Professional Documents

Culture Documents

AJI20020 Ajax Integral Engine Compressor DPC 2202 r0 Web

AJI20020 Ajax Integral Engine Compressor DPC 2202 r0 Web

Uploaded by

Mohamed Ashraf SolimanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AJI20020 Ajax Integral Engine Compressor DPC 2202 r0 Web

AJI20020 Ajax Integral Engine Compressor DPC 2202 r0 Web

Uploaded by

Mohamed Ashraf SolimanCopyright:

Available Formats

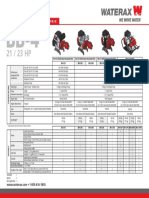

AJAX™ INTEGRAL

ENGINE-COMPRESSOR DPC-2202

296 bhp, 440 rpm

Overview

Robust, reliable Ajax engines have been manufactured in the United States longer than

any other OEM brand engines, with continuous innovations and technologies adding

compliance, strength and simplicity to the original design. The DPC-2202 integral engine

compressor is rated at 296 bhp and features a slow-speed, two-cycle engine design

that results in less wear and fewer moving parts. It offers greater reliability

and efficiency than high-speed separable units. As a result, operating costs are

substantially lower over the life of your equipment. Over 60 DPC-2202s have been

built. The DPC-2202 is the economic choice for a variety of applications, including

gas gathering, injection, processing, transmission, and fuel gas boosting.

Benefits Features

› Minimum maintenance › Integral crankshaft design

› Higher availability › Slow operating speed

› Higher resale value › Fewer moving parts

› Reduced parts stocking requirements › Technically current design

› Single source responsibility available › Low-cycle, low BMEP engine

› More gas compressed per BHP than › Larger valve area

high-speed separable units

› Higher mechanical efficiency

› Flexible

Model STD LE

No. of Cylinders 2 2

Power 296 bhp (221 kWb) 296 bhp (221 kWb)

Rated Speed 440 rpm 440 rpm

Bore & Stroke 13¼" × 16" (337 mm × 406 mm) 13¼" × 16" (337 mm × 406 mm)

Piston Displacement 4,412 in (72 l)

3

4,412 in3 (72 l)

BMEP 60.4 psi (4.2 bar) 60.4 psi (4.2 bar)

Piston Speed 1,173 ft/min (6 m/s) 1,173 ft/min (6 m/s)

Legends don’t stop. We make sure of it.™

CALL +1 855-2COOPER

24/7 TECH SUPPORT: SUPPORT@COOPERSERVICES.COM

Cooperservices.com

Model STD LE

Fuel Gas System 1

Fuel pressure range 150 psi (10.3 bar) 150 psi (10.3 bar)

Exhaust System 2

Exhaust Temperature 470°F (243°C) 470°F (243°C)

Exhaust Flow 93 lb/min (42 kg/min) 93 lb/min (42 kg/min)

Cooling Water System

Capacity 25 gal (95 l) 25 gal (95 l)

Lube Oil System 3

Capacity 25 gal (95 l) 25 gal (95 l)

Consumption 5.0 pints/day (2.3 l/day) 5.0 pints/day (2.3 l/day)

Crankcase Makeup 2.54 pints/day (1.2 l/day) 2.54 pints/day (1.2 l/day)

Brake Specific Fuel Consumption

100% Load (LHV) 8,000 Btu/bhp-hr (11,319 kJ/kWh) 7,800 Btu/bhp-hr (11,036 kJ/kWh)

Engine Emissions 2

NOx 10 g/bhp-hr 2 g/bhp-hr

CO 1.3 g/bhp-hr 1.4 g/bhp-hr

NMHC 0.6 g/bhp-hr 0.6 g/bhp-hr

VOC 0.5 g/bhp-hr 0.5 g/bhp-hr

Formaldehyde 0.3 g/bhp-hr 0.3 g/bhp-hr

CO2 470 g/bhp-hr 458 g/bhp-hr

Compressor Specifications

No. of Throws 2 2

Stroke 11" (279 mm) 11" (279 mm)

Piston Speed 807 ft/min (4 m/s) 807 ft/min (4 m/s)

Rod Load 33,000 lb (147 kN) 33,000 lb (147 kN)

Rod Diameter 2.5" (64 mm) 2.5" (64 mm)

