Professional Documents

Culture Documents

Day 3 - Training

Day 3 - Training

Uploaded by

Tebeje TesfawOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Day 3 - Training

Day 3 - Training

Uploaded by

Tebeje TesfawCopyright:

Available Formats

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

LO3: Perform Operation SWP System

This learning guide is developed to provide you the necessary information regarding the following

content coverage and topics:

Identifying PPE, operational tools and supporting SWP System

Performing safe operation SWP System

Evaluating the functionality of SWPS.

Learning Instructions:

1. Read the specific objectives of this Learning Guide.

2. Read the information written in the information “Sheet 1 and Sheet 2”.

3. Accomplish the “Self-check 1, and Self-check 2”.

Information Sheet 1 Identify PPE, operational tools and supporting SWP System

1. Introduction

PV water pumping systems require much less operation compared to other water pumping systems.

However, they will still require proper operation. Responsibilities for solar water pumping system

operation and maintenance must be clearly specified after system handover and adequate resources

must be provided. Inadequate operation is the reason cited most frequently for PV water pumping

system failure in Ethiopia and in other countries. Some of the issues include unclear responsibilities

for operation inadequate human capacity for proper care and operation of the system (due to no or

insufficient training, salaries for operators and guards), lack of funds for maintenance and service

(sometimes even for minor maintenance).

The following are tasks to be performed to operate solar water pumping system. Before we start to

operate, we have to do pre start checks (listed in C1 as follows) and after we perform those checks, we

can go through to the steps for starting the PV generator (listed in C2 as follows). Then we have to

ensure that the PV generator can generate an output that is needed and we have to shut down the PV

generator properly (stated in C3) then finally we have to clean the PV generator area and return the

tools to their position.

A. We do not have to attempt to operate the PV water pumping systems without consideration of

OH & S precautions

JANUARY, 2024 G.C 1

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

B. We have to ensure that the PV water pumping systems is protected from shadow or dust and is

located in the appropriate area that is free from any insecure items that could inhibit operation

or cause injury, damage of system are screened clear safe guards.

C. Next, we have to avail tools & instruments that are necessary for this operation.

D. Let us to be proceed with the following steps before start, to start & operate and stop or

provided as follows in C1 C2 & C3. While doing these we have to see and record related data

on the operation log and operation checklist.

1.2 . Safety Instructions on SWPS operation

Safe operation of this system depends on its correct transportation, installation, operation and

maintenance. Failure to follow these instructions can be dangerous to life or health and/or properties.

Read and follow all instructions

Warning – Disregard can lead to injury, death or damage the system.

Caution – Recommended to avoid damage, premature ageing of the pump or similar negative

consequences. When installing and using this electrical equipment, basic safety precautions

should always be followed, including the following:

Warning – To reduce the risk of injury, do not permit children to use this product unless they

are closely supervised at all times.

Warning – The appliance is not to be used by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they are

instructed and closely supervised.

Warning – To reduce the risk of electric shock, replace damaged cords immediately.

Warning – It must be assured that all grounding connections are properly made and that the

resistances meet local codes or requirement

The manual contains basic instructions which must be observed during installation, operation and

maintenance. Before installation and start-up, the manual should be carefully read by the person in

charge of the installation. The manual should also be read by all other technical personnel/operators

and should be available at the installation site at all times.

Personnel qualifications and training: - All personnel for the operation and inspection must

be fully qualified to perform that type of job. Responsibility, competence and the supervision

of such personnel must be strictly regulated by the operator. Should the available personnel be

JANUARY, 2024 G.C 2

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

lacking the necessary qualification, they must be trained and instructed accordingly. If

necessary, the operator may request the manufacturer supplier to provide such training.

Furthermore the operator/user must make sure that the personnel fully understand the contents

of the manual.

Dangers of ignoring the safety symbols: – Ignoring the safety directions and symbols may

pose a danger to humans as well as to the environment and the equipment itself. Non

observance may void the warranty. Non-observance of safety directions and symbols may for

example entail the following: Failure of important functions of the equipment/plant; failure of

prescribed methods for maintenance and repair; danger to persons through electrical,

mechanical and chemical effects; danger to the environment because of leakage of hazardous

material; danger of damage to equipment and buildings.

Safety-oriented operation: – The safety directions contained in the manual, existing national

regulations for the prevention of accidents as well as internal guidelines and safety-regulations

for the operator and user must be observed at all times.

