50,8

Dia. 12,7 (1/2) Mat: Steel 2 (.080) Thick

46 (1.81)

30 (2)

Fit to slide steel tubes 2 required

(1.18)

12,7

(1/2) FIGHTER ULTRALIGHT -

R. 17 (.67)

134 (5.27) Landing Gear

110 (4.33)

Plans delivery.com Designed and drawn by Osvaldo Durana 13

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

Rear axle

Landing gear leg Mat: Steel - 2 Required

Dia 22 Dia 16

Dia 17

Dia 15

(.87) (0.63)

Brake positioning lug (.67)

(.60)

Thread Thread

25,4(1)

2(.08)

42(1.65)

52(2.04)

Brake plate 86(3.38)

100(3.94)

115(4.53)

Rear axle

Spring

Brake arms Wheel

Brake drum

Inner wheel half

Bearing

Bearing housing

Bearing housing

Inner wheel half

Bearing

Control cable

A

N

A

R

U

D

O

D

L

A

V

S

O

Self locking nuts

Actuator arm

Slot for positioning lug

FIGHTER ULTRALIGHT -

Brake plate rear view Rear Wheel Assembly / Axle

Plans delivery.com Designed and drawn by Osvaldo Durana 14

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

Central Bracket

Mat: Stainless steel - 2,5 (.100) Thick 2 Required

Dia 8

R 16

(.312)

(.63) Front Mast

Dia 8

Bending line

Aluminum Alloy tube Dia 32 (1-1/4)

30(1.18)

(.312)

Central brackets 1,47 (.058) Wall Thk

A

N

A

Lenght: 1000 (39.37)

R

U

D

O

D

L

A

V

S

O

Dia 11

(7/16)

30 (1.18)

62 (2.44)

Side Stick

Aluminum

tube Dia 25,4 (1)

300 (11.8) length

Torque tube

Aluminum Dia 25,4 (1)

500 (19.68) length

attached to longerons

by Nylon bushing

(allowing rotation)

Control Arm

FIGHTER ULTRALIGHT -

Fuselage /Tail Boom Assembled

Plans delivery.com Designed and drawn by Osvaldo Durana 15

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

AILERONS

PEDALS

RUDDER

MIXER

CONTROL SIDE STICK

ELEVATOR

CONTROL CABLES

TELEFLEX TYPE

TAIL GROUP

FIGHTER ULTRALIGHT -

Control System

Plans delivery.com Designed and drawn by Osvaldo Durana 16

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

Control Stick end Mat: Aluminum- 1 Required Control Arm 2(.090) Pedal Mat: Aluminum sheet 3(.125) thick. -2 Required

Dia12,7(.5)

*Dia 22(.87) 12,7(1/2) Mat: Steel - 1 Reqd.

12,7(1/2)

130(5-1\8)

* Diameter to fit snuggly in 1 dia. alum tube

** Insert in torque

101(4)

35(1.38)

tube before drill.

**5(.187)

5(.187)

47(1.85)

8

weld

50(1.97)

(.312)

76(3)

**5(.187) 36(1.42)

36(1.42)

*Dia 22(.87)

R

45(1.77)

R 3 (.12)

135(5.31)

25,4 15(.60)

60(2.36)

12,7

(1/2) (1)

R15(.60)

55(2.16)

50,8(2)

Aileron mixer Pedal Bushing

2(.090)

12(.47)

Mat:Steel 1 Rqrd.

5(.187)

Dia 8 Mat: Grilon 4 Reqd.

R10

(.312) 6,35(1/4)

(.40) 32(1.26)

3,5(.137)

12,7(1/2)

60(2.36)

20(.79)

R13(.51)

Dia 12,7(1/2)

15(.60)

10(.39)

Push-Pull Barr end Mat: Aluminum- 1 Required 15(.60) 26(1.02)

285(11.22)

130(5.19)

36(1.42) 8(.312)

R13(.51)

30

(1.18) 38(1.50)

60(2.36)

*Dia22(.87) 32(1-1/4)

155 (6.10)

Pedal Tang

47(1.85) 40(1.60)

R9(.35) 6,35

104(4.09)

15(.60) (1/4)

12(.48)

R

R3(.12)

10(.40)

5

12,7(1/2)

85(3.35)

53(2.08)

20(.79) (.187)