Crankshaft Centerline 20" (508 mm) 20" (508 mm)

Dry Weight

Frame Weight 18,500 lb (8,391 kg) 18,500 lb (8,391 kg)

Dimensions

Frame Length 163" (4,140 mm) 163" (4,140 mm)

Frame Width 91" (2,311 mm) 91" (2,311 mm)

Frame Height 59" (1,499 mm) 59" (1,499 mm)

Stack Diameter 12" (305 mm) 12" (305 mm)

Stack Height 190" (4,826 mm) 190" (4,826 mm)

Flywheel

Outside Diameter 48" (1,219 mm) 48" (1,219 mm)

Weight 2,200 lb (998 kg) 2,200 lb (998 kg)

1

Fuel Gas System pressure noted is maximum pressure at customer connection

2

Exhaust and Emissions noted based on: PLQNG, 1500 FASL Elevation, 65°F ambient temperature for STD and LE

3

Lube Oil System consumption rates based on full load and full speed operation. Values do not indicate break-in consumption rates.

Legends don’t stop. We make sure of it.™

CALL +1 855-2COOPER

24/7 TECH SUPPORT: SUPPORT@COOPERSERVICES.COM

Cooperservices.com

© 2023 Cooper Machinery Services LLC – All rights reserved. AJI20020 11/2023

Cooper Machinery Services LLC reserves the right to make changes or updates to any specifications and features shown herein to the products or services described at any time without notice or

obligation. Contact your Cooper Machinery Services representative for the most current information. The Cooper and AJAX logos and tagline are trademarks of Cooper Machinery Services LLC.

You might also like

- LPTRP FinalDocument96 pagesLPTRP FinalJoelNo ratings yet

- Ficha Técnica Ajax DPC-2802LEDocument2 pagesFicha Técnica Ajax DPC-2802LEJUAN CARLOS velazquez hernandez100% (1)

- CAT 561 Pipe LayerDocument4 pagesCAT 561 Pipe LayerAadityaa PawarNo ratings yet

- Daewoo Excavadora Hidráulica SOLAR 130W-VDocument8 pagesDaewoo Excavadora Hidráulica SOLAR 130W-VMaquinza100% (3)

- Credit Card Tracking SheetDocument2 pagesCredit Card Tracking SheetMohamed Ashraf SolimanNo ratings yet

- Welding Booth Layout DrawingDocument1 pageWelding Booth Layout DrawingJavier GutierrezNo ratings yet

- AJI20020 Ajax Integral Engine Compressor DPC 2202 r0 WebDocument2 pagesAJI20020 Ajax Integral Engine Compressor DPC 2202 r0 WebJavier TisalemaNo ratings yet

- Ajax Integral Engine-Compressor Dpc-2803: Legends Don't Stop. We Make Sure of ItDocument2 pagesAjax Integral Engine-Compressor Dpc-2803: Legends Don't Stop. We Make Sure of ItSebei ChakibNo ratings yet

- AJI20021 Ajax Integral Engine Compressor DPC 2801 r0 WEBDocument2 pagesAJI20021 Ajax Integral Engine Compressor DPC 2801 r0 WEBMohamed Ashraf SolimanNo ratings yet

- AJI20024 Ajax Integral Engine Compressor DPC 2804 r0 WebDocument2 pagesAJI20024 Ajax Integral Engine Compressor DPC 2804 r0 WebfsajnmasNo ratings yet

- 01 DPC 2802 - DatasheetDocument2 pages01 DPC 2802 - DatasheetJusril HidayatNo ratings yet

- Ajax DPC-2802 PDFDocument2 pagesAjax DPC-2802 PDFdvcher78No ratings yet

- Ajax Integral Engine-Compressor DPC-2804: 800-845 BHP 440 RPMDocument2 pagesAjax Integral Engine-Compressor DPC-2804: 800-845 BHP 440 RPMRafael ZuritaNo ratings yet

- Ajax Integral Engine-Compressor DPC-2201: 148 BHP 440 RPMDocument2 pagesAjax Integral Engine-Compressor DPC-2201: 148 BHP 440 RPMAlexNo ratings yet

- EU - AX29u-52u-5 08 03 11 Small LeafletDocument2 pagesEU - AX29u-52u-5 08 03 11 Small LeafletYakupovmmNo ratings yet

