Professional Documents

Culture Documents

Innna 1

Uploaded by

Thịnh VănOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Innna 1

Uploaded by

Thịnh VănCopyright:

Available Formats

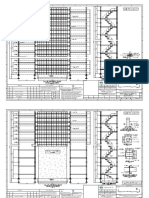

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A A

B B

C C

D D

E E

F F

G G

H H

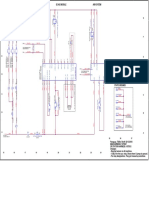

18 Pass partition h=1275mm 41 X17H13M2T

17 Baffle h=22mm X17H13M2T

16 Gasket s=3mm 1 Paronit

15 Arrangement heat exchanger tubes Dout=52mm 322 X17H13M2T

I I

14 Stationary tube sheet D=1800mm 1 X17H13M2T

13 Flange connecting shell and head D=1940mm 36 X17H13M2T

950 10200

900 1 3 I 12 Heat exchanger tubes D=52mm 1 X17H13M2T

11 Weir plate D=2000mm 1 X17H13M2T

10

11 10 Bottom 50 D=3600mm

20

65

1 X17H13M2T

12 17 110

A IV 140

4 140

90

A

D

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

D

9 50

Tube for bottom product

II out Din=20mm

III 1 X17H13M2T

J J

E E

110

F F

K

15

14

13

12

10

9

8

7

6

5

4

3

2

1

Part No. Part name Material Quality Remarks

G

K

Ratio 1:2 Ratio 1:2

Scale

Tube for 5bottom product in

No. of sheet

Student Sheet No.2

L Instructor L

HoD

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

8 18 Din=50mm 1 X17H13M2T

V 78

Ø52

7 Tube for condensate out Ø46

Din=200mm 1 X17H13M2T

14

78

9 III 6 II Saddle support L=6200mm 2 X17H13M2T

6200 8

6 A 7

5 Head D=1800mm 1 X17H13M2T

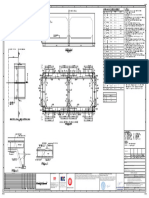

A-A. V

Ratio 1:2 Ratio 1:2

4 Tube for steam in 36xM20 Din=50mm 1 X17H13M2T

Flange connecting pipe with

3 M16,M12 1 X17H13M2T

Ø1940

50

∅5 40

equipment

∅1

∅260

8 ∅1

Ø1890

∅3608

∅1808

∅225 ∅110

K ∅16

K

Ø1860

∅1

2 2 Tube for steam out Din=150mm 1 X17H13M2T

Ø1808

Ø1800

1 ShellB L=10200mm 1 X17H13M2T

Ratio 1:2

NO. Part name Parameters Quantity Materials

260

225

150

120°

12 12 Student Văn Xuân Thịnh

Designing Kettle reboiler in distillation

1350

1996

Instructor Nguyễn Thị Lê Liên of acid acetic and water

16

17

L 2800 250

Ho Ratio 1:20 City

Chi Minh

Scale: 1:20 L

3200 I Kettle reboiler details

6 Ratio 1:2 University of Technology Sheet: 1/1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

You might also like

- February Monthly Collection, Grade 5From EverandFebruary Monthly Collection, Grade 5Rating: 3 out of 5 stars3/5 (1)

- Fun Home PlotDocument1 pageFun Home PlotMike WoodNo ratings yet

- Esquema Elétrico t600Document2 pagesEsquema Elétrico t600Codeiro SilvaNo ratings yet

- Fisher & Paykel Washer Fault CodesDocument21 pagesFisher & Paykel Washer Fault CodesRichard RothNo ratings yet

- Schematic Diagram - Integration: Series: RT 90 /RT 100USDocument86 pagesSchematic Diagram - Integration: Series: RT 90 /RT 100USNelson ConselhoNo ratings yet

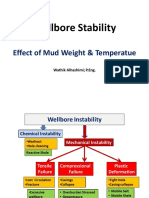

- Wellbore Stability Effect of Mud Weight 1645782860Document27 pagesWellbore Stability Effect of Mud Weight 1645782860Muhammad Husein MahfudzNo ratings yet

- Turbine Start UpDocument15 pagesTurbine Start UprobiansahNo ratings yet

- C STR DWG 000 40010 0001 5Document1 pageC STR DWG 000 40010 0001 5HUSSEIN FNEISHNo ratings yet

- Energy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case StudyDocument12 pagesEnergy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case Study1977julNo ratings yet

- d0203 FST Erz Ds 71519 Sheet 7 ScheduleDocument1 paged0203 FST Erz Ds 71519 Sheet 7 ScheduleVignesh WaranNo ratings yet