General safety directions for the operator/user: – If hot or cold equipment parts pose a

danger then they must be protected by the operator/user against contact with people. Protective

covers for moving parts (e.g. couplings) must not be removed when the equipment is running.

Leaks (e.g. at the shaft seal) of hazardous pumping media (e.g. explosive, toxic, hot liquids)

must be disposed of in such a way that any danger to personnel and the environment is

removed. All government and local regulations must be observed at all times. Any danger to

persons from electrical energy must be eliminated by using good installation practices and

working to local regulations.

Unauthorized operation: – The operational safety of the equipment delivered is only

guaranteed if the equipment is used in accordance with the directions contained in this manual.

Limits stated in the data sheets may not be exceeded under any circumstances.

1.3. Developing an Electrical Safety in SWPS Program

An electrical safety in SWPS program outlines requirements, policies and practices to address hazards

associated with working near electricity. It should be aligned with the requirements of the safety

management system, be practical, sustainable and a measurable program to mitigate or reduce the risk

of exposure to electrical hazards. On the other end of the spectrum, a small operation that undertakes

work with a low risk profile may need only a small task-specific program that requires only minor

JANUARY, 2024 G.C 3

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

amendments to an existing safety management system. Regardless of the size and scope, what matters

is that an electrical safety in SWPS program is designed and implemented to keep people safe.

1.4. Safety rules

Safe working habits in work shop is essential to prevent accidents which may result i n personal injury

or health hazards, damage to tools, equipment & property.

Common causes for accidents are:

Improper use of tools & equipment's, etc.

Failure to use protective equipment

Failure to follow correct procedure

Faulty equipment & tool

Condition of walking & working surfaces

Unguarded or inadequately guarded machinery

Safety is a matter of a common sense & good work habits. A person who has does not have knowledge

of or regard for his tools, machines, equipment & himself cannot effectively & safely perform his

work. A good knowledge of tool is very important for safety. Any tool can cause harm if not properly

used. So any one who uses tools must use them carefully & safely to avoid injury. Anyone who knows

about safety rules takes good care of himself & the tools. He can avoid the danger that may be caused

by carelessness & ignorance.

SAFETY - is the control of hazard to attain an acceptable level of risk

HAZARD - unsafe acts/unsafe conditions.

RISK - chance of personal or physical loss.

ACCIDENT - is an undesired event that results in physical harm to a person or

damage to property.

General Statistics/Data:

Unsafe Acts - people/personnel- 88 %

Unsafe Condition - equipment, material & environment – 10 %

Acts of God - natural calamities – 2%

1.5. Personal Protective Equipment (PPE)

PPE are those that are worn by personnel to protect them against hazard exposure. It sets-up a frail

barrier against hazard.

JANUARY, 2024 G.C 4

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

Classification of PPE

Head and Ear Protection

Face and Eye Protection

Respiratory Protection

Hand, Foot & Leg Protection

Body or Torso Protection, Protective Clothing

Fall Protection

Requirement on PPE

Employees shall be required to wear and be provided with appropriate PPE when performing any

activity where potential hazard exists.

Common PPE Used

Head Protection - bump caps, safety helmets, and hard hats.

Body Protection – hand gloves, safety shoes, coverall, vests, rain coats, safety

belts.

Eye Protection - safety glasses, goggles, masks or face shields.

Respiratory Protection - dust/gas mask

Ear protection

Basic tool safety rules

Maintain on a regular basis

Inspect before use

Operate according to manufacturer‟s recommendation

Use the right personal protective equipment(PPE)

Use guards

1.6. Safety signs

These are special signs posted to warn against immediate danger or potential hazards that the

Personnel may be exposed to and instruct them on the special precautionary measures they have to

take in order to prevent accidental injury to personnel, property damage or both.

Classification of Safety Signs According to Use

Danger Sign - these signs shall be used only where immediate danger /hazards exist

to make the personnel aware of the immediate danger and special precautions they

JANUARY, 2024 G.C 5

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

have to take prevent accidents. Ex. DANGER, HIGH VOLTAGE. These are in red

letters with white background

Figure1: Danger Sign

Caution Sign - used to remind personnel against potential hazards and to instruct

them to take the proper precautionary measures to prevent accident. Ex. CAUTION:

Watch your step. These are in black letters with yellow background.

