Professional Documents

Culture Documents

Validity Unknown

Uploaded by

SURYA SHAKTI VESSELS PVT. LTD.Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Validity Unknown

Uploaded by

SURYA SHAKTI VESSELS PVT. LTD.Copyright:

Available Formats

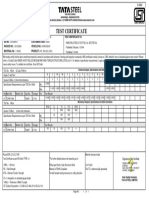

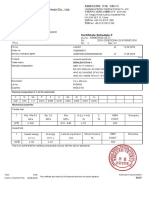

STEEL AUTHORITY OF INOIA LIM ITEO Page No :A-1 of 1

BHILAI STEEL PLANT IS: 2062

RESEARCH & CONTROL LAB (MECHANICAL TESTING LAB)

TEST CERTIFICATE FOR HOT ROLLED MEOIUM ANO HIGH TENSILE STRUCTURAL

STEEL

CM/L-0057534

MTL-11/QR-2

Sold-to-Party: T.C.No : RCUMTUPLM/80750599

BM BSO FARIDABAD T.C. Date : 02.05.2023

GOVIND BHAWAN NEELAM CHOWK NIT SALES ORDER NO : 1100457285

FARIDABAD 121001 DA No : 80750599

Ship-to-Party:

WHM FARIDABAD,Faridabad. Wagon No/ Trailer No : SR21 061810124

Process of Manufacture of Steel : Basic Oxygen Converter> Continuous Casi> Fully Killed Steel

Specification: IS 2062 E250 BR: 2011 RA 2021

We certify that the material described below fully conforms to IS 2062 : 2011 RA 2021. Chemical composition and Mechanical properties of the product, as

tested in accordance with the scheme of testing and inspection contained in the BIS certification mark Number CM/L 0057534 are as indicated against each

Order No.

(Please refer to IS 2062 : 2011 RA 2021 for details of specification requirements)

TEST RESULTS

SECTION (NOMINAL SIZE) MECHANICAL PROPERTIES

Test

THICK WIDTH LENGTH Plate No Heat No YS

14

322

Heat CHEMICAL COMPOSITION (LADLE ANALYSIS)

No C s p Mn Si Al Cu Cr Ni Mo Nb V Ti B CE

% % % % % % % % % % % % % % %

350367 0.14 0.015 0.024 0.76 0.25 0.021 < 0.02 0.030 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 < 0.0005 0.27

Total Pieces Page/ Sales Order : 1 / 1 Total Pieces/ TC 20

The Material supplied conforms to the standard rolling and weight tolerances.,

CE calculated by formula: [C + Mn/6 + (Cr+ Mo+ V )/5 + (Ni+ Cu )/15],

Size of impact test specimen:10x1 0x55 mm(above 10mm thickness); 7.5x10x55 mm(upto 10mm thickness),

Note:*• M = Mandrel Dia, T = Plate Thickness, Length is the rolling direction of the plate,

TC as per BSEN 10204 Type 3.1,

Validity unknown

Digitally signed by S SAIJU

Date: 2023.05.02 12:32:36 1ST

Reason: Authorized Signatory RCL,

BSP

Authorised Signatory Authorized Signatory

SAIU CMO/ BSO Research & Control Laboratory, Bhilai Steel Plant

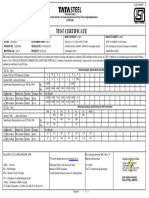

STEEL AUTHORITY OF INOIA LIM ITEO Page No :B-1 of 1

BHILAI STEEL PLANT IS: 2062

RESEARCH & CONTROL LAB (MECHANICAL TESTING LAB)

TEST CERTIFICATE FOR HOT ROLLED MEOIUM ANO HIGH TENSILE STRUCTURAL

STEEL

CM/L-0057534

MTL-11/QR-2

Sold-to-Party: T.C.No : RCUMTUPLM/80750599

BM BSO FARIDABAD T.C. Date : 02.05.2023

GOVIND BHAWAN NEELAM CHOWK NIT SALES ORDER NO : 1100457285

FARIDABAD 121001 DA No : 80750599

Ship-to-Party:

WHM FARIDABAD,Faridabad. Wagon No/ Trailer No : SR21 06181O124

Process of Manufacture of Steel : Basic Oxygen Converter> Continuous Casi> Fully Killed Steel

Specification: IS 2062 E250 BR: 2011 RA 2021

We certify that the material described below fully conforms to IS 2062 : 2011 RA 2021. Chemical composition and Mechanical properties of the product, as

tested in accordance with the scheme of testing and inspection contained in the BIS certification mark Number CM/L 0057534 are as indicated against each

Order No.

