Professional Documents

Culture Documents

Nozzle flange pressure calculation

Uploaded by

sudoku0 ratings0% found this document useful (0 votes)

74 views2 pagesThe document discusses nozzle design parameters including nozzle projection length, flange design pressure, static liquid head, flange rating, and forces and moments applied per API 660. It then calculates the external tensile force, moment factor, gasket reaction diameter, external moment, equivalent pressure acting on the flange, required flange rating, and determines if the flange is adequate based on the design pressure.

Original Description:

Original Title

ASME Code Case 2901

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses nozzle design parameters including nozzle projection length, flange design pressure, static liquid head, flange rating, and forces and moments applied per API 660. It then calculates the external tensile force, moment factor, gasket reaction diameter, external moment, equivalent pressure acting on the flange, required flange rating, and determines if the flange is adequate based on the design pressure.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

74 views2 pagesNozzle flange pressure calculation

Uploaded by

sudokuThe document discusses nozzle design parameters including nozzle projection length, flange design pressure, static liquid head, flange rating, and forces and moments applied per API 660. It then calculates the external tensile force, moment factor, gasket reaction diameter, external moment, equivalent pressure acting on the flange, required flange rating, and determines if the flange is adequate based on the design pressure.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 2

L (Nozzle Projection from Flange Face to ext.

surface of parent element) =

PD (Flange/Equipment Design Pressure @ Design Temp.) =

PS (Liquid Static Head) =

PR (@ Design Temp.) [Flange MAWP rating in Compress] =

Fx (Longitudinal Force Applied on Nozzle-Parent Component Junction from API 660) =

Fy (Axial Force Applied on Nozzle-Parent Component Junction from API 660) =

Fz (Circumferential Force Applied on Nozzle-Parent Component Junction from API 660) =

Mx (Longitudinal Moment Applied on Nozzle-Parent Component Junction from API 660) =

My (Torsional Moment Applied on Nozzle-Parent Component Junction from API 660) =

Mz (Circumferential Moment Applied on Nozzle-Parent Component Junction from API 660) =

ML (Longitudinal Moment Applied on Nozzle Flange Face) = M x-Fx*L =

MC (Circumferential Moment Applied on Nozzle Flange Face) = M z-Fz*L =

M (Resultant Moment Applied on Nozzle Flange Face) = SQRT[M L2+MC2] =

FE (External Tensile Axial Force - Fy from API 660 Applied on Nozzle-Parent Component Junction) =

FM (Moment Factor by Table 1 from Code Case 2901) =

G (Gasket Reaction Diameter by ASME VIII Div.1 App.2, Para. 2-3) =

ME (External Moment) = M (Resultant Moment) =

Pm (As Nominated in Compress) = (16*ME)/(PI*G 3) =

Pr (As Nominated in Compress) = (4*FE)/(PI*G 2) =

Equivalent Pressure Acting on Flange = MAWP reduction = max[Pm + Pr , 0]

MAWPflange = min[PR, PR*(1+FM)-MAWPreduction]-PS =

Flange is adequate if MAWPflange >= PD (Flange/Equipment Design Pressure)

Required Flange Rating = [PD+PS+MAWP reduction] =

144 mm

2114000 N/m2 21.14 bar

8000 N/m2 0.08 bar

4321000 N/m2 43.21 bar

1990 N 202.92 kgf

1590 N 162.13 kgf

1990 N 202.92 kgf

340 N*m 34.67 kgf*m

540 N*m 55.06 kgf*m

430 N*m 43.85 kgf*m

53.4 N*m 5.45 kgf*m

143.4 N*m 14.63 kgf*m

153.1 N*m 15.61 kgf*m

1590 N 162.13 kgf

0.5

77.9 mm

153.1 N*m 15.61 kgf*m

1649118.707 N/m2 16.491 bar

333604.828 N/m2 3.336 bar

1982723.535 N/m2 19.827 bar

4313000.000 N/m2 43.130 bar

Adequate

N/m2 bar

You might also like

- Multiphase Flow 1995From EverandMultiphase Flow 1995A. SerizawaNo ratings yet

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- Mechanics of Slow Draining of Large Cylindrical Tank Under GravityDocument11 pagesMechanics of Slow Draining of Large Cylindrical Tank Under GravityReliusman DachiNo ratings yet

