Professional Documents

Culture Documents

BR GT Gasturbine

Uploaded by

SergeievOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BR GT Gasturbine

Uploaded by

SergeievCopyright:

Available Formats

Turbine GAS

INLET AIR FOGGING

Me e F o g

S Y S T E MS

w w w. m e e f o g . c o m

phone 1.626.359.4550

Mee Industries Inc., Corporate Headquarters

Gas Turbine Products Division

16021 Adelante St., Irwindale, California 91702, USA

Telephone: 1.626.359.4550

Fax: 1.626.359.4660

Website: www.meefog.com

To learn how MeeFog systems can increase your profitability contact:

Mee Industries Inc. is a high technology corporation with

a demonstrated history of providing innovative, cost-

effective fog solutions for applications including gas

turbine inlet air cooling. In 1969, Thomas Mee Jr., a former

Cornell University research scientist, founded the company

that also specializes in fog solutions for industrial

humidification, outdoor air conditioning, greenhouse climate

control, wine barrel humidification, and special effects.

MeeFog turnkey solutions include carefully engineered,

high quality, integrated packages delivering an outstanding

combination of price and performance. Our products are

backed by Mee Industries experienced technical staff of

employees which includes leading researchers, project

managers and engineers, and production and installation

specialists. An active research & development group

guarantees that Mee Industries maintains its fog system

market and technology lead. Mee Industries is an ISO 9001

certified corporation and manufactures components to meet

UL or CE requirements.

Mee Industries is a privately held company with corporate

headquarters in Irwindale, California.

MEE INDUSTRIES

CORPORATE PROFILE

Simply the worlds most cost-effective gas turbine power augmentation system.

GAS TURBINE PRODUCTS DIVISION

Copyright 2009 by Mee Industries Inc. All Rights Reserved.

Initiating the Fog Revolution

1

Gas Turbine

The MeeFog

ConceptElegant IdeaDramatic Results

2

Mee Industries Inc. pioneered the gas turbine inlet fogging

concept with its first MeeFog installation in 1989. Today

Mee is the world market leader in inlet fogging installations.

The strong interest in fog cooling is based on the fact that

gas turbine power drops with increasing ambient

temperatures and the MeeFog system is simply the

worlds most cost-effective augmentation technology com-

pared to other options such as refrigeration or traditional

evaporative media cooling systems. Mee Industries revolu-

tionized the gas turbine power augmentation industry and

the company remains the market leader today having over

750 installations on gas turbines ranging from 5 to 250 MW.

Mee Industries commitment to an aggressive research &

development program and engineering excellence ensures

delivery of top value to its customers.

A system of high-pressure pumps pressurizes demineralized

water, which flows through a network of stainless steel

tubes to the MeeFog nozzles located in the gas turbine

inlet duct. Each proprietary MeeFog nozzle atomizes the

water into trillions of ultra-fine fog droplets per second. Due

to its large evaporative surface area and the small droplet

size, the fog evaporates, cooling the inlet air and providing a

cost-effective power boost. The self-contained MeeFog

skid comes complete with a programmable logic controller

(PLC) control system.

The high-pressure MeeFog skid is reliable and

carefully engineered. MeeFog skids have been

supplied to several major utilities and GT OEMs

with a large number of repeat orders. Installations

can be done with only a 1-2 day outage.

Trillions of microfine droplets evaporate and cool the inlet air every second. This revolution-

ary approach, pioneered by Mee Industries in 1989, is today the fastest growing inlet cooling

technology on the market.

MARKET INNOVATOR AND LEADER

OVER 750 GAS TURBINE INSTALLATIONS

Turnkey installation at a 600 MW combined cycle power

plant. This project involved six MeeFog skids and the

turnkey installation of 2.5 km of high-pressure tubing, fog

system commissioning, and start-up.

Ambient Temperature, C

The significant loss in gas turbine power and worsening of heat rate can be mitigat-

ed by the MeeFog system which lowers the ambient temperature by direct fog

cooling in the gas turbine inlet duct.