Weld

Dia. 5 5(.187)

5(.187)

(.187) 25,4(1)

12(.47)

Bending lines

6(.24)

Aileron Control Link 20(.79) 11(.43)

Mat steel tube Dia 11(7/16) - 2 Required

33(1.30)

101 (4)

170(6.70) 140 (5.51)

200 (7.87)

Mat: S.Steel 2(.090)

2 Required

FIGHTER ULTRALIGHT -

Rod End Bearings Tap tubes 1/4-28 thread or Control components

Male thread weld nut at both ends

Plans delivery.com Designed and drawn by Osvaldo Durana 17

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

WING STRUTS PEDALS

Steel tube to connect teleflex

REAR SPAR

Bushings

FRONT SPAR

Steel cable connect to fork

Wing strut

fitting

Strut inner link

Aluminum tubes

Spacers

Wing strut tip

Wing Strut

Weld

Wing strut are made from THROTTLE ASSY

streamlined steel tube.

FIGHTER ULTRALIGHT -

Wing Struts / Pedals Assembly

Plans delivery.com Designed and drawn by Osvaldo Durana 18

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

ENGINE

Upper Bracket

Rubber mounts

Lower Bracket

Boom

Side Bracket

A

N

A

R

U

D

O

D

L

A

V

S

O

External Adapter

Inner Adapter

FIGHTER ULTRALIGHT -

Engine Mount Assembly

Plans delivery.com Designed and drawn by Osvaldo Durana 19

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

Engine Mount Side Bracket

Inner Adapter

Mat: Stainless Steel

Front View 1)

25,4 Mat: Aluminum 2 required

(1) 3 (1/8) Thick

135º 2 Required

135º

164 (6.46)

According inner

diameter of

Boom Dia 8 60 (2.36)

(5/16)

135º Bending line

Dia 8

(5/16) 15

65 (2.60)

(.60)

50,8

35(1.38)

(2)

R 10 (.39)

Upper Bracket Boom 50.8 (2)

Mat: Stainless Steel Aluminum tube Dia. 101 (4)

3 (1/8) Thick

2 Required

25.4 (1)

1) R 10 (.39)

Bending Line

Bending Line

2) 50,8 (2)

50,8 (2) NOTE

1) Diameter according Rubber

mounts

25,4 25,4

2) Diameter according en-

(1)

3) R. 50,8 (2)

60 (1) 65

60 gine bolts

(2.36) (2.36) (2.56)

273 (10-3/4) 3) Length according engine Dia 8

(5/16)

15

(.60)

310 (12.20)

25,4 25,4

(1) (1)

External Adapter

R 10

Bending Line

1) Mat: Aluminum 2 Required

Bending Line

(.39)

50,8 (2)

FIGHTER ULTRALIGHT -

65 65 Engine Mount Details

(2.56) (2.56)

Plans delivery.com Designed and drawn by Osvaldo Durana 20

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

220 220 230 220 240

(8.66) (8.66) (9.05) (8.66) (9.45)

Polycarbonate windshield

450(17.72)

340(13.38)

230(9.05)

(16.93)

(12.40)

430

(7.87)

315

(984)

200

250

(27.95)

(21.65)

(26.38)

(17.72)

(11.42)

710

550

670

450

290

220 220 230 220 240 FIGHTER ULTRALIGHT -

(8.66) (8.66) (9.05) (8.66) (9.45)

Cockpit Enclosure Three view

Plans delivery.com Designed and drawn by Osvaldo Durana 21

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

Fighter Ultralight

Building guidelines

Welcome! You are about to get involve in one of Dont for get the safety equipment like eye protec- Fasten the pulley and the support block to your two o three fillets of the thread should be vis-

the most rew arding projects that you can make tors, gloves, and respirators, always protect your worktable. ible.

with your own hands: eyes when drilling or working with power tools. Before cutting the tubes to be bend, be sure to If you want to assemble provisory the parts don t

An ultral ight aircraft that will bring you hours of Wel l, you got the space, the tools, get some raw allow material in ex cess. use self-locking nuts, but remember to replace

excitement and fun! material and start... Insert a plug into one of the tube ends, pour dry them when the assembly is definitive.

