Professional Documents

Culture Documents

L6M3 LO3 Transcript

Uploaded by

Tlotlo RamotlhabiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L6M3 LO3 Transcript

Uploaded by

Tlotlo RamotlhabiCopyright:

Available Formats

Techniques to achieve effective strategic supply

chain management

This podcast gives an overview of the techniques to achieve effective strategic supply chain

management.

This section looks at approaches to developing and implementing supply chain collaboration.

For the procurement professional, managing relationships between customers and suppliers is

a clear strategic role. It may include developing preferred suppliers to reduce the focus on price

reduction within contract negotiations and demonstrating a willingness to co-operate in order

to transition from transactional forms of supplier relationships.

Collaborative relationships need to be approached in a structured way, using techniques that

enable the procurement organisation and the supplier to communicate their expectations,

agree goals, develop a plan to achieve those goals, and develop measures by which success can

be monitored.

In order to achieve this in collaborative relationships, both parties need to invest resources to

establish an effective and mutually beneficial supply chain strategy. They must then work

together to implement the strategy throughout the supply chain network.

Whipple and Russell identified the key building blocks for collaborative relationships, which are:

developing mutual objectives with relevant performance measures, integrating policy,

developing decision-making domains, establishing mechanisms for information sharing, and

aligning rewards and incentives.

They also identified three types of collaborative approach:

• Type 1 is collaborative transaction management

• Type 2 is collaborative event management, and

• Type 3 is collaborative process management.

It is important to define a clear way of working for the parties involved in the collaborative

relationship. Defining the nature of the relationship will allow the supply partners to move

beyond acting purely competitively, and instead begin to deliver shared value and relational

benefits.

This brings us to the end of the section on approaches to developing and implementing supply

chain collaboration.

Now answer these questions to check your understanding. Pause the podcast to write down

your answers.

Leading global excellence in procurement and supply

1. Write down an example of collaboration in the supply chain.

2. Name at least three of the building blocks for collaborative relationships.

3. What are the three types of collaborative approach identified by Whipple and Russell?

This section looks at the approaches to change management when working with stakeholders.

Gauging acceptance of strategic change involves considering whether the stakeholders are

receptive towards the change, whether they believe it can be achieved and whether they are

embracing the change journey.

There are three aspects that should be considered when gauging acceptance. They are the

reaction to the change, the way in which people’s behaviour is changed or influenced as a result

of the strategic change process, and the way that stakeholders apply the strategic change to

tasks and activities that they are responsible for. Stakeholders who accept strategic change will

continue to reflect on their experiences and find new ways of applying what they have learned

through the strategic change process, so this is the desired effect.

A number of evaluation methods can be used to gauge the acceptance of strategic change, for

example, interviews, group reviews, feedback and surveys, observation, process mapping, and

assessment tools such as the organisational readiness change assessment tool. The methods

should be set up at the start, so the impact of the change can be monitored throughout.

The information obtained can be fed into the change management process to determine

communication plans with key stakeholders and create an understanding for the procurement

professional as to what additional activity would be needed to improve acceptance of the

strategic change process.

This brings us to the end of the section on the approaches to change management when

working with stakeholders.

Now answer these questions to check your understanding. Pause the podcast to write down

your answers.

1. What three factors are assessed when gauging acceptance of strategic change?

2. What is the benefit of stakeholders accepting change?

3. Write down at least three evaluation methods that can be used to gauge acceptance of

strategic change.

This section looks at the approaches to measuring supply chain performance.

Key performance indicators (or KPIs) are focused on important elements of supply chain

performance, for example, quality, speed, dependability, flexibility and cost. There is no set

number of KPIs that is considered ‘right’ for the supply chain. However, too many KPIs can dilute

the effectiveness of performance measurement and make it difficult to identify areas for

improvement or challenge.

Leading global excellence in procurement and supply

KPIs should relate to the strategic objectives of the overall business strategy, be relevant to the

needs and requirements of customers, and focus on how the supply chain is performing in

relation to the activities of competitors to ensure that the organisation maintains its competitive

advantage.

