Professional Documents

Culture Documents

2-Design and Drafting-20at42p

Uploaded by

MD HUZAIFA HANDUROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2-Design and Drafting-20at42p

Uploaded by

MD HUZAIFA HANDURCopyright:

Available Formats

Government of Karnataka

DEPARTMENT OF COLLEGIATE AND TECHNICAL EDUCATION

Programme Automobile Engineering Semester IV

Course Code 20AT42P Type of Course Programme Core

8 hours/week

Course Name Design and Drafting Contact Hours

104 hours/semester

Teaching Scheme L: T:P: 3:1:4 Credits 6

CIE Marks 60 SEE Marks 40

1.Rationale: Machine design is the most important activity in the mechanical industries. Success or failure

of any industry is product design. Designers are individuals who use their talents to solve user-product

problems on an on-going basis. Since design is the first step toward manufacturing, it is important that

potential designers have some experience in manufacturing and industrial engineering. Design drawing will

develop in detail from block drawings and sketches to very detailed technical drawings describing every

component in a way that will enable them to be constructed and operated. This course enables the students

to design and draw simple machine components using 3D modelling software.

2. Course Outcomes/Skill Sets: At the end of the course the student will be able to:

Analysis the behaviour of simple load carrying members which are subjected to an axial and shear

CO-01

loading and record the resulting impact of both loads.

CO-02 List the standards and codes used in the design process.

Design automobile components and draft machine components used in a given automobile by

CO-03

computer-based techniques.

3. Course Content

Tutorial

Lecture Practice

(Activity

(Knowledge Criteria) (Performance Criteria)

Week CO PO Criteria)

4 hours/week (2

3 hours/week 1 hour/week hours/batch twice in a

week)

1. Drawing stress-strain

1. Introduction to design. Simple

diagram using UTM

stress and strains – tensile

machine and record the

compressive, shear and Hooke’s law.

resulting impact of both

Factor of safety.

loads.

2. Young’s modulus, modulus or

1 1,3 1,2,3 Refer Table 1 2. Finding Centre of

rigidity, bulk modulus. Centre of

gravity and moment of

gravity & moment of Inertia –

inertia of different shapes

importance.

using analytical method

3. Moment of Inertia about C.G for L-

and software like

section and Channel section.

AutoCAD/Solid edge etc.

Department of Collegiate and Technical Education, Government of Karnataka 53

1. a) Represent and

1. Moment of Inertia about C.G for I interpret tolerances

Section, tubular section.

given in drawings.

2. Limits-Need for limit system. Fit-

Types of Fit – Clearance fit, b) List the standards and

interference fit, transition fit and codes used in the design

2 1,2 1,2,3 their designation. Refer Table 1 process.

3. Allowance, Tolerance – System of

tolerance dimensions (system of 2. Practice to insert

different fit, tolerance,

writing tolerance). Unilateral

system and bilateral system. precision and limit

symbols using any CAD

software.

1. Practice to insert

1. Specifying tolerances in appropriate ISO system of

assembly. Geometrical tolerance, Limits, Fits and

positional tolerance.

tolerances.

2. Terminologies used in limits and 2. Practice calculating

3 2 1,2,3 fits – shaft, hole, basic size, actual Refer Table 1 limits for a given

size, zero-line, upper deviation, tolerance case.

lower deviation.

3. System of Fits - Hole Basis

System-Shaft Basis system.

1. Using part modelling

work bench tools and

1. Fasteners-types-screw assembly workbench

terminology-types of screw profiles. tools create a square nut

Find the max

2. Locking of bolts-need-types. and bolt.

stress in the

3. Stresses acting in a bolt. Stresses 2. Using part modelling

4 1,3 1,2,3,4 bolt using

in screw fastening due to external work bench tools and

any CAD

loading- Tensile-compressive- assembly workbench

software.

combined tensile & shear stress. tools create a hexagonal

Simple problems nut and bolt using any

CAD software like-solid

edge, UG-NX etc.