Before starting, take a moment to study the plans, sand inside the tube, tap gently to compact the

so you can understand the whole project and how Building the Tail group sand inside and place another plug on the other Use only stainless steel pop rivets; the alumi-

each part are made and assembled. This is the best starting point, especially to those end, the sand helps to avoid deformation in the num rivets will not have the str ength needed.

of you who need to gain practice in mechanical tube when it is bend.

Building process constructions. Once the tube is placed in the bending jig, secure The elevator is linked to the rudder wi th two

In the page #2 you can see the tai l group assem- it against the pulley with the support block and struts, which give strength to the tai l and help

It is recommendable to start with the tail group; bly and how it is fasten to the boom tube. start bending it very slowly, dont try to bend it in to maintain the rudder and the elevator at 90

this will give you the experience needed to con- In page # 3 you ha ve all speci fications needed for one stroke, you will get wrinkles in the whole bend. degrees from each other. You will have to verify

tinue with more demanding or complex parts. building each element. The bending is made little by little moving the tube the length of each strut (they should be identi-

Begin with the fin, its the simplest part of the tai l forward in smal l increments till the curve is com- cal) measuring it once the tail group is finished

Your workshop and tools group. plete. and assembled.

This ultral ight can be build in an average home Bending the tubes Draw the desir e curve as a guide in the floor or in

garage, however more space will be required to If you don t have a tube bender, you can make a board and use it to check the progress of the The wing

assemble the complete aircraft. your own bending jig curve, placing the tube frequently against the draw- As you study the pages # 5; 6 and 7 you will

Put special attention to illumination of your work Using a hardwood pulley as depicted in the fol- ing. Try not to over-bend the tubes, it will be al- realize that the wing is not as complex as it ma y

area, working in a poorly illuminated area will lowing drawing. most impossible to un-bend. seem.

get you tired sooner and also prone to commi t The most difficult part of this operation is to ob- I recommend you to start with the compression

mistakes (some of them can be costly and some tain symmetric o equal curves as the ones required struts, these parts are made from 1 diameter

Support Block

dangerous) in the elevator, but don t dismay, wi th some prac- aluminum alloy tubes, cut them at the indicated

Keep your shop clean and organized, which will tice you will be able to create good curves. length and then make the stainless steel links

save you time and effort. After cutting the tubes to the r equired length use (page 8)

Equipment needed: a small round file or a deburring tool to clean the

A strong worktable is a definitive must. inside part of the tube. After cutting the spars and prior to start assem-

Measuring tools: bling the wing it is advisable to get a large board

Venier caliper, metallic ruler, measuring tape, The brackets are made from stainless steel sheet, where you can place and assembly the complete

Hardwood pulley

square, center punch, fel t point marker pen. this material is very tough and you will need well wing, since the dimension of each wing is more

Hand tools: sharpened drill bits to make the holes, make them large than the average worktables, you can en-

Hammer, hacksaw with several spare blades (with Diameter to fit tube smaller than the diameter required, then use a large the working surface of your table or bench,

different number of teeth per inch, to cut alumi- reamer in order to enlarge the holes at the right by placing a particle board over it.

num and steel) pop riveter, files (flat and r ound, size (the bolts should fit snuggly) Its a good idea to nail wood blocks to the table

nd

2 and smooth cut) pl iers, aviation snips, com- Draw the contour of each bracket in the steel sheet, in order to secure the wing spars and other wing

bination wrenches, deburring tool, reamers. mark the holes with a punch marker, cut along the elements being added to the assembly.

Harwood pulley

Equip your worktable with a medium size vise to lines, clean the cuts with a file and bend as needed,

hold the parts been made. only then make the required holes. Page 5 shows the wing strut fi ttings bolted into

Drill and drill bits, a bench drill press can also be FIGHTER ULTRALIGHT

the spar with two reinforcement bushing,

- which

a great addition to your shop. In every assembly check the lengths of the bolts, are made from aluminum tubes.

once tighten with a nut (self locking nuts) only (Read Reinforcement bushing)

Plans delivery.com Designed and drawn by Osvaldo Durana

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

Once the spars and compression struts are bolted

Now with the Nicopr ess Tool, you can compress num tubes that will support the boom (page 11)

together, you can connect them with the tensor

the nicopress sleeve (usually making three grooves Rear boom support use an aluminum ring (page

cables which will give the wing an extraordinary

along sleeves length), after that you can take away 12) to attach the boom (don t forget to rivet it

rigidity

the cable clamp and the hose. to the boom)