5 14 23 32 41 50 59F 68 77 85 95 104

115%

110%

105%

100%

95%

90%

85%

80%

-15 -10 -5 0 5 10 15 20 25 30 35 40

Heat Rate

Effects of Ambient Temperature - Typical Heavy-duty GT

Air Flow

Power

Discover MeeFog

Benefits

Gas Turbine

Increased output by up to 20%.

Improved heat rate up to 5%.

Reduces NOx emissions up to 30%.

Field tested and proven technologyover 750 installations.

Lowest capital, installation, and O&M costs compared to other

cooling technologies; on the order of $20-$40 per incremental kW.

Approaches 100% saturation with low inlet pressure drop.

100% evaporation efficiency if required.

Easy retrofit, only 1-2 day outage.

Fog intercooling possible.

Greater profitability and fast payback.

Delay capital expenditure by increasing existing generating capacity.

Fog boost during peak hours will not cause parasitic inlet

pressure losses in remaining hours of operation.

3 4

Gas Turbine

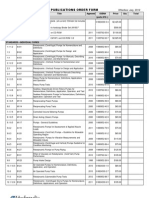

Model

ISO Output

kW

Water Fog

Flow

Alstom GT 8C

Alstom GT 11N

GE 7111EA

GE 7221 FA

GE 9171E

52600 41061

70013

69533

128621

102777

12.1

21.7

20.2

29.0

28.1

W

A

T

E

R

a

n

d

P

O

W

E

R

R

E

Q

U

I

R

E

M

E

N

T

S

Saturation

GE LM2500+PK

GE LM6000PA

Solar Mars

W501 D5

83880

84920

161650

126206

27017

41020

10685

109307

19001

25310

8443

88153

5.5

8.0

2.8

25.0

4919

4907

5500

11377

8669

3916

8165

1083

7845

Power

Increase

%

12.0

7.0

7.9

8.8

8.4

20.6

32.3

9.0

12.8

Table showing typical water consumption for 20F (11C) of inlet cooling with typical gas turbine

power increases attainable. Actual numbers are site specific. A detailed analysis can be pro-

vided by Mee Industries for your application.

NUMEROUS BENEFITS

P

e

r

c

e

n

t

P

o

w

e

r

I

n

c

r

e

a

s

e

Amount of Fog Cooling

10F 15F 25F 20F 30F 35F

0%

5%

10%

15%

20%

Aeroderivative

(Simple Cycle)

Older Industrial

(Simple Cycle)

Newer Industrial

(Simple Cycle)

Older Industrial

(Combined Cycle)

P

O

W

E

R

B

O

O

S

T

f

o

r

V

A

R

I

O

U

S

T

U

R

B

I

N

E

S

MeeFog cooling power boost for various types of gas

turbines and cycles. MeeFog systems have been

applied to turbines up to 250 MW in size, both base load

and peaking units.

The MeeFog

ConceptElegant IdeaDramatic Results

MeeFog array for a frame 7FA gas turbine.

Superior construction and materials ensure no

possibility of FOD. All MeeFog arrays are

carefully evaluated for rigidity and analyzed for

vortex shedding frequencies. The location of

the array may be optimized by inlet duct

Computational fluid dynamics (CFD) studies.

The pressure drop across the nozzle array is

almost zero.

R

e

l

a

t

i

v

e

H

u

m

i

d

i

t

y

8:00 10:00 14:00 12:00 16:00 18:00

65F

70F

75F

80F

85F

Power drop coincides with hot summer afternoons in humid areas

when coincident relative humidity is low allowing the MeeFog sys-

tem to be very effective in boosting power when it is most needed.

Power increases of up to 10% can be attained by cooling to wet

bulb. Many of the over 750 MeeFog installations are located in so

called high humidity areas.

90F

95F

30%

40%

50%

60%

70%

80%

90%

Evaporative Cooling

Potential 16F (9C)

Dry Bulb Temp.

