Professional Documents

Culture Documents

Portable Cart 5mf and 10mf

Uploaded by

Gustavo CardenasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Portable Cart 5mf and 10mf

Uploaded by

Gustavo CardenasCopyright:

Available Formats

click here to return to website

Precision Filtration Products • P.O. Box 218 Pennsburg, PA 18073

Phone: 215-679-6645 Fax: 215-679-6648 E-mail: sales@precisionfiltration.com web site: www.precisionfiltration.com

click here to return to website

5MF and 10MF

Portable Filter Cart

Applications for Parker filter carts are the ideal extremely high affinity for free

Parker Filter Carts way to prefilter and transfer fluids water. Once water comes into

into reservoirs or to clean up contact with this material,

■ Filtering new fluid before putting existing systems. it is removed from the system.

into service

■ Transferring fluid from drums or Fluid should always be filtered The Parker filter cart uses two high

storage tanks to system reservoirs before being put into use. New fluid capacity ModuFlow filters for

is not necessarily clean fluid. Most long element life and better system

■ Conditioning fluid that

new fluids (right out of the drum) protection. The first stage (inlet)

is already in use are unfit for use due to high initial filter captures larger particles, while

■ Complimenting existing contamination levels. Contamina- the second stage (outlet) filter

system filtration tion, both particulate and water, controls finer particles or removes

may be added to a new fluid water. A rugged industrial quality

■ Removing free water from during processing, mixing, gear pump gets the job done fast.

a system handling and storage.

■ For use with fluids such as Using a Parker portable filter cart is

hydraulic, gear and lube oils Water is removed by installing the most economical way to protect

Par-Gel elements in the outlet your system from the harm that can

filter. Par-Gel elements are made be caused by contamination.

from a polymer which has an

Features Advantages Benefits

Two filters instead of one. Pump protection and long Element cost savings and

element life. trouble-free service.

Wide variety of particulate Capable of getting a fluid to Avoids excess costs due filter

elements available. a desired cleanliness level. to over or under filtration.

Par-Gel water removal Removes “free water” from Gets dirt and water out of

elements available. a system. system with one process.

Heavy duty frame. Rugged and durable. Built to last for many hours

of use.

Lightweight and portable. Easy to move from One person operation.

place-to-place.

Two flow rates available Enables use in low or high Matched to your needs.

(5 gpm or 10 gpm). viscosity applications.

Eleven-foot hose and Additional hardware Ready to use as received.

wand assemblies included. not necessary.

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

Phone: 215-679-6645 Fax: 215-679-6648 E-mail: sales@precisionfiltration.com web site: www.precisionfiltration.com

click here to return to website

5MF and 10MF

Portable Filter Cart

Features

Service Cover

■ Top-accessible

for easy changing

of elements Visual Indicator

■ Tells you when to

change elements

Dual Filters

■ Two-stage

filtration for long

element life and Motor

pump protection ■ Industrial brand

name

Hose & Wand

Assembly Heavy Duty Frame

■ Ready to use; ■ Rugged and

no additional built to last

hardware needed

■ Flexible hoses for

tight spots

■ Kink-resistant hose

prevents pump

cavitation Drip Pan

■ Helps keep the

work area safe

Gear Pump and clean

■ Industrial quality

■ Quiet operation

■ Dependable, long life

Elements Electrical Cord

(not shown) (not shown)

■ Available for both ■ 6ft. with on/off switch

particulate and water ■ Optional 20 ft. cord

removal with reel

Parker Hannifin Corporation

Hydraulic Filter Division

171 Metamora, OH

Phone: 215-679-6645 Fax: 215-679-6648 E-mail: sales@precisionfiltration.com web site: www.precisionfiltration.com

click here to return to website

5MF and 10MF

Portable Filter Cart

Specifications

Maximum Recommended Fluid Viscosity: Electrical Motor:

10MF: 500 SUS (108 cSt) (.85 specific gravity) l0MF - ¾ hp @ 3450 rpm, O.D.P.

5MF: 3000 SUS (627 cSt) (.85 specific gravity) 5MF - ½ hp @ 1725 rpm, O.D.P.

Thermal overload protection

Visual Indicator:

Visual differential type Construction:

3-band (clean, change, bypass) Cart Frame: Steel

Filter Head: Aluminum

Filter Bypass Valve Settings:

Filter Bowl: Steel

Inlet: 3 psid (.2 bar)

Hoses: PVC (Std.)