The wing tip tube is riveted to the main spar as

The central boom support tubes (page 11) are

indicated in page 6 (detail F) and bolted to the

attached to the boom using steel brackets (page

rear spar. Now you can start making the wing ribs, accord-

15 Central brackets)

Tensor cables At the end of the cable, slide a short piece of rub- ing to the drawing in page 9, to make all ribs equal,

Be careful when making the holes in the boom,

The following drawings show you step by step ber hose. cut a pattern from a ½ inch wood slab and use it

have the tail group in place befor e attaching the

how to make them. Now slide the nicopress sleeve, mak e a loop with to bend the ribs.

chassis, this will help to keep the assembly

The cable used is 1/8 x 1 x 19 steel cable that the cable and pass the end of the cable again Cut the end of every rib as shown in page 9 to fi t

aligned.

can be galvanized or stainless. through the nicopress and the hose. over the main spar.

Finally measure and cut the front mast, you can

(Diameter 1/8 x one strand of 19 wires) 9 ribs are required for each half wing, and are

use a streamlined aluminum tube, and two stain-

Be sure to measure correctly each cable before riveted to the spars with the attaching fitting (made

less steel brackets to connect the mast wi th the

cutting them. from aluminum sheet)

boom tube and the chassis.

Use a square to align each rib at 90 degrees from

the spars and perpendicular to the span.

Reinforcement bushings

When tubes are to be bolted, to avoid been flat-

Ailerons

tened when the bolt union is tighten, you can

Measure and cut to the required length the aile-

insert a short piece of hardwood or Nylon turned

ron spar from an aluminum tube diameter 38 (1-

to fit the inside diameter of the tube.

In the eye formed by the cable, put a thimble and 1/2) mark the position of every aileron rib and

In some instances the reinforcement can be

adjust all the assembly, you can use a cable clamp drill a small hole through the spar, enlarge the

achieved using small aluminum tube as bush-

to keep them in place. hole in the inboard face of the spar to accept the

ing.

aluminum rib (3/8 diameter tube) the trailing edge

e.g. for a 5/16 bolt (AN5) use as a bushing a 3/

Thimble tube is fastened to the ribs with pop rivets.

8 x .028 wall thickness tube

Once finished, place the aileron next to the wing

for a 7/16 bolt (AN7) you can use a ½ x .028

in the right position, mark the position of each

wal l thickness tube.

hinge, drill and bolt them in place.

Wing Spar (page 5)

Cockpit chassis

Now you can start wi th the cockpit chassis, cut-

To cut the cable, wr ap it with electrical tape and

ting and bending the side members, using the

cut it with chisel and hammer (never cut them

Cable clamp bending method previously explained (you will

with a welding torch, doing this could modify

need to make another har dwood pulley to accept

their mechanical properties)

the 2 diameter tube)

Cut the straight r ear member and make al l brack-

ets and plates as explained in page 10 ;11 and 12.

Fuselage nose plate (two are needed: upper and

lower) make the upper first, fasten it to the side

members as depicted in page 10 and using a card-

board as a template trace the lower plate which

will be a little longer in order to ac cept the fork. (it

could be convenient to have the fork already made)

FIGHTER ULTRALIGHT -

1) make the required holes through the spar

(use a drill bit = bolt size)

This is a Nicopress sleeve that wi ll be use to Once the chassis is made and all the parts bolted

assemble the cables. Nicopress Tool together you can cut and bend the 1-1/8

Plansalumi-

delivery.com Designed and drawn by Osvaldo Durana

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

the brakes of this craft were taken from a small This is just a general guideline to help y ou to tackle this

Updated Mar-20-2001

motorcycle, you should search for some available project, more information about speci fically subjects like

Bushing

Bolt diameter holes

within your zone. welding, covering or working with composites/fiberglass

Diameter holes

can be find at your local l ibrary .

Abundant material and help can be found at the Ex-

Attaching the wing

perimental Aircraft Association (www.eaa.org)

Once finished the main groups, and before to cover

the wings, attach them to the boom tube, make a

couple of wing supports out of wood to place the

wings in the right position, verify the dihedral angle

(2,5 degrees) and then take the measure of each

wing strut.

