0 ratings0% found this document useful (0 votes)

47 views11 pagesBolt Allow AISC

standard

Uploaded by

sudokuCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

0 ratings0% found this document useful (0 votes)

47 views11 pagesBolt Allow AISC

standard

Uploaded by

sudokuCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

im weeps (seat

6, Filler Metal Requirements

‘The choice of electrode for use with complete joint-penetration groove welds

subject to tension normal to the effective area shall comply with the requirements

for matching filer metals given in AWS D1.1

User Note: The following User Note Table summarizes the AWS DI.1 provi-

sions for matching filler metals. Other restrictions exist. Fora complete list of

‘base metals and prequalified matching filler metals see AWS DI.1, Table 3.1.

Base Motal ‘Matching Fllor Mota

SG = ioe ‘508 70s! Eiacrodes

AG0> Hein. ABT (Gi BO KBB) | SMAW: E7015, E7016, E718, E70DB

2013 (Gr. 50)

seer ose, ‘Otnr processes: 70 ks lates

mort to16

1S (OE BOERS] ‘ors leavodes

* Fer ln wea COG Tara Uae a AWE D1 SEE BTS

Note

"cra la eer ANS AS, AS, A, A, 520, A829,

2 Ijin hbase mol fan sees ute ear er metal at rates to

Tiger sil ce meta iar tlat matcero oer srg ans poas

Stbwhyeogen pos

Filler metal with a specified Charpy V.Notch (CVN) toughness of 20 ft-lbs

(27 3) at 40 °F (4 -C) shal be used inthe following joins

(1) Complete joint penetration groove welded T and corner joints with stel

backing lft place, subject to tension normal tothe effective area, unless the

joints are designed using the nominal strength and resistance factoror safety

{factor ws applicable for « PIP weld

(2) Complete oint-penetration groove welded spices subject to tension normal

Co the effective area in heavy sections as defined in A3.Le and A3.Ld.

‘The manufacturer's Certificate of Conformance shall be sufficient evidence of

‘compliance

7. Mixed Weld Metal

‘When Charpy V-Notet toughness is specified, the process consumables forall

‘weld metal tack welds, root pass and subsequent passes deposited ina jin shall,

bbe compatible io ensure notch-ough composite weld metal

BOLTS AND THREADED PARTS

Hy

Strength Bolts

‘Use of high-stength bolts shall conform to the provisions of the Specification

for Structural Joints Using ASTM_A325 or A490 Bolts, hereafer referred 10

‘as the RCSC Specification, as approved by the Research Council on Stevetural

‘Connections, except as otherwise provided i this Specification.

‘When assembled, all join surfaces, including those adjacent tothe washer, shall

be fre of scale, except tight mill scale, All ASTM A325 or A325M and A490

Seeton or Str Set Bldgs, March 9,205,

DNERICAN INSITTUTE OF STEAL. CONSERLCTION INC

Sect 13)

[BOLTS AND THREADED PARTS 103

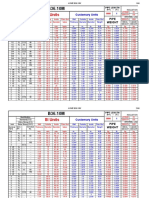

TABLE J3.1

Minimum Bolt Pretension, kips*

Bolt Siza, in. ‘AG25 Bolts “hago Bolts

We 2 15

Se 16 2

on 2 5

he 2 2

. 5 66

th 55 0

We n 102

Phe 5 1

a 103 148

“ule 070tnes i arivam Bae stong tba, unde oe aarp

spclogn AST spelen fr Aan AS bak wt UNG oc

TABLE J3.1M

Minimum Bolt Pretension, kN*

Balt Size, mm ‘A325M Bois —_AasoM Bons

mio er 118

20 18 1

tee i% 221

Mes os sr

Mer ber 3a

a0 5 408

m8 is 508

Ei 70 nes nu lense Seno lbs, ound io need,

ead n ASTM spleor r AtSN an AED oe mts UNE Ursa,

for AA9OM bolts shal be tightened toa bolt tension not less than that giver

‘Tule 13.1 oF 13.1M, except as noted below. Except as permitted below, instal-

lation shall be assural by any of the following methods: tur-of-nut method, 3

iret tension indicat, calibrated wrench or alternative design bal.

Bolts are permitted tobe installed to oaly the snug.