Figure 2: Caution Sign

1.7. General First Aid

First aid, by definition, is the immediate and temporary care given to a person or those suddenly

taken ill before the services of a physician can be obtained. Adequate first aid kits and/or

paraphernalia should be available, generally, in working areas where personnel have access

especially during emergencies.

Objectives of first aid

To prolong life

To alleviate sufferings

To prevent additional sufferings

JANUARY, 2024 G.C 6

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

DO’s and DON’T’s in FIRST AID

DON’T’s:

Do not arouse unconscious person by means of pulling, biting and pouring water into

his face

Don‟t give fluids to an unconscious person

Don‟t panic

Don‟t let the person see his own injuries

DO’s:

Keep calm and deliberate

Keep handling to the minimum

1.8. General Safety Practices

ON THE JOB:

If you are not sure about how to do the job safely and correctly, ask your immediate

supervisor or manager.

If you are transferred to another department, learn the safe practices of that department.

Report at once to your supervisor/manager any unsafe practices or potential hazards.

Wear the appropriate PPE.

Walk cautiously on wet or slippery floors and stairs. Running in the control building is

not safe. Use care in going up or down the stairs. Hold on to the hand rail. Take one step at a

time.

Ask for help when lifting objects which are unusually heavy. When lifting, keep the legs

as close together as possible and the back straight. Lift with your leg muscles - not your

back.

Practice good housekeeping. Place oil waste, scrap, and waste paper in covered metal

cans. Wrap broken glass separately or place in special container.

Avoid wearing oil-soaked clothes. They could readily catch fires.

1.9. Handling of material

Handling of material is responsible for approximately one fourth (1/4) or 25% of the

occupational disabling injuries. In order to establish efficient material handling procedures, it is

necessary to consider the following:

JANUARY, 2024 G.C 7

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

The properties of the material.

The characteristic of the operation process or location to or from which the material is to

be moved.

The quantities to be handled to maintain a constant flow.

1.10. Safety tagging:

Tagging is an effective safety method wherein tags are posted and/or attached on

component/equipment/system which is/are under testing or maintenance/repair as one of the control

protection to personnel and equipment/system.

When Do You Need to Post a Tag?

During testing of equipment or system;

Maintenance/repair of substation which require opening of PCBs and DS;

Maintenance/repair of transmission line/s;

Force outage which requires inspection & clearance before energization.

Requirements on Tagging

Complete all the necessary information needed.

Log all the tag posted with corresponding control number.

Post and/or attach the tag/s to the equipment/item.

Generally, never use aluminum ladders on any electrical job. A metal is always an electric conductor.

2. Tools and instruments for operation solar water pumping system.

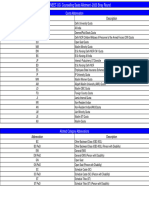

Table 1. Tools and instruments for operation solar water pumping system

No. Tools Purpose

1 Total station Use to measure distance, angles in

both the horizontal and vertical

planes.

JANUARY, 2024 G.C 8

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

2 Used to indicate directions

Compass

3 Used for indicating direction,

Global Positioning location, altitude

System (GPS)

4 Used to measure current, Voltage,

Multi-meter resistance and other parameters

5 Megger (insulation Used to measure insulation

tester) resistance of the cable and motor

against the ground.

6 Marking tool set (pencil, Used to mark

market, chalk)

7 Distance measuring Used to measure distance

tape

8 Levels measuring Used for water level and structures

angle adjustment

9 Well depth meter Used to measure depth of water

level

JANUARY, 2024 G.C 9

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

10 Set of pliers and Used for turning or twisting nuts,

socket wrench bolt heads or the like.

11 Set of screw drivers Used for turning or twisting

screws heads or the like

12 Set of pliers Used for cutting, to hold objects

firmly, for bending, or physical

compression.

13 Crimping tool Used to join two pieces of metal

by deforming one or both pieces to

hold the other. And also used to

attach a terminal or contact to an

electrical conductor

14 Hammer Used to manually drive nails,

brads, and other fasteners into /out

of softer materials

15 Rubber Hammer Used for striking a surface without

causing damage.