(Please refer to IS 2062 : 2011 RA 2021 for details of specification requirements)

TEST RESULTS

SECTION (NOMINAL SIZE) MECHANICAL PROPERTIES

Test

THICK WIDTH LENGTH Plate No Heat No YS UTS %E %E2 CHARPY V NOTCH () Impact Values (J)

OK 2.0 T

OK 2.0 T

Heat CHEMICAL COMPOSITION (LADLE ANALYSIS)

No C s p Mn Si Al Cu Cr Ni Mo Nb V Ti N2 B CE

% % % % % % % % % % % % % ppm % %

358014 0.21 0.019 0.024 1.09 0.26 0.017 < 0.02 0.030 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 60 < 0.0005 0.40

Total Pieces Page/ Sales Order : 1 / 1 Total Pieces/ TC 20

Ultrasonic Testing Level :ASTM A 578 Level B Satisfactory & level of acceptance as per TDC,

The Material supplied conforms to the standard rolling and weight tolerances.,

CE calculated by formula: [C + Mn/6 + (Cr+ Mo+ V )/5 + (Ni+ Cu )/15],

Note:*• M = Mandrel Dia, T = Plate Thickness, Length is the rolling direction of the plate,

TC as per BSEN 10204 Type 3.1,

Validity unknown

Digitally signed by S SAIJU

Date: 2023.05.02 12:32:36 1ST

Reason: Authorized Signatory RCL,

BSP

Authorised Signatory Authorized Signatory

SAIU CMO/ BSO Research & Control Laboratory, Bhilai Steel Plant

STEEL AUTHORITY OF INOIA LIM ITEO Page No :C-1 of 1

BHILAI STEEL PLANT IS: 2002

RESEARCH & CONTROL LAB (MECHANICAL TESTING LAB)

TEST CERTIFICATE FOR STEEL PLATES FOR PRESSURE VESSELS FOR

INTERMEDIATE ANO HIGH TEMPERATURE SERVICE INCLUDING BOILERS

CM/L-1488364

MTL-11/QR-2

Sold-to-Party: T.C.No : RCUMTUPLM/80750599

BM BSO FARIDABAD T.C. Date : 02.05.2023

GOVIND BHAWAN NEELAM CHOWK NIT SALES ORDER NO : 1100457288

FARIDABAD 121001 DA No : 80750599

Ship-to-Party:

WHM FARIDABAD,Faridabad. Wagon No/ Trailer No : SR21 06181O124

Process of Manufacture of Steel : Basic Oxygen Converter> Continuous Casi> Fully Killed Steel> Normalising Rolling

Specification : IS 2002 GR 3 : 2009 RA 2018

It is certified that the material described below fully conforms to IS 2002 : 2009 RA 2018. Chemical composition and Mechanical properties of the product

as tested in accordance with the scheme of testing and inspection contained in the BIS certification marks Licence Number CM/L 1488364 are as indicated

against each Order No.

(Please refer to IS 2002 : 2009 RA 2018 for details of specification requirements)

TEST RESULTS

SECTION (NOMINAL SIZE) MECHANICAL PROPERTIES Bend

Test

THICK LENGTH Plate No Heat No YS CHARPY V NOTCH() Impact Values (J)

mm

--

CHEMICAL COMPOSITION (LADLE ANALYSIS)

No C s p Mn Si Al Cu Cr Ni Mo Nb V Ti B CE

% % % % % % % % % % % % % ppm % %

349290 0.20 0.019 0.021 1.08 0.18 0.006 < 0.02 0.030 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 70 < 0.0005 0.39

Total Pieces Page/ Sales Order : 1 / 1 Total Pieces/ TC 20

All the plate surfaces & dimension checked by BSP & each plate bears a stamp thus.

Ultrasonic Testing Level :ASTM A 435 Satisfactory & level of acceptance as per TDC,

The Material supplied conforms to the standard rolling and weight tolerances.,

CE calculated by formula: [C + Mn/6 + (Cr+ Mo+ V )/5 + (Ni+ Cu )/15],

Note:*• M = Mandrel Dia, T = Plate Thickness, Length is the rolling direction of the plate,

TC as per BSEN 10204 Type 3.1,

Validity unknown

Digitally signed by S SAIJU

Date: 2023.05.02 12:32:36 1ST

Reason: Authorized Signatory RCL,

BSP

Authorised Signatory Authorized Signatory

SAIU CMO/ BSO Research & Control Laboratory, Bhilai Steel Plant

STEEL AUTHORITY OF INOIA LIM ITEO Page No :D-1 of 1

BHILAI STEEL PLANT IS: 2002

RESEARCH & CONTROL LAB (MECHANICAL TESTING LAB)

TEST CERTIFICATE FOR STEEL PLATES FOR PRESSURE VESSELS FOR

INTERMEDIATE ANO HIGH TEMPERATURE SERVICE INCLUDING BOILERS

CM/L-1488364

MTL-11/QR-2

Sold-to-Party: T.C.No : RCUMTUPLM/80750599

BM BSO FARIDABAD T.C. Date : 02.05.2023

GOVIND BHAWAN NEELAM CHOWK NIT SALES ORDER NO : 1100457288

FARIDABAD 121001 DA No : 80750599

Ship-to-Party:

WHM FARIDABAD,Faridabad. Wagon No/ Trailer No : SR21 06181O124

Process of Manufacture of Steel : Basic Oxygen Converter> Continuous Casi> Fully Killed Steel> Normalising Rolling

Specification : IS 2002 GR 3 : 2009 RA 2018

It is certified that the material described below fully conforms to IS 2002 : 2009 RA 2018. Chemical composition and Mechanical properties of the product

as tested in accordance with the scheme of testing and inspection contained in the BIS certification marks Licence Number CM/L 1488364 are as indicated

against each Order No.