Control system

This aircraft emplo y a flexible push-pull control

system often called Teleflex which simplified the

task and its very r eliable.

2) enlarge the holes (only on this face of the

spar) to insert the reinforcement bushings, com-

Covering

plete the assembly.

This aircraft is covered with Dacr on fabric (wings

and tail group, ev en there are good books that

Engine mount shows step by step how to cover your airplane we

The drawing in page 19 and 20 ar e self explana- are preparing an e-booklet that will show how to

tory, ac cording to the engine selected you will do it, i f you are interested, please send us a mai l.

have to vary the position of some holes (our pro-

totype used a Rotax engine) Fuel Tank

The design of this mount allows i t to slide over There are many models ready made, attach it to

the boom tube, dont bolt to i t now, when the the central support tubes behind the seat.

airplane is finished you wi ll have to calculate the

weight and balance in order to place the center

of gravity in the right position (between 25% and A word of caution

30 % of the wing chord) allowing the engine to Warning! the set of plans and the instructions pr ovided

be able to slide forward or backward will help to here are for educational and recreational purposes only,

nor the designer neither Plans Del ivery.com can be re-

achieve the right C.G. position.

sponsible for injur es, property damages or ev en the

death to someone following the indications giv en here.

Landing gear

Flying could be a dangerous activity if is not done wi th

Page 13 shows al l the components of this sturdy

the expertise and knowledge required, we advise you

landing gear, almost all parts are made from steel

to take flying lessons prior to at tempt to fly in any aerial

tubing which are welded using oxyacetylene or

vehicle, been this experimental, ultralight or a home

TIG /MIG process, if you don t have the equip- built creation.

ment or the knowledge to do the welding find a Working wi th power tools, paints, solvents and related

welding shop in your area and get your gear chemicals also can be dangerous to people and prop-

erty if not done properly.

welded.

We advise you to use eye, body protection and f ollow

The EAA have several good books about welding

manufacturers recommendations. FIGHTER ULTRALIGHT -

that can guide you through this process.

Page 14 shows the wheel and br ake assembly,

Plans delivery.com Designed and drawn by Osvaldo Durana

Descargado por electronica (jcpintos@gmail.com)

Encuentra más documentos en www.udocz.com

You might also like

- 70 1911 Auto P94 149Document56 pages70 1911 Auto P94 149Stan BrittsanNo ratings yet

- Fighter Ultralight: Osvaldo DuranaDocument24 pagesFighter Ultralight: Osvaldo Duranaandres silvestreNo ratings yet

- Premium Components: Symons Cone CrushersDocument1 pagePremium Components: Symons Cone CrushersAhmadNo ratings yet

- Murex Arc Gas Conumables 3Document58 pagesMurex Arc Gas Conumables 3cfcshaker100% (1)

- WPS1Document10 pagesWPS1bhavin178No ratings yet

- 01 A Tower Material 220kv Line ZebraDocument15 pages01 A Tower Material 220kv Line ZebraVaibhav JainNo ratings yet

- Crusher Cross-Section (AC-Svedala)Document1 pageCrusher Cross-Section (AC-Svedala)Juan ArosNo ratings yet

- Demersal TrawlsDocument13 pagesDemersal TrawlssahnaNo ratings yet

- EBS 315 L2 - Intro Hydrometallurgy (13 Sept 2012)Document55 pagesEBS 315 L2 - Intro Hydrometallurgy (13 Sept 2012)Amy AckerNo ratings yet

- Steel Pipe VesselDocument122 pagesSteel Pipe VesselHarish HarishNo ratings yet

- Piping Design Reference InfoDocument254 pagesPiping Design Reference InfoDr. M. Praveen Sandeep100% (1)

- A 276 - A 276M - 16aDocument8 pagesA 276 - A 276M - 16aNguyễn Như Thế100% (2)

- Aisi 1020 Carbon Steel (Uns g10200)Document5 pagesAisi 1020 Carbon Steel (Uns g10200)Dimas Dwi HNo ratings yet

- Engineering All in OneDocument245 pagesEngineering All in OneozchrisNo ratings yet

- Summative Test Smaw 8Document3 pagesSummative Test Smaw 8Krizzie Jade Cailing100% (1)

- Avión Ultraligero 1Document24 pagesAvión Ultraligero 1Abelardo Luna GarciaNo ratings yet