(@) bearing-1ype contections

(b) tension or combined shear and tension applications, for ASTM. A325 or

‘A325M bolts only, where loosening or fatigue due to vibeation o load uc-

‘ations are not design considerations.

bt condition when used in

‘The snug.tight condition is defined as the tightness attained by either a few im

pacts of an impact wrench or the full effort of « worker with an ordinary spud

‘wrench that brings the connected plies into firm contact. Bots to be tightened

‘only tothe stug-tight condition shall be clearly identifed on the design and

‘erection drawings

When ASTM A490 or A490M bolts over | in, (25 mm) in diameter axe used in

slotted or oversized holes in external plies, a single hanened washer conforming

to ASTM F436, except with /1in. (8 mm) minimum thickness, shall be used

in iew ofthe standard washer.

Speciation for rat Stet Biking, Mash 9, 2005

ANIARICAY INSTITUTE OF STEL CONSTRUCTION,

101 HOLS AND THREADED PARTS Ise.

¥ og TABLE J3.2

\. 2’ | Nominal Stress of Fasteners and Threaded Parts,

a ksi (MPa)

s Nominal Tensile

Sg Sean

w , [ beseripton of Fasteners | “ket

e 3 ‘A307 bolts 45 (310) I 24 (165) PIE

= ‘25 or ADEM ba, wbon 0 (20) 1 4330)

SE | tread ae not xtc oo =

tom shear planes

SQ | 25 0 A025 bts sion ro wae

SS | eat avai

3 [series

= /Ad90 or AABOM bolls, when 113 (780) 60 (414)

z fronds are poled

irom sew pres _

yy “A490 or AABOM bolts, when 113 (780) 75 (820)

= te ar onctased m |

x Svar lros —

5 ‘Threaded parts meeting the 0.75 FA

x Tegument of Scion

{en trea arrat

ccctdbotomsteapanes | = 646,5 MPa

2 075 Fa 0.50Fy

‘chided om Shear panes

teh iene ota

‘err Sos te ed tsa fsa pea Ye 2m oS contre

cineiteste

Pens pen nae pes

tne nol wal ro le headed pation tl acd tn boos dion ee

2 cy | terre Atop soa eo a pg

SS | mre asx ace anoae hs bt ste eens, so Aopen 3

"inn ep snes tnd on esn enter have ata str hors gh

Bg | ERIGONTG Sie Tice a a a ey

S&S [Beal

»

et ‘User Note: Washer requirements are provide in the RCSC Specification,

Mey Section 6.

t In slip-rtcal connections in which the direction of loading is toward an edge

ofa connected pat adequate available bearing strength sal be provided based

be ‘pon the applicable requirements of Seton 13.10

si ‘When bolt equtements sannot be provided by @STM A325iand A325M, F1852,

oa ‘or A490 and 4490M bolts beetse of requirements for lengths exceeding 12

S liametrs or imstrs exceeding 17s in. 38 mm), ols or threaded os con

N forming to ASTM A354 Gr, BC, A354 Gr. BD, or A449 are. iitted 10 be used

| & inaocortance with the provisions for teaded rods in Table 132.

‘Syciiation or caro Stel Bing, March 9, 2008

"ANEICAN INSHTIUTE OF STE CONSERLCTION.

sect 13) BOLTS AND THREADED PARTS tos

TABLE J3.3

| Nominal Hole Dimensions, in.

+ Hole Dimensions

Bolt ‘Oversize | Short slot Long-sfot

Diameter Dia} | cwidth> Length) | (wien = Length

ve i 6x hex 1

cn he 896 She x the

te "he Bhat hex Phe

te 8 hex 1% Whe x 28

4 Mm Wha x 196, ag 2

21h ite | (atid eidro | (she) @Sxa) |

TABLE J3.3M

Nominal Hole Dimensions, mm

Hole Dimensions

Bolt | Standard | Oversize | ShortSlot Long-siot

Diameter | “(Oia)” | (Dia) | (Wisth'x Length) | (Widths Length)

M6 18 2 18x22 18x40

N20 2 2 2x % x50

za 2 2 24x90 Bax 55

Nes a 20 Bre 32 260

—Le wer 35 50x37 20x67

Mao 3 Sax 40 B75

236 rp are | (+3) x(a+10) (49) 3280

lanes rove slows a0

When ASTM A3S4 Gr, BC, A354 Gr. BD, or A449 bolts and threaded rods

‘ate used in slip-critcl connections, the bolt geometry including the head and

‘ut(s) shall be equal to oF (i larger in diameter) proportional to that provided

by ASTM A325 and A325M, or ASTM A490 and A490M bolts. Installation

shall comply with all applicable requirements of the RCSC Specification with

‘modifications as required forthe increased diameter and/or length to provide the

design pretension.