Measuring and analysing performance against KPIs enables the procurement professional to

identify any component of the supply chain that is underperforming, or where bottlenecks may

be accumulating. Collecting data and publishing metrics only adds value if it’s used for

monitoring and control in order to improve performance in the supply chain.

The procurement professional needs to ensure that the performance metrics applied help to

identify both the symptoms and the root cause of performance issues.

A balanced scorecard is a performance management tool. It can be used by supply chain

managers to ensure suppliers are performing to the agreed standard. It can also be used to

report on supplier performance to key stakeholders. The balanced scorecard is multi-

dimensional, reinforcing to the supplier the importance of performing, in equal measure,

against a range of different measures.

The balanced scorecard provides a framework that can be adapted to the business context of

the organisation, and provides a suitable template for measuring performance that can be used

at every tier of the supply chain and throughout the supply partner network.

The performance measures that are included in the balanced scorecard have a significant

influence on the behaviour of supply partners throughout the supply chain.

The measures should be linked at each level of the supply chain and should focus on efficiency

and effectiveness in order to ensure supply partners focus on the same outcomes throughout

the supply chain. This can lead to improvements in productivity and profitability.

The conventional scorecard, devised by Kaplan and Norton, focused on four key areas of

performance: internal processes, customer, financial, and learning and growth. However, these

can be adapted to suit the organisation’s specific requirements.

This brings us to the end of the section on the approaches to measuring supply chain

performance.

Now answer these questions to check your understanding. Pause the podcast to write down

your answers.

1. What five factors are KPIs usually based on?

2. What is the purpose of the balanced scorecard?

3. What are the four perspectives that should be included in the balanced scorecard?

This section looks at the development of knowledge and skills that can help achieve effective

strategic supply chain management.

Competency analysis involves evaluating the scope and work required for a particular supply

chain task or activity in comparison with other tasks or activities within the supply chain.

Leading global excellence in procurement and supply

Competencies are a list of statements that outline how an individual employee or supply chain

partner is expected to carry out job tasks, and what skills and knowledge they will need to be

able to do the job tasks effectively. The statements provide information about what knowledge

and skills will contribute to success, and how that links to organisational performance.

The CIPS Global Standard can be used to identify the competency requirements of teams and

individuals, enables the procurement professional to develop fair and unbiased criteria for

choosing who to employ in a particular role, and ensures everyone is assessed against the same

framework.

The competency framework can be used in a number of different human resources processes

including developing job descriptions, recruitment and selection, performance management,

learning and development, and talent management and succession planning.

The competency framework may also outline the behaviours that the procurement and supply

function values in supply partners and the expertise needed to achieve the strategic objectives

of the organisation.

This brings us to the end of the section on how the development of knowledge and skills can

help achieve effective strategic supply chain management.

Now answer these questions to check your understanding. Pause the podcast to write down

your answers.

1. What are competencies?

2. What is the CIPS Global Standard?

3. What HR activities can the competency framework be used in?

This is the end of this podcast. You should now be able to:

• Evaluate approaches to developing and implementing supply chain collaboration

• Evaluate approaches to change management when working with stakeholders

• Analyse approaches to measuring supply chain performance, and

• Analyse how the development of knowledge and skills can help achieve effective strategic

supply chain management.