1. Types of shafts, shaft materials, 1. Create a model of

5 3 1,2,3,4 Refer Table 1

standard sizes. shaft and key using any

Department of Collegiate and Technical Education, Government of Karnataka 54

2. Design of Shafts subjected to CAD software like-solid

twisting & bending moment (Hollow edge, UG-NX etc.

and Solid) using strength and

rigidity criteria. Simple problems 2. Create an 3D-

3. Keys-need, types. Design of keys assembly model of shaft

under different load conditions- and key then create a 2D

shear and crush. Simple problems. drawing using any CAD

software like-solid edge,

UG-NX etc.

1. Create an 3D-

assembly model of Muff

coupling and then create

1. Couplings-purpose- a 2D drawing using any

requirements-types- applications. CAD software like-solid

2. Design of Muff coupling. Simple edge, UG-NX etc.

6 3 1,2,3,4 Refer Table 1

problems. 2. Create an 3D-

3. Design of Flange coupling- assembly model of flange

Unprotected. Simple problems. coupling and then create

a 2D drawing using any

CAD software like-solid

edge, UG-NX, etc.

1. Using part modelling

1. Coil spring-terms used in helical

work bench tools create a

compression spring. Simple

helical spring CAD

problems

software like-solid edge,

2. Stresses & deflection of helical

UG-NX etc.

7 3 1,2,3 spring. Simple problems Refer Table 1

2. Using part modelling

3. Leaf springs- Effective &

work bench tools and

ineffective length, camber, stresses

assembly workbench

& deflection of semi elliptic leaf.

tools create a leaf spring

Simple problems.

assembly.

1. Create an 3D-

1. Design concepts of piston.

assembly model of

2. Design of piston, piston pin &

piston, piston rings and

8 3 1,2,3,4 piston rings based on strength and Refer Table 1

piston pin and then

heat transfer.

create a 2D drawing

3. Simple problems.

using any CAD software

Department of Collegiate and Technical Education, Government of Karnataka 55

like-solid edge, UG-NX,

etc.

2 Create an assembly

model of piston, piston

rings and piston pin and

then create a 2D drawing

using any CAD software

like-solid edge, UG-NX,

etc.

1. Create an 3D-

assembly model of

connecting rod and then

create a 2D drawing

1. Forces acting on connecting rod. using any CAD software

2. Design parameters of connecting like-solid edge, UG-NX,

9 3 1,2,3,4 rod. Refer Table 1 etc.

3. Design of connecting rod. Simple 2. Create an assembly

problems. model of connecting rod

and then create a 2D

drawing using any CAD

software like-solid edge,

UG-NX, etc.

1. Create an assembly

3D-model of flywheel

and ring gear and then

1. Design of flywheel. Simple

create a 2D drawing

Problems.

using any CAD software

2. Cam and followers-types, Cam

like-solid edge, UG-NX,

profile-types.

10 3 1,2,3,4 Refer Table 1 etc.

3. Construct a cam profile using

2. Create an 3D-

uniform velocity method. Simple

assembly model of

Problems.

camshaft and then create

a 2D drawing using any

CAD software like-solid

edge, UG-NX, etc..

1. Create an 3D-assembly

1. Torque transmitted through Refer Table

11 3 1,2,3,4,7 model of single plate-

single and multi-plate clutches. 1,

clutch assembly and then

Department of Collegiate and Technical Education, Government of Karnataka 56

2. Uniform intensity of pressure- Study the create a 2D drawing using

uniform rate of wear conditions. latest any CAD software like-

3. Design of single plate clutch and technological solid edge, UG-NX, etc.

multi-plate clutch. Simple problems. changes in 2. Create an assembly

this course in 3D-assembly model of

this course single plate clutch

and present assembly and then create

the impact of a 2D drawing using any

these CAD software like-solid

changes on edge, UG-NX, etc.

industry.

Refer Table

1. Create an 3D-

1,

assembly model of spur

Study the

gear and then create a 2D

1. Gear-terminology of gear-gear latest

drawing using any CAD

teeth profiles. technological

software like-solid

2. Design of spur gear. Simple changes in

edge/UG-NX.

12 3 1,2,3,4,7 problems. this course in

2. Create an 3D-

3. Find gear ratio, number of teeth this course

assembly model of a

and distance between lay shaft and and present

helical gear and then

main shaft. the impact of

create a 2Ddrawing using

these

any CAD software like-

changes on

solid edge/UG-NX.

industry.

