Professional Documents

Culture Documents

Old Procedure

Old Procedure

Uploaded by

Hammad Khan0 ratings0% found this document useful (0 votes)

4 views8 pagesOld Procedure

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentOld Procedure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views8 pagesOld Procedure

Old Procedure

Uploaded by

Hammad KhanOld Procedure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

ICI PAKISTAN LTD.

SODA ASH BUSINESS SA HSE P-19.13.01

Page 1 of 7

CONTROLLED EQUIPMENT

Written/Updated By | Syed Abid Mehdi

Project & Development

Manager

We 4

S| qo

| Signature with Date

Reviewed By | Adeel Hassan

Maintenance Manager Power

Services

Signature with Date

Farooq Sharif

HSE & Training Manager be bed

Ahir

Signature with Date

‘Muhammad Saeed Anwar

Manager Power Services cs

(Operations) ae Tff2h

Signature with Date |

Tee za ‘

Engineering Manager as

ee

ature with Date

Muhammad Umer Mustaq

| Works Manager

ol

Signature ih Date

‘Approved By Muhammad Abid Ganatra

| Vice President

a

e, ICI PAKISTAN LTD.

SODA ASH BUSINESS SA HSE P-19.13.01

Page 2 of 8

CONTROLLED EQUIPMENT

1 PURPOSE

To define responsibilities and essential requirements for sustained safe operations

through the implementation of Controlled Equipment programs at ICI Pakistan Soda

‘Ash Works.

SCOPE

‘This procedure is based upon principles established in ICI Pakistan HSE&S CG 19.13;

it supports the ICI Pakistan HSE&S Standard that requires safe systems of work for the

design, installation, operation, maintenance and integrity of equipment. This guideline

identifies the HSE principles required to be incorporated into management systems and

procedures to ensure integrity of controlled equipment. it applies to new, reused,

modified and existing equipment at ICI Pakistan Limited, Soda Ash Works, Khewra.

DEFINITIONS,

3.4 Controlled Equipment

Equipment that should be given special attention because of legislative or company

HSE&S reasons for purposes of ensuring integrity.

3.2. Competent Person(s)

Person(s) having demonstrable ability in terms of qualities, skills, experience, and

training to consistently carry out specific work activities to a defined standard,

3.3 Responsible Executive

The Responsible Executive is the person identified by the Business, Region or Group

Department as having the following responsibilities that are included in each Group

Engineering Procedure:

(@) Ensuring that local engineering procedures are provided in accordance with the

Group Engineering Procedure, and that they are implemented

(b) Approval, in consultation with the IC Group Engineering Manager (or nominee), of

the appointment of Responsible Engineers and other key individuals required by the

Group Engineering Procedure; (See Group Engineering Manager)

(©) Ensuring that staff with the required competence are appointed in wri

(d) Ensuring that systems for GEP compliance audits are established.

In case of PE, this role is assigned to Business V.P.

3.4 Responsible Engineer

The responsibilities of the Responsible Engineer are specified in Group Engineering

we Ox

- ICI PAKISTAN LTD.

SODA ASH BUSINESS SAHSE P-19.13.01

Page 3 of 8

CONTROLLED EQUIPMENT

Procedures. Itis essential that the individual has both the competence and the authority

to fulfl the accountabilities. On appointment the Responsible Engineer shall carefully

consider such factors and refer any concems to the Responsible Executive and, if

necessary, the ICI Group Engineering Manager.

‘The Responsible Engineer is responsible for ensuring the appointment of the

‘appropriate key individuals for the production unit/facilty

3.5 Operations Manager

Operating Manager is a person responsible for the management of a production unit or

facility. The responsibilities of the Operating Manager are specified in Group

Engineering Procedures. Itis essential that the individual has both the competence and

the authority to fulfil the accountabilities. On appointment, the Operating Manager shall

carefully consider such factors and refer any concerns to the Responsible Executive.

‘The Operating Manager is responsible for the appointment of the appropriate key

individuals for the production unitfacilty

3.6 Registration

Registration means identifying each Controlled Equipment, allocating and marking such

systems with a unique identitication number and assembling key information in a system

of equipment files.