Relative

Wet Bulb

Dew Point

SW501 F 171790 139596 30.1 11216 8.0

SW701 F 252560 206463 44.6 17049 8.3

45980

74920

75033

139998

111446

22917

33475

9526

95998

150812

223512

Power

Increase

kW

T Y P I C A L H U MI D C L I MA T E C O N D I T I O N S

T

e

m

p

e

r

a

t

u

r

e

GE 5341N 20252 19 24750 1891 9 22143

GE 6541 B 32707 21 39615 2793 8.5 35500

SW V94.2 159410 133185 82 12052 9 145237

Time of Day

45.8

82.3

76.47

110

106

20.8

30.3

10.6

95

114

169

71

79

302

gpm lpm

kW

80F (27C)

kW

100F (38C)

Gas Turbine

5 6

MeeFog systems have been installed on over 60,000 MW of

gas turbine capacity. With over 750 systems installed, the

power boost from installed MeeFog inlet air fogging systems

exceeds 6,000 MW. Fogging of a gas turbine engine is an art

and a science, and there are several complexities that only

our years of experience can address. Among our many repeat

customers is a U.S. utility company that has installed

MeeFog systems on over 60 of its heavy-duty gas turbines.

Mee Industries has worked closely with several utility

companies worldwide in accommodating their special

requests, accelerating delivery schedules to meet power

crunches, and providing responsive after sales support. Our

experience covers a wide range of heavy-duty and

aeroderivative units ranging from 5 MW to 250 MW, and

includes several projects with gas turbine OEMs.

TENNESSEE vALLEY AuTh0FlTY FL0FlA F0WEF & LIGHT

ALST0M FlTlSh FETF0LEuM FFATT & WHITNEY

ME0S 0EMMA F0WEF ELC00AS

DAYTON POWER & Ll0hT N0FThEFN STATES F0WEF

ElS0N MlSSl0N ENEF0Y ENTEF0Y TENASKA

CALFlNE YNE0Y u.S. 0FAX C0MFANY

ClTlZEN'S uTlLlTY C0. LA C0uNTY SANlTATl0N

F0FTLAN 0ENEFAL ELECT. NlJECT SEFvlCES C0.

MADISON GAS & ELECTFlC 0TTEF TAlL

uTlLlC0FF ENEF0Y 0F0uF TFANS ALTA

K0FEAN ELECT. F0WEF CENTFAL huS0N

ShELL AuSTlN ENEF0Y FELlANCE lN.

ENEF0Y SEFvlCES lNC. SYFACuSE C00EN

ClNEF0Y C0MFANY huNT 0lL

lNEC ClTY 0F SFFlN0FlEL

TEFFA N0vA ClTY 0F FElN0 AK ENEF0Y

0lLALE ENEF0Y EL FAS0 NATuFAL 0AS

MlTSulShl hEAvY lN. uKE FLu0F ANlEL

uNlMAF lNlANA MuNlClFAL F0WEF ENEFJlSA

lEC 0uJAFAT F0WEF0EN NEW CENTuFY ENEF0Y

TuFlNE TEChN0L00Y TAMFA ELECTFlC L'ENEF0lA

MANlT0W0K FuLlC uTlLlTlES ASlN ELECTFlC F0WEF

ChEvF0N ClTY 0F LAKELAN F0FM0SA FLASTlCS

ClTY 0F 0LENALE TFACTAEL

uKE ENEF0Y KAuAl ELECTFlC ShuNE EShEN0 F0WEF

N0FTh AMEFlCAN ENEF0Y TlC0NA F0LYMEFS lNC.

ALAAMA ELECTFlC C00F. AFC0 NF0 ENEF0Y

S0LAF TuFlNES JACKS0NvlLLE ELECTFlC AuTh0FlTY

AhMEAA ELECTFlC S0LuTlA lNC.