- Overflow Line DesignDocument2 pagesOverflow Line DesignAngshuman Roy ChoudhuryNo ratings yet

- Flush Bottom ValvesDocument3 pagesFlush Bottom ValvesErkan TakNo ratings yet

- RUH Umpen: Ruhrpumpen GMBHDocument40 pagesRUH Umpen: Ruhrpumpen GMBHjacobo nasimbaNo ratings yet

- Appendix02 - The SI Metric System of Units and SPE Metric Standard PDFDocument38 pagesAppendix02 - The SI Metric System of Units and SPE Metric Standard PDFluisinho100% (1)

- 2013 SECTION IX GUIDANCE FOR USING CUSTOMARY AND SI UNITSDocument3 pages2013 SECTION IX GUIDANCE FOR USING CUSTOMARY AND SI UNITSMohdBadruddinKarimNo ratings yet

- Origins of Internal Flow SystemsDocument2 pagesOrigins of Internal Flow SystemsobumuyaemesiNo ratings yet

- Salts in Crude Oil (Electrometric Method) : Standard Test Method ForDocument6 pagesSalts in Crude Oil (Electrometric Method) : Standard Test Method ForJulian Felipe Noguera CruzNo ratings yet

- Vessel Heads BottomDocument9 pagesVessel Heads BottomFahad RockingNo ratings yet

- Boletim Tecnico DupontDocument2 pagesBoletim Tecnico DupontjoseocsilvaNo ratings yet

- Two Phaseflowgas Flowlinesizing 170303054950Document24 pagesTwo Phaseflowgas Flowlinesizing 170303054950Trần Tuấn VũNo ratings yet

- A New Method For Calculating The Busemann Head Coefficients For Radial ImpellersDocument7 pagesA New Method For Calculating The Busemann Head Coefficients For Radial ImpellersIvan RaulNo ratings yet

- Flow pattern based two-phase frictional pressure drop modelDocument13 pagesFlow pattern based two-phase frictional pressure drop modelSandro Goisis100% (1)

- Selection of Gas Compressors - Part 1Document5 pagesSelection of Gas Compressors - Part 1sauroNo ratings yet

- Discharge Coefficients Through Perforated Plates at Low Reynolds NumbersDocument3 pagesDischarge Coefficients Through Perforated Plates at Low Reynolds NumbersAlastairNo ratings yet

- Side Mounted HandwheelDocument20 pagesSide Mounted HandwheelaaaNo ratings yet

- Cryogenic Ball Valves: Installation, Operation and Maintenance InstructionsDocument8 pagesCryogenic Ball Valves: Installation, Operation and Maintenance InstructionsDv Maria PradhikaNo ratings yet

- Borda CarnotDocument52 pagesBorda CarnotSamujawal Kumar SumanNo ratings yet

- ClydeBergemannSootblowers PrinceGeorge06Document36 pagesClydeBergemannSootblowers PrinceGeorge06Arun YogaNo ratings yet

- Analisis of Stress in BellowsDocument101 pagesAnalisis of Stress in BellowsOswaldo GuerraNo ratings yet

- Api - 2000Document49 pagesApi - 2000Carlos SandinoNo ratings yet

- Astm F436.04 PDFDocument6 pagesAstm F436.04 PDFWelington Volpatto MoraisNo ratings yet

- Drainage from Tank in 35 minutesDocument6 pagesDrainage from Tank in 35 minutesmlarakahanNo ratings yet

- Bornemann Full Product RangeDocument10 pagesBornemann Full Product RangeLuis LopezNo ratings yet

- Annex F Design of Tanks For Small Internal PressuresDocument9 pagesAnnex F Design of Tanks For Small Internal PressuresJamir Diaz MechanNo ratings yet

- Introduction To WRC 107 Concepts Limitations and FormulaDocument5 pagesIntroduction To WRC 107 Concepts Limitations and FormulamoryNo ratings yet

- Detection of Slug FlowDocument9 pagesDetection of Slug FlowSachin ChoubeyNo ratings yet