3.7 Unacceptable Situation

‘An unacceptable situation is one resulting in one or more of:

2) Harm or serious nuisance to public

b) Serious harm to public on site

©) Serious harm to the environment

4 REQUIREMENTS AND RESPONSIBILITIES,

44, REQUIREMENTS

a. The following should be identified as controlled equipment:

(1) Electrical Safety (see GEP 2) (as categorized in CG 19.15);

54 86

Q ICI PAKISTAN LTD.

‘SODA ASH BUSINESS SAHSE P-19.13.01

Page 4 of 8

CONTROLLED EQUIPMENT

(2) Lifting equipment (e.g. hoists, cranes) (see GEP 9);

(3) Machine guarding (including robots and automatic guided vehicles and

interlocks to prevent injury by machinery);

(4) Fixed and portable gas detectors;

(8) Temporary access equipment or structures (e.g. ladders, scaffold, mobile

work platforms).

b. The following additional equipment should also be assessed as a minimum:

(1) Portable power tools;

(2) Emergency equipment;

(3) Equipment whose operation is key to SHE performance (e.g. local

exhaust ventilation, vent gas analyzers, dust filters, PPE).

. Registration of all equipment (as mentioned in “a” above as Controlled Equipment)

d. Assessment of equipment (as mentioned in "b” above for registration / listing /

identification as Controlled Equipment)

e. Formal review process for all isted Controlled Equipment.

f. Implementation of a registration, periodic inspection regime for all listed controlled

equipment.

9. A documentation file to be maintained for all listed controlled equipment.

fh. Trained competent resource to implement above requirements.

i, All Controlled Equipment to be operated within design limits,

i. No Controlled Equipment to be operated beyond inspection due date without

appropriate approval by competent authority,

4.2, RESPONSIBILITIES

4.2.1. Vice President as Responsible Executive shall have an overall responsibility to

ensure that requirements of this procedure are implémented in Soda Ash

Business. He shall make available necessaty resources and make

, 4 86

. ICI PAKISTAN LTD.

SODA ASH BUSINESS SA HSE P-19.13.01

Page 5 of 8

CONTROLLED EQUIPMENT

the appointments of Responsible Engineer, Operating Manager and Project

‘Manager in writing

4.2.2. The Responsible Engineer shall ensure that:

a. A formal review procedure is applied to those items assessed as controlled

equipment to ensure that:

(1) The appropriate design standards and construction materials are used,

and

(2) To establish the safe design, working limits and protective systems for

the control of hazards,

No modifications or re-rating of controlled equipment should be carried

cut without the approval of the competent person and should include the

appropriate documentation.

b. Planned and preventative maintenance schedules are defined,

©. Periodic inspection frequencies and inspection requirements are defined

d. All controlled equipment is inspected as per defined frequency, calibrated

against defined criteria. The inspection and any work done should be recorded

The inspection status should be made visible to users (e.g. use of colour coding

or labels).

e. Adocumentation file for each item or groups of items, of controlled equipment is

established and maintained

{Personnel employed in the use, maintenance, repair, examination of controlled

equipment is competent by virtue of having the appropriate knowledge, training

and experience.

g. Equipment is kept secure when not in use,

h. Any required local procedures are in place to implement the requirements of this

procedure.

4.2.3, The Operating Managers (respective plant managers) shall ensure that:

a. Controlled equipment are operated and maintained so as to stay within its

design limits.

fh ve

be ICI PAKISTAN LTD.

SODA ASH BUSINESS SAHSE P-19.13.01

Page 6 of 8

CONTROLLED EQUIPMENT

b. NO controlled equipment is operated beyond its specified "Next Inspection Due

Date" without prior approval from Responsible Executive.

c. Persons using controlled equipment are competent by virtue of having the

appropriate experience, training and experience.

4.2.4. For new projects, the Project Manager shall ensure that identification /

assessment of equipment for registration as Controlled Equipment is carried out

as specified in this procedure.