16 Hack saw Used to cut or grind metallic

materials

17 Wooden saw Used to cut wooden materials

18 Ladder Used to access elevated areas from

the ground during installation

JANUARY, 2024 G.C 10

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

19 Water pipe wrench Is an adjustable wrench/spanner

used for turning soft iron pipes and

fittings with a rounded surface

20 Ratcheting pipe Used to manual cut pipe threading

threading set and cutting

21 Plastic tube cutter/ Used to cut plasitice pipes

scissor type

22 Calliper Used to measure external or

internal dimensions

23 Cordless drill machine User to drive drill bits and nuts

24 Safety, Used for safty

Gloves/goggles/ear plugs

25 Tripod and pulley For lowering and rising pipes and

pump from a well

26 Swivel nipple For holding a pipe during raising

or lowering

27 Pipe clump Securing pipe during lowering and

raising

JANUARY, 2024 G.C 11

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

28 Propane burner/ For heating water proof epoxy

torch sealant for electric wire

connections

29 Teflon coating/tape For sealing pipe joints to make

them water tight

Information Sheet 2 Perform safe operation SWP System

1. Operation and checking of SWPSC

Figure 3 SWPS controller unit

Check 1 - Pre-Operation Checks

Below are routine Operation Procedures that need to be followed by a SWPS operator:

During start up, operation and shutting down the SWPS:

1. Check that all valves are in open position (Gate valves, check valves, etc.)

JANUARY, 2024 G.C 12

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

2. Make sure that the solar array is clean from dirt

3. Check weather condition of the site

4. Check status of the system reservoir.

5. Switch ON/OFF the Strat Button on the System Controller

Figure 4 clean array from dirt

Figure 5: check ON /Off switch

Check 2 – during operation -Start

1. If the pump starts properly, make a regular check on the piping system for any Leakages

2. If the pump starts but no or small amount of water is supplied, check the pressure gage.

3. If the pressure gage indicates a high pressure, this means there is a blockage in the pipe system.

Stop the pump and check if all valves are open, in case of mechanical overflow control in the

water tank, check that it is not stack in the close position, read the controller for any error code

generated and refer the manual for the type of error it refers to.

4. If these actions don‟t resolve the problem, then the blockage could most probably be due to

piling up of silt in the pipe system. This requires a thorough check if the whole pipe system.

5. Check if all signals and displays on the controller indicate normal operation of the pump

JANUARY, 2024 G.C 13

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

6. If the display signals in the controller indicate a problem, Switch Off the pump and refer the

manual to follow the instruction. If the required action is beyond the level that the operator is

trained to address, an expert technician must be called.

2. Operating the solar water Pump

1.Make sure that an unhindered water flow is possible and not blocked, e.g. by closed valves.

2. Switch on the PV generator disconnect switch.

3.Toggle the power switch on the controller to ON.

4.A solar-direct pump will now start when sufficient irradiation levels are reached and neither

the well probe nor float switch respond to a low water Source or full tank.

Figure 6: Starting operation of SWPS

3. Time Delays pump start

Table 2 time delay pump start

Event Time delay

Pump stops due to insufficient irradiation 120 seconds

Full-tank float switch resets 2 - 3 seconds

Low water well probe regains contact with water 15 Minutes

Shutdown due to over temperature Automatic restart after cooling down

Shutdown due to overload Manual reset of POWER switch necessary

To force a quick start: - the above listed delays can be by passed by switching the POWER switch

OFF/ON. The pump should now start immediately if sufficient power is present

NOTE – Please always refer to the Pump Scanner documentation available on Partner NET for the

latest developments. It is highly recommended to make an initial configuration of the Data Module

inside the PS controller using manufacture Pump Scanner

JANUARY, 2024 G.C 14

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

Check 3- switching off: -

To shut down the SWPS, turn off the load by switching the pump controller to “OFF”.

Allow the SWPS to keep on no load by OFF position of the controller for few seconds‟

Then turn the key switch to OFF‟ position .Then PV generator shuts down safely.

In case of an emergency where immediate shutdown is necessary, stop using emergency stop

(if the SWPS has an emergency stop) or use the key switch should be turned to „STOP‟

position immediately without disconnecting the load (if the SWPS has no emergency stop)

4. Inspections or evaluating SWPS

The electrical inspection verifies that your installation meets minimum requirements for electrical

safety, according to current codes. In other words, its purpose is to protect you, the homeowner, and

anyone else who will be occupying the premises, from fire or electrocution.

Electrical inspection is a must for every SWPS to ensure the safety and security of the habitants. In

fact, it is required, but it most certainly does not need to be a cause for high blood pressure. Knowing

what to expect beforehand can be one of the best ways of dealing with electrical inspection. If you

have the loopholes rectified as per the requirements of the state, then there is no way you will fail the

inspection.