- Chetan Infratech Consultants Pvt. LTDDocument1 pageChetan Infratech Consultants Pvt. LTDvishal18mNo ratings yet

- Ceramic Fibre Lining of Atr Heater Radiant Arch: Unifrax India Private LimitedDocument1 pageCeramic Fibre Lining of Atr Heater Radiant Arch: Unifrax India Private Limitedมิตร อันมาNo ratings yet

- Ceramic Fibre Lining of Atr Heater Radiant Endwalls: Unifrax India Private LimitedDocument1 pageCeramic Fibre Lining of Atr Heater Radiant Endwalls: Unifrax India Private Limitedมิตร อันมาNo ratings yet

- GA-Ref For ErectionDocument1 pageGA-Ref For ErectionSoumitra GuptaNo ratings yet

- 746 525 108ec 0Document1 page746 525 108ec 0มิตร อันมาNo ratings yet

- 746 525 108fa 0Document1 page746 525 108fa 0มิตร อันมาNo ratings yet

- 746 525 108eb 1Document1 page746 525 108eb 1มิตร อันมาNo ratings yet

- 746 525 108aa 1Document1 page746 525 108aa 1มิตร อันมาNo ratings yet

- Ceramic Fibre Lining of Atr Heater Rad. To Conv. Duct 2: Unifrax India Private LimitedDocument1 pageCeramic Fibre Lining of Atr Heater Rad. To Conv. Duct 2: Unifrax India Private Limitedมิตร อันมาNo ratings yet

- 746 525 108ab 1Document1 page746 525 108ab 1มิตร อันมาNo ratings yet

- 746 525 108da 1Document1 page746 525 108da 1มิตร อันมาNo ratings yet

- 746 525 108ja 0Document1 page746 525 108ja 0มิตร อันมาNo ratings yet

- 746 525 108FB 0Document1 page746 525 108FB 0มิตร อันมาNo ratings yet

- 746 525 108KC 0Document1 page746 525 108KC 0มิตร อันมาNo ratings yet

- 746 525 108ca 1Document1 page746 525 108ca 1มิตร อันมาNo ratings yet

- 746 525 108ba 1Document1 page746 525 108ba 1มิตร อันมาNo ratings yet

- 746 525 108GB 0Document1 page746 525 108GB 0มิตร อันมาNo ratings yet

- 746 525 108ea 1Document1 page746 525 108ea 1มิตร อันมาNo ratings yet

- Ceramic Fibre Lining of Atr Heater - Rad. To Conv. Duct 1: Unifrax India Private LimitedDocument1 pageCeramic Fibre Lining of Atr Heater - Rad. To Conv. Duct 1: Unifrax India Private Limitedมิตร อันมาNo ratings yet

- Me DW 3000Document1 pageMe DW 3000calidadNo ratings yet

- 4.1. Nquiriquele Health Center - General Plan Materniy + External Services - StructureDocument6 pages4.1. Nquiriquele Health Center - General Plan Materniy + External Services - StructuredevisguibsonNo ratings yet

- Layout-Matheu ARAUCARIA PDFDocument1 pageLayout-Matheu ARAUCARIA PDFFmwingenieriasa MarojaNo ratings yet

- Cross Country Line F Layout, Elevation & Bom List A0 - : Cerro Pabellon IiiDocument13 pagesCross Country Line F Layout, Elevation & Bom List A0 - : Cerro Pabellon IiicristianNo ratings yet

- 4L BOx Girder Concrete Dimension DRGDocument1 page4L BOx Girder Concrete Dimension DRGarif_rubinNo ratings yet

- 31.25m 4L Concrete Dime DRG - 1Document1 page31.25m 4L Concrete Dime DRG - 1arif_rubinNo ratings yet

- R1c01-Ilf-Cv-Prm-Con-Dga-1012-General Arrangement of Platform LevelDocument1 pageR1c01-Ilf-Cv-Prm-Con-Dga-1012-General Arrangement of Platform LevelrohitNo ratings yet

- Ddi-2704-R0-Pky-Rc - Details of 28M Span (6 Lane) - Wing (DS)Document1 pageDdi-2704-R0-Pky-Rc - Details of 28M Span (6 Lane) - Wing (DS)rohitNo ratings yet

- For Discussion: SpectrumDocument2 pagesFor Discussion: Spectrumshubhamoffice007No ratings yet

- Mahsr-C7-Drg-Ts-Ps-002 R2Document5 pagesMahsr-C7-Drg-Ts-Ps-002 R2Ashish BhartiNo ratings yet

- Fipl DK Acr MJB CH 38+345 Gad 001 - Op 06Document10 pagesFipl DK Acr MJB CH 38+345 Gad 001 - Op 06panikarickyNo ratings yet