Outlet: 25 psid (1.7 bar)

EDPM (high temp option)

Operating Temperatures: Wands: PVC (Std.)

Buna N (Nitrile) -40°F to 150°F Steel tube (high temp option)

(-40°C to 66°C)

Weight (approximate): 110 Lbs. (45.4 kg)

F3 (high temp option)

-15°F to 200°F

(-26°C to 93°C)

Electrical Service Required:

10MF - 110/220 volts, 60/50 Hz,

single phase, 10/5 amps

5MF - 110/220 volts, 60/50 Hz,

single phase, 8/4 amps C

Dimensions: inches (millimeter)

A - Height: 40.5" (1029)

B - Width: 25.5" (648)

C - Depth: 19.0" (483)

Parker Hannifin Corporation

Hydraulic Filter Division

172 Metamora, OH

Phone: 215-679-6645 Fax: 215-679-6648 E-mail: sales@precisionfiltration.com web site: www.precisionfiltration.com

click here to return to website

5MF and 10MF

Portable Filter Cart

Typical Fluid Cleanliness Filter Cart Performance

Level Requirements Fluid cleanliness levels are a function of initial

Many manufacturers of hydraulic components have contamination levels, contamination ingression rates,

established fluid cleanliness levels for their compo- reservoir size and filter element efficiency. The chart

nents. Using a portable filter cart can be a very effective below lists approximate time requirements to achieve

way to reach and maintain these cleanliness levels. certain cleanliness levels based on the assumptions

noted.

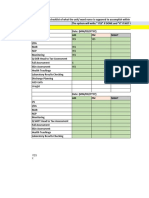

ISO Reservoir Time Projected

Component Cleanliness Level Capacity Required Cleanliness

(Gallons) (Hours) Level (ISO)

Servo control valves 16/14/11 50 0.5 20/18/15

Proportional valves 17/15/12 50 1.0 17/15/12

Vane and piston 50 2.5 16/14/11

pumps/motors 18/16/13 100 1.5 18/16/13

Directional and pressure 100 2.5 17/15/12

control valves 18/16/13 100 4.0 16/14/11

Gear pumps/motors 19/17/14 200 2.5 19/17/14

200 3.5 18/16/13

Flow control valves

200 5.0 17/15/12

cylinders 20/18/15

Notes: The results in the chart are based on the following assumption:

New fluid 20/18/15 1. Initial contamination level is 500,000 particles greater than

10 micrometers per 100 ml of fluid (10MF cart).

2. Inlet filter fitted with 40SA element. outlet with 10C element.

3. System ingression rate equal to 1 X 106 particles greater

than 10 micrometers entering the system per minute.

Filter Cart Element Performance

Time Averaged

Media Filter Beta x/y/z =2/20/75 Capacity Efficiency at x,y,z

Code Media Where x/y/z is: (Grams) Beta Rating Particle Size

Bx = 2 ........................................................ 50.0%

74W Woven Wire 0.00291 * By = 20 ...................................................... 95.0%

40W Woven Wire 0.00161 * Bz = 75 ...................................................... 98.7%

40SA Synthetic 40 Micron Nominal2 *

20C Cellulose 20 Micron Nominal2 *

Notes: Multipass test run @ 40 gpm to 25 psid.

10C Cellulose 6/18/22 Micron 15 ANSl/NFPA T3.10/8.8 R1-1990 w/50 ppm anti-static additive

03C Cellulose 2/6/9 Micron 18 *Not Applicable.

20Q Microglass II 7.5/12.5/17 Micron 47 1. Not multipass tested- Number shown Is actual

10Q Microglass II <2/6/9 Micron 42 pore size in inches.

05Q Microglass II <2/<2/3.3 Micron 46 2. Not multipass tested.

02Q Microglass II <2/<2/2 Micron 45

Par-Gel™ Media Water Capacity

Model Fluid Viscosity Capacity Notes: 1. Par-Gel elements are designed to remove “free water”,

which is defined as water that is above a particular fluid’s

5MF 75 SUS 250 ml saturation level.

200 SUS 140 ml 2. Capacity is very dependent on flow rate and viscosity. Not

recommended with fluids in excessof 500 SUS.