1. Inspection cover Guidelines specifying the electrical inspection criteria for your location may

be obtained at the time you apply for your permit. The basic areas are:

equipment listing and labeling

electrical services

general circuitry

AFCI (arc-fault) protection

GFCI (ground fault) protection

grounding and bonding

underground wiring

Wiring methods.

JANUARY, 2024 G.C 15

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

Figure7: Testing and measuring

1.1 Clean up all the system

Clean the SWPS operation area & return the necessary tools used for pre & post operations

and adjustments

Now after you confirm that the SWPS starts its operation safely & after you properly shutdown

it, keep clean the surrounding of a SWPS and return the tools used for operating the SWPS.

Operation Sheet 1 Perform safe operation SWP System

Techniques or procedures for Perform safe operation SWP System:

Step 1- Use PPE and Wear safety clothes

Step 2- Follow all the electrical & mechanical safety procedure required in SWPS installation

manual

Step 3- Plan and prepare work place

Step 4- Select appropriate tools and equipment for operation

Step 5- Check all PV module, installation cable, PV power disconnector controller, PV pump

equipment and accessories

Step 6 – Check Connection of the PV array generator

Step 7 – Operate the solar water Pump

Step 8- Check time of Delays pump start

Step 9 - Check the functionality of the system with multimete

JANUARY, 2024 G.C 16

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

Step 10 - Inspections or evaluating SWPS condition during operation.

Step 11- To shut down the SWPS, turn off the load by switching the pump controller to “OFF

Step 12- clean up the operation system

Self-check Sheet -1 Identify PPE, operational tools and supporting SWP System

Name: ___________________ Date: _______________

Time started: ______________ Time finished: __________

Directions: Answer all the questions listed below. Use the answer box below.

Multiple Choice Questions: Choose one. (1 point)

1. The following operation tools are used to test live power

A/ Compass and GPS B/Tape meter C/.meltimeter D/ All of the above

2. Tools used to during operation lowering and rising pipes and pump from a well

A/ Pipe clump B/ Bench C/ Tripod and pulley D/ Ladder

3. Instrument Use to measure water flow is____

A /. Water flow meter B/ Compass C /.Try square D/ Meter

4. Daily SWPS maintenance is_______

A. Cleaning PV module B. pump casing C. Controller D. All

Mach the following question column A to column B

A B

1. Compass A. Used to measure current, Voltage, resistance and other

parameters

2. Global Positioning

System (GPS) B. Used to measure depth of water level

3. Multi-meter C. Used for indicating direction, location, altitude

4. Well depth meter D. Used to indicate directions

5. Pipe clump E. Used to join two pieces of metal by deforming one or both pieces

6. Set of screw drivers F. Used for striking a surface without causing damage

7. Rubber Hammer G. Securing pipe during lowering and raising

8. Crimping tool H. Used for turning or twisting screws heads or the like

JANUARY, 2024 G.C 17

WOLDIA UNIVERSITY

SOLAR WATER PUMPING SISTEM TRAINNING MANUAL

Self-check Sheet -2 Perform safe operation SWP System

Name: ___________________ Date: _______________

Time started: ______________ Time finished: __________

Directions: Answer all the questions listed below. Use the answer box below.

Multiple Choice Questions: Choose one. (1 point)

1. The following general safety rules are furnished as a guide

A/ Obey safety rules and regulations-they are for your protection. B/, Wear proper clothing and

protective equipment. C/. Conduct yourself properly at all times-horseplay is prohibited

D/ All of the above

2. Pre-Start Checks operations are------------

A/ Check that all valves are in open position B/ Check weather condition of the site

C/ Make sure that the solar array is clean from dirt D/all

3. An OHS Policy is simply a method of how stating ------------

A/ working with environment policy B/ simple work C /. Checking work D/ hazard

4. The mechanical protection needed against cuts, abrasions, punctures and electrical injuries

by_______

A/. Goggle B/.Glove C/.Helmet D/.Apron

5. During operation If the pump starts but no or small amount of water is supplied _______

A/ If the pressure gage indicates a high pressure B/ check the pressure gag C /. Blockage in the

pipe system D/ All

JANUARY, 2024 G.C 18

You might also like

- DIESEL Engine FundamentalsDocument28 pagesDIESEL Engine Fundamentalsfrankhil ramosNo ratings yet

- Lockout Tagout ProgramDocument9 pagesLockout Tagout Programminhduc2010100% (1)