Leading global excellence in procurement and supply

You might also like

- Five Steps To Effective ProcurementDocument7 pagesFive Steps To Effective ProcurementtkurasaNo ratings yet

- Deed of Extra Judicial SettlementDocument3 pagesDeed of Extra Judicial SettlementEric CamposNo ratings yet

- Matter and Chemistry - Property Changes QuizDocument1 pageMatter and Chemistry - Property Changes Quizapi-368213959No ratings yet

- The Performance Appraisal Tool Kit: Redesigning Your Performance Review Template to Drive Individual and Organizational ChangeFrom EverandThe Performance Appraisal Tool Kit: Redesigning Your Performance Review Template to Drive Individual and Organizational ChangeNo ratings yet

- QA Onboarding Basics - CentralDocument53 pagesQA Onboarding Basics - CentralRodrigo Hidalgo100% (1)

- Poka Yoke PDFDocument62 pagesPoka Yoke PDFmartinNo ratings yet

- Supply Chain Performance ManagementDocument33 pagesSupply Chain Performance ManagementDebashishDolon100% (1)

- Packaging Industry ReportDocument44 pagesPackaging Industry ReportKunalNo ratings yet

- Causes of Disequilibrium in Balance of PaymentCAUSES OF DISEQUILIBRIUM IN BALANCE OF PAYMENTDocument36 pagesCauses of Disequilibrium in Balance of PaymentCAUSES OF DISEQUILIBRIUM IN BALANCE OF PAYMENTAlisha Singh67% (3)

- Understand What Is A Benchmark and How It Is UsedDocument8 pagesUnderstand What Is A Benchmark and How It Is UsedSharah Del Tabudlong TudeNo ratings yet

- L5 03 Improving Supply Chain Performance Integrative UnitDocument156 pagesL5 03 Improving Supply Chain Performance Integrative UnitRitesh KumarNo ratings yet

- Evangelista vs. Abad SantosDocument2 pagesEvangelista vs. Abad Santosmitsudayo_No ratings yet

- Supply Chain Performance MetricsDocument4 pagesSupply Chain Performance MetricsAyoub CharroufNo ratings yet

- 7 Steps To Better BenchmarkingDocument4 pages7 Steps To Better BenchmarkingHan HanNo ratings yet

- TATA Businesss Excellence ModelDocument4 pagesTATA Businesss Excellence ModelSaurabh ChoudharyNo ratings yet

- 10 Best Practices Supply ChainDocument5 pages10 Best Practices Supply ChainAseem SangarNo ratings yet

- Q8 IM08 FinalDocument59 pagesQ8 IM08 FinalJb MacarocoNo ratings yet

- Improve Operational PerformanceDocument9 pagesImprove Operational PerformanceFarheen FurqanNo ratings yet

- APICS CSCP 2020 Module 1 Section BDocument427 pagesAPICS CSCP 2020 Module 1 Section Bmd shadman akif67% (3)

- Rule 4 Golden Arches Development VS ST FrancisDocument1 pageRule 4 Golden Arches Development VS ST FrancisJoh MadumNo ratings yet

- Organization:: Overview of Core FrameworksDocument91 pagesOrganization:: Overview of Core FrameworksfwfsdNo ratings yet

- What Is The Balanced ScorecardDocument21 pagesWhat Is The Balanced ScorecardAndi Yanuar100% (1)

- Expanded Withholding Tax RatesDocument7 pagesExpanded Withholding Tax RatesJaemar FajardoNo ratings yet

- 10 Best PracticesDocument4 pages10 Best PracticesMihaela BotezanNo ratings yet

- Demand PlanningDocument17 pagesDemand PlanningArijit SamantaNo ratings yet

- Chapter 16 - Strategic Challenges and Change For Supply ChainsDocument26 pagesChapter 16 - Strategic Challenges and Change For Supply ChainsArmanNo ratings yet

- Seminar Procurement Strategy Development DubaiDocument10 pagesSeminar Procurement Strategy Development Dubaikhan4luvNo ratings yet

- Atriark WhitepaperDocument40 pagesAtriark Whitepaperbudi satrio pratamaNo ratings yet

- Article - Benchmarking IntroDocument5 pagesArticle - Benchmarking Introkary290790No ratings yet

- Module 4 (Final) : Supply Chain Management in Hospitality IndustryDocument14 pagesModule 4 (Final) : Supply Chain Management in Hospitality Industryクイーンクイーン ロペス100% (1)