10MF 75 SUS 190 ml

200 SUS 80 ml

Parker Hannifin Corporation

Hydraulic Filter Division

173 Metamora, OH

Phone: 215-679-6645 Fax: 215-679-6648 E-mail: sales@precisionfiltration.com web site: www.precisionfiltration.com

click here to return to website

5MF and 10MF

Portable Filter Cart

Assembly Maintenance

Instructions

1) Install hoses to inlet and outlet 6) The inlet filter Is provided with

filters by threading the hose end a 3PSI bypass spring, and 1) Turn switch to OFF position and

with the straight thread “o”-ring seal prevents the pump from cavitat- unplug cord from electrical outlet.

fitting into the filter flange. ing If the element is not 2) Remove tube wands from oil to

changed. The outlet filter is prevent siphoning.

2) Connect the PVC tube wands to provided with a 25PSl bypass

the swivel fitting on the hose end. 3) Loosen hex head screws on

spring to prevent excessive filter cover. Turn cover to clear

Whenever servicing the PVC tube pressure which may be harmful screws, remove cover.

wand do not overtorque the metal to personnel or to the filter cart.

fittings going into the PVC coupling. 4) Pull flow diverter assembly from

Overtorque will result in cracking Warning: the filter head. Filter element will

the coupling. Generally, 1/4 turn The filter bypass spring acts as a follow the diverter.

beyond handtight is sufficient. relief valve for the pump. Do not a) Replace the cellulose,

restrict the discharge hose with synthetic or Microglass II

Operating Instructions a shut-off valve which will defeat elements. Verify replacement.

1) Insert the inlet wand assembly the function of the bypass valve, b) Wire mesh elements can be

into the supply fluid receptacle causing excessive pressure, cleaned. Ultrasonic cleaners

(drum/reservoir). The “RF". filter is which may be harmful to person- provide best results.

the inlet filter. nel or to the filter cart.

5) Install element on flow diverter

2) Insert the outlet wand assembly 7) The cleanliness indicator and reinstall in filter housing. Make

into the clean fluid receptacle works on differential pressure sure diverter “o"-rings seat

(drum/reservoir). The “CF” fIlter and will indicate the condition of properly into the head.

is the outlet filter. the element (CLEAN, CHANGE, 6) Check to be sure that the notch

or BYPASS). on the flow diverter lines up with

Caution: the notch in the head.

Do not kink the hose assemblies, NOTE:

this may result in excessive 7) Inspect the cover “o"-ring and

The filter cart must be in replace if necessary.

vacuum or pressure at the pump. operation for the indicator

to read properly. 8) Replace cover and tighten hex

3) Verify that the ON/OFF switch is head screws until they are snug.

OFF and plug the cord into a 115V Do not over-torque these screws.

10A grounded outlet (3 wire). Do not interchange the inlet filter

cover with the outlet filter cover.

4) Turn switch to ON position and (The inlet filter has a “RF” prefix,

check outlet wand for oil flow. the outlet filter has a "CF" prefix).

Allow 30 to 60 seconds for filters to

fill with oil. If repeated attempts to

Trouble Shooting

obtain oil flow fail, check pump inlet

fittings for tightness, remove inlet Problem Cause Solution

filter access cover and verify the Does not start. ON/OFF switch. Turn switch ON, replace switch if defective.

cover sealing “o”-ring is in place. No electrical power. Plug in cart.

For very viscous fluids it may be Defective motor. Replace.

necessary to pour 1 or 2 quarts of No oil flow or Filter housing not filled with oil. Allow pump to run 30 to 60 seconds.

fluid into the “RF” inlet filter housing erratic pump noise.

Suction leak. Check tightness of inlet fittings.

to prime pump initially. Check "o"-ring in inlet filter cover for nicks.

Kink or restriction in inlet hose.

5) The condition of the filter ele- Add 1 or 2 quarts of oil to inlet filter.

ment should be monitored by Defective pump. Replace pump.

observing the cleanliness indicator Indicator reads Element dirty. Replace or clean elements (both filters).

on the discharge filter. When the CHANGE Oil extremely cold or viscous. Change element to coarser micron rating.

Indicator is in the CHANGE posi- or BYPASS.

tion, both inlet and outlet filter Indicator does not No outlet element. Install element.

elements MUST be replaced to seem to move. 40 micron element installed Check cart model number to verify correct

prevent fluid from going into in outlet filler. element. The inlet filter has a rating "RF"

prefix; the ouflet filter has a "CF" preflx.

bypass in the filters.