- FP - Engineering700 - Spare PartsDocument1 pageFP - Engineering700 - Spare PartsDaniel LagosNo ratings yet

- All Steel HarrisonDocument1 pageAll Steel HarrisonJosh BarronNo ratings yet

- All Steel GeppDocument1 pageAll Steel GeppJosh BarronNo ratings yet

- Audiometric BoothDocument1 pageAudiometric BoothIdayuNo ratings yet

- Allorde - P2Document1 pageAllorde - P2flor johnNo ratings yet

- WBR Bicycle Maintenance Manual PDFDocument11 pagesWBR Bicycle Maintenance Manual PDFMaxNo ratings yet

- Airbus 330-900 NEO StarluxDocument14 pagesAirbus 330-900 NEO StarluxTony HpongNo ratings yet

- 07-515.pdf Valvula Eaton AutonivelanteDocument4 pages07-515.pdf Valvula Eaton AutonivelanteVictor Garcia VillegasNo ratings yet

- Svelti Wheel Replacement InstructionsDocument1 pageSvelti Wheel Replacement InstructionsAnonymous EdbHXuNo ratings yet

- MR - Ser4 Service en - 8 14Document7 pagesMR - Ser4 Service en - 8 14grantNo ratings yet

- Parts of Pipe Supports As Used in Petro and Chemical IndustryDocument1 pageParts of Pipe Supports As Used in Petro and Chemical Industrysowman tungNo ratings yet

- EXCEL Identification Spare Parts Poster For HP Cone CrushersDocument1 pageEXCEL Identification Spare Parts Poster For HP Cone CrushersabcNo ratings yet

- AaaaaDocument24 pagesAaaaaLathif SeswitoNo ratings yet

- Main Deck PlanDocument1 pageMain Deck PlanElmer HabloNo ratings yet

- Scrap TicketDocument11 pagesScrap TicketVikas KashyapNo ratings yet

- Mecha Lock - MisumiDocument1 pageMecha Lock - MisumiDuong NguyenNo ratings yet

- 03 HWDP Spiral 3 1-2 New ReportDocument2 pages03 HWDP Spiral 3 1-2 New ReportKhalil ChabbouhNo ratings yet

- Double Chamber / Triple Function Air Valve: Upper CoverDocument7 pagesDouble Chamber / Triple Function Air Valve: Upper CoverMohamed AliNo ratings yet

- Issa Yacht Crew: StudentDocument10 pagesIssa Yacht Crew: StudentкатяNo ratings yet

- Crusher Cross-Section (Symons) PDFDocument1 pageCrusher Cross-Section (Symons) PDFAnonymous 8t0V9S100% (1)

- 2019 Us 0448 1Document1 page2019 Us 0448 1Shinya Takeda(武田 慎也)No ratings yet

- Rafter Detail: Roofing InsulationDocument1 pageRafter Detail: Roofing InsulationRODEAN HOPE LACSINo ratings yet

- ACCESS-DOOR (1) - Model - PDF With FrameDocument1 pageACCESS-DOOR (1) - Model - PDF With Frameahmed elhadadNo ratings yet

- Piping - Design - Info (Version 2)Document245 pagesPiping - Design - Info (Version 2)mehul10941No ratings yet

- Nit Raipur Name-Abhishek Kumar Topic-Steel Connection Assignment No. - DATE - 9-4-2017 ROLL NO.-13114903Document1 pageNit Raipur Name-Abhishek Kumar Topic-Steel Connection Assignment No. - DATE - 9-4-2017 ROLL NO.-13114903DOMINICNo ratings yet

- 20M Shallow Draft Tug - General ArrangementDocument1 page20M Shallow Draft Tug - General ArrangementEdi sonNo ratings yet

- Three Storey Residential Building Engr. Henry Florendo: 1: 100 Typ. RC Beam ElevationDocument1 pageThree Storey Residential Building Engr. Henry Florendo: 1: 100 Typ. RC Beam ElevationMark AnchetaNo ratings yet

- Toma Siamesa Elkhart Modelo 1 PDFDocument2 pagesToma Siamesa Elkhart Modelo 1 PDFSANTONo ratings yet

- Toma Siamesa Elkhart Modelo 1 PDFDocument2 pagesToma Siamesa Elkhart Modelo 1 PDFRICHINo ratings yet

