Professional Documents

Culture Documents

WPS-MET-01-03, Rev. 4-Dissimilar

Uploaded by

walid0 ratings0% found this document useful (0 votes)

7 views4 pagesWPS-MET-01-03, Rev. 4-Dissimilar

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWPS-MET-01-03, Rev. 4-Dissimilar

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views4 pagesWPS-MET-01-03, Rev. 4-Dissimilar

Uploaded by

walidWPS-MET-01-03, Rev. 4-Dissimilar

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

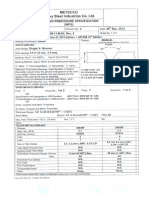

z METSCCO

tw Heavy Steel Industries Co. Ltd.

WELDING PROCEDURE SPECIFICATION

METSCCO (wPs)

WPS No.: MET-01-03 Revision No.: 4 Date: 04" Dec. 2016

‘Supporting POR No(s): MET-01A-03, Rev. 0 Sheet No. 1 of 2

Code: ASME B&PV Code, Section IX, 2015 Edition. + AWWA D100

Welding Process(es): SMAW Type(s): a fice wide

JOINTS (QW-=402) Details

Joint Design: Single V- Groove & “T” Joint [>|

Root spacing: 2.5 (+1.6 mm, -1.0 mm) ot

Backing: Yes [ ¥ ] For E309/E309L No[ ] ai x {

Backing Material (Type): (Refer to both backing and retainers) ct

1 Metal. CO Non-fusing Metal. (2 Nonmetallic. 0 Other. tes e

‘Sketches, Production Drawings, Weld Symbols or Written 1.5 mm (+1.6 mm, -1.0 mm)

Description should show the general arrangement ofthe parts | d= 2mm (#1 mm)

to be welded, Where applicable, he root spacing and the | This WPS is applicable to other type of welds Ike tack

details of the weld grove may be specified welds, socket welds, branch welds, repair welds, otc

Skeiches may be attached to iustrate joint design, weld

layers and bead sequence, e.¢,, for notch toughness

procedures, for multiple process procedures, etc

“BASE METALS (QW-403)

P-No.: 8 Group No.: All To P-No.: 1 Group No.; All

oR

Specification and typelgrade or UNS Number: A 240/A 276

To Specification and typelgrade or UNS Number: A 36/A 573 Gr. 70

OR

Chem. Analysis and Mech. Properties:

To Chem. Analysis and Mech. Properties:

Thickness Range: 1.5 to 12mm

Base Metal Groove: 1.5 to 12 mm. Fillet: All

Max. Pass Thickness < 1/2 in. (18 mm) Yes: (71 No:

Other:

SFILLER METALS (QW-404) =|

Process: : ‘SMAW |

Spec. No. (SFA) 54

‘AWS No. (Class) ES09/E308L

F-No. 5

A-No 3

Size of Filer Metals 25, 32mm o

Filler Metal Product Form NA

Supplemental Filler Metal NA.

‘Weld Metal Thickness Range: Groove: 42 mm Max.

Fillet All

Electrode-Flux (Class) NIA

Flux Type NIA

Flux Trade Name NA

Consumable Insert NIA

‘Other None =

“Each base metal filer metal combination should be recorded individually.

Form: QF/A22, Rev. 0, Dated: 21/10/2009

ey

METSCCO

Heavy Steel Industries Co. Ltd.

WELDING PROCEDURE SPECIFICATION

METSCCO (WPS)

WPS No: MET-01-03 Rev: 4 Sheet No.2 of 2

POSITIONS (QW-405) POST WELD HEAT TRAETMENT (QW-407)

Position (s) of Groove: All Temp. Range: NIA Time Range: NIA

Welding Progression: Up{v J Down{ ] Rotation] Heating Rate: N/A Cooling Rate: NIA

Position of Fillet; All co.

ercent Composition

AT (QW.