(Please refer to IS 2002 : 2009 RA 2018 for details of specification requirements)

TEST RESULTS

SECTION (NOMINAL SIZE) MECHANICAL PROPERTIES Bend M Dia

Test

THICK WIDTH LENGTH Plate No Heat No YS UTS %E %E2 CHARPY V NOTCH () Impact Values (J)

285 MPa 460-580 11 12 13 lavg oc

mm mm mm /Pc.No. in21(5.6

Min MPa 5SqrtS0)

17 2550 10161 3001036/1 359097 365 555 29 -- OK 3.0 T

17 2550 10161 3001036/2 359097 365 555 29 -- OK 3.0 T

17 2550 10161 3003230/2 359231 367 510 24 -- OK 3.0 T

17 2550 10161 3004083/1 359234 359 508 24 -- OK 3.0 T

17 2550 10161 3004083/2 359234 359 508 24 -- OK 3.0 T

Heat CHEMICAL COMPOSITION (LADLE ANALYSIS)

No C s p Mn Si Al Cu Cr Ni Mo Nb V Ti B CE

% % % % % % % % % % % % % % %

359097 0.19 0.025 0.028 1.06 0.23 0.016 < 0.02 0.040 0.030 < 0.015 < 0.010 < 0.010 < 0.005 72 < 0.0005 0.38

359231 0.21 0.023 0.020 1.11 0.22 0.016 < 0.02 0.020 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 62 < 0.0005 0.40

359234 0.21 0.021 0.022 1.08 0.24 0.014 < 0.02 0.030 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 64 < 0.0005 0.40

Total Pieces Page/ Sales Order : 5 I 5 Total Pieces/ TC 20

All the plate surfaces & dimension checked by BSP & each plate bears a stamp thus.

Ultrasonic Testing Level :ASTM A 578 Level B Satisfactory & level of acceptance as per TDC,

The Material supplied conforms to the standard rolling and weight tolerances.,

CE calculated by formula: [C + Mn/6 + (Cr+ Mo+ V )/5 + (Ni+ Cu )/15],

Note:** M = Mandrel Dia, T = Plate Thickness, Length is the rolling direction of the plate,

TC as per BSEN 10204 Type 3.1,

Validity unknown

Digitally signed by S SAIJU

Date: 2023.05.02 12:32:36 1ST

Reason: Authorized Signatory RCL,

BSP

Authorised Signatory Authorized Signatory

SAIU CMO/ BSO Research & Control Laboratory, Bhilai Steel Plant

STEEL AUTHORITY OF INOIA LIM ITEO Page No :E-1 of 2

BHILAI STEEL PLANT IS: 2002

RESEARCH & CONTROL LAB (MECHANICAL TESTING LAB)

TEST CERTIFICATE FOR STEEL PLATES FOR PRESSURE VESSELS FOR

INTERMEDIATE ANO HIGH TEMPERATURE SERVICE INCLUDING BOILERS

CM/L-1488364

MTL-11/QR-2

Sold-to-Party: T.C.No : RCUMTUPLM/80750599

BM BSO FARIDABAD T.C. Date : 02.05.2023

GOVIND BHAWAN NEELAM CHOWK NIT SALES ORDER NO : 1100457288

FARIDABAD 121001 DA No : 80750599

Ship-to-Party:

WHM FARIDABAD,Faridabad. Wagon No/ Trailer No : SR21 06181O124

Process of Manufacture of Steel : Basic Oxygen Converter> Continuous Casi> Fully Killed Steel> Normalising Rolling

Specification : IS 2002 GR 3 : 2009 RA 2018

It is certified that the material described below fully conforms to IS 2002 : 2009 RA 2018. Chemical composition and Mechanical properties of the product

as tested in accordance with the scheme of testing and inspection contained in the BIS certification marks Licence Number CM/L 1488364 are as indicated

against each Order No.

(Please refer to IS 2002 : 2009 RA 2018 for details of specification requirements)

TEST RESULTS

SECTION (NOMINAL SIZE) MECHANICAL PROPERTIES Bend M Dia

Test

THICK WIDTH LENGTH Plate No Heat No YS UTS %E %E2 CHARPY V NOTCH () Impact Values (J)

285 MPa 460-580 11 12 13 lavg oc

mm mm mm /Pc.No. in21(5.6

Min MPa 5SqrtS0)