Parker Hannifin Corporation

Hydraulic Filter Division

174 Metamora, OH

Phone: 215-679-6645 Fax: 215-679-6648 E-mail: sales@precisionfiltration.com web site: www.precisionfiltration.com

click here to return to website

5MF and 10MF

Portable Filter Cart

Filter Cart Replacement Parts

Replacement Element Part Numbers

Buna Seals Fluorocarbon

Media Code (Standard) Seals

74W 924456 925043

40W 924455 925042

40SA 924448 925035

20C 924451 925038

10C 924450 925037

03C 924449 925036

20Q 933742Q 933743Q

10Q 924453Q 925040Q

05Q 924452Q 925039Q

02Q 933068Q 933069Q

WR 927584 928908

Item Part Item Part

No. No. Description Quantity No. No. Description Quantity

1 928690 Frame 1 12 928749 Pipe Reducer 1

2 928653 Axle 1 13 928729 Adapter Fitting 1

3 928650 Wheel 2 14 928676 Discharge Tube Assembly

4 928651 Handle Grip 2 15 928727 Tube Fitting 1

5 928649 Cord Cleat 1 16 928663 Hose Assy. - Buna N 2

Opt. 5 928623 Cord Reel 1 16 928621 Hose Assy. - Fluorocarbon —

6. 928731 Pump 1 17 928784 Tube Wand Assy. Buna N 2

7 928678 Motor 10MF 1 17 928620 Tube Wand Assy. Fluorocarbon —

7 929692 Motor 5MF — 18 932187 Name Plate 1

8 928748 Pipe Reducer 1 19 RF2-1-**-PP3-YN-F9-1 Inlet Filter - Buna N 1

9 928728 Tube Fitting 1 19 F3-RF2-1-**-PP3-YN-F9-1 Inlet Filter - Fluorocarbon —

10 928652 Adapter Fitting 1 20 CF2-1**-MP25-F9-YN-1 Outlet Filter - Buna N 1

11 928677 Suction Tube Assembly 20 F3-CF2-1-**-MP25-F9-YN-1 Outlet Filter - Fluorocarbon —

**Refer to table above

Parker Hannifin Corporation

Hydraulic Filter Division

175 Metamora, OH

Phone: 215-679-6645 Fax: 215-679-6648 E-mail: sales@precisionfiltration.com web site: www.precisionfiltration.com

click here to return to website

5MF and 10MF

Portable Filter Cart

HOW TO ORDER:

Select the desired symbol (in the correct position) to construct a model code.

Example:

BOX 1 BOX 2 BOX 3 BOX 4 BOX 5 BOX 6

Design number

F3 10MF 40SA 10Q 6 assigned by Parker

BOX 1: SEALS BOX 3 : INLET FILTER BOX 5 : OPTIONS

Symbol Description Symbol Description Symbol Description

None (Std.) Buna N (Nitrile) 40SA Synthetic 1 None

F3 High temperature 40W Stainless Steel Mesh 3 Magnets in inlet filter

service 74W Stainless Steel Mesh 6 20 FT electrical cord

20C Cellulose (retractable reel)

20Q Microglass III 9 Indicator on inlet filter

BOX 2 : MODEL BOX 4 : OUTLET FILTER BOX 6 : DESIGN NUMBER

Symbol Description Symbol Description Symbol Description

10MF 10 GPM 10C Cellulose Applied to the filter by Parker

(500 SUS MAX.) 03C Cellulose Hydraulic Filter Division. Use

5MF 5 GPM 20Q Microglass III the full model code, including

(3000 SUS MAX.) 10Q Microglass III the design number when

05Q Microglass III

ordering replacement parts.

02Q Microglass III

WR PAR-GEL™

Water Removal

Please note the bolded options reflect

standard options with a reduced

lead- time. Consult factory on all

other lead-time options.