- Managing Supply Chains A Logistics Approach International Edition 9Th Edition Coyle Solutions Manual Full Chapter PDFDocument36 pagesManaging Supply Chains A Logistics Approach International Edition 9Th Edition Coyle Solutions Manual Full Chapter PDFgrace.hawkins682100% (12)

- Chapter-3 Research Methodology and Survey Instrument: 3.1 Need For The StudyDocument28 pagesChapter-3 Research Methodology and Survey Instrument: 3.1 Need For The StudyArun Kumar SatapathyNo ratings yet

- A Fact-Based Management ApproachDocument2 pagesA Fact-Based Management ApproachAbril BarbosaNo ratings yet

- Benchmarking Supply ChainDocument8 pagesBenchmarking Supply ChainsanoNo ratings yet

- TQM ReviewerDocument54 pagesTQM ReviewerMaryan SabelNo ratings yet

- 1 Answer Introduction: Companies Having Advanced Functions of Procurement Often KnowDocument7 pages1 Answer Introduction: Companies Having Advanced Functions of Procurement Often KnowAkshatNo ratings yet

- TBEMDocument4 pagesTBEMSubhamay DebNo ratings yet

- Benchmarking: What It Is, What It Isn'tDocument6 pagesBenchmarking: What It Is, What It Isn'tSatya KumarNo ratings yet

- OM CH 2Document23 pagesOM CH 2Nicole Anne Villanueva PacificoNo ratings yet

- Project Report-Sakshi Arora (OM)Document100 pagesProject Report-Sakshi Arora (OM)BrahmmanandNo ratings yet

- 3 RD ModuleDocument3 pages3 RD Moduleniveditha_shyamsundaNo ratings yet

- EagersaverDocument3 pagesEagersaverMostafa ElghifaryNo ratings yet

- Ten Key Elements To Strategic PlanningDocument5 pagesTen Key Elements To Strategic Planningwuay1991No ratings yet

- TBEMDocument3 pagesTBEMAnonymous ggwJDMh8No ratings yet

- Q # 3 Mustijab Ahmed Khan FA18-MBAP-0095Document4 pagesQ # 3 Mustijab Ahmed Khan FA18-MBAP-0095QURAT UL AINNo ratings yet

- Core Values of Total Quality Management 1. Customer-Driven QualityDocument6 pagesCore Values of Total Quality Management 1. Customer-Driven QualityLloydNo ratings yet

- Week 10Document21 pagesWeek 10Arishragawendhra NagarajanNo ratings yet

- SIMA PresentattionDocument2 pagesSIMA PresentattionS2018401 STUDENTNo ratings yet

- MER Plan OutlineDocument6 pagesMER Plan OutlinelonlinnessNo ratings yet

- Evaluating Management Practices Through Performance ManagementDocument12 pagesEvaluating Management Practices Through Performance Managementhkhan88No ratings yet

- 1:1 ABSTRACT: The Continuous Pursuit of Excellence Is The Underlying and EverDocument29 pages1:1 ABSTRACT: The Continuous Pursuit of Excellence Is The Underlying and EveryudhistharNo ratings yet

- Partnership and ResourcesDocument9 pagesPartnership and ResourcesDunia MiqdadNo ratings yet

- Supply Chain ManagementDocument23 pagesSupply Chain ManagementSri Sarveentaran100% (1)

- Analytics Plan ReadingDocument4 pagesAnalytics Plan ReadingcorderomarenasNo ratings yet

- Why Should Companies Benchmark?: What Is Benchmarking?Document13 pagesWhy Should Companies Benchmark?: What Is Benchmarking?Naresh Kumar Surepelly100% (1)

- SOM Unit IDocument16 pagesSOM Unit Ishabeena ShahNo ratings yet

- SQM Nugrain Arvi Allan Paul Wm80Document4 pagesSQM Nugrain Arvi Allan Paul Wm80allanNo ratings yet

- Improving Warehouse Productivity: WarehousingDocument14 pagesImproving Warehouse Productivity: WarehousingEllah Mae Cao - CasitasNo ratings yet