17 2550 9700 2964684/2 355087 399 545 28 -- OK 3.0 T

17 2550 9500 2964731/2 355090 345 512 29 -- OK 3.0 T

17 2550 9700 2966356/2 355307 380 526 26 -- OK 3.0 T

17 2550 10161 3003192/2 359177 362 527 26 -- OK 3.0 T

17 2550 10161 3003202/2 359177 380 531 25 -- OK 3.0 T

17 2550 9900 3001891/2 359185 355 521 23 -- OK 3.0 T

17 2550 9900 3003221/2 359231 387 533 25 -- OK 3.0 T

Heat CHEMICAL COMPOSITION (LADLE ANALYSIS)

No C s p Mn Si Al Cu Cr Ni Mo Nb V Ti N2 B CE

% % % % % % % % % % % % % ppm % %

355087 0.22 0.015 0.027 1.13 0.30 0.013 < 0.02 0.030 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 60 < 0.0005 0.41

355090 0.20 0.012 0.022 1.08 0.23 0.011 < 0.02 0.030 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 63 < 0.0005 0.39

355307 0.20 0.015 0.023 1.12 0.23 0.016 < 0.02 < 0.015 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 64 < 0.0005 0.39

359177 0.21 0.024 0.029 1.10 0.24 0.015 < 0.02 0.030 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 78 < 0.0005 0.40

359185 0.22 0.022 0.024 1.05 0.23 0.014 < 0.02 0.030 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 65 < 0.0005 0.40

359231 0.21 0.023 0.020 1.11 0.22 0.016 < 0.02 0.020 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 62 < 0.0005 0.40

Total Pieces Page/ Sales Order : 7 / 7 Total Pieces/ TC 20

All the plate surfaces & dimension checked by BSP & each plate bears a stamp thus.

Ultrasonic Testing Level :ASTM A 578 Level B Satisfactory & level of acceptance as per TDC,

The Material supplied conforms to the standard rolling and weight tolerances.,

CE calculated by formula: [C + Mn/6 + (Cr+ Mo+ V )/5 + (Ni+ Cu )/15],

Note:*• M = Mandrel Dia, T = Plate Thickness, Length is the rolling direction of the plate,

Validity unknown

Digitally signed by S SAIJU

Date: 2023.05.02 12:32:36 1ST

Reason: Authorized Signatory RCL,

BSP

Authorised Signatory Authorized Signatory

SAIU CMO/ BSO Research & Control Laboratory, Bhilai Steel Plant

STEEL AUTHORITY OF INOIA LIM ITEO Page No :E-2 of 2

BHILAI STEEL PLANT IS: 2002

RESEARCH & CONTROL LAB (MECHANICAL TESTING LAB)

TEST CERTIFICATE FOR STEEL PLATES FOR PRESSURE VESSELS FOR

INTERMEDIATE ANO HIGH TEMPERATURE SERVICE INCLUDING BOILERS

CM/L-1488364

MTL-11/QR-2

Sold-to-Party: T.C.No : RCUMTUPLM/80750599

BM BSO FARIDABAD T.C. Date : 02.05.2023

GOVIND BHAWAN NEELAM CHOWK NIT SALES ORDER NO : 1100457288

FARIDABAD 121001 DA No : 80750599

Ship-to-Party:

WHM FARIDABAD,Faridabad. Wagon No/ Trailer No : SR21 06181O124

Process of Manufacture of Steel : Basic Oxygen Converter> Continuous Casi> Fully Killed Steel> Normalising Rolling

Specification : IS 2002 GR 3 : 2009 RA 2018

TC as per BSEN 10204 Type 3.1,

Validity unknown

Digitally signed by S SAIJU

Date: 2023.05.02 12:32:36 1ST

Reason: Authorized Signatory RCL,

BSP

Authorised Signatory Authorized Signatory

SAIU CMO/ BSO Research & Control Laboratory, Bhilai Steel Plant

STEEL AUTHORITY OF INOIA LIM ITEO Page No :F-1 of 1

BHILAI STEEL PLANT IS: 2002

RESEARCH & CONTROL LAB (MECHANICAL TESTING LAB) CM/L-1488364

TEST CERTIFICATE FOR STEEL PLATES FOR PRESSURE VESSELS FOR MTL-11/QR-2

INTERMEDIATE ANO HIGH TEMPERATURE SERVICE INCLUDING BOILERS

Sold-to-Party: T.C.No : RCUMTUPLM/80750599

BM BSO FARIDABAD T.C. Date : 02.05.2023

GOVIND BHAWAN NEELAM CHOWK NIT SALES ORDER NO : 1100457288

FARIDABAD 121001 DA No : 80750599

Ship-to-Party:

WHM FARIDABAD,Faridabad. Wagon No/ Trailer No : SR21 06181O124

Process of Manufacture of Steel : Basic Oxygen Converter> Continuous Casi> Fully Killed Steel> Normalising Rolling

Specification: IS 2002 GR 3 : 2009 RA 2018/ASME SA 515 GR 70:2021

It is certified that the material described below fully conforms to IS 2002 : 2009 RA 2018. Chemical composition and Mechanical properties of the product

as tested in accordance with the scheme of testing and inspection contained in the BIS certification marks Licence Number CM/L 1488364 are as indicated

against each Order No.