- Proarc: Section AADocument1 pageProarc: Section AASyed AbuthahirNo ratings yet

- (RFC) PE-V1-417-165-N023 R2P0 StaircaseDocument6 pages(RFC) PE-V1-417-165-N023 R2P0 StaircaseParshuram ManjareNo ratings yet

- K354-M-120-MH05-515 - 01 - 01 - Pipe Mod Engine - Circ Module ArrDocument1 pageK354-M-120-MH05-515 - 01 - 01 - Pipe Mod Engine - Circ Module ArrWilber MontenegroNo ratings yet

- Structure-07032022-Second Floor PlanDocument1 pageStructure-07032022-Second Floor PlanBindresh KumarNo ratings yet

- 02a-4 D-Can Xlrteh4300g033850Document1 page02a-4 D-Can Xlrteh4300g033850Daniel PricopNo ratings yet

- 02a-4 D-Can Xlrteh4300g033850Document1 page02a-4 D-Can Xlrteh4300g033850ПавелNo ratings yet

- Issued For Construction: NotesDocument1 pageIssued For Construction: NotesjebripahlaviNo ratings yet

- Gre - Eec.d.99.cl.p.07576.14.087.01 - Ifc PDFDocument6 pagesGre - Eec.d.99.cl.p.07576.14.087.01 - Ifc PDFpabloNo ratings yet

- HS2 Map West Midlands wm15103Document1 pageHS2 Map West Midlands wm15103HighSpeedRailNo ratings yet

- Mapa de Aforos 2017Document1 pageMapa de Aforos 2017jesus manuel cediel martinezNo ratings yet

- Spectrum: Techno Consultants PVT LTDDocument4 pagesSpectrum: Techno Consultants PVT LTDjkchennai2023No ratings yet

- Power Pack-BCT (PCB11) Key Card (Option) : Operation Panel Board (GW) (PCB12)Document2 pagesPower Pack-BCT (PCB11) Key Card (Option) : Operation Panel Board (GW) (PCB12)pabloingresonuevoNo ratings yet

- To Be Re Vise D: Brown Fintube France Sa NDocument4 pagesTo Be Re Vise D: Brown Fintube France Sa Ndhiaa mohammedNo ratings yet

- DR-CST-800-0014 - Rev ADocument1 pageDR-CST-800-0014 - Rev APinak ProjectsNo ratings yet

- Proyecto Constructivo 2-Layout1Document1 pageProyecto Constructivo 2-Layout1Itzel RomeroNo ratings yet

- Puntoapunto MP1600Document3 pagesPuntoapunto MP1600Juan Carlos Pino CamposNo ratings yet

- Kec RG301 S&B MNB 898 1 201 - R0Document1 pageKec RG301 S&B MNB 898 1 201 - R0The Rational ReporterNo ratings yet

- Bizhub 423 - 363 - 283 - 223 Overall Wiring DiagramDocument1 pageBizhub 423 - 363 - 283 - 223 Overall Wiring DiagramHugo Luis Escalante50% (2)

- Spare Part List 2201690123Document2 pagesSpare Part List 2201690123Ndikumasabo EtienneNo ratings yet

- B262/B284/B288/B292 (GW) POINT TO POINT DIAGRAM: Power Pack-BCT (PCB11) Key Card (Option)Document2 pagesB262/B284/B288/B292 (GW) POINT TO POINT DIAGRAM: Power Pack-BCT (PCB11) Key Card (Option)Mahmoud RabiehNo ratings yet

- A7pum0nc812db 2of4Document1 pageA7pum0nc812db 2of4COPIATOR BIZHUBNo ratings yet

- Chapter 5 - Dispersion - Part1Document35 pagesChapter 5 - Dispersion - Part1Thịnh VănNo ratings yet

- Chapter6 ExerciseDocument1 pageChapter6 ExerciseThịnh VănNo ratings yet

- Application of VOF ModelDocument9 pagesApplication of VOF ModelThịnh VănNo ratings yet

- CamScanner 2024-02-29 21.13Document1 pageCamScanner 2024-02-29 21.13Thịnh VănNo ratings yet

- The Future of Computational Fluid DynamicsDocument1 pageThe Future of Computational Fluid DynamicsThịnh VănNo ratings yet

- Fundamentals-Of-Toxicology HCMUT 2023 OISP.2Document43 pagesFundamentals-Of-Toxicology HCMUT 2023 OISP.2Thịnh VănNo ratings yet

- CRE Chapter 1 Overview of Chemical Reaction EngineeringDocument34 pagesCRE Chapter 1 Overview of Chemical Reaction EngineeringThịnh VănNo ratings yet