Proven Technology From the Market Leader

MEETING OUR PERFORMANCE

COMMITMENTS

OVER 60% REPEAT CUSTOMERS

After two full summers, we are fully satisfied

with the MeeFog system.

GE Frame 7EA MeeFog user

We obtain a power boost of 12-16 MW.

GE Frame 7FA MeeFog user

Due to its low cost, we use fog as much as

possible. It is simple, reliable, and relatively

maintenance free.

LM6000 MeeFog user

The MeeFog system was the least expen-

sive option to install and operate. The system is

capable of 20F cooling and reduced NOx emis-

sions.

Solar Mars MeeFog user

The additional power we attained easily paid

for the MeeFog system within one year. We

have not experienced any problems with the

system in the two years of operation. It is easy

to operate and maintain.

W 251B5 MeeFog user

We achieve as much as 40F cooling when

humidity is less than 30% which results in a 7.5

MW power boost.

GE Frame 5 MeeFog user

We are very happy with fog and count on it for

extra power. Depending on ambient conditions,

we can get about 2-3 MW per machine.

LM6000 MeeFog user

We are very pleased with fog and plan to fog

every turbine we have the money for. It gives

us a power boost of 68 MW per turbine.

GE Frame 7EA MeeFog user

Impaction-

pin

Nozzle

Body

Adapter

Nozzle

Filter

O-ring

Seal

Stainless

Steel Tube

Advanced Nozzle Design

Mee Industries Inc. manufacturers the worlds best

impaction-pin type fog nozzle. Droplet size is the single

most important factor governing fog system performance.

Smaller droplets mean faster and more efficient cooling,

less wetting of duct surfaces and greatly reduced

compressor blade distress. The MeeFog nozzle sets the

standard for inlet fogging nozzles and has been shown to

consistently out perform other nozzles.

The standard MeeFog impaction-pin nozzle is constructed

entirely from high-grade stainless steel. It has a 0.006 inch

(150 micrometer) diameter orifice. At an operating pressure

of 2000 psi (138 bar), the average droplet size is well below

10 microns, about one tenth the diameter of a single strand

of hair. The DV90 diameter is less than 20 microns; meaning

90% of the water mass flow is in droplets that are 20

microns or smaller. Mee Industries also produces nozzles

with reduced orifices, which produce even smaller droplets.

MeeFog

Nozzles reliably produce the

smallest droplets of any high-pressure

nozzle available today.

MeeFog nozzle construction. This nozzle

is manufactured by Mee Industries and has

been proven on thousands of installations.

Each and every nozzle is tested prior to

installation into fog manifolds.

Cumulative Volume

Volume Frequency

0

5

10

15

20

20 30 40 50

Particle Diameter (microns)

V

o

l

u

m

e

F

r

e

q

u

e

n

c

y

(

%

)

MeeFog Nozzle (Impaction-pin type with 0.006 inch orifice @ 2000 psi)

Cumulative Volume and Volume Frequency vs. Diameter

Performance of MeeFog nozzle at 2000 psi

(138 bar) operating pressure. Note that 90%

of the volume (water mass flow) is in drop-

lets that are less than 18 microns. Droplet

sizing was performed with a laser particle

analyzer in air with 100% humidity and 3000

ft. per minute (15.2 m/sec) velocity.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Heat TransferDocument382 pagesHeat TransferManish Chouhan100% (1)

- Supplement To M6.11 - M7.07 EWIS - Bonding and Grounding Network On Carbon Structure AIrcraftDocument54 pagesSupplement To M6.11 - M7.07 EWIS - Bonding and Grounding Network On Carbon Structure AIrcraftjamesclh100% (1)

- The World's First Industrial Gas Turbine Set at Neuchâtel (1939)Document8 pagesThe World's First Industrial Gas Turbine Set at Neuchâtel (1939)boukhari39100% (1)

- A Study On The Performance Analysis of Francis HydDocument9 pagesA Study On The Performance Analysis of Francis HydAru Mithayatri RamlanNo ratings yet