(Please refer to IS 2002 : 2009 RA 2018 for details of specification requirements)

TEST RESULTS

SECTION (NOMINAL SIZE) MECHANICAL PROPERTIES Bend M Dia

Test

THICK WIDTH LENGTH Plate No Heat No 0

mm mm mm /Pc.No. 29; Pa48 :;80r, ,n: 1 5 5 1 : GL.

Min M Pa 5SqrtS0) 00)

12 2500 11000 2983848/2 349478 401 566 25 19 OK 13.0 T

Heat CHEMICAL COMPOSITION (LADLE ANALYSIS)

No C s p Mn Si Al Cu Cr Ni Mo Nb V Ti B CE

% % % % % % % % % % % % % ppm % %

349478 0.21 0.017 0.022 1.08 0.27 0.009 < 0.02 0.030 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 65 < 0.0005 0.40

Total Pieces Page/ Sales Order : 1 / 1 Total Pieces/ TC : 20

All the plate surfaces & dimension checked by BSP & each plate bears a stamp thus.

Ultrasonic Testing Level :ASTM A 578 Level B Satisfactory & level of acceptance as per TDC,

The Material supplied conforms to the standard rolling and weight tolerances.,

CE calculated by formula: [C + Mn/6 + (Cr+ Mo+ V )/5 + (Ni+ Cu )/15],

Yield strength determined by 0.2% offset method,

Note:*• M = Mandrel Dia, T = Plate Thickness, Length is the rolling direction of the plate,

TC as per BSEN 10204 Type 3.1,

Validity unknown

Digitally signed by S SAIJU

Date: 2023.05.02 12:32:36 1ST

Reason: Authorized Signatory RCL,

BSP

Authorised Signatory Authorized Signatory

SAIU CMO/ BSO Research & Control Laboratory, Bhilai Steel Plant

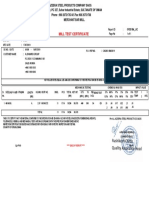

STEEL AUTHORITY OF INOIA LIM ITEO Page No :G-1 of 1

BHILAI STEEL PLANT IS: 2041

RESEARCH & CONTROL LAB (MECHANICAL TESTING LAB)

TEST CERTIFICATE FOR STEEL PLATES FOR PRESSURE VESSELS USED AT

MODERATE ANO LOW TEMPERATURE

CM/L-3016535

MTL-11/QR-2

Sold-to-Party: T.C.No : RCUMTUPLM/80750599

BM BSO FARIDABAD T.C. Date : 02.05.2023

GOVIND BHAWAN NEELAM CHOWK NIT SALES ORDER NO : 1100457288

FARIDABAD 121001 DA No : 80750599

Ship-to-Party:

WHM FARIDABAD,Faridabad. Wagon No/ Trailer No : SR21 06181O124

Process of Manufacture of Steel : Basic Oxygen Converter> Continuous Casi> Fully Killed Steel> Normalising Rolling> Fine Grain Practice

Specification: IS 2041 R260: 2009 RA 2018 / ASMESA 516 GR70: 2021

It is certified that the material described below fully conforms to IS 2041 : 2009 RA 2018. Chemical composition and Mechanical properties of the product

as tested in accordance with the scheme of testing and inspection contained in the BIS certification marks Licence Number CM/L 3016535 are as indicated

against each Order No.

(Please refer to IS 2041 : 2009 RA 2018 for details of specification requirements)

TEST RESULTS

SECTION (NOMINAL SIZE) MECHANICAL PROPERTIES

Test

THICK WIDTH LENGTH Plate No Heat No YS UTS %E %E2 CHARPY V NOTCH () Impact Values (J)

16 2500 7000 3013266/7 359167 374 550 28 22

16 2500 8300 3015345/6 360197 364 515 26 21

Heat CHEMICAL COMPOSITION (LADLE ANALYSIS)

No C s p Mn Si Al Cu Cr Ni Mo Nb V Ti N2 B CE

% % % % % % % % % % % % % ppm % %

359167 0.23 0.016 0.016 1.14 0.32 0.024 < 0.02 0.020 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 65 < 0.0005 0.42

360197 0.19 0.016 0.019 1.15 0.29 0.031 < 0.02 0.030 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 63 < 0.0005 0.39

Total Pieces Page/ Sales Order : 2 / 2 Total Pieces/ TC 20

All the plate surfaces & dimension checked by BSP & each plate bears a stamp thus.