- Fundamentals-Of-Toxicology HCMUT 2023 OISP.1Document24 pagesFundamentals-Of-Toxicology HCMUT 2023 OISP.1Thịnh VănNo ratings yet

- Data Sheet - Rev 01 (Compaginando Las 1500)Document67 pagesData Sheet - Rev 01 (Compaginando Las 1500)Martin DanzeNo ratings yet

- Cot - DLP - Science Q3Document4 pagesCot - DLP - Science Q3Nymfreda LequipNo ratings yet

- Building Construction: Century, Andrea Palladio Presented A Design of Truss Bridge Based On ADocument2 pagesBuilding Construction: Century, Andrea Palladio Presented A Design of Truss Bridge Based On Aallyssa monica duNo ratings yet

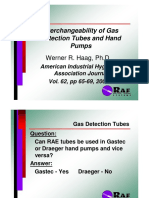

- Tube InterchangeDocument21 pagesTube Interchangeshiladitya banerjeeNo ratings yet

- Construction of Series and Parallel Circuits Using ResistorsDocument7 pagesConstruction of Series and Parallel Circuits Using ResistorsBisma QamarNo ratings yet

- Test Series For Neet-2020Document12 pagesTest Series For Neet-2020kavyareddyNo ratings yet

- Instruction Sheet: ExampleDocument5 pagesInstruction Sheet: ExampleMohammad ArifNo ratings yet

- Reed'S General Engineering Knowledge FOR Marine Engineers: Leslie JacksonDocument265 pagesReed'S General Engineering Knowledge FOR Marine Engineers: Leslie JacksonJose RamonNo ratings yet

- Sample Theory With Ques.-Quantum Mechanics (NET PH Unit-6) PDFDocument21 pagesSample Theory With Ques.-Quantum Mechanics (NET PH Unit-6) PDFKuchibhotla MahatiNo ratings yet

- The Schott Energy and The Reactive Energy in Electromagnetic Radiation and Mutual CouplingsDocument6 pagesThe Schott Energy and The Reactive Energy in Electromagnetic Radiation and Mutual Couplingsالعامري أبو عبد الرحمانNo ratings yet

- DP Flange Transmitter (Arita)Document6 pagesDP Flange Transmitter (Arita)Diki Permana SNo ratings yet

- HIWIN - Carrinhos PDFDocument150 pagesHIWIN - Carrinhos PDFPaulo CarvalhoNo ratings yet

- Physical Science Week 2Document7 pagesPhysical Science Week 2ruel rinconadaNo ratings yet

- Unit 6 - Redox Reactions Student VersionDocument34 pagesUnit 6 - Redox Reactions Student VersionAmadu sallieuNo ratings yet

- Laplace TransformDocument5 pagesLaplace TransformjohnNo ratings yet

- Gas Dynamics and Jet Propulsion - NewDocument12 pagesGas Dynamics and Jet Propulsion - NewShanmugam SNo ratings yet

- Uce Physics Paper Two 2Document8 pagesUce Physics Paper Two 2Okiror GeorgeNo ratings yet

- Completion Diagram: Re-Run Ex BN-22 Re-Run Ex BN-22 RedalineDocument1 pageCompletion Diagram: Re-Run Ex BN-22 Re-Run Ex BN-22 Redalinefauzan kartiyasaNo ratings yet

- ESDB AC Servo Drive User ManualDocument92 pagesESDB AC Servo Drive User ManualUsama ZaheerNo ratings yet

- Folheto TBS Insulated Lightning Protection 9131887 09-2017 ENDocument44 pagesFolheto TBS Insulated Lightning Protection 9131887 09-2017 ENLuis PintoNo ratings yet

- Kích thước để chế tạo Robot Delta kiểu ba khớp trượt ngang - LTĐịnhDocument22 pagesKích thước để chế tạo Robot Delta kiểu ba khớp trượt ngang - LTĐịnhLê Thúc ĐịnhNo ratings yet

- 39 - (Systems) (12) Radial Frame (2016)Document64 pages39 - (Systems) (12) Radial Frame (2016)mohammedNo ratings yet

- Electrical Circuits Question Bank - PDF JntuDocument18 pagesElectrical Circuits Question Bank - PDF Jntudivya sakhamuriNo ratings yet

- P Block Elements - Practice Sheet - (NSEC)Document4 pagesP Block Elements - Practice Sheet - (NSEC)aryanNo ratings yet

- Pendulum-Cart System: Analysis of The Equations of MotionsDocument30 pagesPendulum-Cart System: Analysis of The Equations of MotionsLourdes Evia Landagan ManiscanNo ratings yet

- Voids in CrystalsDocument30 pagesVoids in CrystalssohamNo ratings yet