- Radial Ball Bearing IJ K: Multistage Centrifugal PumpDocument1 pageRadial Ball Bearing IJ K: Multistage Centrifugal PumpDavide KunNo ratings yet

- Steel PipeDocument186 pagesSteel PipeMarti H JNo ratings yet

- Screw Selector Guide 032906Document1 pageScrew Selector Guide 032906mohitvats916711No ratings yet

- 20m HM PO 6 FL 19 0928Document3 pages20m HM PO 6 FL 19 0928Murad ALahdalNo ratings yet

- Piping - Design - Info (Version 2)Document245 pagesPiping - Design - Info (Version 2)vj kumarNo ratings yet

- 03 230000 4200000011 Ido Civ DRG 013204 - 01Document1 page03 230000 4200000011 Ido Civ DRG 013204 - 01Anuar ChinNo ratings yet

- 111-Piping Design InfoDocument248 pages111-Piping Design Infobakhtyar21No ratings yet

- Piping Design AidsDocument248 pagesPiping Design AidsSunday PaulNo ratings yet

- BrayDocument2 pagesBrayOscar Horta PolaniaNo ratings yet

- Connection Schedule - Base Plate Connection Schedule - Beam Column (Major Axis)Document1 pageConnection Schedule - Base Plate Connection Schedule - Beam Column (Major Axis)Haider AuniNo ratings yet

- AppendixDocument21 pagesAppendixEcho CanyonNo ratings yet

- Homes NVR Drawings 1Document3 pagesHomes NVR Drawings 1j3ark0No ratings yet

- Tabela Completa Especificação de TubulaçãoDocument240 pagesTabela Completa Especificação de TubulaçãojuliermeribeiroNo ratings yet

- Attachment Chain: Over 300 Years of Chain ExperienceDocument2 pagesAttachment Chain: Over 300 Years of Chain ExperienceGustavo Urueña OrozcoNo ratings yet

- Ukuran Junior Orifice Plate Avc 1Document1 pageUkuran Junior Orifice Plate Avc 1bodZkeeNo ratings yet

- Rubber Hoses Steel Wire SpiralDocument2 pagesRubber Hoses Steel Wire SpiralАндрей КулешовNo ratings yet

- Details: 2" X 4" X " C - PurlinsDocument1 pageDetails: 2" X 4" X " C - PurlinsMark Christian Esguerra100% (1)

- Piping Data - MetricDocument250 pagesPiping Data - MetricSteve WanNo ratings yet

- Standard Drawing 3904 F Shape Connection Pin and Loop Dec 2020Document1 pageStandard Drawing 3904 F Shape Connection Pin and Loop Dec 2020Mhd ThrNo ratings yet

- Reinforcement Schedule:-: Section C-C T Section D-DDocument1 pageReinforcement Schedule:-: Section C-C T Section D-DyogendraNo ratings yet

- New Piping DesignDocument277 pagesNew Piping DesignSurya Kiran KNo ratings yet

- Power Supply Skyworth 5851-A7M01B-0P00 схемаDocument2 pagesPower Supply Skyworth 5851-A7M01B-0P00 схемаcharly36No ratings yet

- PTW40N50: General FeaturesDocument9 pagesPTW40N50: General Featurescharly36No ratings yet

- AOT1606L/AOB1606L: General Description Product SummaryDocument6 pagesAOT1606L/AOB1606L: General Description Product Summarycharly36No ratings yet

- Portable Gas Leak Detector: Operation ManualDocument12 pagesPortable Gas Leak Detector: Operation Manualcharly36No ratings yet

- FXN32N55T: General Description FeaturesDocument5 pagesFXN32N55T: General Description Featurescharly36No ratings yet

- Using A Collated Cybersecurity Dataset For Machine Learning and Artificial IntelligenceDocument5 pagesUsing A Collated Cybersecurity Dataset For Machine Learning and Artificial Intelligencecharly36No ratings yet

- Detecting 0dayDocument8 pagesDetecting 0daycharly36No ratings yet

- ZM R380B ManualDocument20 pagesZM R380B Manualcharly36No ratings yet

- SRC 1206Document3 pagesSRC 1206charly36No ratings yet

- Dual 105 MW Headphone Amplifier: General Description Key SpecificationsDocument18 pagesDual 105 MW Headphone Amplifier: General Description Key Specificationscharly36No ratings yet