The Material supplied conforms to the standard rolling and weight tolerances.,

CE calculated by formula: [C + Mn/6 + (Cr+ Mo+ V )/5 + (Ni+ Cu )/15],

Yield strength determined by 0.2% offset method,

Note:** M = Mandrel Dia, T = Plate Thickness, Length is the rolling direction of the plate,

TC as per BSEN 10204 Type 3.1,

Validity unknown

Digitally signed by S SAIJU

Date: 2023.05.02 12:32:36 1ST

Reason: Authorized Signatory RCL,

BSP

Authorised Signatory Authorized Signatory

SAIU CMO/ BSO Research & Control Laboratory, Bhilai Steel Plant

STEEL AUTHORITY OF INOIA LIM ITEO Page No :H-1 of 1

BHILAI STEEL PLANT IS: 2041

RESEARCH & CONTROL LAB (MECHANICAL TESTING LAB)

TEST CERTIFICATE FOR STEEL PLATES FOR PRESSURE VESSELS USED AT

MODERATE ANO LOW TEMPERATURE

CM/L-3016535

MTL-11/QR-2

Sold-to-Party: T.C.No : RCUMTUPLM/80750599

BM BSO FARIDABAD T.C. Date : 02.05.2023

GOVIND BHAWAN NEELAM CHOWK NIT SALES ORDER NO : 1100457288

FARIDABAD 121001 DA No : 80750599

Ship-to-Party:

WHM FARIDABAD,Faridabad. Wagon No/ Trailer No : SR21 06181O124

Process of Manufacture of Steel : Basic Oxygen Converter> Continuous Casi> Fully Killed Steel> Normalising Rolling> Fine Grain Practice

Specification: IS 2041 R260: 2009 RA 2018 / ASMESA 516 GR70: 2021

It is certified that the material described below fully conforms to IS 2041 : 2009 RA 2018. Chemical composition and Mechanical properties of the product

as tested in accordance with the scheme of testing and inspection contained in the BIS certification marks Licence Number CM/L 3016535 are as indicated

against each Order No.

(Please refer to IS 2041 : 2009 RA 2018 for details of specification requirements)

TEST RESULTS

SECTION (NOMINAL SIZE) MECHANICAL PROPERTIES

Test

THICK WIDTH LENGTH Plate No Heat No YS UTS %E %E2 CHARPY V NOTCH () Impact Values (J)

16 2500 8100 3013258/7 359167 380 546 26 21

16 2500 8000 3018532/2 360524 352 547 26 21

Heat CHEMICAL COMPOSITION (LADLE ANALYSIS)

No C s p Mn Si Al Cu Cr Ni Mo Nb V Ti N2 B CE

% % % % % % % % % % % % % ppm % %

359167 0.23 0.016 0.016 1.14 0.32 0.024 < 0.02 0.020 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 65 < 0.0005 0.42

360524 0.23 0.021 0.024 1.10 0.32 0.032 < 0.02 0.030 < 0.015 < 0.015 < 0.010 < 0.010 < 0.005 65 < 0.0005 0.42

Total Pieces Page/ Sales Order : 2 / 2 Total Pieces/ TC 20

All the plate surfaces & dimension checked by BSP & each plate bears a stamp thus.

The Material supplied conforms to the standard rolling and weight tolerances.,

CE calculated by formula: [C + Mn/6 + (Cr+ Mo+ V )/5 + (Ni+ Cu )/15],

Yield strength determined by 0.2% offset method,

Note:** M = Mandrel Dia, T = Plate Thickness, Length is the rolling direction of the plate,

TC as per BSEN 10204 Type 3.1,

Validity unknown

Digitally signed by S SAIJU

Date: 2023.05.02 12:32:36 1ST

Reason: Authorized Signatory RCL,

BSP

Authorised Signatory Authorized Signatory

SAIU CMO/ BSO Research & Control Laboratory, Bhilai Steel Plant

You might also like

- 304 1.5MM PCDocument1 page304 1.5MM PCsabir hussain100% (1)

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOshekarNo ratings yet

- 1.20mm T.C - Mehta SteelsDocument1 page1.20mm T.C - Mehta SteelsRonak FireNo ratings yet

- Macbeth Classwork WorkbookDocument36 pagesMacbeth Classwork WorkbookMairead KellyNo ratings yet

- 10MMDocument1 page10MMStructures ProductionNo ratings yet

- Test Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811Document1 pageTest Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811akash_smhs0% (1)

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- Page 2 of 6: Test Certificate No. 0000052877Document1 pagePage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- Unknown 1966 O7Document132 pagesUnknown 1966 O7Hugard100% (1)

- Grail Quest 2Document112 pagesGrail Quest 2Tamás Viktor TariNo ratings yet

- Vedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKDocument23 pagesVedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKPRAKASH PANDEYNo ratings yet

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedDocument1 pageMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech0992000% (1)

- Test Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesDocument1 pageTest Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesSuman Jana100% (1)

- 2452169253-6x1500mm E250Document1 page2452169253-6x1500mm E250Mohd YaskeenNo ratings yet

- 0707711343Document2 pages0707711343venkata krishna reddy MorthlaNo ratings yet

- Page 1 of 1: Test Certificate No. 0000141878Document1 pagePage 1 of 1: Test Certificate No. 0000141878Vishwanathan NagarajanNo ratings yet

- TC - ASTM 517 GR FDocument1 pageTC - ASTM 517 GR FPremnath YadavNo ratings yet

- Test Certificate: Signature Not VerifiedDocument1 pageTest Certificate: Signature Not VerifiedSLKK DELHINo ratings yet