- Lord of The Flies (Themes, Messages, Literary Devices)Document20 pagesLord of The Flies (Themes, Messages, Literary Devices)Meltem Işık67% (3)

- The Construction Safety Guide: Injury and Illness Prevention through DesignFrom EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignRating: 4 out of 5 stars4/5 (6)

- Detailed Excavation Installation of Formwork & Reinforcement ConcretingDocument29 pagesDetailed Excavation Installation of Formwork & Reinforcement ConcretingRio Handoko100% (2)

- Employee Compensation and BenefitsDocument46 pagesEmployee Compensation and BenefitsJuanito Cabiles JrNo ratings yet

- HexaflexDocument3 pagesHexaflexfdfdsfasdNo ratings yet

- 1 Control of HazardousDocument5 pages1 Control of HazardousVinz Hexon BalangueNo ratings yet

- Electrical Safety Written Program (Example) FORMDocument3 pagesElectrical Safety Written Program (Example) FORMrev2000No ratings yet

- Answers: Chapter 1 Cell As A Unit of LifeDocument6 pagesAnswers: Chapter 1 Cell As A Unit of LifeSuliman50% (2)

- Assessme NT Nursing Diagnosis Planning Nursing Interventions Rationale Evaluation Subjective CuesDocument3 pagesAssessme NT Nursing Diagnosis Planning Nursing Interventions Rationale Evaluation Subjective CuesTricia100% (1)

- A Guide To Safety: Health & Safety at Work Act 1974Document18 pagesA Guide To Safety: Health & Safety at Work Act 1974Chanel Maglinao100% (1)

- CitectSCADA - Quick Start Tutorial - Part 1Document89 pagesCitectSCADA - Quick Start Tutorial - Part 1Adit GilaNo ratings yet

- Puwer 1998Document9 pagesPuwer 1998Jogi Oscar SinagaNo ratings yet

- SmallEnergyMonitoringSystem TVD v1.0Document31 pagesSmallEnergyMonitoringSystem TVD v1.0VũDuyTânNo ratings yet

- Vijeo Citect - Quick Start Tutorial - Part 1 Ver D PDFDocument97 pagesVijeo Citect - Quick Start Tutorial - Part 1 Ver D PDFAlex Chua Kok KeongNo ratings yet

- KODAK 2200 Intraoral X-Ray System: Installation & Service ManualDocument76 pagesKODAK 2200 Intraoral X-Ray System: Installation & Service Manualprairote pengCNo ratings yet

- 10 Life Saving Rules ManualDocument32 pages10 Life Saving Rules ManualDamqn TodorovNo ratings yet

- How Can I Implement SCD6000 With IPMCC and Control Software TVDADocument113 pagesHow Can I Implement SCD6000 With IPMCC and Control Software TVDAEdwinNo ratings yet

- Vir SadhanaDocument60 pagesVir SadhanaVivek TyagiNo ratings yet

- Managing Alarms in SCADA Expert Vijeo Citect 7.5Document84 pagesManaging Alarms in SCADA Expert Vijeo Citect 7.5phongNo ratings yet

- How Can I : Improve Motor Management With iPMCC - V3.1Document72 pagesHow Can I : Improve Motor Management With iPMCC - V3.1Kiran ReddyNo ratings yet

- A1.2 2025 Topic Test v3Document5 pagesA1.2 2025 Topic Test v3valentinaNo ratings yet

- SoMachine Basic V1.1 Self StudyDocument182 pagesSoMachine Basic V1.1 Self Studydpd190890No ratings yet

- Manual Bomba NetzschDocument40 pagesManual Bomba Netzschjotapin843352No ratings yet

- User - Manual: Thies T858Document124 pagesUser - Manual: Thies T858Luis Morales100% (6)

- DH-2000 Manual and PrecautionDocument57 pagesDH-2000 Manual and PrecautionMichael Louis UyNo ratings yet

- Installation, Operation, & Maintenance ManualDocument24 pagesInstallation, Operation, & Maintenance ManualPablo Jefferson MedinaNo ratings yet

- Electrical Safety Program: in Compliance With The Basic Occupational, Health, and Safety CourseDocument11 pagesElectrical Safety Program: in Compliance With The Basic Occupational, Health, and Safety Coursearlene borborNo ratings yet

- Vijeo Citect Quick Start Tutorial Part 1Document97 pagesVijeo Citect Quick Start Tutorial Part 1frenchcmmNo ratings yet