- Dike Wall Height Calculation Sheet OptimizationDocument7 pagesDike Wall Height Calculation Sheet OptimizationSaqib LaeeqNo ratings yet

- Pages From Centrifugal Pumps HandbookDocument4 pagesPages From Centrifugal Pumps HandbooksalamrefighNo ratings yet

- The New NSF 350 AND 350-1Document6 pagesThe New NSF 350 AND 350-1Rossy IP100% (1)

- FreeseDocument15 pagesFreeseBrandon HaleNo ratings yet

- Es7 PDFDocument4 pagesEs7 PDFayoungaNo ratings yet

- Calculating Flow Over Rectangular Sharp Edged WeirsDocument14 pagesCalculating Flow Over Rectangular Sharp Edged WeirsBabyface888No ratings yet

- Exact Solution Tank DrainageDocument8 pagesExact Solution Tank DrainageFelipe CastNo ratings yet

- PIPESIM Valves Fittings PluginDocument15 pagesPIPESIM Valves Fittings PluginJUANNo ratings yet

- Vertical turbine, axial, and mixed flow pumps guideDocument10 pagesVertical turbine, axial, and mixed flow pumps guideKitikhun VichanarksornsitNo ratings yet

- Design Note For Air Reciever TankDocument6 pagesDesign Note For Air Reciever TankJoshua Balaram RaoNo ratings yet

- Bellmouth SpillwayDocument19 pagesBellmouth SpillwayRavi ChandranNo ratings yet

- Practical Design Approaches for Pressure Vessels and Heat ExchangersDocument10 pagesPractical Design Approaches for Pressure Vessels and Heat ExchangersballisnothingNo ratings yet

- API 682 Accumulator Data SheetDocument1 pageAPI 682 Accumulator Data SheetBhyrappaNo ratings yet

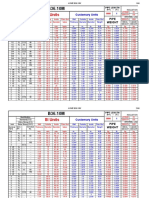

- MATERIAL COMPARISONDocument8 pagesMATERIAL COMPARISONrouquinNo ratings yet

- Etab RSM Eccc Basics SCMDocument2 pagesEtab RSM Eccc Basics SCMsathiyaseelann.sNo ratings yet

- Spring - Hanger - Basic PSA Inc PDFDocument26 pagesSpring - Hanger - Basic PSA Inc PDFViji SvrNo ratings yet

- Technical DataDocument48 pagesTechnical Datashekhar2681No ratings yet

- FE107 Experimental ResultsDocument11 pagesFE107 Experimental ResultsEsapermana RiyanNo ratings yet

- Air Valve BrochureDocument27 pagesAir Valve Brochuredamith030No ratings yet

- Comparison of Friction Factor Equations For Non-Newtonian Fluids in A Pipe FlowDocument28 pagesComparison of Friction Factor Equations For Non-Newtonian Fluids in A Pipe FlowManu K MohanNo ratings yet

- Resolving Excessive Vibration in Steam and Feed-Water Piping at Loviisa Nuclear Power PlantDocument8 pagesResolving Excessive Vibration in Steam and Feed-Water Piping at Loviisa Nuclear Power PlantJose PradoNo ratings yet

- Phase Equilibria: Basic Principles, Applications, Experimental TechniquesFrom EverandPhase Equilibria: Basic Principles, Applications, Experimental TechniquesNo ratings yet

- Annexure - Bolt Torque CalculationDocument4 pagesAnnexure - Bolt Torque CalculationDarshan Panchal100% (1)

- Load case and design calculations for pressure vesselDocument11 pagesLoad case and design calculations for pressure vesselCaptainToniesNo ratings yet

- ENDPLMC9.xlsDocument4 pagesENDPLMC9.xlsmahhor82_635643838No ratings yet

- Connessione A Taglio EC3 IngleseDocument15 pagesConnessione A Taglio EC3 Inglesemihai_serban13No ratings yet

- Prog 1 - BackupDocument10 pagesProg 1 - BackupJuricaNo ratings yet

- Design Slip-Critical Steel ConnectionDocument9 pagesDesign Slip-Critical Steel ConnectionKURONo ratings yet