- Essentials of Marketing Research 5th Edition Zikmund Test BankDocument18 pagesEssentials of Marketing Research 5th Edition Zikmund Test Bankbrittanylamsfwkpbmzce100% (18)

- Bishweshwar Lal Steels: Hot Rolled Steel Strip For Welded Tubes and Pipes As Per Is: 10748 - 2004Document1 pageBishweshwar Lal Steels: Hot Rolled Steel Strip For Welded Tubes and Pipes As Per Is: 10748 - 2004ravigurajapuNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOBilal Luhar100% (2)

- 6X1830 HR CoilDocument1 page6X1830 HR CoilBhavik PanchalNo ratings yet

- Jindal Steel & Power Limited: Test Certificate No. 0000247591, Revision No. 000 Date: 03.09.2018Document1 pageJindal Steel & Power Limited: Test Certificate No. 0000247591, Revision No. 000 Date: 03.09.2018Mohammad Adil50% (2)

- Test Certificate 16mmDocument1 pageTest Certificate 16mmSabyasachi Bangal67% (3)

- Experiment 11 Lab ManualDocument12 pagesExperiment 11 Lab ManualIlse Barrera100% (1)

- R.K Steel Udyog PVT - LTD: Test Certificate For High Strength Deformed Steel Bars and Wires For Concrete ReinforcementDocument2 pagesR.K Steel Udyog PVT - LTD: Test Certificate For High Strength Deformed Steel Bars and Wires For Concrete Reinforcementnanda kishopre100% (4)

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOMANIMARAN QC100% (1)

- Fme Mesaieed MTC 1103Document1 pageFme Mesaieed MTC 1103KyNo ratings yet

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- TC No 1201 StudDocument2 pagesTC No 1201 StudGaurav100% (1)

- Sau - MTC 0001-002163 - Acc.aºcºDocument24 pagesSau - MTC 0001-002163 - Acc.aºcºrosa aurora montesano somarribaNo ratings yet

- Test Certificate 12mmDocument1 pageTest Certificate 12mmSabyasachi Bangal67% (9)

- Brunei OverviewDocument29 pagesBrunei OverviewTee MendozaNo ratings yet

- Plate 25Document1 pagePlate 25Cyril J PadiyathNo ratings yet

- Banjo Beam - MTC 3.5 MM E 46Document1 pageBanjo Beam - MTC 3.5 MM E 46Rajhans PressingNo ratings yet

- HR 3.50MM July 2019Document1 pageHR 3.50MM July 2019satrughana patraNo ratings yet

- CHARPY V NOTCH Impact Values (J) (I)Document1 pageCHARPY V NOTCH Impact Values (J) (I)trivendra kumarNo ratings yet

- Test Certificate: Signature Not VerifiedDocument1 pageTest Certificate: Signature Not Verifiedreportdaily819No ratings yet

- 6X1250 JSWDocument1 page6X1250 JSWParesh MehtaNo ratings yet

- 1 20mm T C Mehta SteelsDocument1 page1 20mm T C Mehta Steelsmadhav jadhavNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- 1.5MM 304Document1 page1.5MM 304pankaj kumarNo ratings yet

- Certificate of ComplianceDocument7 pagesCertificate of ComplianceNabilah HusnaNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh Mehta100% (1)

- Combined Registration Certificate QCMjIyNASXlOd2JXVjBjbThqSTBoWlJFMHdNREF5TWtJPQ-EEQLDocument2 pagesCombined Registration Certificate QCMjIyNASXlOd2JXVjBjbThqSTBoWlJFMHdNREF5TWtJPQ-EEQLDuong BachNo ratings yet

- Arat At: Length of RopeDocument2 pagesArat At: Length of RopeNiranjan KumarNo ratings yet

- MTC 2257 SPECTRA 304 HR COIL 8mm X 1250Document1 pageMTC 2257 SPECTRA 304 HR COIL 8mm X 1250Amit Kumar OjhaNo ratings yet

- 30 MM Gi Threaded Rod GR 8.8 - Tbi PDFDocument1 page30 MM Gi Threaded Rod GR 8.8 - Tbi PDFm.aliNo ratings yet

- Inspection Certificate 3.1Document1 pageInspection Certificate 3.1YUDI IRMAWANTONo ratings yet

- 21055-Acoustics India - 15nosDocument27 pages21055-Acoustics India - 15nosgowtham_venkat_4No ratings yet

- ANG 40 X 5 X 6 MtrsDocument1 pageANG 40 X 5 X 6 MtrsBastin NavinNo ratings yet

- Jyoti Steel Industries: Test Certificate As Per en 10204-3.1Document1 pageJyoti Steel Industries: Test Certificate As Per en 10204-3.1Gagat GongatNo ratings yet

- Certificado Calidad 3MMDocument1 pageCertificado Calidad 3MMLiliana CondoriNo ratings yet

- Chemical Analysis of A Sample65x65x8Document1 pageChemical Analysis of A Sample65x65x8Amit ChaitNo ratings yet