- Sección 1 Especificación PV271-275Document1 pageSección 1 Especificación PV271-275Luis RuizNo ratings yet

- Caterpillar 2015Document2 pagesCaterpillar 2015adahilquispechNo ratings yet

- Expert Solutions From The Laundry Experts: 120 LB (54.4 KG) Tumbler 170 LB (77.1 KG) TumblerDocument4 pagesExpert Solutions From The Laundry Experts: 120 LB (54.4 KG) Tumbler 170 LB (77.1 KG) TumbleryousrykNo ratings yet

- Technical Specifications: Hydraulic ExcavatorDocument12 pagesTechnical Specifications: Hydraulic ExcavatorArvind HarryNo ratings yet

- Drilling Depth GuidelinesDocument7 pagesDrilling Depth GuidelinesPeter LeanoNo ratings yet

- ZX 350 LCDocument8 pagesZX 350 LCRaynaldiSaputra100% (1)

- 336 GC SpecsDocument18 pages336 GC Specsyankyawoo.tgoNo ratings yet

- 2-8 Especificaciones Mayores ComponentesDocument4 pages2-8 Especificaciones Mayores ComponentesJorge RojasNo ratings yet

- Product Selection Matrix: Approximated and Varies Based Off Option SelectionsDocument1 pageProduct Selection Matrix: Approximated and Varies Based Off Option SelectionsWalter Dario LopezNo ratings yet

- Kitfox2 Owners ManualDocument19 pagesKitfox2 Owners ManualNofriagara Davit HarnawanNo ratings yet

- 4-1200 NOV ALS PCP Line CardDocument2 pages4-1200 NOV ALS PCP Line CardKesley Gleidson do Nascimento Gomes MeloNo ratings yet

- CAT 950H Spec LoaderDocument9 pagesCAT 950H Spec Loaderjeremih alhegnNo ratings yet

- Technical Specifications: Hydraulic ExcavatorDocument18 pagesTechnical Specifications: Hydraulic ExcavatorFelipe Pisklevits LaubeNo ratings yet

- CAT 320 SpecsDocument23 pagesCAT 320 SpecsFelipe Pisklevits LaubeNo ratings yet

- MFWD Tractors: 190 To 220 HPDocument2 pagesMFWD Tractors: 190 To 220 HPSergey TyaskoNo ratings yet

- ZX670LC-5 Specs PDFDocument12 pagesZX670LC-5 Specs PDFRobert Thomas OppermanNo ratings yet

- FeaturesDocument1 pageFeaturesSherwin BenschopNo ratings yet

- Caterpillar Performance Handbook 49 62020 Partie86Document4 pagesCaterpillar Performance Handbook 49 62020 Partie86ali alilouNo ratings yet

- 323d3 Cat Eng Ficha Tecnica - RemovedDocument10 pages323d3 Cat Eng Ficha Tecnica - RemovedVlyn GallardoNo ratings yet

- Hydraulic System Engine: Meets The Following StandardsDocument3 pagesHydraulic System Engine: Meets The Following StandardsAsri GenisaNo ratings yet

- CX210B-LR SS Cce2140701rDocument6 pagesCX210B-LR SS Cce2140701rricardo.leandichoNo ratings yet

- Versatile MFWD - ROW CROP TRACTOR 265 - 295 - 315Document2 pagesVersatile MFWD - ROW CROP TRACTOR 265 - 295 - 315Patrik GubinaNo ratings yet

- 72 KW (97 HP) : Utility-Class ExcavatorsDocument8 pages72 KW (97 HP) : Utility-Class Excavatorsmarisal efendiNo ratings yet

- 320DRR 320DLRR PDFDocument9 pages320DRR 320DLRR PDFALEXANDRANo ratings yet

- Downloaded From Manuals Search EngineDocument48 pagesDownloaded From Manuals Search Enginebal3_huNo ratings yet

- 9851 3430 01 - L PDFDocument4 pages9851 3430 01 - L PDFDiego Egoávil MéndezNo ratings yet

- FFCDocument2 pagesFFCCesar ZarateNo ratings yet

- RAM Data Book-1Document10 pagesRAM Data Book-1charly cruzNo ratings yet

- Ultraviolet Water Disinfection Systems: From VIQUADocument2 pagesUltraviolet Water Disinfection Systems: From VIQUAWendy LopezNo ratings yet