Preheat Tenpesatue Nan: 20°C Minimum fd re ret eed

Sec la Shielding NIA NIA NIA

Inter-pass Temperature Max. jaximum ling MA an ae

Preheat Maintenance: NIA. Eoung NIA NIA NIA

ELECTRICAL CHARACTERISTICS (QW-408)

Filler Metal Current Travel Other

Weld Volt

layerts)| PrOess Type | Amp Speed | g,temme comet

layer(s) Glass ee Polarity | Range | "2"9° | Range ey

foot | MAN aaamm| ocep | co-110 | 2208 | 62,28 |

ot pass E3097 ‘|

} | Fit SMAW | E309. 2.5/3.2 DGEP 65-150 20-35 75-225,

mm smmvmin,

[cap | smaw pce | 100-145 | 20-36

(mps and Volts range should be recorded for each size, position and thickness, etc.)

Pulsing Current: N/A Heat input (max): N/A

‘Tungsten Electrode Size and Type (Pure Tungsten, 2% Thoriated, ete: NIA

Mode of Metal Transfer for GMAW (FCAW) (Spray ar, Short Cireuiting ar, ete): NIA

Electrode Wire Feed Speed Range: NIA

Other: None.

TECHNIQUE (QW-410)

String or Weave Bead: String & Weave.

Orifice, Nozzle or Gas Cup Size: N/A

Max. Weave Width: 3 x Core Diameter.

Initial and Inter-pass Cleaning (Brushing, Grinding, etc): Grinding and/or Brushing. Also %” surface either side

Method of Back Gouging: N/A

Oscillation: NIA

Pass per side (Multiple or Single Pass): Multiple,

Electrode Spacing: N/A

Other: QW 410.64 is N/A.

of the joint shall be clean before welding.

| contact Tube to Work Distance: N/A

Electrodes (Multiple or Single): Single.

Peening: Not Permitted.

Reman

Prepared By: QC Inspector Approved By: QA/QC Manager Reviewed By: Al /Client /TPI

[mame ‘Aeemudain ROSH ip

Sonate | _ A

Date 04" December 2016 04" December 2016

Form: QF/A22,

>, Rev, 0, Dated: 21/10/2009

AL HOTY-STANGER LTD. CO. Bagh Fl slew b tlic o

Independent Laboratories & Materials Testing out Addl op gary Ol pe

PROCEDURE QUALIFICATION RECORD (PQR)

Company Name _METSCCO

Joint Design used

Fr combination queliications, the deposited weld metal thicness shal be recorded foreach file metal or process used

BASE METALS (QW-403)

Material Spec. __ SA240 TP.316L to SA283GR.C

Type or Grade SA 240

P.No.

Thickness

Diameter

FILLER METALS (QW-404)

‘SFA Spectiication

AWS Caassification

Filler Metal F. No.

Weld Metal Analysis A-No.

Size of Filler Metal

Other _ - Oscillation NA

MANUFACTURER Mutipass or Single Pass (par sid6)

Position of Groove 1G _

Weld Progression (Uphil, Downhil) FLAT PREHEAT (QW-406)

Other Nia Preheat Temp.

- Interpass Temp”

Other _

AL HOTY-STANGER LTD. CO. Baht! pAlew bp thas pd

Independent Laboratories & Materials Testing Na oy jar Opie

WELDING PROCEDURE QUALIFICATION RECORD

TSC

ISSUE DATE : 09 JULY 2003

W.P.S.# MET-01-03-REV.00 P.Q.R.# MET-01A-03

TENSILE TEST

séeciuena | wiTH | HCE | area YIELD ULTIMATE % TALURE

(ns) (sa) | LOAD | STRESS] LOAD | STRESS | ELGN| LOCATION

(ins) (ils) esi) (lbs) Avs)