1. Create an 3D-

Study the assembly model of pinion

1. Find different vehicle speed at latest and gear and then create

different engine speed and gear technological a 2D drawing using any

ratios. changes in CAD software like-solid

2. Brakes: Stopping distance, this course in edge/ UG-NX.

13 2,3 1,2,3,4,7 braking efficiency, Braking torque. this course 2. Create an 3D-

Leading and trailing shoe, and present assembly model of

3. Equation for Braking Torque on the impact of Leading and trailing

Leading and Trailing Shoe. Simple these shoe(drum brake) and

Problems. changes on then create all 2D views

industry. using any CAD software

like-solid edge/UG-NX.

Total in hours 39 13 52

Department of Collegiate and Technical Education, Government of Karnataka 57

* PO= Program Outcome as listed and defined in year 1 curriculum and PO – CO mapping with

strength (Low/Medium/High) has to be mapped by the course coordinator. (Above only suggestive)

Table 1: Suggestive Activities for Tutorials: (The List is only shared as an Example and not inclusive of all

possible activities of the course. Student and Faculty are encouraged to choose activities that are relevant to

the topic and on the availability of such resources at their institution)

Sl. No. Week Suggested Activity

Study on “influence of center of gravity on vehicle performance.” Present on the

1 1

suitable location of CG.

Study and give a presentation of GD&T drawings & symbols. Read and document an

2 2

industrial drawing using GD&T.

3 3 Study and present on classification of tolerance with examples.

Using part modelling work bench tools create a different type of helical spring (assume

4 4

suitable dimensions)

Using part modelling work bench tools create a lock nut with split pin (assume suitable

5 5

dimensions)

6 6 Study and present with suitable video/diagrams on different stresses in shafts and keys.

Study and document on failures of universal joint and its advancements to overcome

7 7

the problem.

Discuss on different methods of designing of piston. Design a suitable piston to increase

8 8

volumetric efficiency.

Study on analysis of forces on connecting rod and use simulation software to show

9 9

forces acting on connecting rod.

Study dual mass flywheel. Refer a journal paper and present on the advantages of using

10 10

dual mass flywheel.

11 11 Study and present on the topic “design consideration of heavy-duty clutches”

12 12 Study gear nomenclature and submit a report as an assignment.

4. CIE and SEE Assessment Methodologies

Sl. Duration Max

Assessment Test Week Conversion

No In minutes marks

1. CIE-1 Written Test 5 80 30 Average of three

2. CIE-2Written Test 9 80 30 tests

3 CIE-3Written Test 13 80 30 30

4. CIE-4 Skill Test-Practice 6 180 100 Average of two skill

tests

5 CIE-5 Skill Test-Practice 12 180 100

20

CIE-6 Portfolio continuous

6 evaluation of Activity through 1-13 10 10

Rubrics

Total CIE Marks 60

Semester End Examination (Practice) 180 100 40

Total Marks 100

5. Format for CIE written Test

Course Name Design and Drafting Test I/II/III Sem III/IV

Course Code 20AT42P Duration 80 Min Marks 30

Note: Answer any one full question from each section. Each full question carries 10 marks.

Department of Collegiate and Technical Education, Government of Karnataka 58

Cognitive Course

Section Assessment Questions Marks

Levels Outcome

1

I

2

3

II

4

5

III

6

Note for the Course coordinator: Each question may have one, two or three subdivisions. Optional questions in each

section carry the same weightage of marks, Cognitive level and course outcomes.