- DocumentDocument90 pagesDocumentBAlaNo ratings yet

- Material Description: HR Coil Is 10748 Gr2 SialkDocument1 pageMaterial Description: HR Coil Is 10748 Gr2 SialkTARUNKUMARNo ratings yet

- JSW Steel LimitedDocument1 pageJSW Steel LimitedVenkatesh Kumar100% (1)

- 375 - 50WT Cat 3Document2 pages375 - 50WT Cat 3ATF PrécisionNo ratings yet

- JSW Steel Limited: To M/S, Transpares LimitedDocument4 pagesJSW Steel Limited: To M/S, Transpares LimitedSandeep KashyapNo ratings yet

- Jyoti Steel Industries: Test Certificate As Per en 10204-3.1Document1 pageJyoti Steel Industries: Test Certificate As Per en 10204-3.1Gagat GongatNo ratings yet

- Sample Test Certificate (24.12.2022)Document1 pageSample Test Certificate (24.12.2022)PalaniyandiNo ratings yet

- N.R.AGARWAL & Sons: Test Certificate For Mild Steel Wire Rod For General Engineering PurposesDocument2 pagesN.R.AGARWAL & Sons: Test Certificate For Mild Steel Wire Rod For General Engineering PurposessunilmoryaNo ratings yet

- International Trading Corporat: Hot Rolled Carbon Steel Sheet and Strip As Per Is: 1079 - 2017Document1 pageInternational Trading Corporat: Hot Rolled Carbon Steel Sheet and Strip As Per Is: 1079 - 2017SILAMBARASAN KNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic CeramicsFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic CeramicsNo ratings yet

- Processing, Properties, and Design of Advanced Ceramics and CompositesFrom EverandProcessing, Properties, and Design of Advanced Ceramics and CompositesGurpreet SinghNo ratings yet

- Ceramics for Energy Conversion, Storage, and Distribution SystemsFrom EverandCeramics for Energy Conversion, Storage, and Distribution SystemsThomas PfeiferNo ratings yet

- As7263 DS000476 1-00Document45 pagesAs7263 DS000476 1-00Faby ReveloNo ratings yet

- Mobile Computing Unit 5Document138 pagesMobile Computing Unit 5prak530No ratings yet

- ScienceWriting - DUKEDocument50 pagesScienceWriting - DUKEJéssica Almeida100% (1)

- RPH Chem f5 22.07.2020 5S1Document1 pageRPH Chem f5 22.07.2020 5S1yeopeeNo ratings yet

- Course Syllabus Pe 3Document12 pagesCourse Syllabus Pe 3Jonel NoblesNo ratings yet

- Vital Statistics 2019Document258 pagesVital Statistics 2019Rajan ChittoorNo ratings yet

- Unit 3 Controlling The ConversationDocument2 pagesUnit 3 Controlling The ConversationdefiaaaNo ratings yet

- Lesson Plan of Modal Verbs July 29Document4 pagesLesson Plan of Modal Verbs July 29Rosy De VeraNo ratings yet

- Guide Parents StudentsDocument2 pagesGuide Parents Studentsapi-351069520No ratings yet

- 2.philips SuppliesDocument37 pages2.philips Suppliesecarrera1975No ratings yet

- Speaking More Freely: A. Cognitive Development and Language Learning Children As LearnersDocument5 pagesSpeaking More Freely: A. Cognitive Development and Language Learning Children As LearnersRizka KurniaNo ratings yet

- LAT111 Lec Notes 9Document6 pagesLAT111 Lec Notes 9boy andrioNo ratings yet

- Leadership Styles: Related PapersDocument8 pagesLeadership Styles: Related PaperstadiwaNo ratings yet

- Weiner BibDocument6 pagesWeiner Bibiskandar.hai2226No ratings yet

- Hien - Motivational LetterDocument2 pagesHien - Motivational Letterqhuyvu0% (1)

- 301 enDocument263 pages301 enFedja NetjasovNo ratings yet

- 6 Bodies Mortuary FreezerDocument10 pages6 Bodies Mortuary FreezerRaul CostiniucNo ratings yet

- Ra-025142 Civil Engineer Davao 11-2021-With PregnantDocument94 pagesRa-025142 Civil Engineer Davao 11-2021-With PregnantVicent John ParedesNo ratings yet

- Judy of York Hill by Bennett, Ethel Hume, 1881Document104 pagesJudy of York Hill by Bennett, Ethel Hume, 1881Gutenberg.orgNo ratings yet

- SOP For Filling Liquid Cylinder Using Pump Transfer Method Rev 1 PDFDocument9 pagesSOP For Filling Liquid Cylinder Using Pump Transfer Method Rev 1 PDFYASH ENGINEERING SOLUTIONSNo ratings yet

- Chapter 6Document10 pagesChapter 6Elynn TanNo ratings yet

- EI Laying OFC 310107Document21 pagesEI Laying OFC 310107agmtechnical100% (1)

- Portfolio EssayDocument3 pagesPortfolio Essayapi-547515381No ratings yet

- Manual: Ci P Si P SiDocument10 pagesManual: Ci P Si P SisermedNo ratings yet