- Te TC Osh Ef-304 Lecture No 1 WK 9Document18 pagesTe TC Osh Ef-304 Lecture No 1 WK 9Humayun SirajNo ratings yet

- 2850 L2u201 Handout 11Document3 pages2850 L2u201 Handout 11OwenNo ratings yet

- Schneider Panduan ListrikDocument52 pagesSchneider Panduan ListrikBettav AriNo ratings yet

- Revised by Njalbee 5/14Document8 pagesRevised by Njalbee 5/14Srinivas MurthyNo ratings yet

- Safety Procedure ManualDocument15 pagesSafety Procedure Manualaris.arnadiNo ratings yet

- Safety Procedure ManualDocument15 pagesSafety Procedure ManualjhoniNo ratings yet

- Wilo 31895Document30 pagesWilo 31895Titi FiliNo ratings yet

- Tools Req MachineDocument7 pagesTools Req MachineTemp WorkNo ratings yet

- Gangway Operator Course Chapter 2 - HSEDocument8 pagesGangway Operator Course Chapter 2 - HSEsvetlanaNo ratings yet

- Electrical Installation and MaintenanceDocument2 pagesElectrical Installation and MaintenanceACouh CHi JOshNo ratings yet

- HB777-777CE E SCRDocument131 pagesHB777-777CE E SCRArsl aliNo ratings yet

- Policy: All EmployeesDocument22 pagesPolicy: All Employeespreventing becejNo ratings yet

- Corporate Work Equipment: Standard Operating Procedure: Document Control SummaryDocument4 pagesCorporate Work Equipment: Standard Operating Procedure: Document Control SummaryMohammad RehanNo ratings yet

- Solar Pump Inverter ManualDocument56 pagesSolar Pump Inverter ManualNé Togo Yé AbuNo ratings yet

- Power Safety CodeDocument23 pagesPower Safety CodeEngr Imtiaz Hussain GilaniNo ratings yet

- DS-22 - Operation Manual - E - 36Document19 pagesDS-22 - Operation Manual - E - 36houdaNo ratings yet

- Element 9 - Work EquipmentDocument28 pagesElement 9 - Work EquipmentJaveria FatimaNo ratings yet

- Lorentz Pp150-Pp200 Ac Powerpack Manual enDocument3 pagesLorentz Pp150-Pp200 Ac Powerpack Manual enejboerioNo ratings yet

- Eio0000002980 01Document16 pagesEio0000002980 01Junaid AhmadNo ratings yet

- l13892 Towerdryer Quadratouchpro PDFDocument192 pagesl13892 Towerdryer Quadratouchpro PDFKukuh Tak TergoyahkanNo ratings yet

- SIEMENS 33 KV GIS ManualDocument68 pagesSIEMENS 33 KV GIS ManualAnonymous kielG2No ratings yet

- Internal Memo: Hazrds and Unsafe Working ConditionsDocument4 pagesInternal Memo: Hazrds and Unsafe Working ConditionsAsad AwanNo ratings yet

- Safety in Chemical Process PlantsDocument5 pagesSafety in Chemical Process PlantsSrinivasan .MNo ratings yet

- Electrical Maintenance PDFDocument102 pagesElectrical Maintenance PDFsypultrazNo ratings yet

- Ag193 HBDocument22 pagesAg193 HBEduardo PradosNo ratings yet

- Maintop 2013 ReDocument20 pagesMaintop 2013 Reم.حسين العامريNo ratings yet

- Ethiopian TVET-System: Based On May 2011 Occupational StandardsDocument122 pagesEthiopian TVET-System: Based On May 2011 Occupational StandardsYalem Sew YigzawNo ratings yet

- General Series Overhead Crane: User ManualDocument31 pagesGeneral Series Overhead Crane: User ManualjokoNo ratings yet

- Zun SG320 Solar Pumps Inverter Operation ManualDocument70 pagesZun SG320 Solar Pumps Inverter Operation ManualKirollos ShenoudaNo ratings yet

- Eio0000003441 01Document16 pagesEio0000003441 01prasadNo ratings yet

- Notes 4Document12 pagesNotes 4moraine.hills3No ratings yet

- Chapter 5 SAFETY PROCEDURES AND METHODSDocument28 pagesChapter 5 SAFETY PROCEDURES AND METHODSMelchor CarabayasNo ratings yet