6. Rubrics for Assessment of Activity (Qualitative Assessment)

Sl. Dimension Beginner Intermediate Good Advanced Expert Students

No. Score

2 4 6 8 10

1 Descriptor Descriptor Descriptor Descriptor Descriptor 8

2 Descriptor Descriptor Descriptor Descriptor Descriptor 6

3 Descriptor Descriptor Descriptor Descriptor Descriptor 2

4 Descriptor Descriptor Descriptor Descriptor Descriptor 2

Average Marks= (8+6+2+2)/4=4.5 5

Note: Dimension and Descriptor shall be defined by the respective course coordinator as per the activities

7. Reference:

Sl. No. Description

1 A Text book of Machine Design by R.S. Khurmi&J.K.Gupta (S. Chand publication).

2 Design Of Machine Elements Vol I, Vol II by J.B.K. Das, P.L. Srinivas Murthy (Sapna Publication).

3 Auto Design by R B Gupta (Satya Prakashan).

4 Automobile Engineering Drawing by R B Gupta (Satya Prakashan).

5 CADD software for Engineers and Designers by Prof. Sham Tickoo (Dream tech press).

6 Automotive Mechanics by Dr.N.K. Giri (Khanna Publishers))

7 Automobile design Problem by R.S. Agarwal

8 Machine Drawing by K R Gopalakrishna (Subhas Stores)

8. CIE Skill Test and SEE Scheme of Evaluation

SL.

CO Particulars/Dimension Marks

No.

One question on simple load carrying members/The codes and standards used in

1 1,2 design process. 20

Practical question/Interpret the given chart - 20m

One question on “Use computer-based techniques in drafting of machine

components used in automobile”

2 3 a) 3D- drafting of all components - 30 m 50

b) Assembly model -10 m

c) Front view, side view, top view – 10 m

Department of Collegiate and Technical Education, Government of Karnataka 59

3 1,2,3 Portfolio evaluation of practical sessions (1-13 week) 10

4 1,2,3 Viva-voce 20

Total Marks 100

NOTE: Use same format of evaluation for CIE skill test. Portfolio evaluation of practical session

should be considered from “Week 1-6” for 1st CIE and “Week 7-12” for 2nd CIE each 10 marks.

9. Equipment/software list with Specification for a batch of 20 students

Sl.

Particulars Specification Quantity

No.

1 Universal testing machine. 30 ton 1

Any Genuine CAD software or free and open-source CAD

2 30

software (solid edge, solid works, AutoCAD etc.).

3 Any Genuine or free and opensource Simulation Software. 30

Computer with minimum 16inch color monitor, Intel/AMD

4 latest generation i5 processor, 4 GB graphics card, 8 GB RAM, 30

512 GB SSD, 1 TB HDD, DVD read write drive.

5 UPS with 5 KW sine wave. 2

6 LED/LCD Projector with 500 lumens (20000 hrs) 4

Department of Collegiate and Technical Education, Government of Karnataka 60

You might also like

- EE1005 From Computational Thinking To Programming - OBTLDocument5 pagesEE1005 From Computational Thinking To Programming - OBTLAaron TanNo ratings yet

- Math 7 - Summative Test Q2Document5 pagesMath 7 - Summative Test Q2Brian Mary100% (5)

- Balanced Cantilever Bridge Analysis Day 3Document15 pagesBalanced Cantilever Bridge Analysis Day 3Isidro P. BuquironNo ratings yet

- Introduction to Optical Waveguide Analysis: Solving Maxwell's Equation and the Schrödinger EquationFrom EverandIntroduction to Optical Waveguide Analysis: Solving Maxwell's Equation and the Schrödinger EquationNo ratings yet

- Lecture Notes Automobile Electrical SystemsDocument6 pagesLecture Notes Automobile Electrical Systemshardik shahNo ratings yet

- WDM Technologies: Optical NetworksFrom EverandWDM Technologies: Optical NetworksAchyut K. DuttaNo ratings yet

- Modeling Fracture and Failure With AbaqusDocument24 pagesModeling Fracture and Failure With AbaqusFaizan Rashid100% (1)

- Design of Machine ElementDocument11 pagesDesign of Machine ElementAjay Kumar Reddy K100% (1)

- MO Syllabus PDFDocument7 pagesMO Syllabus PDFBHAVINNo ratings yet

- Elements of TechnologyDocument9 pagesElements of TechnologyBhaswati PandaNo ratings yet

- Syllabus of Frist Semester: Applied Mechanics I (Statics) Beg156CiDocument10 pagesSyllabus of Frist Semester: Applied Mechanics I (Statics) Beg156CiSunil MandalNo ratings yet

- Computer Aided Design Course Code: 3341904Document7 pagesComputer Aided Design Course Code: 3341904him88.himNo ratings yet