- Wacker Neuson - RD7-HS Double Drum Vibratory RollerDocument2 pagesWacker Neuson - RD7-HS Double Drum Vibratory RollerMolie1979No ratings yet

- Caterpillar Performance Handbook 49 62020 Partie85Document4 pagesCaterpillar Performance Handbook 49 62020 Partie85ali alilouNo ratings yet

- Technical Specifications: Hydraulic ExcavatorDocument21 pagesTechnical Specifications: Hydraulic ExcavatorArvind HarryNo ratings yet

- SPTM Specifications MinDocument1 pageSPTM Specifications MinJonathan Guzmán MendozaNo ratings yet

- 06 (1) Vol de Ran MedDocument7 pages06 (1) Vol de Ran MedLhau009No ratings yet

- CAT - Excavadora - Orugas - 325C LCR - EnglishDocument8 pagesCAT - Excavadora - Orugas - 325C LCR - EnglishTcristomoradoNo ratings yet

- Reverse Osmosis withCCRO TechnologyDocument3 pagesReverse Osmosis withCCRO TechnologyAsad RazaNo ratings yet

- Max Flow: 100 GPM (379 LPM) : SP80/90 Spin-On Filters Working Pressures To: Rated Static Burst To: Flow Range ToDocument4 pagesMax Flow: 100 GPM (379 LPM) : SP80/90 Spin-On Filters Working Pressures To: Rated Static Burst To: Flow Range Tofrancis_15inNo ratings yet

- CAT 313F SpecificationsDocument19 pagesCAT 313F Specificationsmossamorris100% (1)

- Rotary Drilling Rig: Base Carrier BH 70 BH 70Document12 pagesRotary Drilling Rig: Base Carrier BH 70 BH 70Vistash Buhary50% (2)

- 308 Diesel-Loader-Catalog en Web 20230807Document16 pages308 Diesel-Loader-Catalog en Web 20230807Roberto RojasNo ratings yet

- Cat 312c Spec SheetDocument4 pagesCat 312c Spec SheetKhalid ElseamitNo ratings yet

- Drilling Depth GuidelinesDocument8 pagesDrilling Depth GuidelinesPeter LeanoNo ratings yet

- BXR SeriesDocument2 pagesBXR Seriesaaron mufukNo ratings yet

- Excavadora Hidraulica CLG908DDocument2 pagesExcavadora Hidraulica CLG908DJames Ernest Garcia100% (1)

- Cat 330Document14 pagesCat 330Juan MercadoNo ratings yet

- Dieci Zeus 33.11 35.10 & 40.7 Spec SheetDocument4 pagesDieci Zeus 33.11 35.10 & 40.7 Spec SheetNash ServiceNo ratings yet

- 25stg 862-18000-XA Shell Units New Curve 50HZ 100psiDocument2 pages25stg 862-18000-XA Shell Units New Curve 50HZ 100psiMohamed Ashraf SolimanNo ratings yet

- RF-AVG Assembly InstructionsDocument1 pageRF-AVG Assembly InstructionsMohamed Ashraf SolimanNo ratings yet

- AJI20021 Ajax Integral Engine Compressor DPC 2801 r0 WEBDocument2 pagesAJI20021 Ajax Integral Engine Compressor DPC 2801 r0 WEBMohamed Ashraf SolimanNo ratings yet

- Guardian Anytime App InstructionsDocument1 pageGuardian Anytime App InstructionsMohamed Ashraf SolimanNo ratings yet

- Bloodborne Pathogen PolicyDocument13 pagesBloodborne Pathogen PolicyMohamed Ashraf SolimanNo ratings yet

- Ajax Product Overview PT (Apr2024)Document1 pageAjax Product Overview PT (Apr2024)Mohamed Ashraf SolimanNo ratings yet

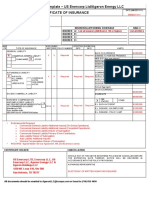

- Sample COI Template - US Enercorp Ltd/Ageron Energy LLC Certificate of InsuranceDocument1 pageSample COI Template - US Enercorp Ltd/Ageron Energy LLC Certificate of InsuranceMohamed Ashraf SolimanNo ratings yet

- Operation Guide 3464: © 2018 Casio Computer Co., LTDDocument22 pagesOperation Guide 3464: © 2018 Casio Computer Co., LTDaaNo ratings yet

