Professional Documents

Culture Documents

SNP Subcontracting Processs

Uploaded by

melih999xOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SNP Subcontracting Processs

Uploaded by

melih999xCopyright:

Available Formats

SUBCONTRACTING

Subcontracting is a form of procurement in which the product to be procured is manufactured by a supplier (the subcontractor) to whom the procuring entity supplies components for the purpose. The procuring entity may provide these components to the subcontractor either directly (using one of its plants), or indirectly (using another of its suppliers). When the manufacturing process has been completed, the subcontractor delivers the ordered product (incorporating the components provided) to the ordering party. Subcontracting involves the procurement of a product from a supplier (the subcontractor) to whom the procuring entity provides components for the purpose. In SAP APO, subcontracting process can be planned in Production Planning and Detailed Scheduling (PP/DS) and in Supply Network Planning (SNP). You have the following options: 1. If the components for the finished product are to be provided by the ordering party (plant), you can plan as follows:

Subcontracting with Source Location in PP/DS Subcontracting Without Source Location in PP/DS Subcontracting with Scheduling Agreements in PP/DS Subcontracting with Source Location in SNP

2. If the components for the finished product are to be provided by another supplier, you can plan as follows:

Subcontracting with Third-Party Provision of Components in PP/DS Subcontracting with Third-Party Provision of Components in SNP

In this document only SNP Subcontracting process will be covered.

SNP Subcontracting Process

In SAP APO, only one plant per subcontractor is currently supported (for each product). This means that always only one plant can order from one subcontractor and the subcontracting components (materials/components provided to the subcontractor) can only come from the plant to which the ordered product is supplied. If you have modeled several plants per subcontractor in SAP R/3, you can transfer these relationships to the SAP SCM system via APO-CIF (SAP APO

Core Interface). They are then represented as one-to-one relationships between subcontractors and plants in SAP APO. Standard subcontracting scenario occurs between plant and vendor. However, if the relationship is not one-to-one; case differs from the standard. For this scenario, subcontractor should be created. Details of this scenario are given in the document. In SNP, the heuristic-based and optimization-based planning approaches are available for the subcontracting process. However, the planning procedures deployment, transport load building (TLB), and capacity leveling are not possible. In order to implement SNP subcontracting scenarios successfully, some important data and settings are needed in R/3 and APO systems; and in integration of these two systems.

You might also like

- Implementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesFrom EverandImplementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesNo ratings yet

- SAP S/4HANA Retail: Processes, Functions, CustomisingFrom EverandSAP S/4HANA Retail: Processes, Functions, CustomisingRating: 5 out of 5 stars5/5 (1)

- Apo Interview QuestionsDocument10 pagesApo Interview QuestionsHari KrishnaNo ratings yet

- Supply Network PlanningDocument251 pagesSupply Network Planningrsn_surya100% (1)

- Process Flow Within SAP SCM APO SystemDocument6 pagesProcess Flow Within SAP SCM APO SystemHari KrishnaNo ratings yet

- 04H - Sub NetworksDocument54 pages04H - Sub Networksharry4sapNo ratings yet

- Supply PlanningDocument34 pagesSupply Planningharry4sapNo ratings yet

- PeggingDocument3 pagesPeggingSai YakkalaNo ratings yet

- SNP Solvers CTM HeuristicsDocument7 pagesSNP Solvers CTM HeuristicsJeevaReddyNo ratings yet

- Sap Apo: Global ATP Production Planing & Detailed SchedulingDocument22 pagesSap Apo: Global ATP Production Planing & Detailed SchedulingMeNo ratings yet

- Function Modules APODocument6 pagesFunction Modules APOHarshvardhan PandereNo ratings yet

- 01 - Introduction and Course OverviewDocument6 pages01 - Introduction and Course OverviewDebebookNo ratings yet

- TCode & Table DataDocument10 pagesTCode & Table DataguniporgaNo ratings yet

- Extended Safety Stock Planning in Capable-To-Match (CTM)Document12 pagesExtended Safety Stock Planning in Capable-To-Match (CTM)Luciano GonzalezNo ratings yet

- Sap ApoDocument16 pagesSap Aponaveen_thumuNo ratings yet

- Why To Choose SPP Instead of APODocument9 pagesWhy To Choose SPP Instead of APOcabhijitNo ratings yet

- Supply Network Planning (SNP) - Deployment and Transportation Load Builder Scenario 1 - Fair Share Rule by Quota ArrangementDocument19 pagesSupply Network Planning (SNP) - Deployment and Transportation Load Builder Scenario 1 - Fair Share Rule by Quota ArrangementPersio KojimaNo ratings yet

- APO BW Planning SNPDocument11 pagesAPO BW Planning SNPash4u2008No ratings yet

- Level of BOM SNP HeuristicDocument15 pagesLevel of BOM SNP HeuristicAvrinz AvrinzNo ratings yet