- Basic SurveyingDocument12 pagesBasic Surveyingmayurcshetty2007No ratings yet

- 4th Sem SylubusDocument26 pages4th Sem SylubusPrasad KalalNo ratings yet

- Robotics & Autotronics Course Code: 3361108Document8 pagesRobotics & Autotronics Course Code: 3361108venkatesh naniNo ratings yet

- Syllabus Analytical - InstrumenationDocument9 pagesSyllabus Analytical - Instrumenationurvish_soniNo ratings yet

- Cad Cam Lab R17a0388 - MallarDocument87 pagesCad Cam Lab R17a0388 - MallardeepakNo ratings yet

- Course Code: 3300007Document8 pagesCourse Code: 3300007k k suraniNo ratings yet

- BS 105 - Integral Calculus and Compex Number - NEP Based - Autonomy - Proposed - SyllabusDocument6 pagesBS 105 - Integral Calculus and Compex Number - NEP Based - Autonomy - Proposed - Syllabus2023.nirmay.kadamNo ratings yet

- PDFDocument9 pagesPDFVipul SolankiNo ratings yet

- CAEG Curriculum PDFDocument15 pagesCAEG Curriculum PDFNever giveupNo ratings yet

- 3300008applied MechanicsDocument4 pages3300008applied MechanicsJayesh GalcharNo ratings yet

- PDFDocument10 pagesPDFvishallchhayaNo ratings yet

- 3341104Document7 pages3341104Vani YamaniNo ratings yet

- ES 104 - C Programing - Autonomy Proposed Syllabus - NEW UpdatedDocument12 pagesES 104 - C Programing - Autonomy Proposed Syllabus - NEW Updated2023.nirmay.kadamNo ratings yet

- PEC-MIRA101B - Embedded System Application For Robotics - M.Tech RA - 2023-25 - MLPDocument5 pagesPEC-MIRA101B - Embedded System Application For Robotics - M.Tech RA - 2023-25 - MLPSUDIPTA CHATTERJEENo ratings yet

- PDFDocument13 pagesPDFShlok PatelNo ratings yet

- CaedDocument21 pagesCaedS santhoshNo ratings yet

- Mechanical Engineering VI Sem SyllabusDocument25 pagesMechanical Engineering VI Sem Syllabussaurabh1116No ratings yet

- Legends: L-Lecture T - Tutorial/Teacher Guided Theory Practice P - Practical C - Credit, CADocument6 pagesLegends: L-Lecture T - Tutorial/Teacher Guided Theory Practice P - Practical C - Credit, CABhaveshNo ratings yet

- Course Title: Fundamental of Mechanical Engineering (Code: 3300015)Document8 pagesCourse Title: Fundamental of Mechanical Engineering (Code: 3300015)Kishan BadiyaNo ratings yet

- Teaching Scheme:: (An Autonomous Institute of Govt. of Maharashtra)Document43 pagesTeaching Scheme:: (An Autonomous Institute of Govt. of Maharashtra)Prathamesh PatilNo ratings yet

- Ae405eDocument8 pagesAe405eVijay KumbharNo ratings yet

- Control Devices (CD) 3342001Document7 pagesControl Devices (CD) 3342001BHATT RONAK MT-04No ratings yet

- 3-Vehicle Body Engineering and Dynamics-20at43pDocument10 pages3-Vehicle Body Engineering and Dynamics-20at43pMD HUZAIFA HANDURNo ratings yet

- Tom New SyllabusDocument13 pagesTom New SyllabusshekhadNo ratings yet

- Applied Mechanics-I (Statics)Document2 pagesApplied Mechanics-I (Statics)Anil MarsaniNo ratings yet

- Course Outline MAT 120Document3 pagesCourse Outline MAT 120Israt ZamanNo ratings yet

- Afd Ec 9 2007Document52 pagesAfd Ec 9 2007Nguyen Co ThachNo ratings yet

- 2018 Winter Model Answer PaperDocument13 pages2018 Winter Model Answer PaperRohan ChavanNo ratings yet

- Cad Lab Manual-2016Document28 pagesCad Lab Manual-2016Dilip Patel100% (1)