- English - Advanced Module 4Document13 pagesEnglish - Advanced Module 4denisNo ratings yet

- Module 1, Lesson 1 - Notes INTRODUCTION TO OPERATIONS MANAGEMENTDocument14 pagesModule 1, Lesson 1 - Notes INTRODUCTION TO OPERATIONS MANAGEMENTGlaziel Anne GerapatNo ratings yet

- Chapter 4Document44 pagesChapter 4JulianNo ratings yet

- Measuring The Supply Chain: Formatted: Normal, LeftDocument4 pagesMeasuring The Supply Chain: Formatted: Normal, LeftColbyNo ratings yet

- A2 SandeshDocument13 pagesA2 SandeshsandeeNo ratings yet

- Learning From Leaders Three 293108Document11 pagesLearning From Leaders Three 293108AndersonVieiraNo ratings yet

- Benchmarking: Is The Process of Comparing Performance With Other Organisations, Identifying Comparatively HighDocument4 pagesBenchmarking: Is The Process of Comparing Performance With Other Organisations, Identifying Comparatively HighUmar SulemanNo ratings yet

- Why Implement A Logistics Strategy?: What Is Involved in Developing A Logistic Strategy?Document4 pagesWhy Implement A Logistics Strategy?: What Is Involved in Developing A Logistic Strategy?SoorajKrishnanNo ratings yet

- IATF - NotesDocument30 pagesIATF - NotesbargunanNo ratings yet

- Tutorial PMS Non-Financial MeasuresDocument10 pagesTutorial PMS Non-Financial MeasuresAisyah ShahidanNo ratings yet

- Supply Chain Strategy Plan A Complete Guide - 2020 EditionFrom EverandSupply Chain Strategy Plan A Complete Guide - 2020 EditionNo ratings yet

- L6M7 Tutorial QuestionsDocument4 pagesL6M7 Tutorial QuestionsTlotlo RamotlhabiNo ratings yet

- L6M7 Test 2Document18 pagesL6M7 Test 2Tlotlo RamotlhabiNo ratings yet

- L6M2 External ReportDocument1 pageL6M2 External ReportTlotlo RamotlhabiNo ratings yet

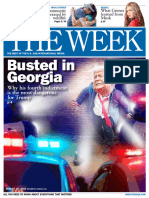

- The Week US 25th Aug 2023Document40 pagesThe Week US 25th Aug 2023Tlotlo RamotlhabiNo ratings yet

- L5M15 LO3 TranscriptDocument6 pagesL5M15 LO3 TranscriptTlotlo RamotlhabiNo ratings yet

- The Nation US 21st Aug 2023Document48 pagesThe Nation US 21st Aug 2023Tlotlo RamotlhabiNo ratings yet

- Cream Purple Abstract Thesis Defense PresentationDocument15 pagesCream Purple Abstract Thesis Defense PresentationTlotlo RamotlhabiNo ratings yet

- The Week US 8th Sept 2023Document44 pagesThe Week US 8th Sept 2023Tlotlo RamotlhabiNo ratings yet

- The Purpose of Holding Inventory 1678532321Document6 pagesThe Purpose of Holding Inventory 1678532321Tlotlo RamotlhabiNo ratings yet

- Cips L5M4 1.1Document38 pagesCips L5M4 1.1Tlotlo RamotlhabiNo ratings yet

- L5M1 Session 1.3 (2) 1Document39 pagesL5M1 Session 1.3 (2) 1Tlotlo RamotlhabiNo ratings yet

- TUTORIAL 3 - L6M1 (Strategic Ethical Leadership) : (Due Date:17/03/2023)Document1 pageTUTORIAL 3 - L6M1 (Strategic Ethical Leadership) : (Due Date:17/03/2023)Tlotlo RamotlhabiNo ratings yet

- CIPS L2M2 - LectureDocument93 pagesCIPS L2M2 - LectureTlotlo RamotlhabiNo ratings yet