- LUM-HQL Cut Off ManulDocument26 pagesLUM-HQL Cut Off Manulmohamed kamalNo ratings yet

- NXC 3Document90 pagesNXC 3ABMOHENo ratings yet

- Engineering Health and SafetyDocument24 pagesEngineering Health and SafetyKobby BrineNo ratings yet

- Refrigeration and Air Conditioning Trade Safety For Construction, Service, and Maintenance Workers ForewordDocument34 pagesRefrigeration and Air Conditioning Trade Safety For Construction, Service, and Maintenance Workers ForewordParag ShrivastavaNo ratings yet

- Ww85k5410uw - DC68 03677F 03 PDFDocument56 pagesWw85k5410uw - DC68 03677F 03 PDFGeoffrey VillanuevaNo ratings yet

- Edited QuestionaireDocument11 pagesEdited QuestionaireTebeje TesfawNo ratings yet

- Chapter 1 & 2Document70 pagesChapter 1 & 2Tebeje TesfawNo ratings yet

- Chapter Four PDFDocument41 pagesChapter Four PDFTebeje TesfawNo ratings yet

- Chapter ThreeDocument52 pagesChapter ThreeTebeje TesfawNo ratings yet

- A Comparative Study of The Parental Encouragement Between Art and Science Senior Secondary Students in Relation To Their Academic AchievementDocument13 pagesA Comparative Study of The Parental Encouragement Between Art and Science Senior Secondary Students in Relation To Their Academic AchievementgurumurthalNo ratings yet

- Installation B-Box UkDocument3 pagesInstallation B-Box UkDOGYFERNo ratings yet

- Clinical Nutrition Manual SOFTY COPY SAMPLEDocument270 pagesClinical Nutrition Manual SOFTY COPY SAMPLEpauline mutisyaNo ratings yet

- Collection SystemDocument458 pagesCollection SystemRysllerNo ratings yet

- Chemistry Sba ProjectDocument10 pagesChemistry Sba Project4L Anisha SieudassNo ratings yet

- Presuasive SpeechDocument8 pagesPresuasive SpeechIdzaudin Razak100% (1)

- 2nd PU Chemistry 2014 PDFDocument2 pages2nd PU Chemistry 2014 PDFPrasad C M100% (4)

- Learners Voice SurveyDocument9 pagesLearners Voice SurveyNoel NicartNo ratings yet

- Abbrevation DescriptionDocument88 pagesAbbrevation DescriptionLakshmi ManasaNo ratings yet

- Kumpulan Pidato Bhs InggrisDocument18 pagesKumpulan Pidato Bhs InggrisHamada TaufikNo ratings yet

- Private Networks: Trends and AnalysisDocument5 pagesPrivate Networks: Trends and AnalysisSara MazzarellaNo ratings yet

- Blood Circulation and AnswersDocument2 pagesBlood Circulation and AnswersAyush SinghNo ratings yet

- Assignment 05-A On Chemical KineticsDocument3 pagesAssignment 05-A On Chemical KineticsHarshvardhan SinghNo ratings yet

- Details AliDocument1 pageDetails AliNadim SherifNo ratings yet

- Bittergourd 160718051100 PDFDocument21 pagesBittergourd 160718051100 PDFMahidargowdNo ratings yet

- Coffee (Kopiko Brown Coffee)Document4 pagesCoffee (Kopiko Brown Coffee)COngNo ratings yet

- Infection Control Tools-WhitepaperDocument3 pagesInfection Control Tools-Whitepaperapi-388173202No ratings yet

- Juvenile Justice and Welfare Law Implementation: The Philippine Urban Poor City CaseDocument7 pagesJuvenile Justice and Welfare Law Implementation: The Philippine Urban Poor City CaseShanen LimNo ratings yet

- Tle (Quarter 3) : NotesDocument1 pageTle (Quarter 3) : NotesRedj Zyrylle Garcia SaysonNo ratings yet

- Homework For Supply Chain ManagementDocument2 pagesHomework For Supply Chain ManagementNothing was0% (1)

- Adultery (Jari)Document7 pagesAdultery (Jari)Bidhan PoudyalNo ratings yet

- Evaluation of The Efficacy of Coriolus Versicolor Supplementation in HPV Lesions (LSIL)Document1 pageEvaluation of The Efficacy of Coriolus Versicolor Supplementation in HPV Lesions (LSIL)Abdulkadir SlocumNo ratings yet