- 1 s2.0 S0959652622033212 MainDocument12 pages1 s2.0 S0959652622033212 MainOriza Adi FernandaaNo ratings yet

- 5.1.12 TRO Unit: Part Names of Each ComponentDocument1 page5.1.12 TRO Unit: Part Names of Each ComponentMark Dominic FedericoNo ratings yet

- Micom p127 Directional An Non-Directional RelayDocument3 pagesMicom p127 Directional An Non-Directional RelayMario SitorusNo ratings yet

- Ansi-Hi Pump StandardsDocument2 pagesAnsi-Hi Pump StandardsAndrés Eduardo100% (1)

- Catálogo MultiV IV 2013 EngDocument110 pagesCatálogo MultiV IV 2013 EngANDERSON HERRERANo ratings yet

- An 571Document3 pagesAn 571shah435457No ratings yet

- Ifa 3 - Students Pack Extra ExercisesDocument28 pagesIfa 3 - Students Pack Extra ExercisesSusana Castro Gil0% (1)

- Tower Wagon Manulas PDFDocument165 pagesTower Wagon Manulas PDFkhan11k100% (1)

- Fahrzeugverdichter / Vehicle Compressor / Compresseur Pour AutomobilesDocument1 pageFahrzeugverdichter / Vehicle Compressor / Compresseur Pour AutomobilesZoraida100% (1)

- Petrol Chainsaws: Owner's ManualDocument4 pagesPetrol Chainsaws: Owner's Manualkatta ngaNo ratings yet

- Power Electronics in Motor DrivesDocument7 pagesPower Electronics in Motor DrivesAlfredo Brumnić Fredo0% (1)

- Advance Retrofitting India Central Business DistrictsDocument14 pagesAdvance Retrofitting India Central Business DistrictsKarn KhandelwalNo ratings yet

- Power Supplies Module 02Document20 pagesPower Supplies Module 02Isabela Dos SantosNo ratings yet

- SHS Micro Financing in NepalDocument24 pagesSHS Micro Financing in NepalparipranaNo ratings yet

- Caixa Amplifica Stagg 40GAR - DSP - USADocument2 pagesCaixa Amplifica Stagg 40GAR - DSP - USAMarcelo M. MachadoNo ratings yet

- Preventive Maintenance Checklist UpsDocument1 pagePreventive Maintenance Checklist Upssree100% (9)

- SBSBattery VRLA Tubular Gel VRZ Series PDFDocument1 pageSBSBattery VRLA Tubular Gel VRZ Series PDFAleiska Victoria Gómez BetancourthNo ratings yet

- ASTM A193 GR B7 Vs GR B7M Bolts For Sour Service HXDocument5 pagesASTM A193 GR B7 Vs GR B7M Bolts For Sour Service HXYoussef DaoudNo ratings yet

- E3501 FPU KatalogversionDocument12 pagesE3501 FPU KatalogversionRolando Jara YoungNo ratings yet

- Large Span Timber StructuresDocument34 pagesLarge Span Timber StructuresAnonymous 8f2veZf100% (1)

- 2017 Directory of China's Coal-to-Gas Projects PDFDocument2 pages2017 Directory of China's Coal-to-Gas Projects PDFarapublicationNo ratings yet

- Notes FlamephotometryDocument19 pagesNotes FlamephotometryKaFiAliMirzaNo ratings yet

- Electronics Interview QuestionsDocument8 pagesElectronics Interview QuestionsshyamNo ratings yet

- Wind Energy - University QuesDocument2 pagesWind Energy - University QuesKsn Hari100% (2)

- Bucks Engines 2007 GM Powertrain Owners ManualDocument11 pagesBucks Engines 2007 GM Powertrain Owners ManualJuan Pablo100% (1)

- Week018-019 Presentation Sounds PPT PART 1 PhysicsDocument31 pagesWeek018-019 Presentation Sounds PPT PART 1 PhysicsRouie john dizon100% (1)