- Surveying Course Code: 3330605Document7 pagesSurveying Course Code: 3330605ayushsuhagiya380No ratings yet

- Legends: L-Lecture T - Tutorial/Teacher Guided Theory Practice P - Practical C - Credit, CADocument7 pagesLegends: L-Lecture T - Tutorial/Teacher Guided Theory Practice P - Practical C - Credit, CAMohammed FaizNo ratings yet

- Shell Fabricatio - TrainingDocument7 pagesShell Fabricatio - TraininglingarajanNo ratings yet

- Diploma in Computer Engineering: Course Code: 025020401 Data StructuresDocument6 pagesDiploma in Computer Engineering: Course Code: 025020401 Data StructuresPrince ChaudhriNo ratings yet

- EngMath 9006 2sem 128Document6 pagesEngMath 9006 2sem 128rvshindeNo ratings yet

- Implementation of Strain Gauges: Experimental Stress Analysis (ESA)Document31 pagesImplementation of Strain Gauges: Experimental Stress Analysis (ESA)Anbu nilaNo ratings yet

- Gujarat Technological University, Ahmedabad, Gujarat Course Curriculum Course Title: CourseDocument6 pagesGujarat Technological University, Ahmedabad, Gujarat Course Curriculum Course Title: CourseSher Hai HamNo ratings yet

- Computer Organisation and ArchitectureDocument5 pagesComputer Organisation and ArchitectureHarshil GajjarNo ratings yet

- Course Spec - Last CE360Document6 pagesCourse Spec - Last CE360Ahmed MohammedNo ratings yet

- CN4227R - Course Outline - 2017Document11 pagesCN4227R - Course Outline - 2017Ming XiangNo ratings yet

- First Term: Ch. 1 Introduction Ch. 2 Threads and Fasteners Ch. 3 Fits and ToleranceDocument50 pagesFirst Term: Ch. 1 Introduction Ch. 2 Threads and Fasteners Ch. 3 Fits and ToleranceABDELRHMAN ALINo ratings yet

- MD1 01 Stresses (Feb2021)Document18 pagesMD1 01 Stresses (Feb2021)AwesomeArchie 0No ratings yet

- TEDocument9 pagesTEkeshavuvceNo ratings yet

- Certificate Course in Autocad: Theory Lab TotalDocument5 pagesCertificate Course in Autocad: Theory Lab TotalAshwani dubeyNo ratings yet

- Applsci 11 03259 v2Document20 pagesApplsci 11 03259 v2AntonioNo ratings yet

- It&Ites: General Information For Computer Hardware Assistant Under MesDocument14 pagesIt&Ites: General Information For Computer Hardware Assistant Under MesJaveed AhamedNo ratings yet

- BITSF110-Course Handout 2021-22 IDocument3 pagesBITSF110-Course Handout 2021-22 IJack FrostNo ratings yet

- ME464 Robotics and AutomationDocument2 pagesME464 Robotics and AutomationloopycrowNo ratings yet

- Ijrdet 0314 09 PDFDocument9 pagesIjrdet 0314 09 PDFAnonymous P8Bt46mk5INo ratings yet

- (BS-IEMC) Program SpecificationDocument13 pages(BS-IEMC) Program SpecificationADonutReadingNo ratings yet

- BC9180-STAR: Base Station/ChargerDocument28 pagesBC9180-STAR: Base Station/Chargerel.ambiguoNo ratings yet

- 07a70101 Geotechnical Engineering-IiDocument7 pages07a70101 Geotechnical Engineering-IiSamiullah MohammedNo ratings yet

- L322 TD6 Crankcase Breather BMW Upgrade LandyZone - Land Rover ForumDocument1 pageL322 TD6 Crankcase Breather BMW Upgrade LandyZone - Land Rover Forumjimmy kNo ratings yet

- SCENARIA View 128 Plus: With Dual EnergyDocument8 pagesSCENARIA View 128 Plus: With Dual EnergyGilang RamadhanNo ratings yet