- ALC887 DatasheetDocument82 pagesALC887 Datasheetcharly36No ratings yet

- Diagrama de Sonda LVDS - 1Document1 pageDiagrama de Sonda LVDS - 1charly36100% (3)

- 40 Mt56ee Mad2hgDocument11 pages40 Mt56ee Mad2hgcharly36100% (5)

- Sanyo DCG-105 Sistema Audio CD-MP3 Manual SimpleDocument11 pagesSanyo DCG-105 Sistema Audio CD-MP3 Manual Simplecharly36No ratings yet

- Skhema Na Acer Aspire 4720Z Z01 E3CDocument26 pagesSkhema Na Acer Aspire 4720Z Z01 E3CQuique FerNo ratings yet

- Acer Aspire 3690 5630 5650 5680 - COMPAL LA-2921P HBL50 - REV 0.3Document59 pagesAcer Aspire 3690 5630 5650 5680 - COMPAL LA-2921P HBL50 - REV 0.3Dexter DanielNo ratings yet

- Rca L24FHD Psu PDFDocument1 pageRca L24FHD Psu PDFcharly36No ratings yet

- Tas 5731Document60 pagesTas 5731charly36No ratings yet

- NEMA 17 Stepper Motor - RepRapWikiDocument5 pagesNEMA 17 Stepper Motor - RepRapWikicharly36No ratings yet

- Lc230eue Tda1 LGDocument32 pagesLc230eue Tda1 LGcharly36No ratings yet

- Silicon NPN Power Transistors: Savantic Semiconductor Product SpecificationDocument3 pagesSilicon NPN Power Transistors: Savantic Semiconductor Product Specificationcharly36No ratings yet

- Astm 666Document7 pagesAstm 666JOSEPH REFUERZONo ratings yet

- WPSAmerica 2Document2 pagesWPSAmerica 2Khaled bouhlelNo ratings yet

- MWF BrochureDocument6 pagesMWF BrochurejohnsopranaNo ratings yet

- Otis Abrochure Art in MotionDocument17 pagesOtis Abrochure Art in Motionfethi42No ratings yet

- LME Specification Steelbillet 040511Document3 pagesLME Specification Steelbillet 040511rhuezo8492No ratings yet

- 2013 Truvativ SPC Rev BDocument22 pages2013 Truvativ SPC Rev BMárcio SilvaNo ratings yet

- Tin and Its AlloysDocument2 pagesTin and Its AlloysSri GowthamNo ratings yet

- ChannelNutsHdw PDFDocument28 pagesChannelNutsHdw PDFrefaeNo ratings yet

- Engineering Metallurgy NotesDocument89 pagesEngineering Metallurgy NotesYuvaraja Yuva100% (1)

- Mos Lab ManualDocument57 pagesMos Lab ManualsuswagatNo ratings yet

- Cold Crack Criterion For ADC12 Aluminum Alloy Die CastingDocument6 pagesCold Crack Criterion For ADC12 Aluminum Alloy Die CastingVinodNo ratings yet

- AstmDocument5 pagesAstmjohann tousNo ratings yet

- Tungsten ElectrodesDocument2 pagesTungsten ElectrodesRoyal AccessoriesNo ratings yet

- Merit BrochureDocument20 pagesMerit BrochureAbdel HamidNo ratings yet

- Optional Configuration For Resort House - Emily in Longhe Energy SavingDocument3 pagesOptional Configuration For Resort House - Emily in Longhe Energy Savinghiva berdiNo ratings yet

- Fabrication of Portable Spot Welding MachineDocument4 pagesFabrication of Portable Spot Welding MachineIJIRSTNo ratings yet

- Moduflex FRL TechnicalDocument56 pagesModuflex FRL Technicalking4lifeNo ratings yet

- Chemical Engineering Design Problems (Undergrad Level)Document10 pagesChemical Engineering Design Problems (Undergrad Level)smeilyNo ratings yet

- CH 12Document91 pagesCH 12Saranya HarikrishnanNo ratings yet

- Electrical Steel Product BrochourDocument34 pagesElectrical Steel Product Brochourarvi_vinNo ratings yet

- Us 3024303Document3 pagesUs 3024303Samar RashidNo ratings yet