- APO SNP Training - GlanceDocument78 pagesAPO SNP Training - GlanceTemporaryNo ratings yet

- DP Sap ApoDocument54 pagesDP Sap Apoakeey4uNo ratings yet

- Apo CTPDocument4 pagesApo CTPAnkush Agrawal100% (1)

- SAP APO SNP OverviewDocument21 pagesSAP APO SNP OverviewNitin LalgeNo ratings yet

- SNP Planning Book KeyFigures.Document1 pageSNP Planning Book KeyFigures.yareddyNo ratings yet

- Gatp BOP CompDocument41 pagesGatp BOP CompVishal ..No ratings yet

- SAP APO DP Interview Questions by NKDDocument7 pagesSAP APO DP Interview Questions by NKDnileshNo ratings yet

- Deploy Ement Sap Apo SNP DeploymentDocument24 pagesDeploy Ement Sap Apo SNP DeploymentjeevanNo ratings yet

- Apo - Expert CVDocument10 pagesApo - Expert CVvijay_apoNo ratings yet

- Standard VMI: PrerequisitesDocument8 pagesStandard VMI: PrerequisitessaprajmmNo ratings yet

- APO TablesDocument10 pagesAPO TablesSoma Sekhar Vallabhaneni0% (1)

- GATPDocument29 pagesGATPajay78_hiNo ratings yet

- Assemble To Order: Intel Confidential - Internal OnlyDocument6 pagesAssemble To Order: Intel Confidential - Internal Onlygenius1q2wNo ratings yet

- How Minimum, Total Shelf Life Works !! - SAP BlogsDocument12 pagesHow Minimum, Total Shelf Life Works !! - SAP BlogsraghuNo ratings yet

- CTM - Concepts, Demand Prioritization and Supply CategorizationDocument14 pagesCTM - Concepts, Demand Prioritization and Supply CategorizationReem Moustafa Abo-ZaidNo ratings yet

- Managing Supply Chain RiskDocument8 pagesManaging Supply Chain Riskwasim786nasirNo ratings yet

- Sap Education: Sample Questions: C - Apo1 - 72Document6 pagesSap Education: Sample Questions: C - Apo1 - 72avsomshettiNo ratings yet

- Sap SCMDocument21 pagesSap SCMAffizul AzuwarNo ratings yet

- APO Planning HorizonDocument4 pagesAPO Planning HorizongautamNo ratings yet

- APO Technical Workshop For LG ChemicalDocument12 pagesAPO Technical Workshop For LG ChemicalVenkata Sarma0% (1)

- PPDS Process Flowv.2Document7 pagesPPDS Process Flowv.2Jagannadh BirakayalaNo ratings yet

- IBP-Demand PlanningDocument7 pagesIBP-Demand PlanningAzza ShoukrNo ratings yet

- SAP APO OverviewDocument3 pagesSAP APO Overviewterrace1No ratings yet

- Buying - SAP Integrated Business Planning FAQs - SCNDocument6 pagesBuying - SAP Integrated Business Planning FAQs - SCNAmaanath KhanNo ratings yet

- SNP Heuristics Algorithm: Dhanwantry, Kalyan R SAP Systems Analyst / IT SNC PS WW 11.2 2013Document27 pagesSNP Heuristics Algorithm: Dhanwantry, Kalyan R SAP Systems Analyst / IT SNC PS WW 11.2 2013Varun KumarNo ratings yet

- SAP APO Analyst SCM in Houston TX Resume Fauziah EmbiDocument3 pagesSAP APO Analyst SCM in Houston TX Resume Fauziah EmbiFauziahEmbiNo ratings yet

- SNP Interview PreparationDocument15 pagesSNP Interview PreparationJagannadh BirakayalaNo ratings yet

- Forecast Consumption-PART 1Document18 pagesForecast Consumption-PART 1Shivram KrishnaNo ratings yet

- PP/DS Optimizer: PPDS Optimizer Used To Create An Optimized Production Schedule in Respect To Setup Times, Delays and Total Lead TimeDocument1 pagePP/DS Optimizer: PPDS Optimizer Used To Create An Optimized Production Schedule in Respect To Setup Times, Delays and Total Lead TimetitanantonyNo ratings yet

- Tailor-Making of SCM SNP Deployment Heuristics - Technical InsightsDocument6 pagesTailor-Making of SCM SNP Deployment Heuristics - Technical Insightssrinivas0212No ratings yet

- SAP SCM Demand Planning: Best Practice For Solution ManagementDocument12 pagesSAP SCM Demand Planning: Best Practice For Solution ManagementSagar BabarNo ratings yet

- Sap Apo DP OverviewDocument24 pagesSap Apo DP OverviewSreeram SreeramNo ratings yet

- How To Understand The BOM - Bill of Material in APODocument8 pagesHow To Understand The BOM - Bill of Material in APOAvrinz AvrinzNo ratings yet