- GP2A25J0000F Series: Detecting Distance: 1 To 9mm OPIC Output, Refl Ective Photointerrupter With ConnectorDocument10 pagesGP2A25J0000F Series: Detecting Distance: 1 To 9mm OPIC Output, Refl Ective Photointerrupter With Connectoralias_johndeere2301No ratings yet

- Commercial Faucet Wallmount Sink Faucets: Specification: (Example)Document2 pagesCommercial Faucet Wallmount Sink Faucets: Specification: (Example)jmarrero488307No ratings yet

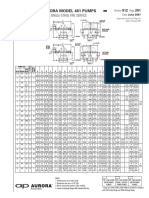

- Aurora Model 481 Pumps: Single-Stage Fire ServiceDocument20 pagesAurora Model 481 Pumps: Single-Stage Fire ServicenhacotungNo ratings yet

- Sinhagad College of Engineering Department of Information TechnologyDocument30 pagesSinhagad College of Engineering Department of Information TechnologyAniket NikamNo ratings yet

- Sas#1-Gen 005Document7 pagesSas#1-Gen 005Aldrin CamatNo ratings yet

- Budget Process Infor LNDocument48 pagesBudget Process Infor LNCoupons TodayNo ratings yet

- Kurmitar Sub-Vendor ListDocument52 pagesKurmitar Sub-Vendor Listmukherjeemohul25No ratings yet

- Foreword February 1971Document1 pageForeword February 1971Marjan BlagojevicNo ratings yet

- Arduino ReportDocument10 pagesArduino ReportSrinan MarvelNo ratings yet

- History: Query Language), Was Designed To Manipulate and Retrieve Data Stored in IBM's OriginalDocument8 pagesHistory: Query Language), Was Designed To Manipulate and Retrieve Data Stored in IBM's OriginalDean PhoebeNo ratings yet

- DRV10983 12-To 24-V, Three-Phase, Sensorless BLDC Motor DriverDocument61 pagesDRV10983 12-To 24-V, Three-Phase, Sensorless BLDC Motor DriverYogesh R SuryawanshiNo ratings yet

- Oracle® Data Relationship Management Suite: User's GuideDocument271 pagesOracle® Data Relationship Management Suite: User's GuideCricket Live StreamingNo ratings yet

- CRM Unit 1 Notes Introduction To CRMDocument16 pagesCRM Unit 1 Notes Introduction To CRMKeerthi Priya100% (1)

- Ceccato Professional Piston Leaflet English LRDocument2 pagesCeccato Professional Piston Leaflet English LRmogwai71No ratings yet

- Activity Proposal School Based MineDocument5 pagesActivity Proposal School Based MineELY FRANZ YABESNo ratings yet

- Ol80 - Bea 220265 en 04Document32 pagesOl80 - Bea 220265 en 04Ds KuzmenkoNo ratings yet

- Understanding The Hazard: Electrical Equipment in Hazardous (Classified) LocationsDocument4 pagesUnderstanding The Hazard: Electrical Equipment in Hazardous (Classified) LocationsVivianNo ratings yet

- Programming With Mobiflight & Prosim - The SimDocument1 pageProgramming With Mobiflight & Prosim - The Simbondomargalitadze margalitadzeNo ratings yet

- Building Electrical Systems Design & DraDocument1 pageBuilding Electrical Systems Design & DraGilbertNo ratings yet

- Prepare and Interpret Technical DrawingDocument42 pagesPrepare and Interpret Technical DrawingJacobo ZGMNHSNo ratings yet

- Integerprogramming Chapter 4Document60 pagesIntegerprogramming Chapter 4Frew Tadesse FreNo ratings yet

- City & Transportation (مفردات المدينDocument5 pagesCity & Transportation (مفردات المدينArmylova OfficialNo ratings yet

- Boarding Pass: Travelling With Check-In Bags? Travelling With Cabin (Carry On) Baggage Only? Airport Reporting TimingsDocument1 pageBoarding Pass: Travelling With Check-In Bags? Travelling With Cabin (Carry On) Baggage Only? Airport Reporting TimingsMahesh GajjelliNo ratings yet

- Literature Review On Effectiveness of Online AdvertisingDocument5 pagesLiterature Review On Effectiveness of Online Advertisingc5tb8kdwNo ratings yet