Parker Hannifin Corporation

Hydraulic Filter Division

176 Metamora, OH

Phone: 215-679-6645 Fax: 215-679-6648 E-mail: sales@precisionfiltration.com web site: www.precisionfiltration.com

You might also like

- Book PHARMACEUTICS 1Document85 pagesBook PHARMACEUTICS 1Muhammad sajjad93% (14)

- 5MF 10MFDocument8 pages5MF 10MFRodrigo Pessoa VespaNo ratings yet

- V80647 Parker Series 15-30P High Pressure FiltersDocument12 pagesV80647 Parker Series 15-30P High Pressure FiltersPaulPaucarCamposNo ratings yet

- Ficha Tec. Filter CartsDocument8 pagesFicha Tec. Filter CartsMakros HRNo ratings yet

- 10MFP Carrito de FiltracionDocument8 pages10MFP Carrito de FiltracionIanNo ratings yet

- 10MFP ParkerDocument8 pages10MFP ParkerJoel PalaciosNo ratings yet

- Compact C Range BrochureDocument6 pagesCompact C Range BrochurePeter RobinsonNo ratings yet

- Viron Vvs Series Ver Ti Cal ScrubberDocument28 pagesViron Vvs Series Ver Ti Cal ScrubberИван ОхотаNo ratings yet

- Compact Wastewater Pumps4Document8 pagesCompact Wastewater Pumps4MartinDiazNo ratings yet

- GX - Great Pump Guide - ENG - 60Hz - 2016-06 - LRDocument44 pagesGX - Great Pump Guide - ENG - 60Hz - 2016-06 - LRIvan RsNo ratings yet

- Flygt Propeller Pumps2-1Document8 pagesFlygt Propeller Pumps2-1Dannyadja RahardjoNo ratings yet

- Meyer Screw PumpsDocument12 pagesMeyer Screw PumpsErhan ŞENTÜRKNo ratings yet

- Submersible Pumps Brochure en Aug20Document10 pagesSubmersible Pumps Brochure en Aug20Karina MedinaNo ratings yet

- PF7系列滤芯件号Document8 pagesPF7系列滤芯件号mona zhangNo ratings yet

- 400 Brochure LaurellDocument2 pages400 Brochure LaurellsinytellsNo ratings yet

- Ts SandMediaFilterDocument2 pagesTs SandMediaFiltermohammudaphNo ratings yet

- SeparatorDocument6 pagesSeparatorGeorge CobraNo ratings yet

- Grindex'S Great Pump Guide: Pump Features and BenefitsDocument44 pagesGrindex'S Great Pump Guide: Pump Features and BenefitsCựu SV Bách KhoaNo ratings yet

- Non-Metallic Sealless Main BrochureDocument4 pagesNon-Metallic Sealless Main BrochuresanthoshkumarplNo ratings yet

- Irits 0418 038 en 1118 - Aro Vs Centrifugal PDFDocument2 pagesIrits 0418 038 en 1118 - Aro Vs Centrifugal PDFSchneider ParadaNo ratings yet

- Catalogo Filtri Donaldson ContenitoriDocument6 pagesCatalogo Filtri Donaldson ContenitorimimmoNo ratings yet

- GuardianDocument8 pagesGuardianAbimael GarayNo ratings yet

- Sika Pump Pro XL: Product Data SheetDocument2 pagesSika Pump Pro XL: Product Data SheetKhin Sandi KoNo ratings yet

- Filter CartDocument28 pagesFilter Cartdavethebox100% (1)

- Grundfosliterature 1891259Document4 pagesGrundfosliterature 1891259Mohammad ZeeshanNo ratings yet

- Eq Excavacion Cargo Minicargador BarredorasDocument8 pagesEq Excavacion Cargo Minicargador Barredorasfernando alfredo rodriguez delgadoNo ratings yet

- Air Compressor Data SheetDocument2 pagesAir Compressor Data Sheetرنا حركاتيNo ratings yet

- A6.200 - Upgrades For Side Discharge FiltersDocument4 pagesA6.200 - Upgrades For Side Discharge FiltersZamfirMarianNo ratings yet

- Torrential: High-Flow Filtration UnitDocument1 pageTorrential: High-Flow Filtration UnitBrahim BenabdallahNo ratings yet

- Rotamat Centrifuge RodDocument6 pagesRotamat Centrifuge RodHemant KaleNo ratings yet

- Pump Tech Spec - c101Document2 pagesPump Tech Spec - c101jonathan flores vegaNo ratings yet

- Tacmina Motor SXDA1Document12 pagesTacmina Motor SXDA1arisqi wahyuNo ratings yet

- Aldrum g3Document4 pagesAldrum g3Raghunath MajeeNo ratings yet

- Air PSD PowerCoreDocument15 pagesAir PSD PowerCoreFredy GutierrezNo ratings yet

- Teknek Webbbbb Cleeeaannnnerr ScraaaapppDocument4 pagesTeknek Webbbbb Cleeeaannnnerr ScraaaapppSP OjhaNo ratings yet