2, Sizeand Use of Holes

“The maximum sizes of holes for bolts are given in Table J3.3 or J3.3M, except

that larger holes, required for tolerance on location of anchor rods in conerete

foundations, ae permite in calunn base details

Standard holes or short-sloted holes transverse tothe direction of the load shall,

bo provided in accordance withthe provisions otis specification, unless over

sized holes, short-sbtted holes parallel to the load or fong-slovted holes ate ap-

provedby the engineer of record. Finger shins upto V/sin, (6mm) are permitted in

slip-crtical connections designed on he basis of standard holes without reducing

the nominal shea strength ofthe fastener to that specified for slotted holes.

Speciation or Sra Se Buln, March 2008

‘sess Insert oF ST, CONSTRUCTION IN

106

[BOLTS AND THREADED PARTS [secu

Oversized holes ate permitted in any oral plies ofsip-riticl connections, but

they shall not be used in bearing-rype connections. Hardened washers shall be

installed over oversized holes in an outer ply.

Shortstotted holes are permitted in any orall plies of lip-critcal or beaving-ype

connections. The slots are permitted without regard to direction of loading in sli-

critical connect ons, but the length shall be normal to the direction ofthe load in

bearing-type eannections. Washers shall be installed over shortsloted hole in

an outer ply: when high-stength bolts are used, such washers shall be hardened

Long-slotted holes are permitted in only one ofthe connected parts of either a

slip-eritical or bearing-type connection at an individual faying surface. Long=

slotted holes are permitted without regard to direction of loading in slip-rtial

connections, bet shall be notmal tothe ditetion of loadin bearing-type con-

nections. Where long-slotied holes are used in an outer ply, plate washes, oa

continuous bar with standard holes, having a size sufficient to completely cover

the slot alter installation, shall be provided, In high-strength bolted connections,

such plate washers or continuous bars shall be not less than /is in, (8 mm) thick

and shall be of structural grade material, but need not be hardened. If hardened

‘washers are required for use of high-strength bolts, the hardened washers shall

be placed over the outer surface of the plate washer or ba

Minimum Spasing

The distance between centers of standard, oversized, or slotted holes, shall not

be less than 27/5 times the nominal diameter, d, ofthe fastener a distance of 3

Js preferred,

Minimum Bdge Distance

The distance from the center ofa standard hole o an edge of a connected pat

inany direction shal no be les than ether the applicable value from Table J3.4

or J3.4M, or as required in Section 13.10. The distance from the eenter of an

‘oversized or slotted hole to an edge of a connected part shall be not less than that

required fora standard hole to an edge of a connected part plus the applicable

‘increment C> from Table J3.5 or J3.5M,

User Note: The edge distances in Tables 13.4 and J3.4M are minimum edge

istances based on standard fabrication praticesand workmanship tolerances,

“The appropriate provisions of Sections J3.10 and 1 must be satioted.

Maximum Spacing and Edge Distance

‘The maximum distance from the center of any bolt or rivet fo the nearest edge

of parts in contact shall be 12 times the thickness of the connected part wider

consideration, but shall not exceed 6 in, (150 mm). The longitudinal spacing

of fasteners between elements in continuous contact consisting of plate and a

shape or two plates shal be as follows:

‘Speiation for Staal Stel dings, Mase 9,208

‘AMERICAN INSTEIUTE OF SHPAL CONSTRUCTION IN

You might also like

- UOP Gauge Glasses Standard SpecificationNo ratings yetUOP Gauge Glasses Standard Specification5 pages

- Flow Meter and Pressure Instrument SpecsNo ratings yetFlow Meter and Pressure Instrument Specs9 pages

- Carbon Steel Pressure Vessels Specification100% (2)Carbon Steel Pressure Vessels Specification34 pages