- B. SGH-screen-wall 2Document57 pagesB. SGH-screen-wall 2MoustafaNo ratings yet

- End Plate DesignDocument4 pagesEnd Plate DesignAgnon Fung100% (4)

- Pressure Vessel Handbook Fourteenth Edition Eugene R MegyesyDocument1,014 pagesPressure Vessel Handbook Fourteenth Edition Eugene R Megyesyluis sepulveda80% (10)

- Standard Specification: UOP Engineering Department Date Status SPNSR ApvdDocument5 pagesStandard Specification: UOP Engineering Department Date Status SPNSR ApvdsudokuNo ratings yet

- 15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)Document22 pages15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)sudokuNo ratings yet

- Technical-specs-Heat ExchangersDocument96 pagesTechnical-specs-Heat ExchangerssudokuNo ratings yet

- 6-18-7 Flow Meters and Pressure InstrumentsDocument9 pages6-18-7 Flow Meters and Pressure InstrumentssudokuNo ratings yet

- 6-14-9 Control ValvesDocument14 pages6-14-9 Control ValvessudokuNo ratings yet

- 3-11-10 Pressure Vessels Carbon SteelDocument34 pages3-11-10 Pressure Vessels Carbon Steelsudoku100% (2)

- Structural Analysis and Design of Process EquipmentDocument360 pagesStructural Analysis and Design of Process EquipmentSurya Tej88% (8)

- 350 - Tray Installation Manual - EngDocument36 pages350 - Tray Installation Manual - EngRashid MadathilNo ratings yet

- E010 - Hydrotest Gland RingDocument5 pagesE010 - Hydrotest Gland RingsudokuNo ratings yet

- KettleDocument185 pagesKettlesudokuNo ratings yet

- E-001 - Hydrotest Device (Loose Ring) - OutDocument13 pagesE-001 - Hydrotest Device (Loose Ring) - OutsudokuNo ratings yet

- Astm A578 - 07 PDFDocument5 pagesAstm A578 - 07 PDFMuhammad Maulana100% (1)

- ASTM A388 Standard Practice For Ultrasonic Examination of Heavy Steel ForgingsDocument8 pagesASTM A388 Standard Practice For Ultrasonic Examination of Heavy Steel ForgingsGonzalo TelleríaNo ratings yet

- Training Manual For PVelite Basic LevelDocument41 pagesTraining Manual For PVelite Basic LevelsudokuNo ratings yet

- Hot Insulation Specification GuideDocument55 pagesHot Insulation Specification Guideapply19842371No ratings yet

- PipeDocument44 pagesPipesudokuNo ratings yet

- 2917 HXGN LIVE 2917 DelaforceDocument58 pages2917 HXGN LIVE 2917 DelaforceVitor OlivettiNo ratings yet

- Tema 9Document300 pagesTema 9sudokuNo ratings yet

- Basics 2016Document81 pagesBasics 2016andy131078No ratings yet

- NI-0253 - J Pressure Vessel DesignDocument45 pagesNI-0253 - J Pressure Vessel DesignsudokuNo ratings yet

- Standard Stud Heavy Hex Nut Specs Peste 4 InchDocument1 pageStandard Stud Heavy Hex Nut Specs Peste 4 InchsudokuNo ratings yet

- Allowable Stress PDFDocument6 pagesAllowable Stress PDFsudokuNo ratings yet

- Rayleigh Method Versus Eigenvalue MethodDocument6 pagesRayleigh Method Versus Eigenvalue MethodCY Lee0% (1)

- B564Document11 pagesB564razvandanutNo ratings yet

- Declaration g4 g7Document1 pageDeclaration g4 g7sudokuNo ratings yet

- Handbook of Mechanical Engineering TermsDocument366 pagesHandbook of Mechanical Engineering Termsjakejohns95% (44)

- Astm A194m 15 PDFDocument13 pagesAstm A194m 15 PDFsudokuNo ratings yet

- Buckling Stress Check For A Vertical VesselDocument11 pagesBuckling Stress Check For A Vertical Vesselmechengg01No ratings yet