- FPG Air CleanerDocument14 pagesFPG Air CleanergeorgeNo ratings yet

- Catalog 4800 Parker Industrial HoseDocument230 pagesCatalog 4800 Parker Industrial HoseNEFTALI VARGAS MANDUJANONo ratings yet

- Screw Pumps: Maximize Your Margins - With Our Twin Screw, Triple Screw and Multiphase Pumping SystemsDocument12 pagesScrew Pumps: Maximize Your Margins - With Our Twin Screw, Triple Screw and Multiphase Pumping SystemsKykyRizkyNo ratings yet

- GLV - Drum Filter (PGS) LR PDFDocument8 pagesGLV - Drum Filter (PGS) LR PDFSamuel MushakaNo ratings yet

- Dewatering Pumps For MiningDocument10 pagesDewatering Pumps For Miningsieged_rj3165No ratings yet

- Automatic Back-Flushing Filter For Process Technology Autofilt Rf3Document8 pagesAutomatic Back-Flushing Filter For Process Technology Autofilt Rf3Steve OsuohaNo ratings yet

- Amico As Scroll Air Systems Sell SheetDocument4 pagesAmico As Scroll Air Systems Sell SheetCAROLINA MONGUINo ratings yet

- FiltrazioneDocument8 pagesFiltrazionebee1406763181No ratings yet

- S Range 2 - 160 KW: 60 HZ VersionDocument28 pagesS Range 2 - 160 KW: 60 HZ VersionVairis Eglītis100% (1)

- Donaldson Air Cleaner Filters - Air-PSD-PowerCoreDocument15 pagesDonaldson Air Cleaner Filters - Air-PSD-PowerCoreWojciech NewlacilNo ratings yet

- Catalogue Bom HCP PDFDocument4 pagesCatalogue Bom HCP PDFGeorge CobraNo ratings yet

- Moyno Mono 2000 Series Pump Flyer ImperialDocument2 pagesMoyno Mono 2000 Series Pump Flyer ImperialRoger GracieNo ratings yet

- Product OverviewDocument2 pagesProduct Overviewherysyam1980No ratings yet

- 50P Series: High Pressure FiltersDocument10 pages50P Series: High Pressure FiltersRobertoNo ratings yet

- Mobilair M50: 185 CFM at 100 PsigDocument2 pagesMobilair M50: 185 CFM at 100 PsigDjNo ratings yet

- Digest: SeparationsDocument1 pageDigest: SeparationsRaul TejedaNo ratings yet

- Fpi Mag Flow Meter With Procomm ConverterDocument10 pagesFpi Mag Flow Meter With Procomm ConverterJamesh Babu0% (1)

- Hydraulic Filter CartDocument3 pagesHydraulic Filter CartyovannyNo ratings yet

- Mann Filter For LiquidsDocument48 pagesMann Filter For LiquidsJunaid AhmedNo ratings yet

- CM20160325 34687 64546Document32 pagesCM20160325 34687 64546Josue Acosta EspinozaNo ratings yet

- Jonell Systems ProGuardDocument8 pagesJonell Systems ProGuardaslam shaikhNo ratings yet

- Folleto Filtro Cristal Flo 2 PentairDocument2 pagesFolleto Filtro Cristal Flo 2 PentairJOSE ALBERTO AMAYA SAUCEDONo ratings yet

- Accessories: Elbow / Grs - Guide Rail Systems: Product FeaturesDocument2 pagesAccessories: Elbow / Grs - Guide Rail Systems: Product FeaturessagbvnNo ratings yet

- Vacuum BlowersDocument16 pagesVacuum BlowersMehdi KharbacheNo ratings yet

- Mixers and Flowakers (GB)Document24 pagesMixers and Flowakers (GB)Magin Idelfonso TorreblancaNo ratings yet

- Product Description: Max 4400LBS Loading Capacity Rotating Engine Repair Stand With Best PerformanceDocument9 pagesProduct Description: Max 4400LBS Loading Capacity Rotating Engine Repair Stand With Best PerformanceGustavo CardenasNo ratings yet

- Cil Rexroth Banco de La RepublicaDocument14 pagesCil Rexroth Banco de La RepublicaGustavo CardenasNo ratings yet

- SKF GE 100 ES-2RS SpecificationDocument4 pagesSKF GE 100 ES-2RS SpecificationGustavo CardenasNo ratings yet