- Installation Drawing: Caliper SpecificationDocument2 pagesInstallation Drawing: Caliper SpecificationJlNo ratings yet

- Aman Graphics & Design LTDDocument42 pagesAman Graphics & Design LTDEngineering Ked SolutionNo ratings yet

- Summative Test in Science: I. Direction: Read The Questions Carefully. Choose The Letter of The Correct AnswerDocument3 pagesSummative Test in Science: I. Direction: Read The Questions Carefully. Choose The Letter of The Correct Answergener r. rodelasNo ratings yet

- Gas Testing COURSE NOTESDocument83 pagesGas Testing COURSE NOTEStahermoh100% (1)

- Intentions Design and Outcomes Reflectio PDFDocument9 pagesIntentions Design and Outcomes Reflectio PDFGaurav PatilNo ratings yet

- Treasures of The DeepDocument2 pagesTreasures of The DeepMaikah Richport50% (2)

- Dement and Kleitman EvaluationDocument1 pageDement and Kleitman EvaluationYashal NadeemNo ratings yet

- Activity 2 Formulating HypothesisDocument1 pageActivity 2 Formulating HypothesisJezreel PalmesNo ratings yet

- A Homemade Wood Gasifier To Keep You With Power AfDocument13 pagesA Homemade Wood Gasifier To Keep You With Power AfrobobbobNo ratings yet

- E. H. Gombrich - Art and Illusion (1984, Princeton Univ PR) - Libgen - lc-7 PDFDocument15 pagesE. H. Gombrich - Art and Illusion (1984, Princeton Univ PR) - Libgen - lc-7 PDFYes Romo QuispeNo ratings yet

- 1 ArtsDocument30 pages1 ArtsAyush PataliyaNo ratings yet

- Lab3 PDFDocument6 pagesLab3 PDFSELVAKUMAR RBNo ratings yet

- Government of Assam: Case Study of Flagship PPP ProjectDocument4 pagesGovernment of Assam: Case Study of Flagship PPP ProjectChothe SaeeNo ratings yet

- General Knowledge Quiz ComparativesDocument1 pageGeneral Knowledge Quiz ComparativesdanisgarcNo ratings yet

- Sverdlovsk-4 Manual (English Version 2008)Document24 pagesSverdlovsk-4 Manual (English Version 2008)algebrayfuegoNo ratings yet

- Aws B1.11 Guide For Visual Inspection of WeldDocument45 pagesAws B1.11 Guide For Visual Inspection of WeldYasser Hammad MohamedNo ratings yet

- Sullivan Ford Auto World Case AnalysisDocument1 pageSullivan Ford Auto World Case AnalysisWalter Insigne100% (1)

- 2018 Book VocationalTeacherEducationInCe PDFDocument217 pages2018 Book VocationalTeacherEducationInCe PDFBenjamin IletoNo ratings yet

- Power Systems by BakshiDocument11 pagesPower Systems by BakshiYash DeoliaNo ratings yet

- 2017 18 Multi MediaDocument101 pages2017 18 Multi MediaPuskesmas BatujajarNo ratings yet

- Challenges Faced by Junior High School Students in The Study of Araling Panlipunan and Its Impactto Their Academic Performance: A Foundation For Intervention InitiativesDocument33 pagesChallenges Faced by Junior High School Students in The Study of Araling Panlipunan and Its Impactto Their Academic Performance: A Foundation For Intervention InitiativesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Annex 1 - Template About MeDocument5 pagesAnnex 1 - Template About MeMari VjaNo ratings yet

- Lesson Plan Daily Commerce PD Form 5Document6 pagesLesson Plan Daily Commerce PD Form 5Sweetie Pinkie100% (1)

- NamesDocument57 pagesNamesKarimatu Mansur BelloNo ratings yet

- Emacs Verilog ModeDocument19 pagesEmacs Verilog ModeMostafa KhairyNo ratings yet

- Shamsudin 2021 J. Phys. Conf. Ser. 2129 012021Document14 pagesShamsudin 2021 J. Phys. Conf. Ser. 2129 012021dlc352-sc1No ratings yet

- Statics Module 14Document10 pagesStatics Module 14pppaaarrrcccooo RRMPNo ratings yet