over | 0242 | 0190 5 : 13.132 | 69.116 | - | SA289GrC

o7ee | 0238 | 0.190 7 2 13.143 | 69.174 | _- | SA2@9GrC

GUIDED BEND TESTS

IDENTIFICATION RESULT IDENTIFICATION RESULT

FACE BEND ~1 ‘SATISFACTORY

FACE BEND —2 ‘SATISFACTORY

ROOT BEND—1 ‘SATISFACTORY

ROOT BEND -2 ‘SATISFACTORY

IMPACT TOUGHNESS TEST (CHARPY) FILLET WELD TEST _ N/A

| IMPACT

SPECIMEN | SIZE | NOTCH | TEST — a

NO. (MM) | LOCATION | TEMP (°F) valure RESULT-SATISFACTORY Yes[ | No

l a

PENETRATION INTO = a

P14, 2, 3 NA | NA NA NA PARENT METAL YES NO

w.4, 2, 3

M1, 2, 3 MACRO RESULTS NIA

L

HARDNESS TEST RESULTS OTHER TESTS RADIOGRAPHY

PARENTMETAL AVE NA Hi NA AVE NA

WELD AVE HI AVE HARDNESS TEST?

Haz AVE _ HAE

WELDER'S NAME K. J. RAPHAEL - 9112

TEST CONDUCTED BY ALHOTY STANGER LTD. CO.

WE CERTIFY THAT THE STATEMENTS IN THIS RECORD ARE CORRECT AND THAT THE TEST SPECIMET

AND TESTED IN ACCORDANCE WITH THE REQUIREMENTS OF WELDING SPECIFICATION. ASME Sec. IX - 2001

WITNESS _- MANUFACTURER _METSCCO

DATE oo ENGR. REGGIE D'SOUZA a

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- WPS-MET-11-A-03 Rev. 2Document4 pagesWPS-MET-11-A-03 Rev. 2walidNo ratings yet

- WPS-MET-11-M-05 Rev. 2Document4 pagesWPS-MET-11-M-05 Rev. 2walidNo ratings yet

- SAIC-A-2009 - Verify Test Equipment (Safety Assessment)Document4 pagesSAIC-A-2009 - Verify Test Equipment (Safety Assessment)walidNo ratings yet

- WPS-MET-06-95 Rev. 3Document4 pagesWPS-MET-06-95 Rev. 3walidNo ratings yet

- WPS-MET-11-M-04 Rev. 1Document4 pagesWPS-MET-11-M-04 Rev. 1walidNo ratings yet

- SAIC-A-2001 - Review Procedure - Pressure Testing (All Applications)Document13 pagesSAIC-A-2001 - Review Procedure - Pressure Testing (All Applications)walidNo ratings yet

- SAIC-A-2008 - Verify Test Medium For Hydrostatic Testing & Lay-UpDocument3 pagesSAIC-A-2008 - Verify Test Medium For Hydrostatic Testing & Lay-UpwalidNo ratings yet

- WPS-MET-01-06 Rev. 3Document4 pagesWPS-MET-01-06 Rev. 3walidNo ratings yet

- SAIC-A-1014 - Preweld Qualification of HDPE WelderDocument1 pageSAIC-A-1014 - Preweld Qualification of HDPE WelderwalidNo ratings yet

- SAIC-A-1014 - Preweld Qualification of HDPE WelderDocument1 pageSAIC-A-1014 - Preweld Qualification of HDPE WelderwalidNo ratings yet

- SAIC-A-1014 - Preweld Qualification of HDPE WelderDocument1 pageSAIC-A-1014 - Preweld Qualification of HDPE WelderwalidNo ratings yet

- SAIC-A-1014 - Preweld Qualification of HDPE WelderDocument1 pageSAIC-A-1014 - Preweld Qualification of HDPE WelderwalidNo ratings yet

- SAIC-A-1006 - Final Fill InspectionDocument1 pageSAIC-A-1006 - Final Fill InspectionwalidNo ratings yet

- SAIC-A-1014 - Preweld Qualification of HDPE WelderDocument1 pageSAIC-A-1014 - Preweld Qualification of HDPE WelderwalidNo ratings yet

- SAIC A 1005 Compaction TestingDocument2 pagesSAIC A 1005 Compaction TestingwalidNo ratings yet