- TE - Series Transmission CatalogDocument30 pagesTE - Series Transmission CatalogGustavo CardenasNo ratings yet

- 50at Fliter Catalog and User ManualDocument8 pages50at Fliter Catalog and User ManualGustavo CardenasNo ratings yet

- 110MLG32179 Order ListDocument1 page110MLG32179 Order ListGustavo CardenasNo ratings yet

- Mounting Solutions: Multi-Parameter Patient MonitorDocument2 pagesMounting Solutions: Multi-Parameter Patient Monitor杨敏杰No ratings yet

- NovorapidDocument16 pagesNovorapidRADITA MAULASARINo ratings yet

- Cognitive Behaviour Therapy (CBT)Document117 pagesCognitive Behaviour Therapy (CBT)Roslan Ahmad FuadNo ratings yet

- PAS Lesson PlanDocument2 pagesPAS Lesson PlanMahesh SinghNo ratings yet

- English - JapanDocument2 pagesEnglish - JapanJoseNo ratings yet

- Visual ImpairmentDocument7 pagesVisual ImpairmentROSE MARIE REVILLA100% (1)

- CVA DVA Werkstuk Bekele - tcm39 91310Document40 pagesCVA DVA Werkstuk Bekele - tcm39 91310s_75No ratings yet

- How To Read A Prescription Drug LabelDocument3 pagesHow To Read A Prescription Drug LabelJefriyanto Saud100% (2)

- DHCS Handbook EnglishDocument33 pagesDHCS Handbook EnglishprabhaNo ratings yet

- Faculty 460 Eng 334 Kust20201 l2 p2 Paragraph WritingDocument20 pagesFaculty 460 Eng 334 Kust20201 l2 p2 Paragraph WritingMuhammad UsmanNo ratings yet

- Teacher Attitudes Towards The Inclusion of Students With Support NeedsDocument10 pagesTeacher Attitudes Towards The Inclusion of Students With Support NeedsAndrej HodonjNo ratings yet

- Stress Diary - Identifying Causes of Short-Term Stress PDFDocument6 pagesStress Diary - Identifying Causes of Short-Term Stress PDFgggNo ratings yet

- 2011UCMC Trauma Care Q&ADocument2 pages2011UCMC Trauma Care Q&ASam CholkeNo ratings yet

- Construction Technology 3Document41 pagesConstruction Technology 3苇菱100% (3)

- Molusco ContagiosoDocument12 pagesMolusco ContagiosoEduardo Medeiros Tabosa PinheiroNo ratings yet

- Revision 5Document4 pagesRevision 5Phương MinhNo ratings yet

- Health Optimizing Physical Education 12 Quarter 1Document6 pagesHealth Optimizing Physical Education 12 Quarter 1psj2013No ratings yet

- CHAPTER LLDocument11 pagesCHAPTER LLDeege BaeNo ratings yet

- Event Safety Check List: Group NameDocument12 pagesEvent Safety Check List: Group NameUs Cosplay SpecialistNo ratings yet

- 07MB105 Financial & Management Accounting - OKDocument21 pages07MB105 Financial & Management Accounting - OKKumaran Thayumanavan0% (1)

- PurinaDocument24 pagesPurinaDee Dee YengNo ratings yet

- Audio/video, Information and Communication Technology Equipment Part 1: Safety RequirementsDocument168 pagesAudio/video, Information and Communication Technology Equipment Part 1: Safety RequirementsneodvxNo ratings yet

- Daily Checklist: YES YES YES YES YES X YESDocument47 pagesDaily Checklist: YES YES YES YES YES X YESEdmar TabinasNo ratings yet

- 1 PDFDocument3 pages1 PDFSugiThanikaNo ratings yet

- Msds of Spray Dried LactoseDocument8 pagesMsds of Spray Dried LactoseAnandaNo ratings yet

- Huda Munir McqsDocument21 pagesHuda Munir McqsAngelo P. VeluzNo ratings yet

- Manual Osciloscopio GOM620FGDocument29 pagesManual Osciloscopio GOM620FGJesus PereiraNo ratings yet

- Posterior Crossbite in Primary and Mixed Dentition - Etiology and Management PedoDocument41 pagesPosterior Crossbite in Primary and Mixed Dentition - Etiology and Management PedoFourthMolar.comNo ratings yet

- GE XKcolumnsDocument12 pagesGE XKcolumnsJavi Profumo-Una Colegiata HumanaNo ratings yet