4.2.8. The Commissioning Manager is responsible for ensuring that the controlled

‘equipment is checked and its installation complies with the design intent prior to

‘commissioning,

DOCUMENTATION

List of Controlled Equipment Appendix |

List of Responsible Persons Appendix I

COMMUNICATION & TRAINING

The requirements of this procedure shall be communicated to all concerned.

Training shall be carried out for all concemed managers and staff and documented.

REFERENCE

ICI Pakistan HSE&S CG 19.13 Controlled Equipment

AMMENDMENTS

This is 2° issue as per ICI Pakistan HSE&S CG-19.13.

we 156

° ICI PAKISTAN LTD.

SODA ASH BUSINESS SA HSE P-19.13.01

Page 7 of 8

CONTROLLED EQUIPMENT

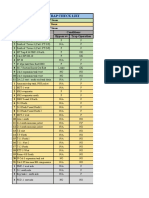

APPENDIX |

LIST OF CONTROLLED EQUIPMENT

‘Sr Title Unique Identification # ‘Area / Location

ge are

+, ICI PAKISTAN LTD.

SODA ASH BUSINESS. SA HSE P-19.13.01

Page 8 of 8

CONTROLLED EQUIPMENT

APPENDIX II

LIST OF RESPONSIBLE PERSONS

Responsible Engineer

[een

1 Electrical Safety QaB

2 instrumented Protective System AB

3__[GEP-14.4 | Pressure System AH

4 [ce-14.5 | critical Machine System AH

S| GeP-14.6 | Hazard studies MYA

| 6 | GeP-14.7 | Plant Structures & Pipe Bridges AR

7 | GkP-14.8 | Ground & Ground Water Protection MYA

8 _[GEP-14.9 [Lifting Equipment AR

9 | GEP-14.10 | HSERS Aspects of Project Equipment UA

10 _| Gep-14.11 | Transport Containers and Loading & off Loading Terminates | HK

a1 | GeP-14.12 [Fire Safety Fs

12 | GeP-14.13 | Work Equipment Guarding & Interlock HK

Operating Managers

Plant °A’ RMAJ

Plant “B/C” AS.

Power Services MSA

Project Managers

To be nominated as and when required

ys £6

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- My Learning Train World Around Me: BookDocument4 pagesMy Learning Train World Around Me: BookHammad KhanNo ratings yet

- 1 Term Block Syllabus: Science PrepDocument4 pages1 Term Block Syllabus: Science PrepHammad KhanNo ratings yet

- WSK Science Prep W2Document2 pagesWSK Science Prep W2Hammad KhanNo ratings yet

- WSK Music PrepDocument2 pagesWSK Music PrepHammad KhanNo ratings yet

- 1 Term Block Syllabus: 24 March 2020 - 13 Sep 2020Document5 pages1 Term Block Syllabus: 24 March 2020 - 13 Sep 2020Hammad KhanNo ratings yet

- Winnington School Khewra: Weekly Homework ScheduleDocument8 pagesWinnington School Khewra: Weekly Homework ScheduleHammad KhanNo ratings yet

- 3/B Canal Bank Extension Mughalpura Hammad Khan: Declaration Acknowledgement Slip Name: AddressDocument4 pages3/B Canal Bank Extension Mughalpura Hammad Khan: Declaration Acknowledgement Slip Name: AddressHammad KhanNo ratings yet

- Winnington School Khewra: Grade: PrepDocument3 pagesWinnington School Khewra: Grade: PrepHammad KhanNo ratings yet

- WSK Music PrepDocument2 pagesWSK Music PrepHammad KhanNo ratings yet

- Klinger Graphite Laminate PSM: Key Features: BenefitsDocument2 pagesKlinger Graphite Laminate PSM: Key Features: BenefitsHammad KhanNo ratings yet

- Corolla Brochure Combined PDFDocument8 pagesCorolla Brochure Combined PDFHammad KhanNo ratings yet

- Steam Trap Check List: # Locations Conditions Bypass VV Trap OperationDocument4 pagesSteam Trap Check List: # Locations Conditions Bypass VV Trap OperationHammad KhanNo ratings yet