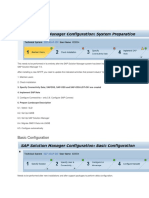

- 02.1 APO SNP ConfigurationDocument15 pages02.1 APO SNP Configurationsankarlikesu100% (2)

- PPDS For Process IndustryDocument6 pagesPPDS For Process IndustryVinay KumarNo ratings yet

- What Are The Basic Components of SAP R/3 Business Framework ?Document2 pagesWhat Are The Basic Components of SAP R/3 Business Framework ?ram krishnaNo ratings yet

- CIF Monitoring Guideline V3Document48 pagesCIF Monitoring Guideline V3giampiero_gallarateNo ratings yet

- Multi Scheduling HeuristicDocument9 pagesMulti Scheduling HeuristicpesimistixNo ratings yet

- Autonomous TransactionsDocument9 pagesAutonomous TransactionsdkmdipeshNo ratings yet

- Router BitDocument44 pagesRouter Bitsunrise designNo ratings yet

- Cover Letter: Vinod Aba Ghangarde (Document3 pagesCover Letter: Vinod Aba Ghangarde (Komal PatilNo ratings yet

- GE FME Plan HYA 2017 - BB CommentsDocument24 pagesGE FME Plan HYA 2017 - BB CommentsAlexandre MelloNo ratings yet

- 21 Sumitava CVDocument2 pages21 Sumitava CVchatuusumitavaNo ratings yet

- Creating VOFM Custom RoutineDocument16 pagesCreating VOFM Custom RoutineSergio Martín Cordero100% (1)

- Castrol Spheerol EPLDocument2 pagesCastrol Spheerol EPLDiego GalvanNo ratings yet

- IGC3 Exam Template 2Document17 pagesIGC3 Exam Template 2mibshNo ratings yet

- System Manager 7.4 User GuideDocument158 pagesSystem Manager 7.4 User GuidemasterboloNo ratings yet

- ABB REL5xx RIOConverterDocument10 pagesABB REL5xx RIOConverterzinab90100% (1)

- J910 DT03 P0ZEN 040001 SQCP 0010 (Quality Control Procedure Index) - Rev.0Document3 pagesJ910 DT03 P0ZEN 040001 SQCP 0010 (Quality Control Procedure Index) - Rev.0Budi SetiawanNo ratings yet

- BPM MasterdataDocument25 pagesBPM MasterdataJignesh HariyaNo ratings yet

- Ansi A118.15Document3 pagesAnsi A118.15Hà Trần MạnhNo ratings yet

- Chloe and SarahDocument2 pagesChloe and Sarahfadhila faquanikaNo ratings yet

- Column Oriented DatabaseDocument16 pagesColumn Oriented DatabaseSoumyaMishraNo ratings yet

- Resume PKDocument3 pagesResume PKChirag DaveNo ratings yet

- Paralleling Generators of Different Makes, Models and ManufacturersDocument3 pagesParalleling Generators of Different Makes, Models and ManufacturersSohail ANo ratings yet

- Cmo 12, S. 2008 - Approved Ps For BsgeDocument15 pagesCmo 12, S. 2008 - Approved Ps For BsgeJeffreySTorcalNo ratings yet

- Solman System PreparationDocument8 pagesSolman System PreparationPranab Kumar DasNo ratings yet

- Sessions 3 and 4: Business Process Re-EngineeringDocument48 pagesSessions 3 and 4: Business Process Re-Engineeringpick YourpetNo ratings yet

- QS - Lesson - Plan PDFDocument2 pagesQS - Lesson - Plan PDFrajaanwarNo ratings yet

- Building Permit Procedures KuwaitDocument2 pagesBuilding Permit Procedures KuwaitArun Chandra BabuNo ratings yet

- Chief Excutive Sitara Chem-1Document4 pagesChief Excutive Sitara Chem-1MUHAMMAD WARIS SQNo ratings yet

- CLL f399 Imp EngDocument73 pagesCLL f399 Imp EngJesus CastroNo ratings yet

- Attachments For MillingDocument59 pagesAttachments For MillingLibin AbrahamNo ratings yet

- EM531 531 RathodH 2Document60 pagesEM531 531 RathodH 2Santosh Kumar SurineediNo ratings yet

- KEFI Minerals Apr 2014 Shareholder UpdateDocument24 pagesKEFI Minerals Apr 2014 Shareholder UpdateDenise CruzNo ratings yet

- Nkumba University BrochureDocument2 pagesNkumba University BrochureApo100% (3)

- Hyscan II IomDocument33 pagesHyscan II Ioma1gulesNo ratings yet

- Scientific American Architects and Builders Edition 1890 Jul-DecDocument240 pagesScientific American Architects and Builders Edition 1890 Jul-DecNickiedeposieNo ratings yet