- Defining Leadership: 1.1.critically Evaluate The Differences Between Leadership and ManagementDocument3 pagesDefining Leadership: 1.1.critically Evaluate The Differences Between Leadership and ManagementTlotlo RamotlhabiNo ratings yet

- The Traits or Qualities Approach: - Managerial Grid by Blake and Moton'sDocument2 pagesThe Traits or Qualities Approach: - Managerial Grid by Blake and Moton'sTlotlo RamotlhabiNo ratings yet

- Asking: Atika Furwati Yolanda 11200932Document10 pagesAsking: Atika Furwati Yolanda 11200932Michael SteroNo ratings yet

- S4hana MorDocument24 pagesS4hana MorARYAN SINHANo ratings yet

- Mrca - 4Document9 pagesMrca - 4Khushi MishraNo ratings yet

- Human Resource ProcuretmentDocument14 pagesHuman Resource Procuretmentjeje jeNo ratings yet

- Srisaila Devasthanam: Phone: 8333901351, 8333901352, 8333901353, 8333901354, 8333901355, 8333901356 Fax: 08524-287126Document1 pageSrisaila Devasthanam: Phone: 8333901351, 8333901352, 8333901353, 8333901354, 8333901355, 8333901356 Fax: 08524-287126Ajay Chowdary Ajay ChowdaryNo ratings yet

- What's New: Informatica Cloud Data Integration Winter 2019 AprilDocument28 pagesWhat's New: Informatica Cloud Data Integration Winter 2019 Aprilsri_plnsNo ratings yet

- Sap Fico and S4 Hana Finance and FioriDocument4 pagesSap Fico and S4 Hana Finance and FioriNafis AlamNo ratings yet

- Section 1 PDFDocument299 pagesSection 1 PDFIbrahim KhalifaNo ratings yet

- Aligning The Private Sector in Fostering Excellent Economic Growth in Sierra LeoneDocument7 pagesAligning The Private Sector in Fostering Excellent Economic Growth in Sierra LeoneInternational Journal of Recent Innovations in Academic ResearchNo ratings yet

- Prolongation Cost Claims - The Basic PrinciplesDocument6 pagesProlongation Cost Claims - The Basic PrinciplesMuhammad ZaimmuddinNo ratings yet

- Review Jurnal - 3Document20 pagesReview Jurnal - 3eko hadiNo ratings yet

- Call For Expression of InterestDocument19 pagesCall For Expression of InterestDavid PanNo ratings yet

- Spatialnet: End-To-End Physical Network Inventory ManagementDocument3 pagesSpatialnet: End-To-End Physical Network Inventory ManagementtalhaNo ratings yet

- Benefits of Online Core Tools TrainingDocument3 pagesBenefits of Online Core Tools TrainingVigneshNo ratings yet

- RP Consumer Behavior 2021Document7 pagesRP Consumer Behavior 2021ArinaNo ratings yet

- Case Study SCMDocument8 pagesCase Study SCMKhổng Nguyễn Hải LongNo ratings yet

- The Total Economic Impact of Fortinet NGFW For Data Center and AI-Powered FortiGuard Security Services SolutionDocument29 pagesThe Total Economic Impact of Fortinet NGFW For Data Center and AI-Powered FortiGuard Security Services Solutiontola02000No ratings yet

- ILO Guide To Myanmar Labour LawDocument62 pagesILO Guide To Myanmar Labour LawKaung Myat HtunNo ratings yet

- MSHEM-02.11-C Level 2 JSA - Veolia - RO Units Pipes Repairing and ReplacementDocument6 pagesMSHEM-02.11-C Level 2 JSA - Veolia - RO Units Pipes Repairing and ReplacementAbdullah AbedNo ratings yet

- Test Bank For Valuation Measuring and Managing The Value of Companies 6th by KollerDocument5 pagesTest Bank For Valuation Measuring and Managing The Value of Companies 6th by KollerJohn Ngo100% (24)