- 09 Exp 11 Buffer SolutionsDocument8 pages09 Exp 11 Buffer SolutionsShainmaugne AdvientoNo ratings yet

- Course Progression Map For 2021 Commencing Students: E3001 Bachelor of Engineering (Honours) Common First YearDocument21 pagesCourse Progression Map For 2021 Commencing Students: E3001 Bachelor of Engineering (Honours) Common First YearNguyễn An KhoaNo ratings yet

- 5020-Article Text-10917-1-10-20220808Document9 pages5020-Article Text-10917-1-10-20220808indah rumah4No ratings yet

- MX 201110 enDocument1,203 pagesMX 201110 envajrahastaNo ratings yet

- Generador APD550PEDocument4 pagesGenerador APD550PEFTL1990No ratings yet

- F825 - Hotcakes Baby Cardigan FinalDocument2 pagesF825 - Hotcakes Baby Cardigan Finaladina100% (1)

- Full Report-Disinfectant and SanitizerDocument19 pagesFull Report-Disinfectant and Sanitizermohd addinNo ratings yet

- Plasma ChemistryDocument6 pagesPlasma ChemistryArief RomadhonNo ratings yet

- 30-300 MHZ Transmission Line Trainer Tla05Document1 page30-300 MHZ Transmission Line Trainer Tla05Kishor HandoreNo ratings yet

- Permeability Test Constant Head MethodDocument10 pagesPermeability Test Constant Head MethodLouise LuyNo ratings yet

- Mitsubishi Motors: Service ManualDocument29 pagesMitsubishi Motors: Service ManualCristobalNo ratings yet

- 1 Proforma of Allotment LetterDocument32 pages1 Proforma of Allotment LetterGovind SandhaNo ratings yet

- Petford & Atherton., 1996Document31 pagesPetford & Atherton., 1996Ivan Hagler Becerra VasquezNo ratings yet

- Differences in Left Ventricular and Left Atrial FuDocument10 pagesDifferences in Left Ventricular and Left Atrial FueugeniaNo ratings yet

- Tooth Development, Eruption & Applied Aspects: Saurabh Roy 09.03.2016Document95 pagesTooth Development, Eruption & Applied Aspects: Saurabh Roy 09.03.2016reema aslamNo ratings yet

- Gem EscortingDocument7 pagesGem Escortingsuman sutharNo ratings yet

- The Future - G&VDocument6 pagesThe Future - G&VManuelHerreraMontoyaNo ratings yet

- Week 7: Nurses Role in Disaster: Home Mitigation and PreparednessDocument10 pagesWeek 7: Nurses Role in Disaster: Home Mitigation and PreparednessRose Ann LacuarinNo ratings yet

- 0610 m16 QP 62Document12 pages0610 m16 QP 62faryal khanNo ratings yet

- GROHE Specification Sheet 19443000-1Document2 pagesGROHE Specification Sheet 19443000-1Fred PrzNo ratings yet

- Auomotivr Fuel TanksDocument9 pagesAuomotivr Fuel Tankscolumba_mcNo ratings yet

- Chapter-1: Introduction of The StudyDocument21 pagesChapter-1: Introduction of The StudyViswanathanNo ratings yet

- Design & Operation of Clean Room-1Document39 pagesDesign & Operation of Clean Room-1Hafizur Rahman0% (1)

- Stereochemistry MSCDocument29 pagesStereochemistry MSCBapu Thorat50% (2)

- Cattlemans Steakhouse MenuDocument1 pageCattlemans Steakhouse Menuapi-300741654No ratings yet

- General Biology 1: Go Fast, or Slow Down?Document23 pagesGeneral Biology 1: Go Fast, or Slow Down?Mikhael OiraNo ratings yet

- MidtermDocument3 pagesMidtermTrisha MondonedoNo ratings yet

- Manufacturing Airbrushes Since 1904Document20 pagesManufacturing Airbrushes Since 1904Sa MiNo ratings yet

- Managed Pressure Drilling MPD BrochureDocument5 pagesManaged Pressure Drilling MPD Brochureswaala4realNo ratings yet

- Deskripsi (Caffein)Document4 pagesDeskripsi (Caffein)jibefahlaNo ratings yet